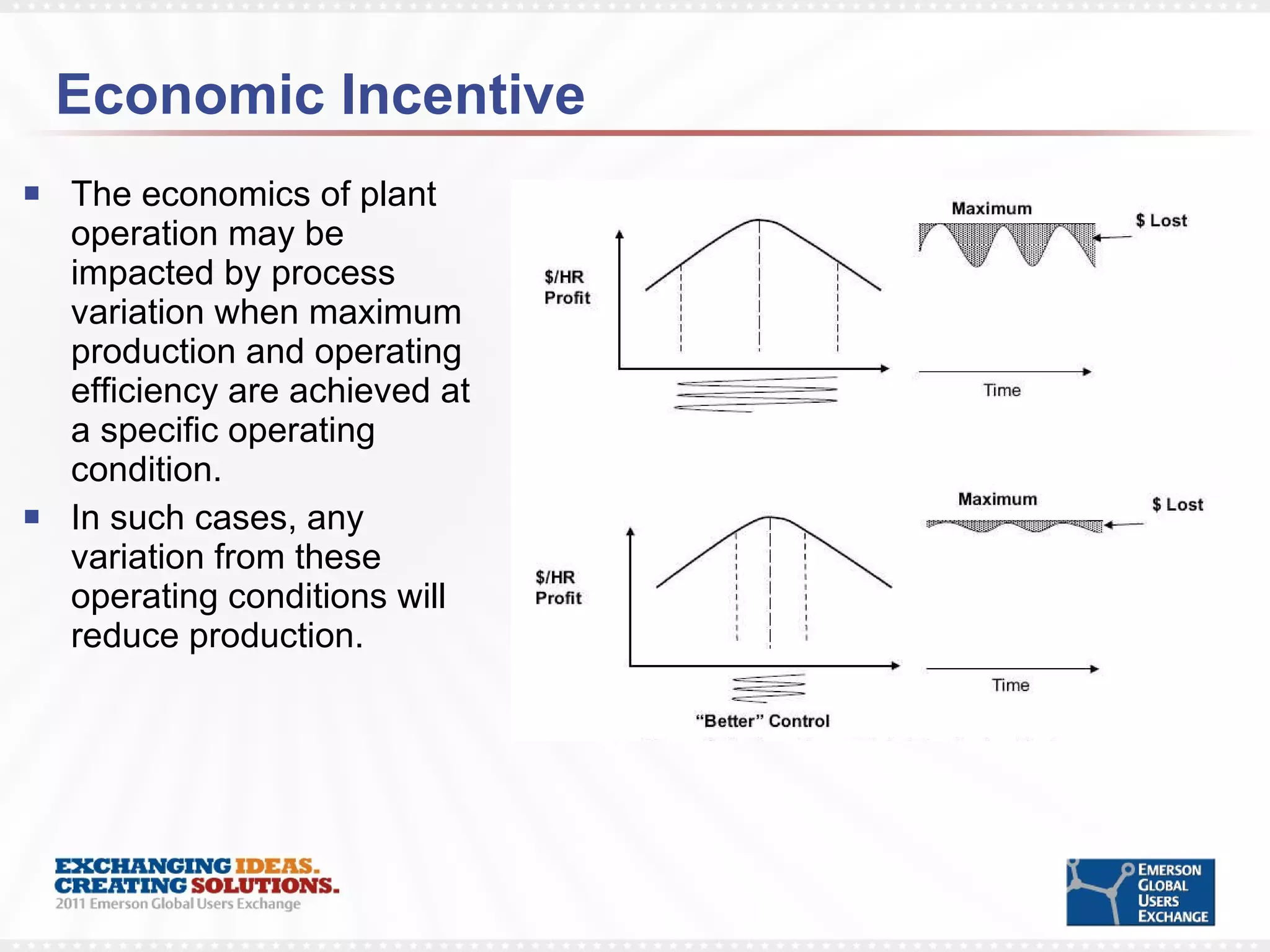

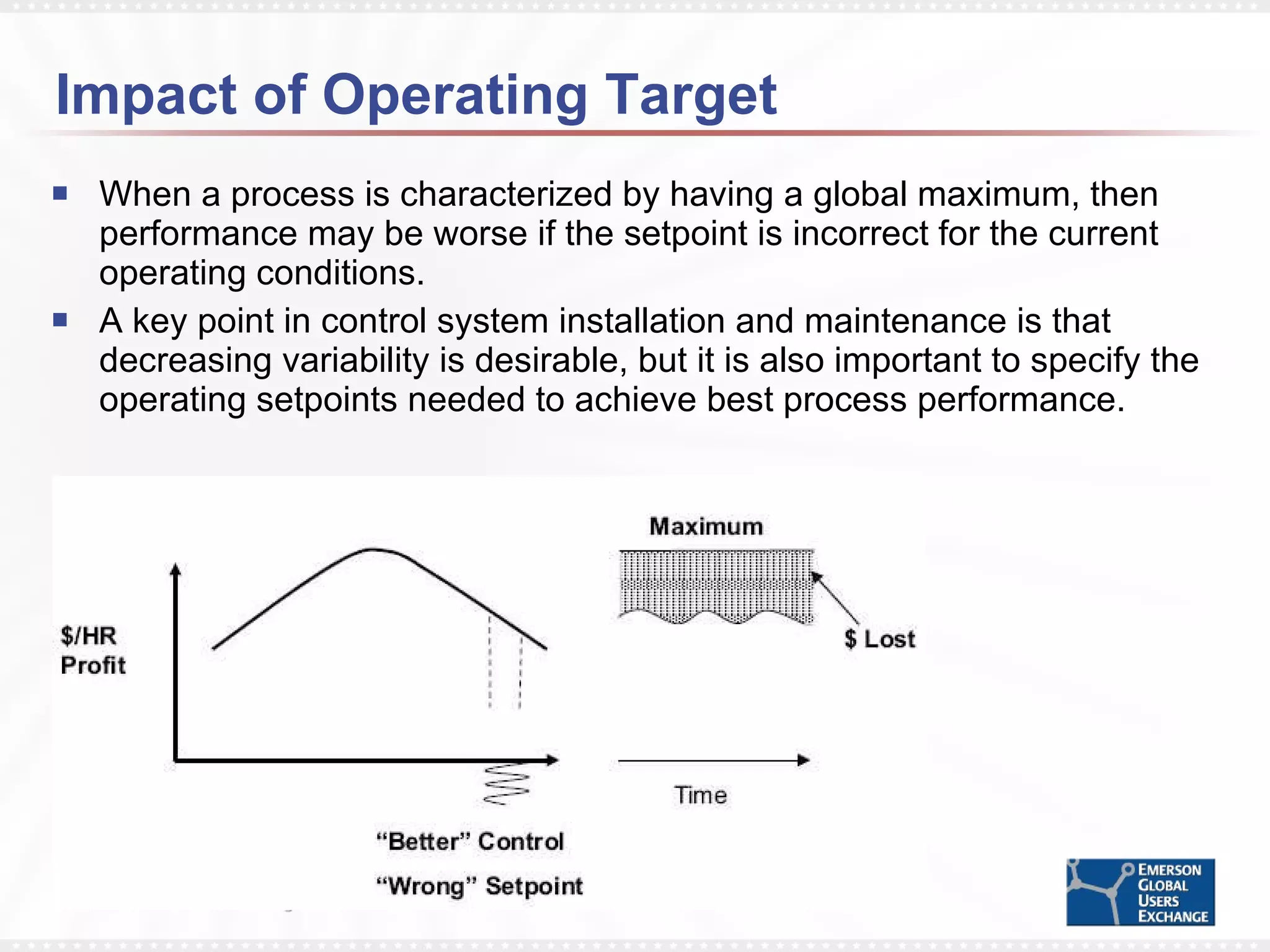

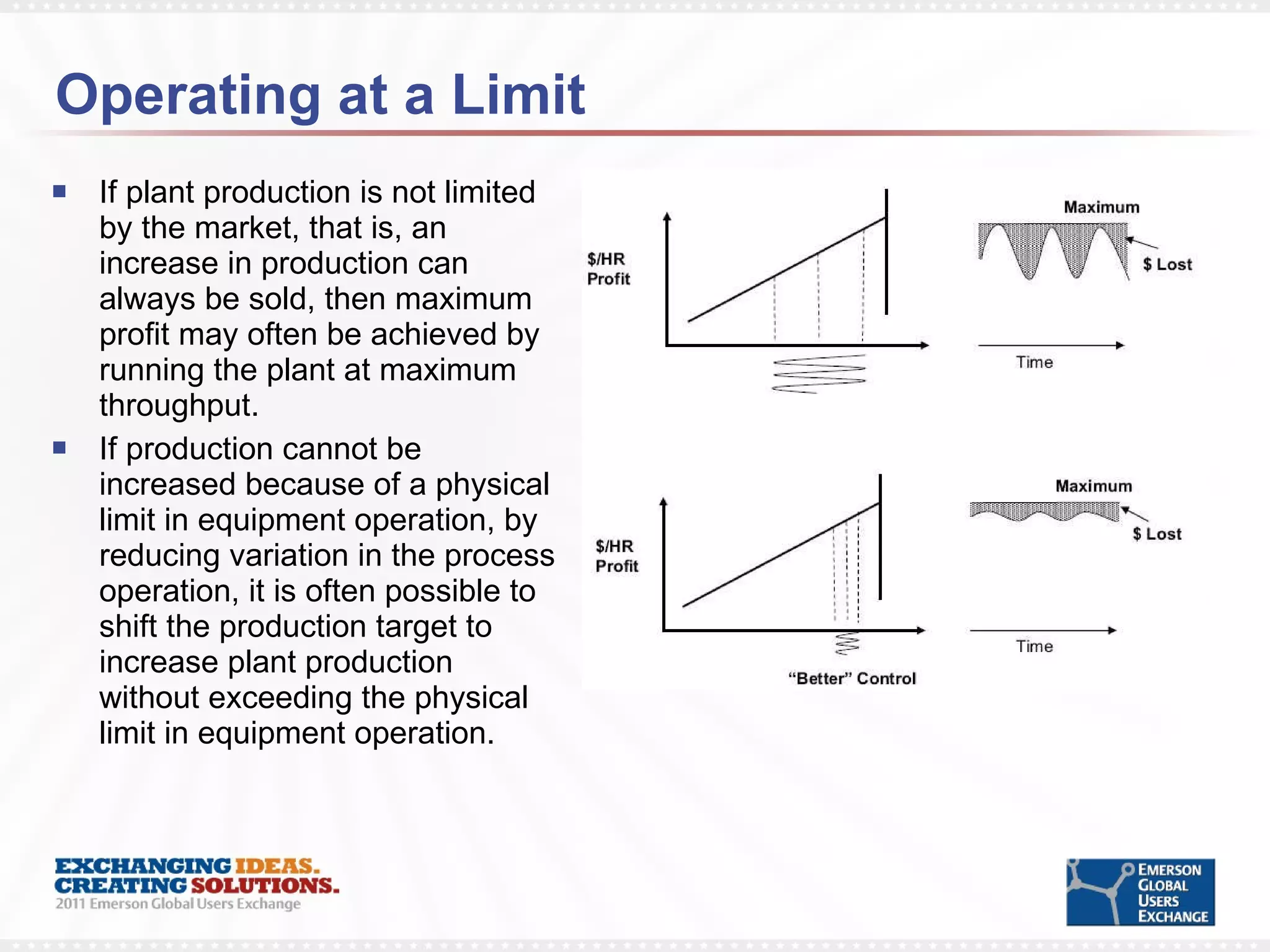

