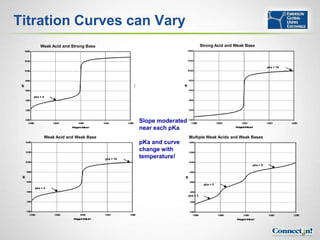

The document discusses pH control and measurement. It provides an overview of pH concepts including:

- The definition of pH and how it relates to hydrogen and hydroxyl ion concentrations

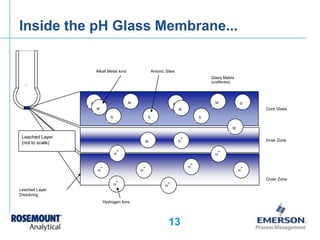

- Details of how a pH sensor works including the glass electrode, reference electrode, and liquid junction

- Benefits of smart pH sensors which store calibration data to enable sensor diagnostics and trending

- Examples of sensor diagnostics provided by smart sensors such as detecting broken glass, coated sensors, and non-immersed sensors

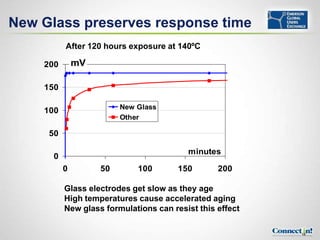

- How sensor parameters change over time and smart sensor trending can identify sensors needing replacement before measurements are compromised

![The definition of pH

pH is the unit of measurement for determining

the acidity or alkalinity of a solution.

The mathematical definition of pH is the

negative logarithm of the molar hydrogen ion

concentration, pH = - log([H+])

pH is measured by various different sensors, H2O

most common and economical is the glass H+ OH-

OH- H+

electrode/silver reference system.

pH measurement requires periodic

maintenance to maintain accuracy.](https://image.slidesharecdn.com/adventures-in-ph-control-greg-mcmillan-dave-joseph-121017142825-phpapp01/85/Adventures-in-pH-Control-7-320.jpg)

![pH Scale vs Moles/Liter Ion

Concentration

pH Hydrogen Ion [H+] Hydroxyl Ion [OH-]

0 Acidic 1.0 0.00000000000001

1 0.1 0.0000000000001

2 0.01 0.000000000001

3 0.001 0.00000000001

4 0.0001 0.0000000001

5 0.00001 0.000000001

6 0.000001 0.00000001

7 Neutral 0.0000001 0.0000001

8 0.00000001 0.000001

9 0.000000001 0.00001

10 0.0000000001 0.0001

11 0.00000000001 0.001

12 0.000000000001 0.01

13 0.0000000000001 0.1

14 Basic 0.00000000000001 1.0](https://image.slidesharecdn.com/adventures-in-ph-control-greg-mcmillan-dave-joseph-121017142825-phpapp01/85/Adventures-in-pH-Control-8-320.jpg)

![What is pH? – technical stuff

pH = - log([H+])

Kw = [H+]*[OH-] = 1.0x10-14 at 25ºC

pH + pOH = pKw

pH is measured using the Nernst equation

E(mV) = Ex + 2.3(RT/F)*log aH+

~ Ex – (S)*pH in simple form

Where Ex = calibration constant

2.3(RT/F) ~ slope (S) in mV/pH units

aH+ = activity of hydrogen ion ~ [H+]](https://image.slidesharecdn.com/adventures-in-ph-control-greg-mcmillan-dave-joseph-121017142825-phpapp01/85/Adventures-in-pH-Control-10-320.jpg)

![Rules of thumb: multiple stages

When the process pH must

be changed by more than 2 pH Hydrogen Ion [H+] Hydroxyl Ion [OH-]

units: 0 Acidic 1.0 0.00000000000001

1 0.1 0.0000000000001

2 0.01 0.000000000001

Use Multiple Stages! 3

4

0.001

0.0001

0.00000000001

0.0000000001

5 0.00001 0.000000001

6 0.000001 0.00000001

Remember that 2 pH units 7 Neutral 0.0000001 0.0000001

8 0.00000001 0.000001

is a factor of 100 in 9 0.000000001 0.00001

concentration. 10 0.0000000001 0.0001

11 0.00000000001 0.001

12 0.000000000001 0.01

13 0.0000000000001 0.1

Can you accurately dilute a 14 Basic 0.00000000000001 1.0

concentrated acid by a factor of

500 in one step?](https://image.slidesharecdn.com/adventures-in-ph-control-greg-mcmillan-dave-joseph-121017142825-phpapp01/85/Adventures-in-pH-Control-71-320.jpg)