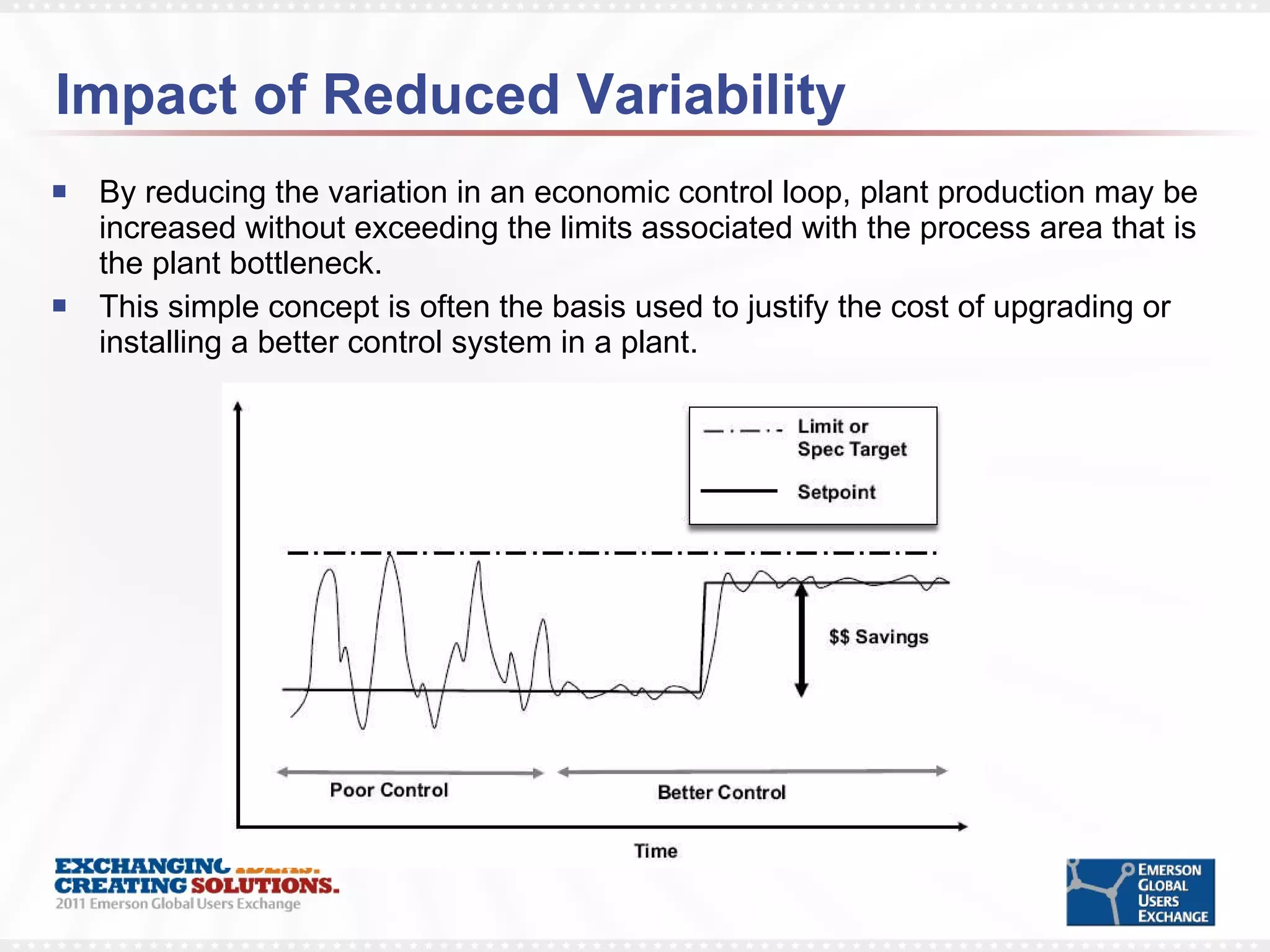

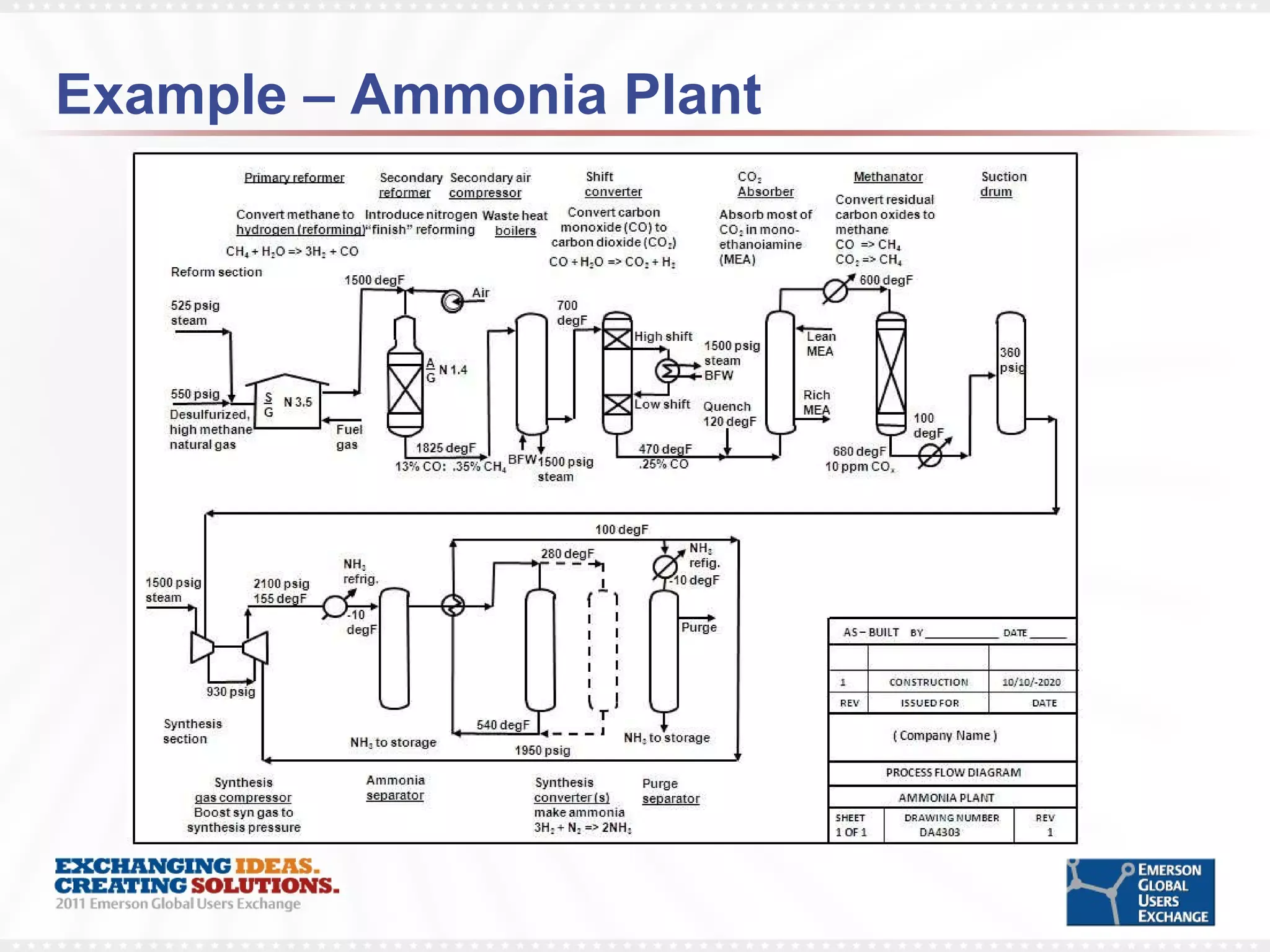

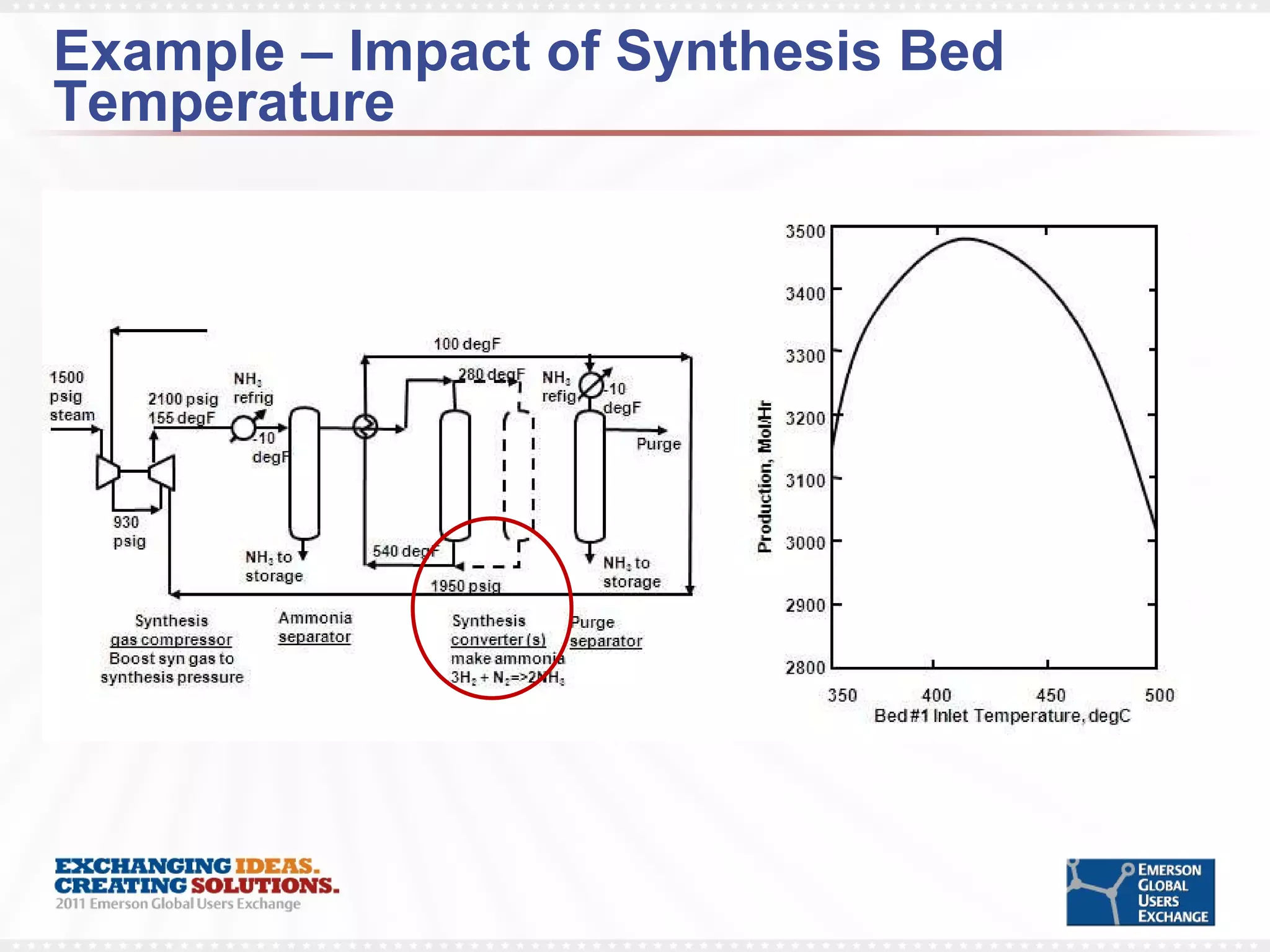

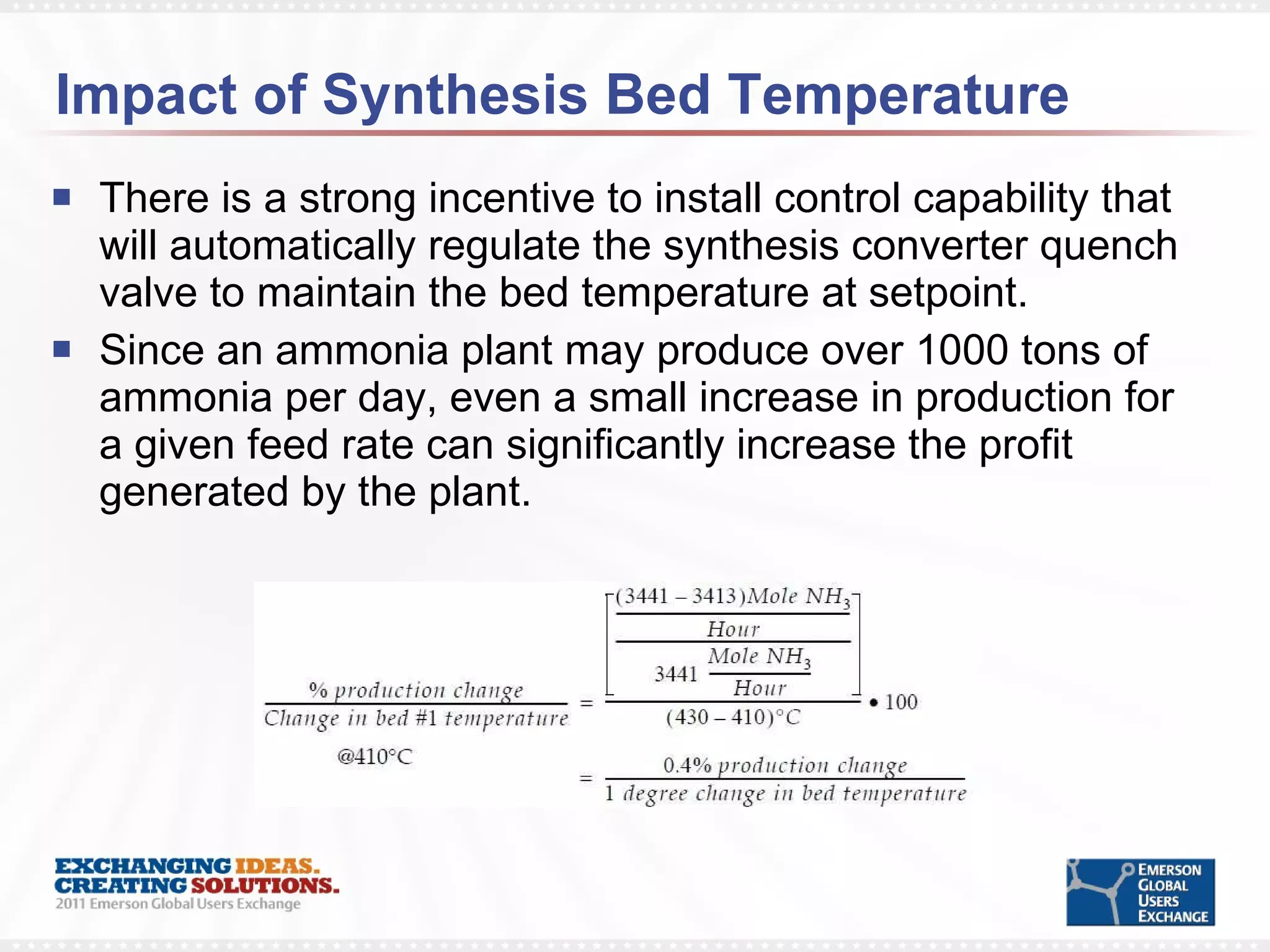

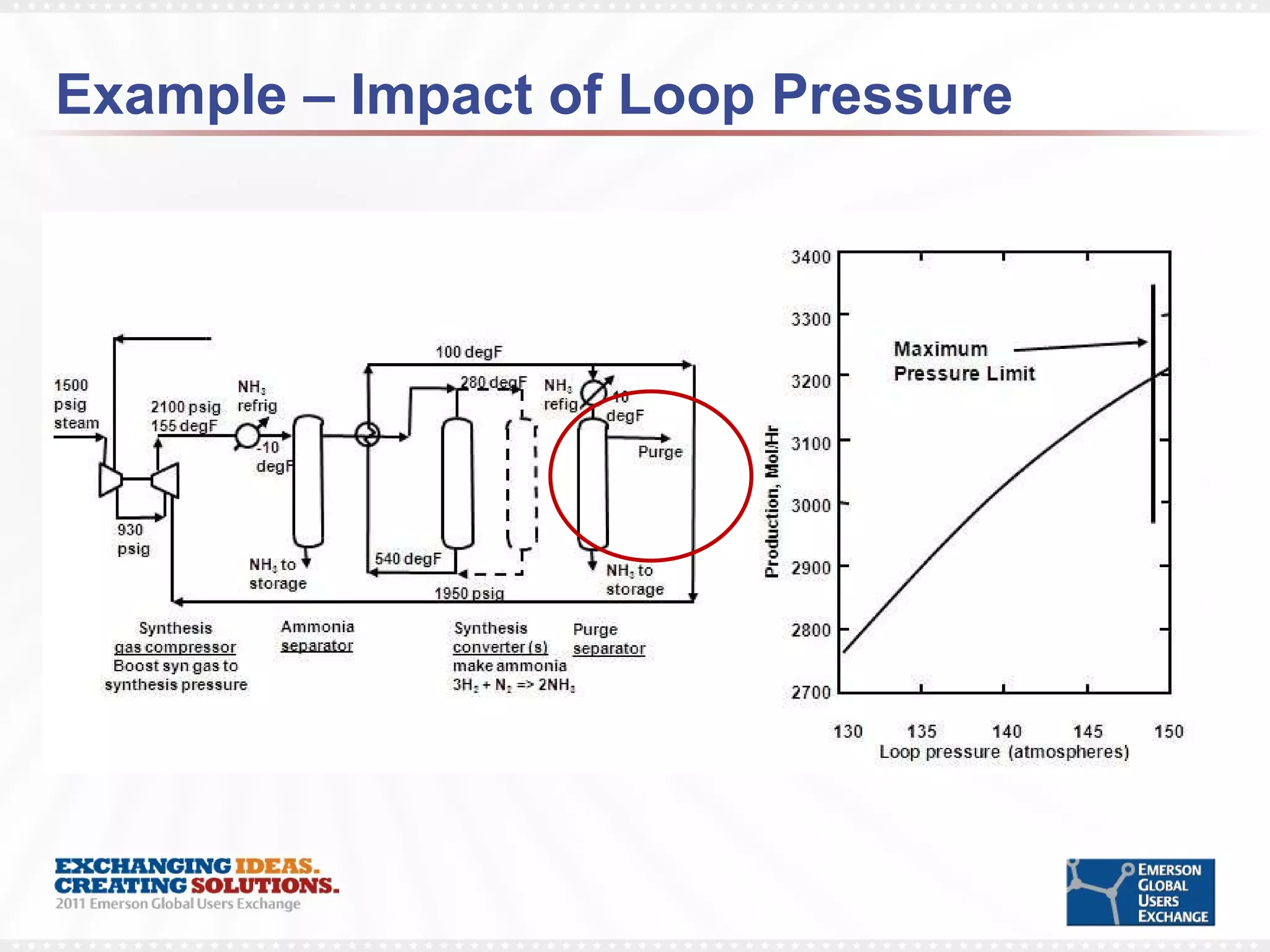

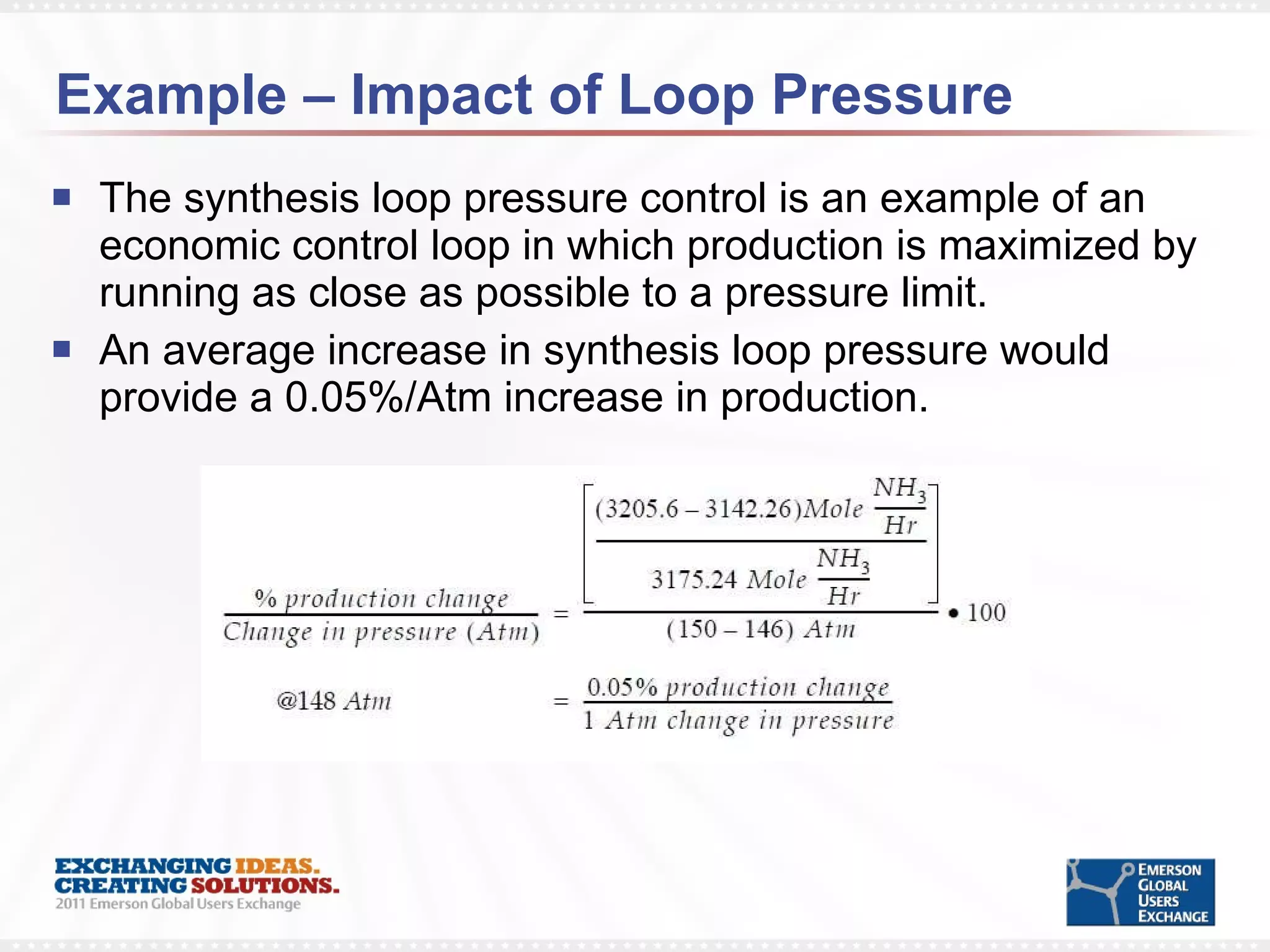

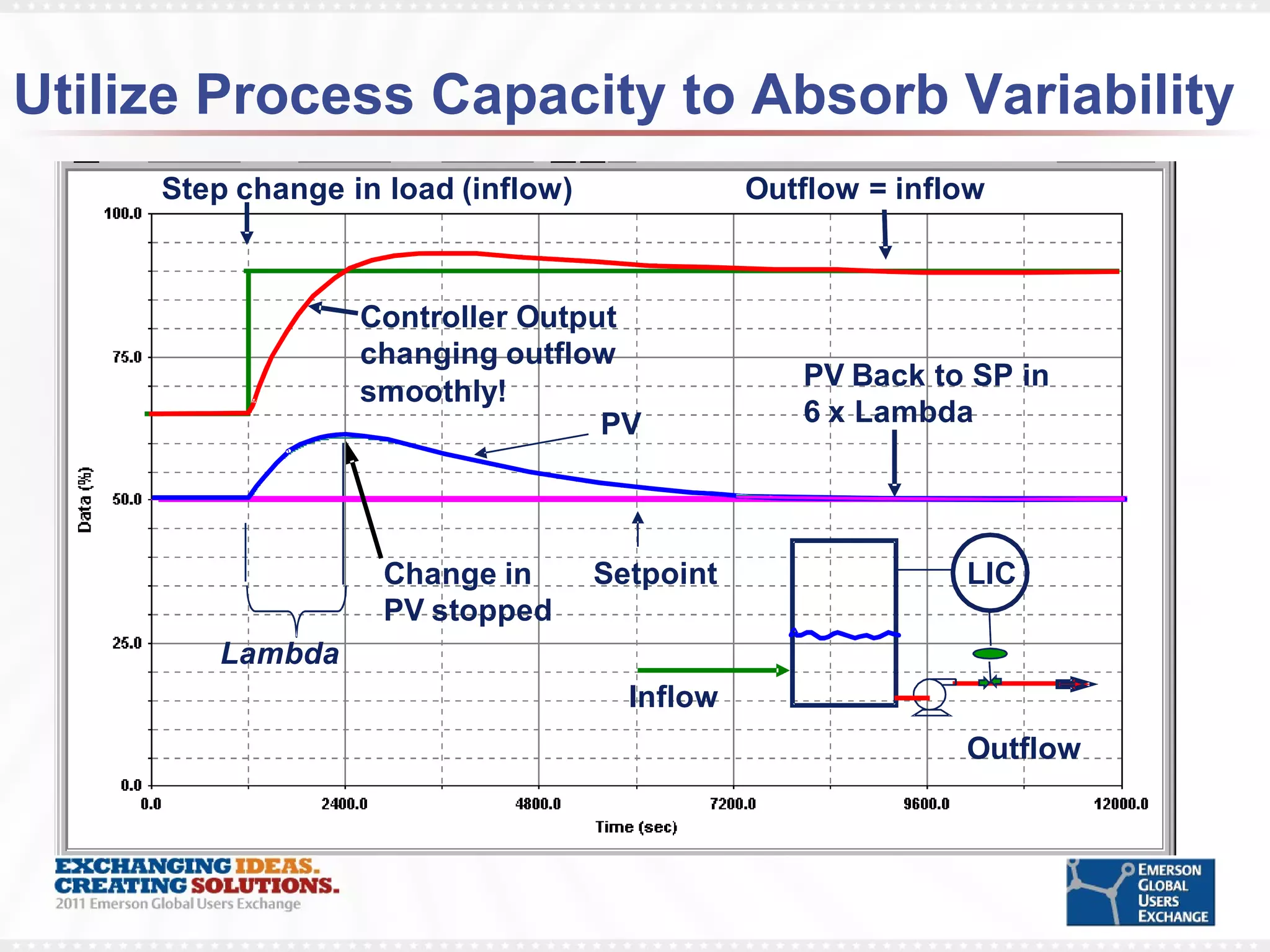

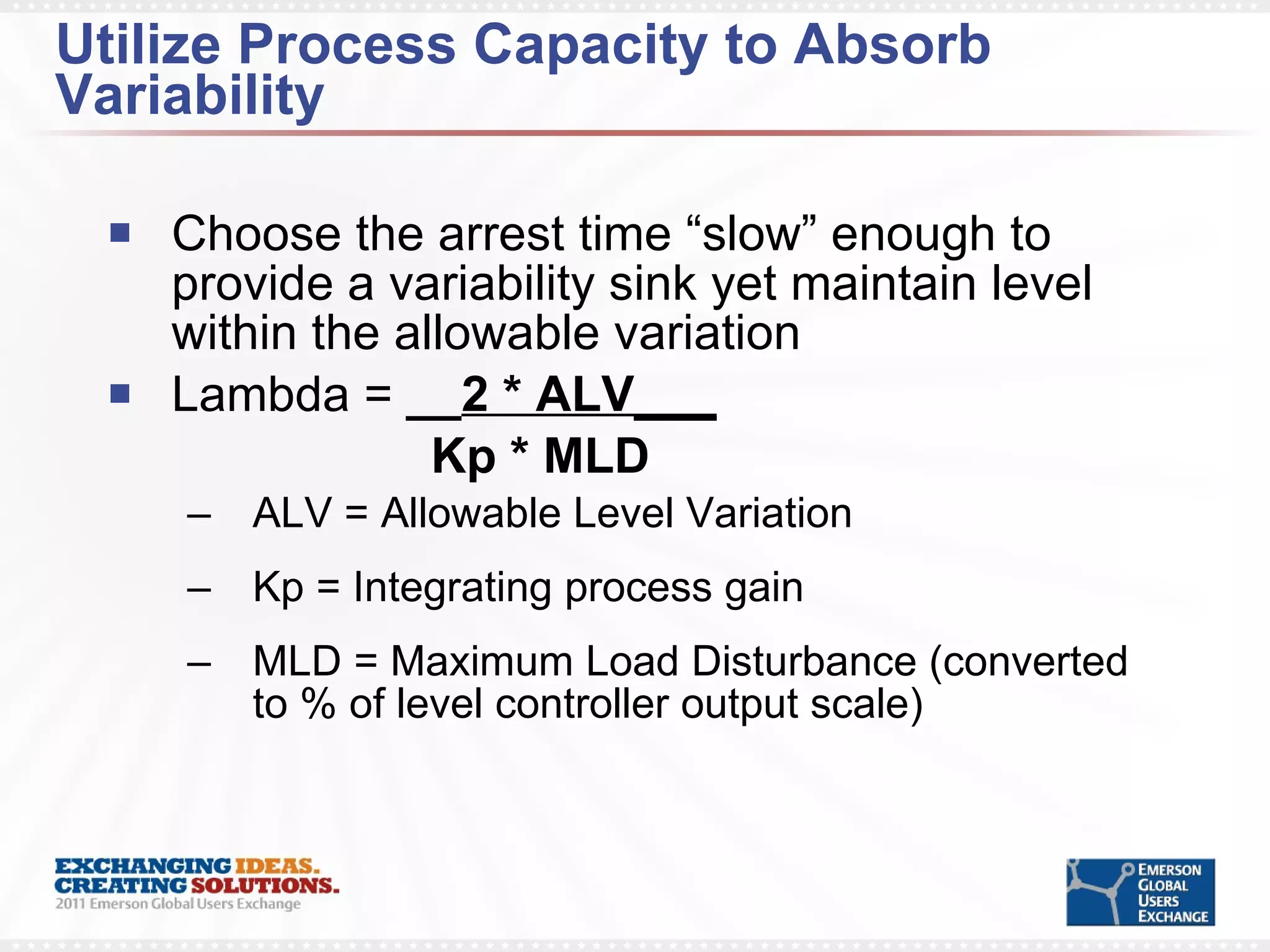

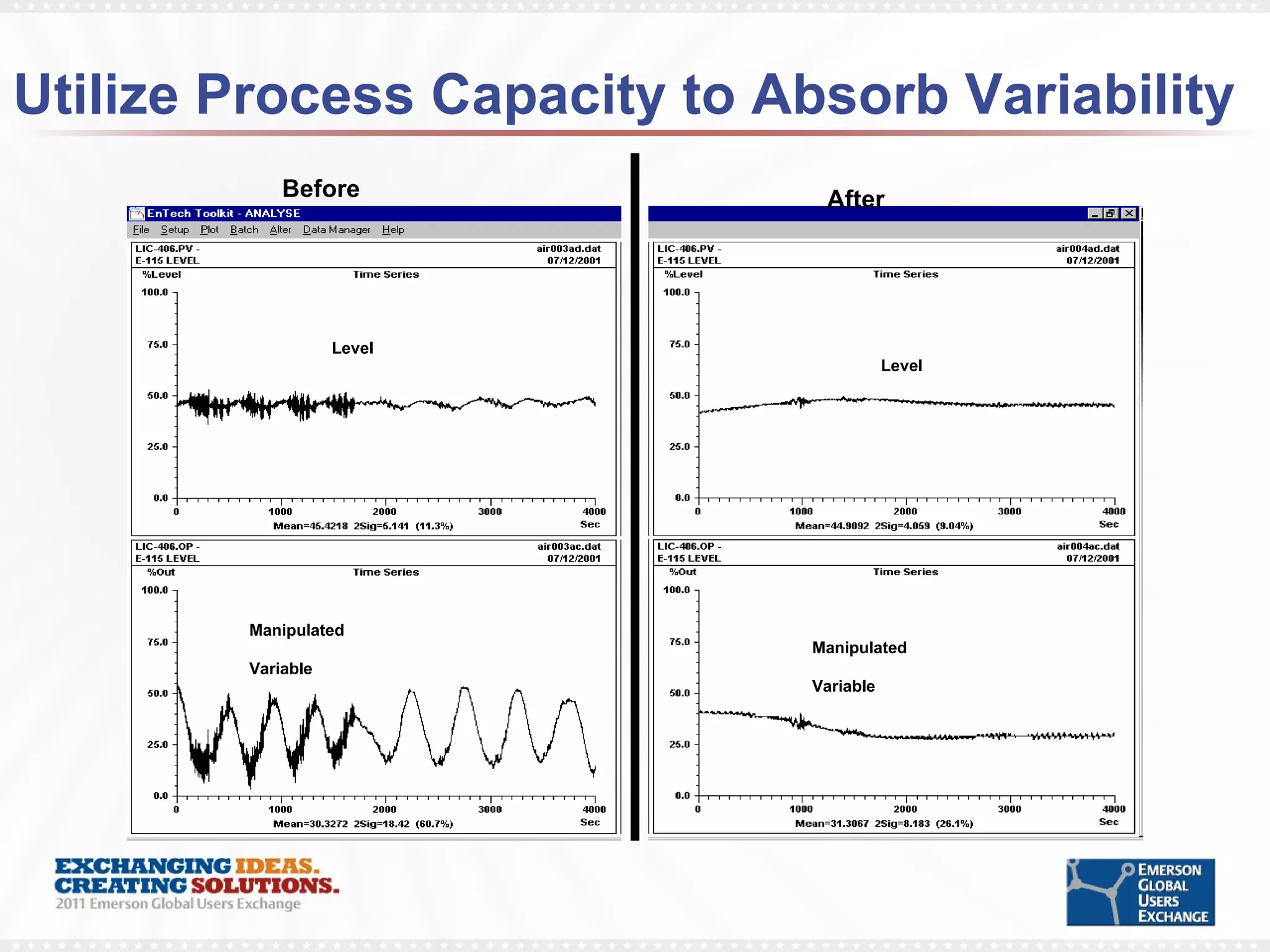

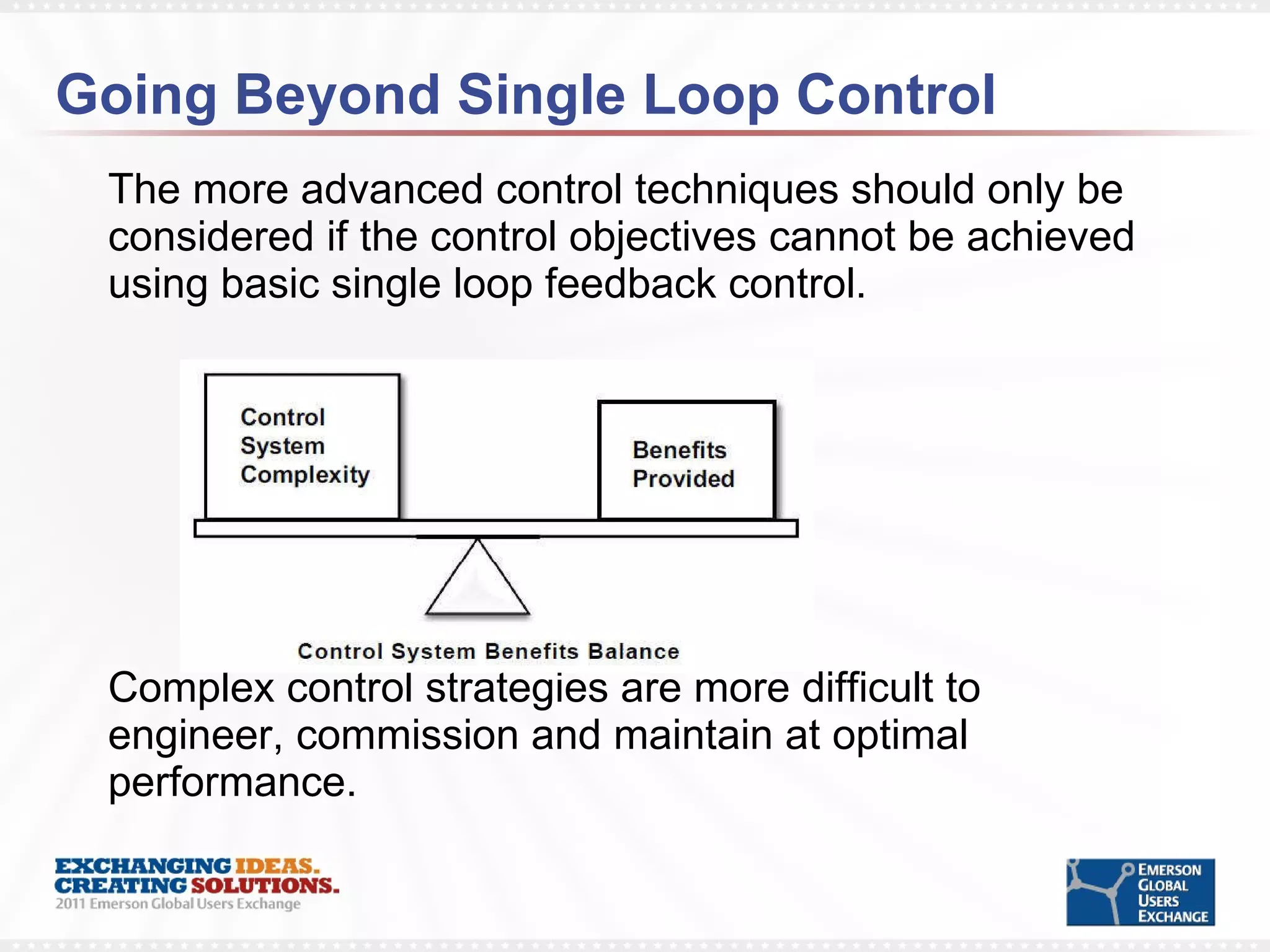

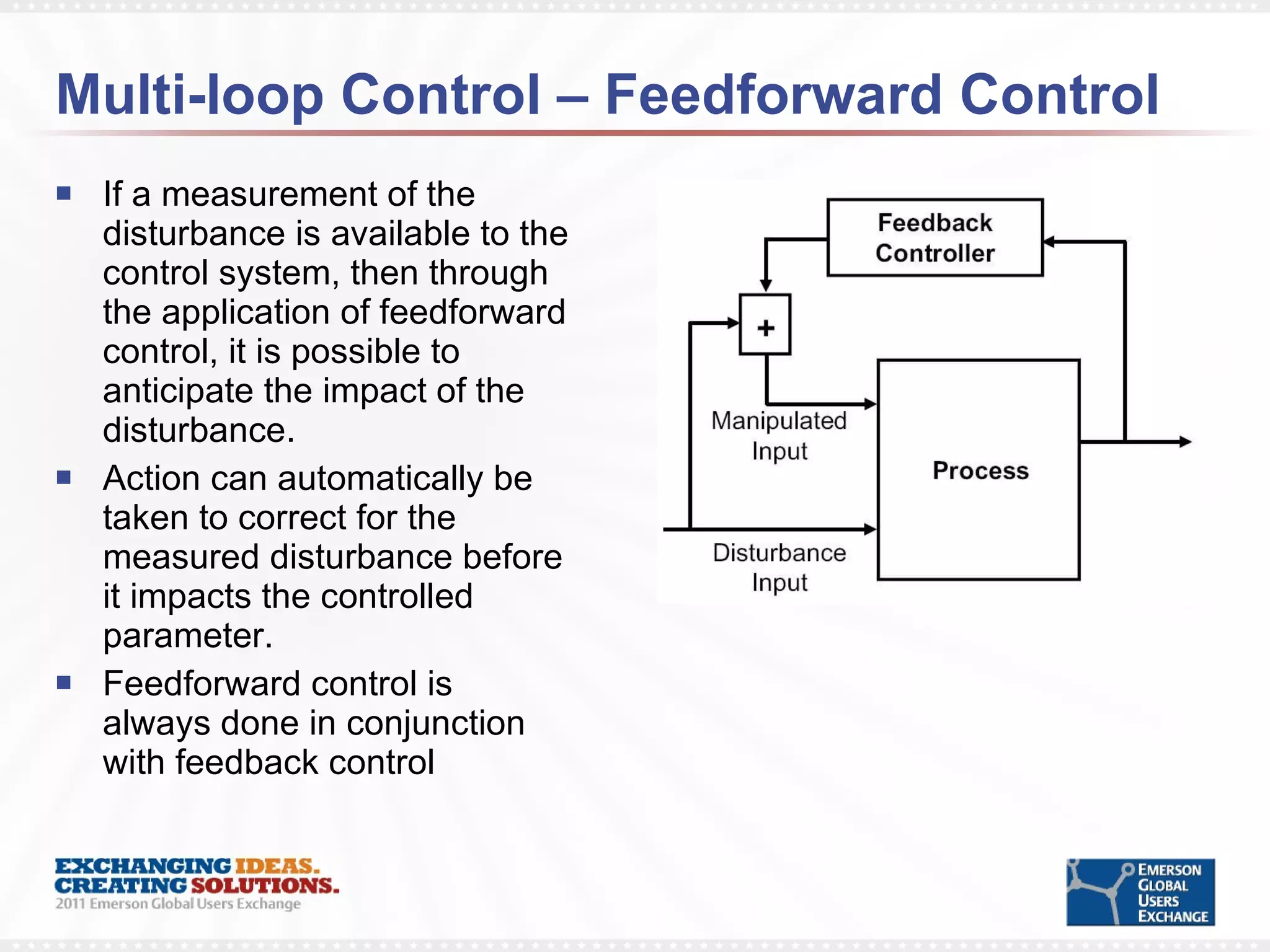

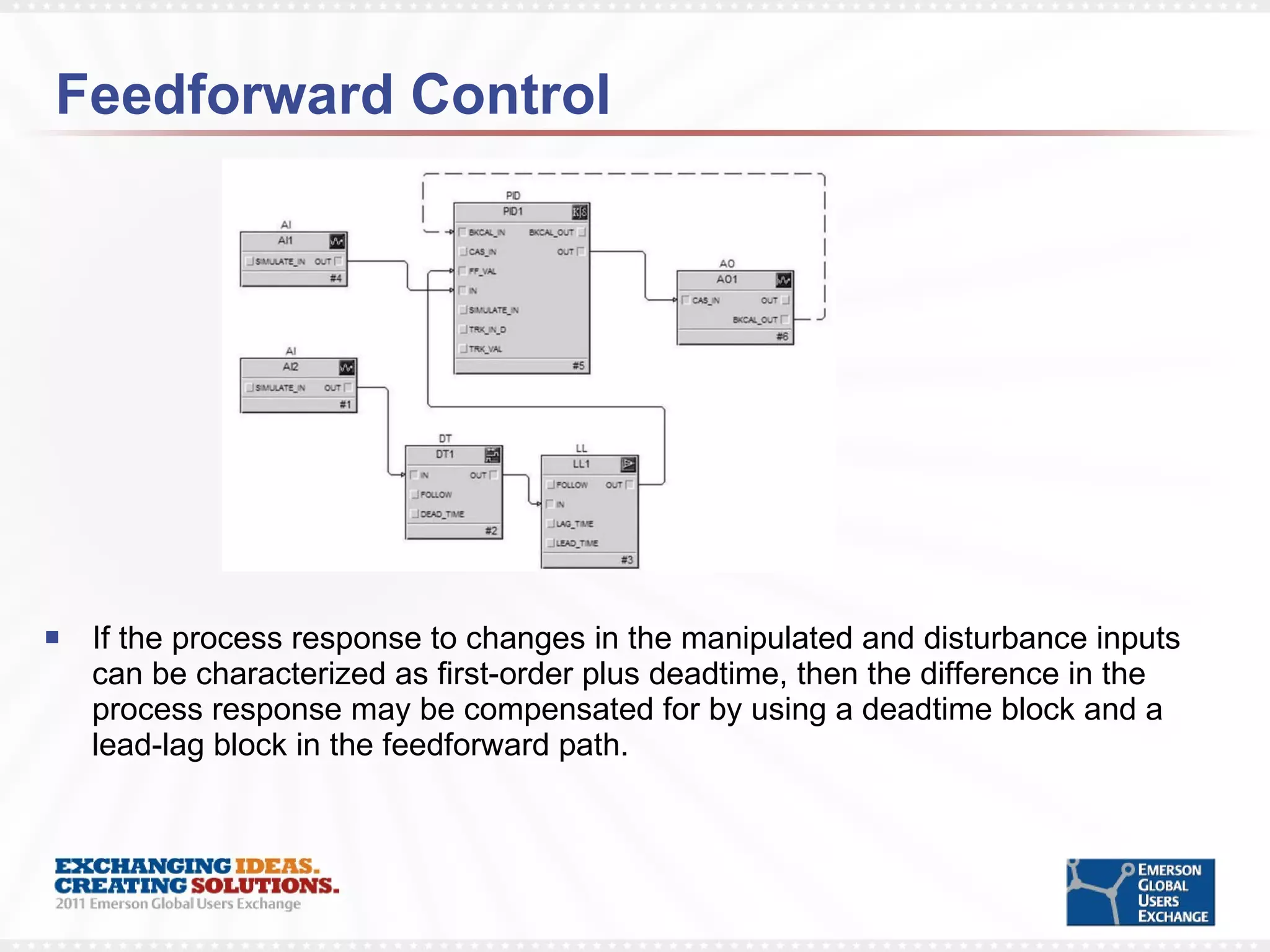

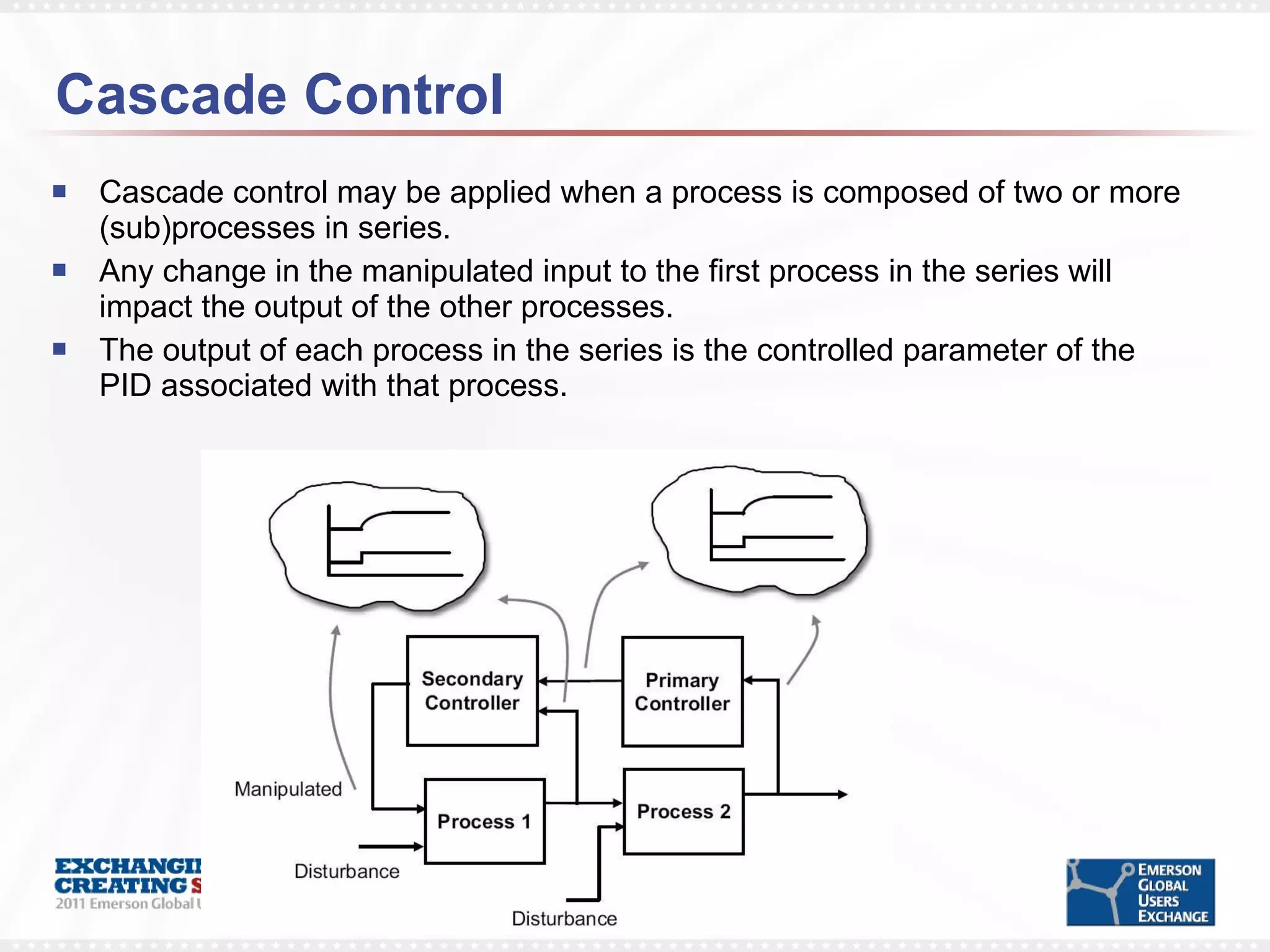

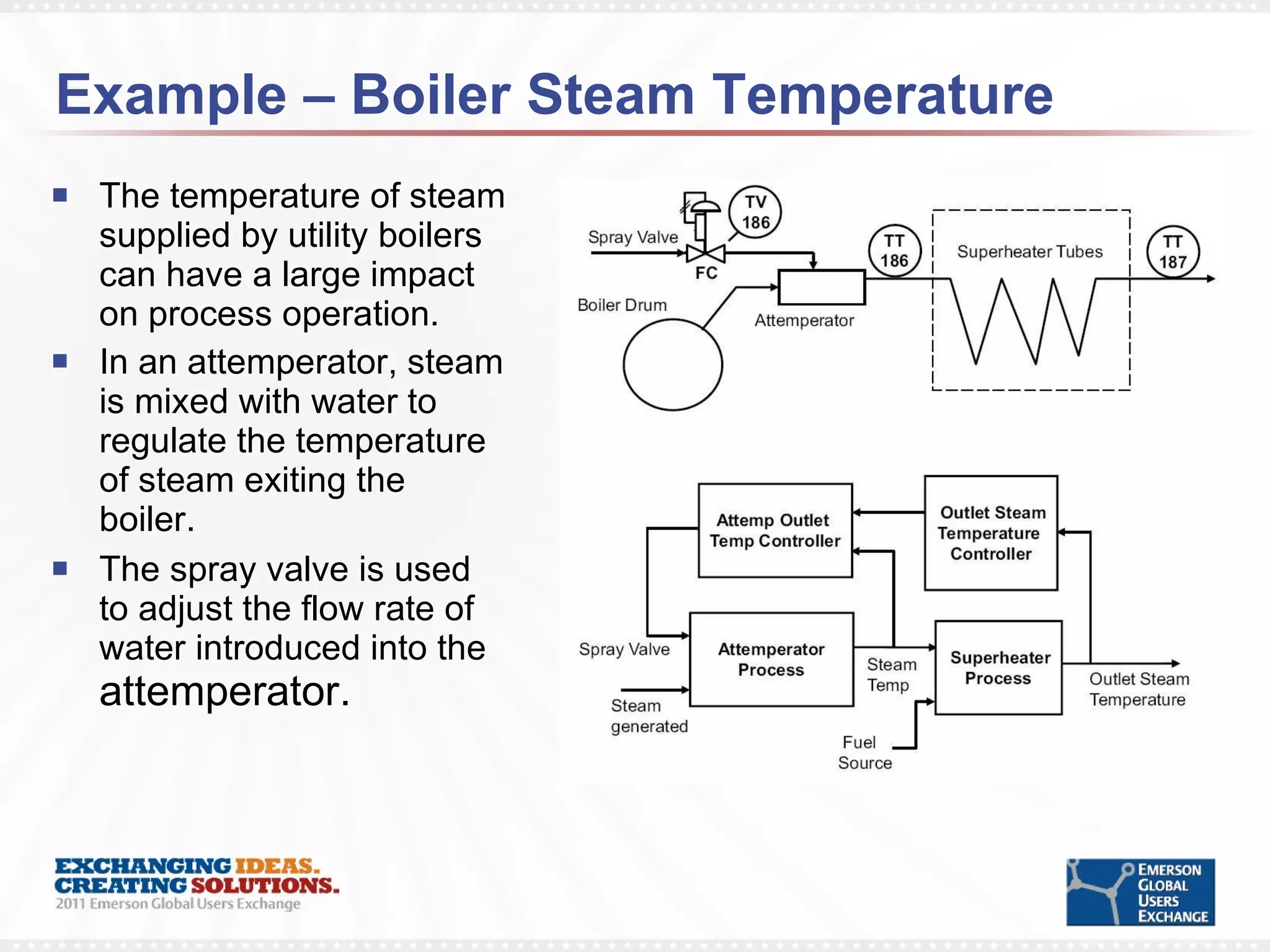

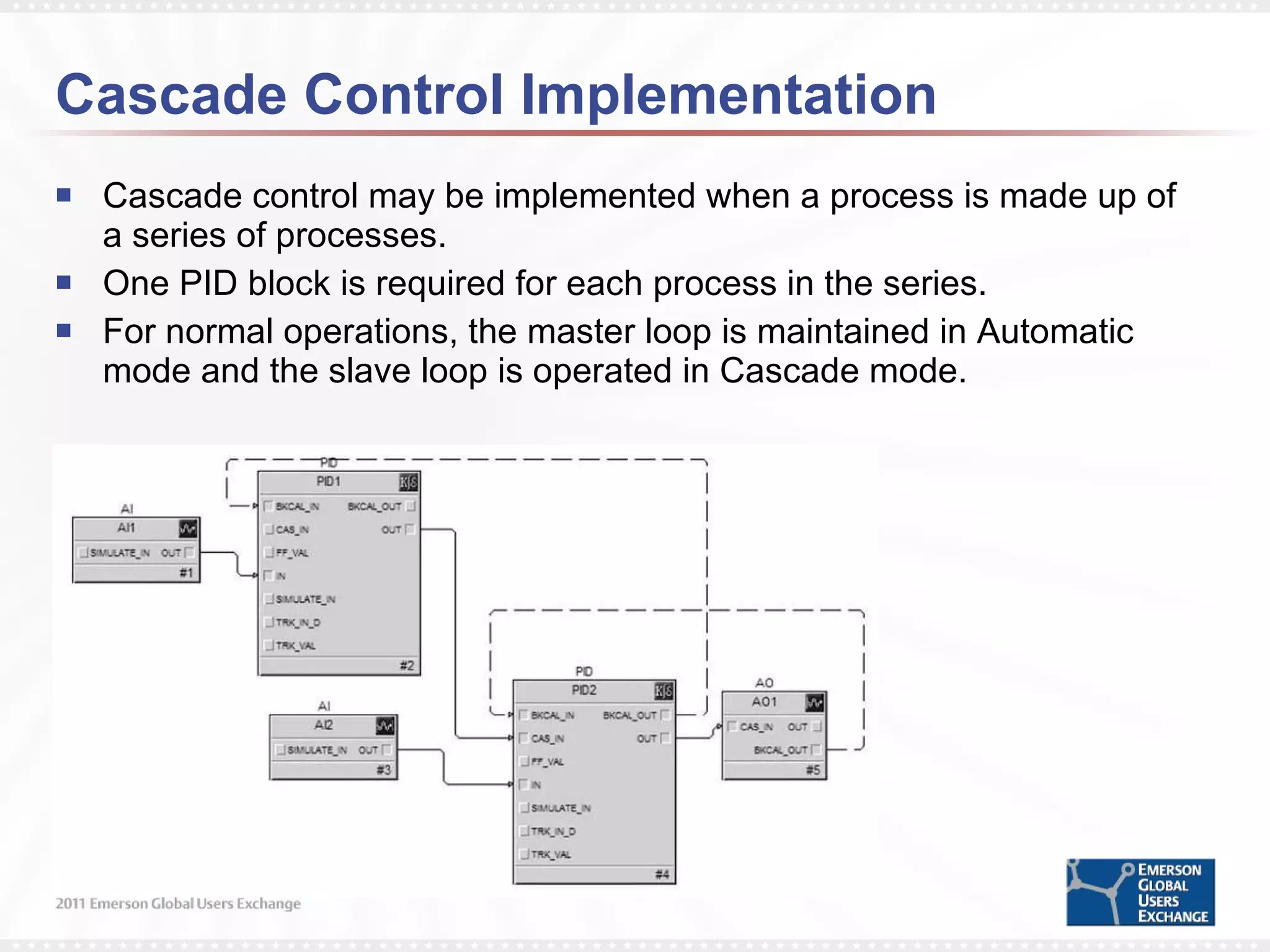

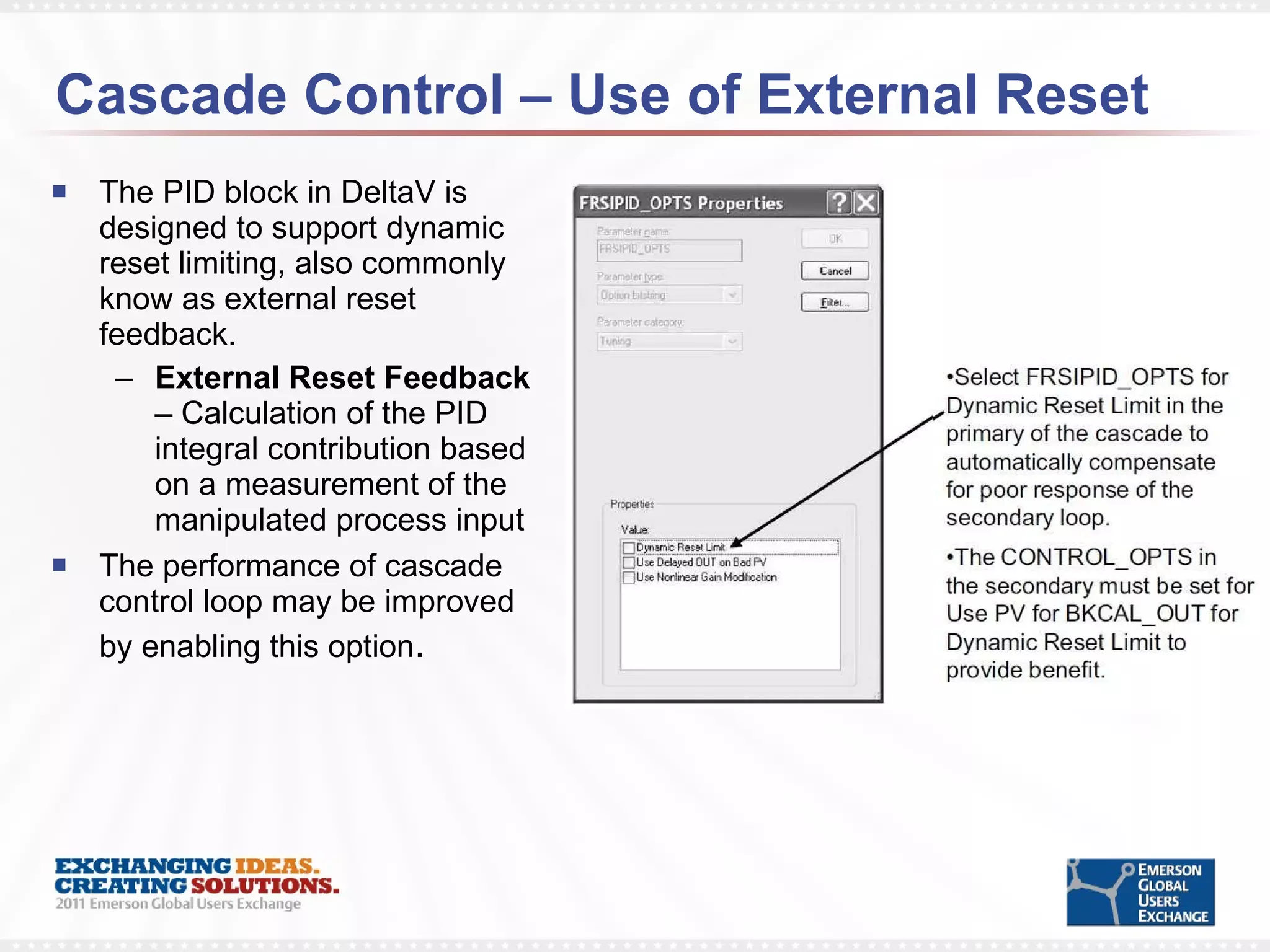

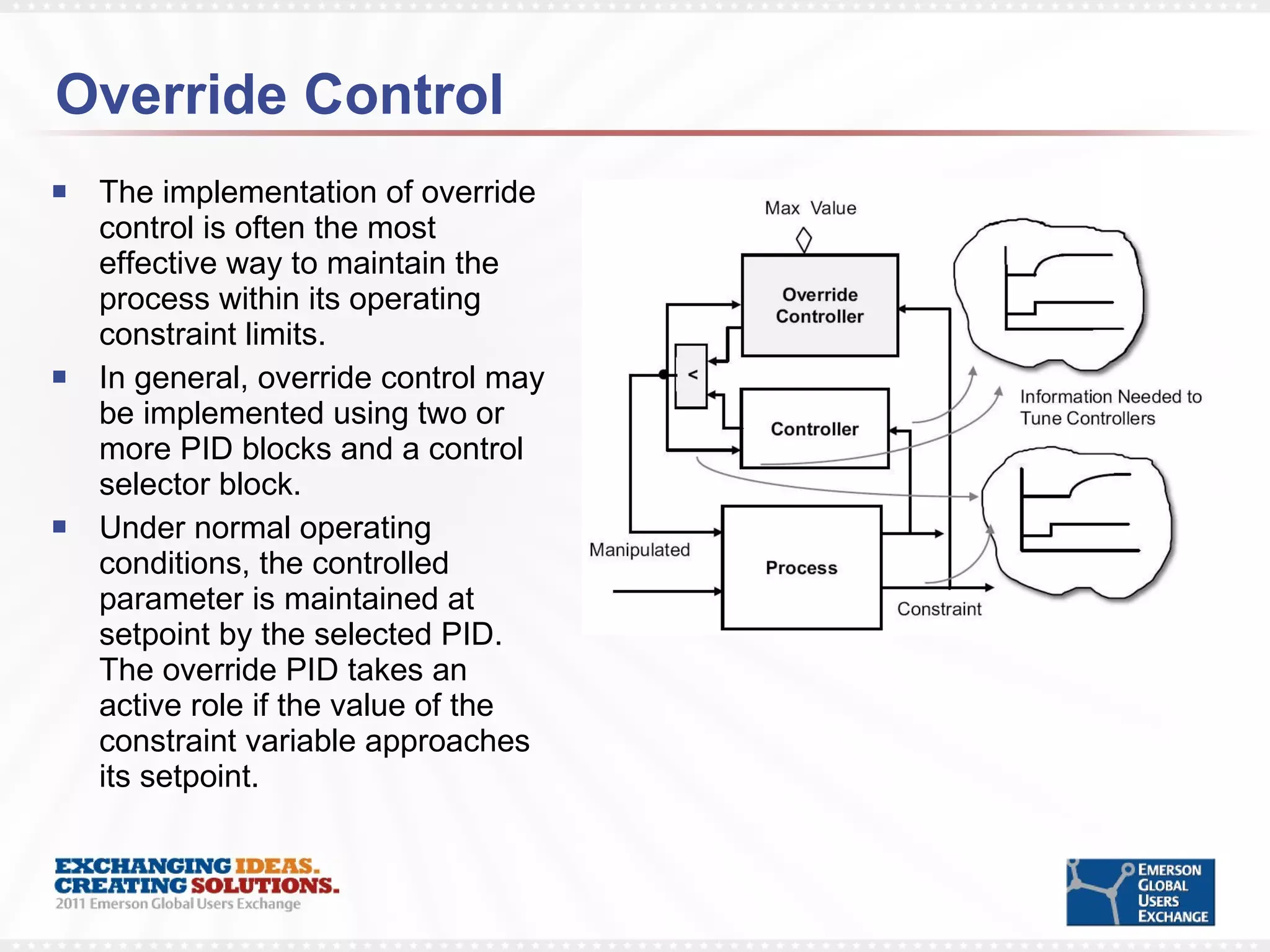

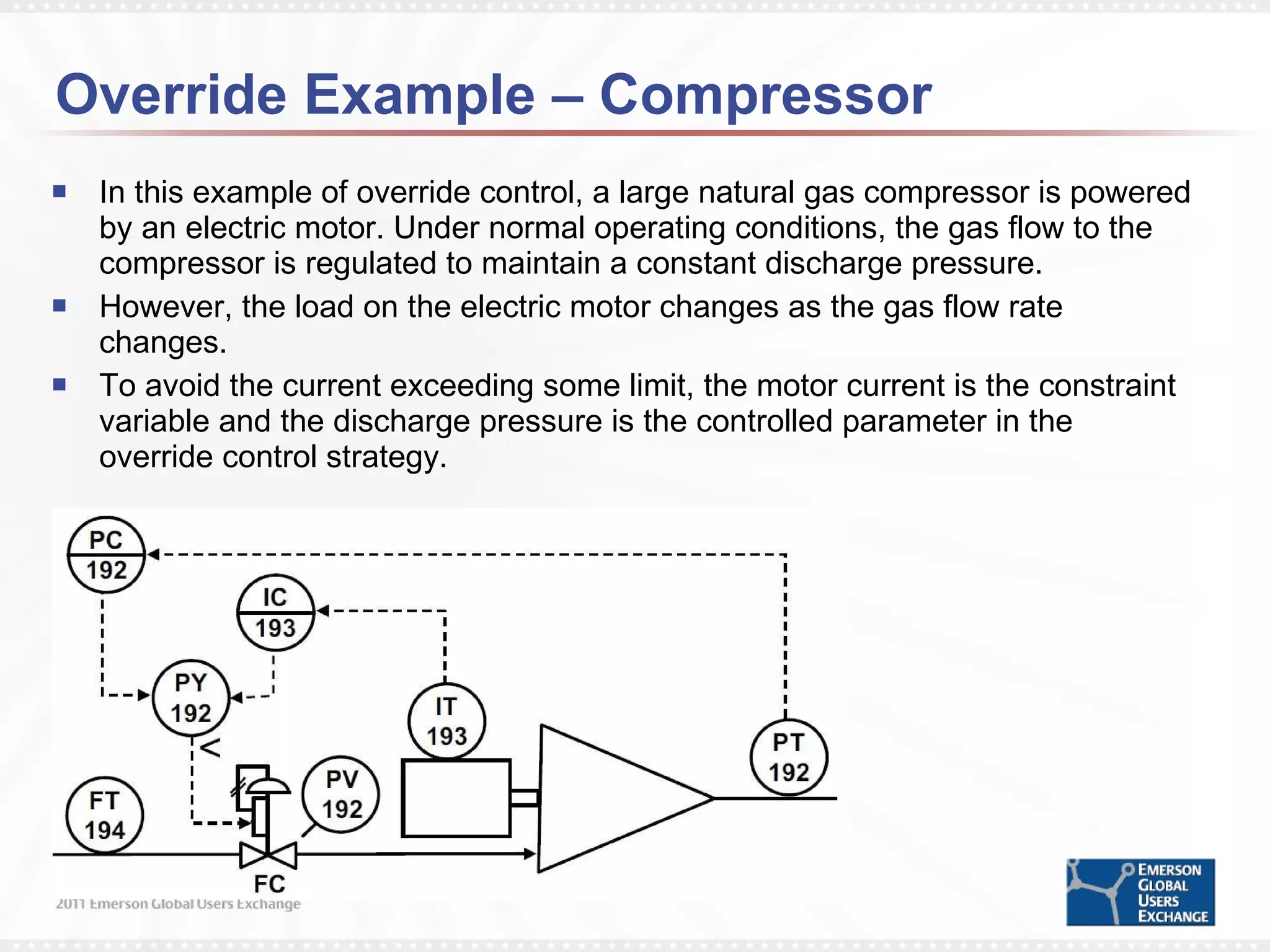

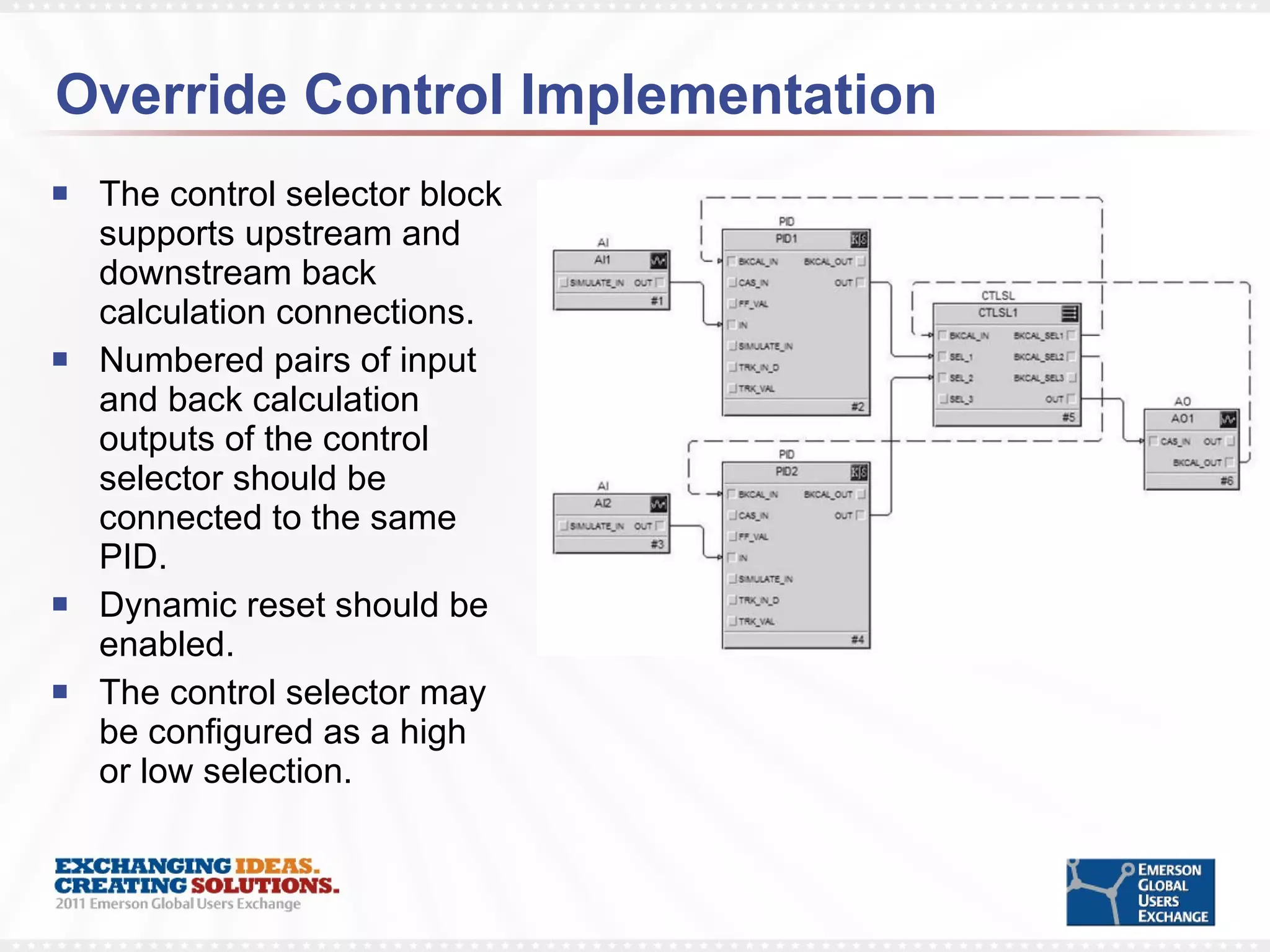

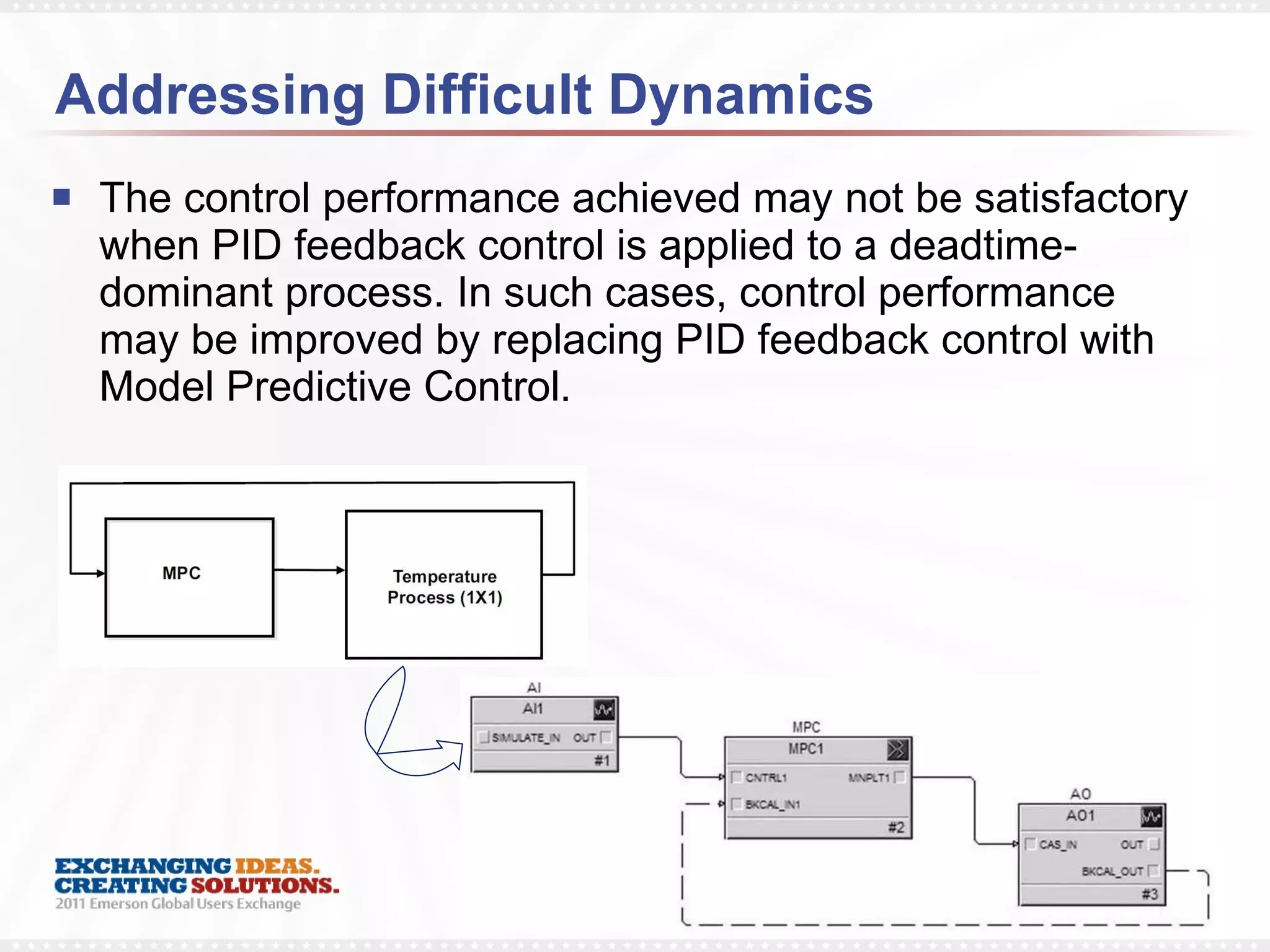

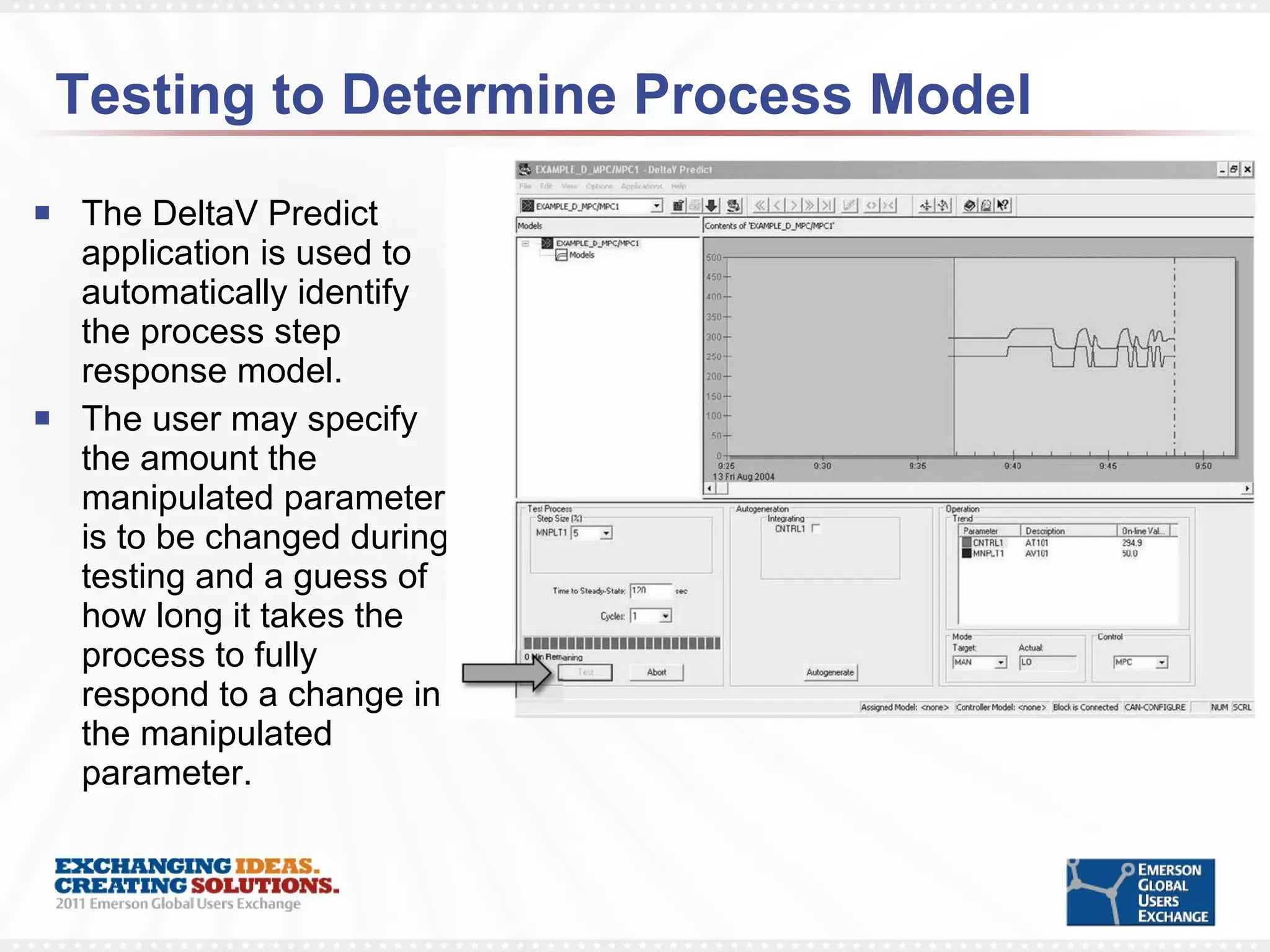

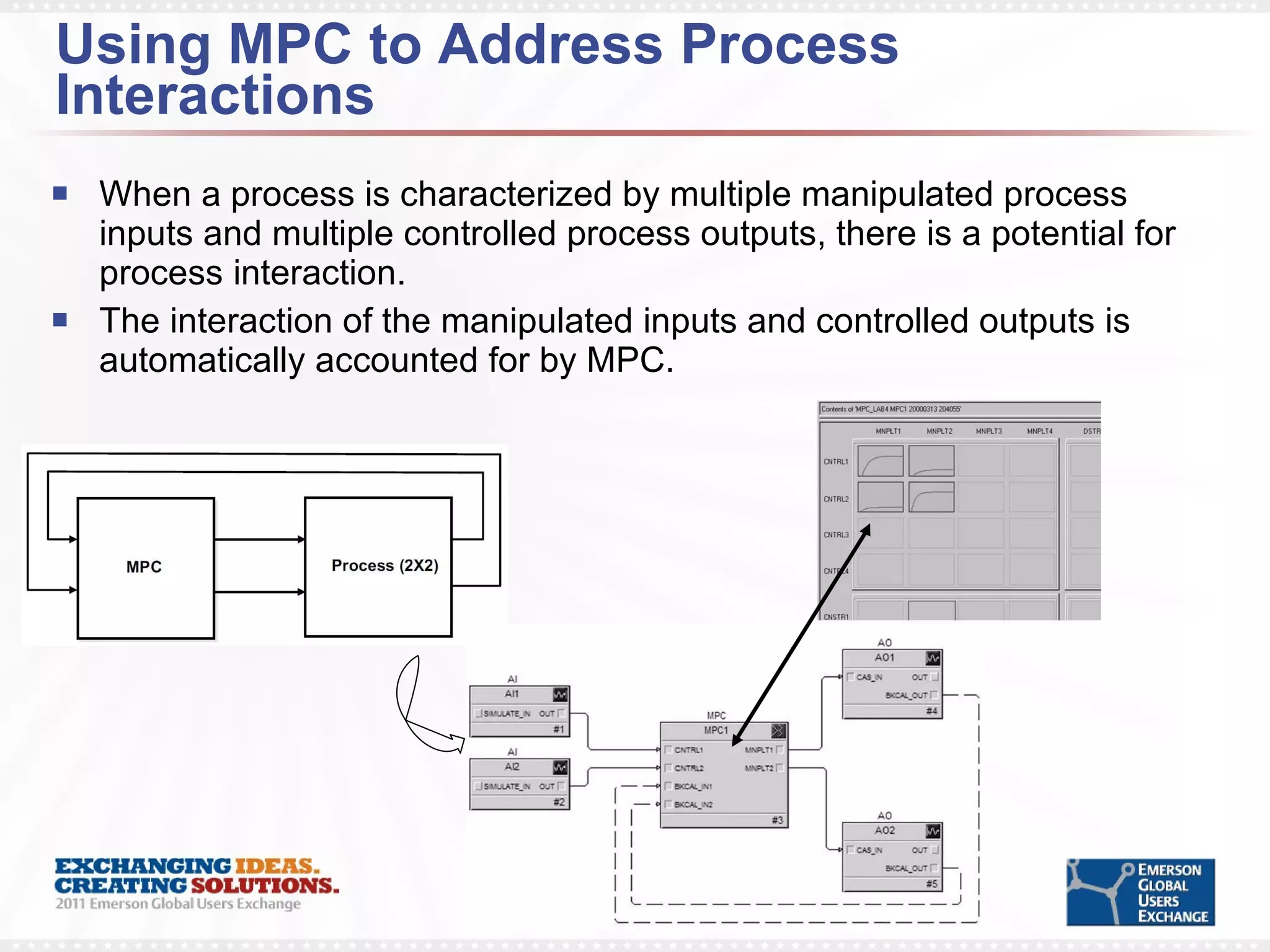

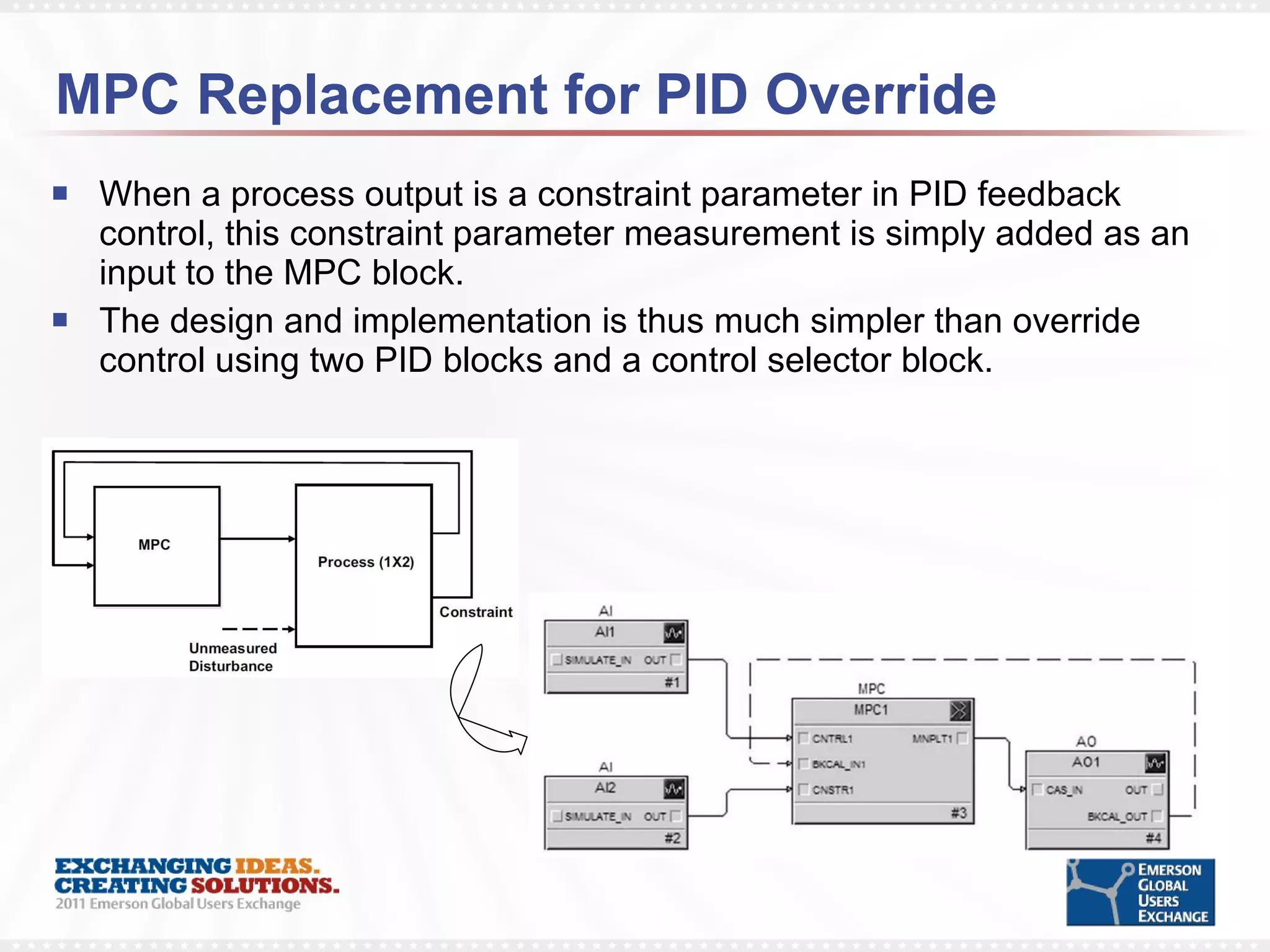

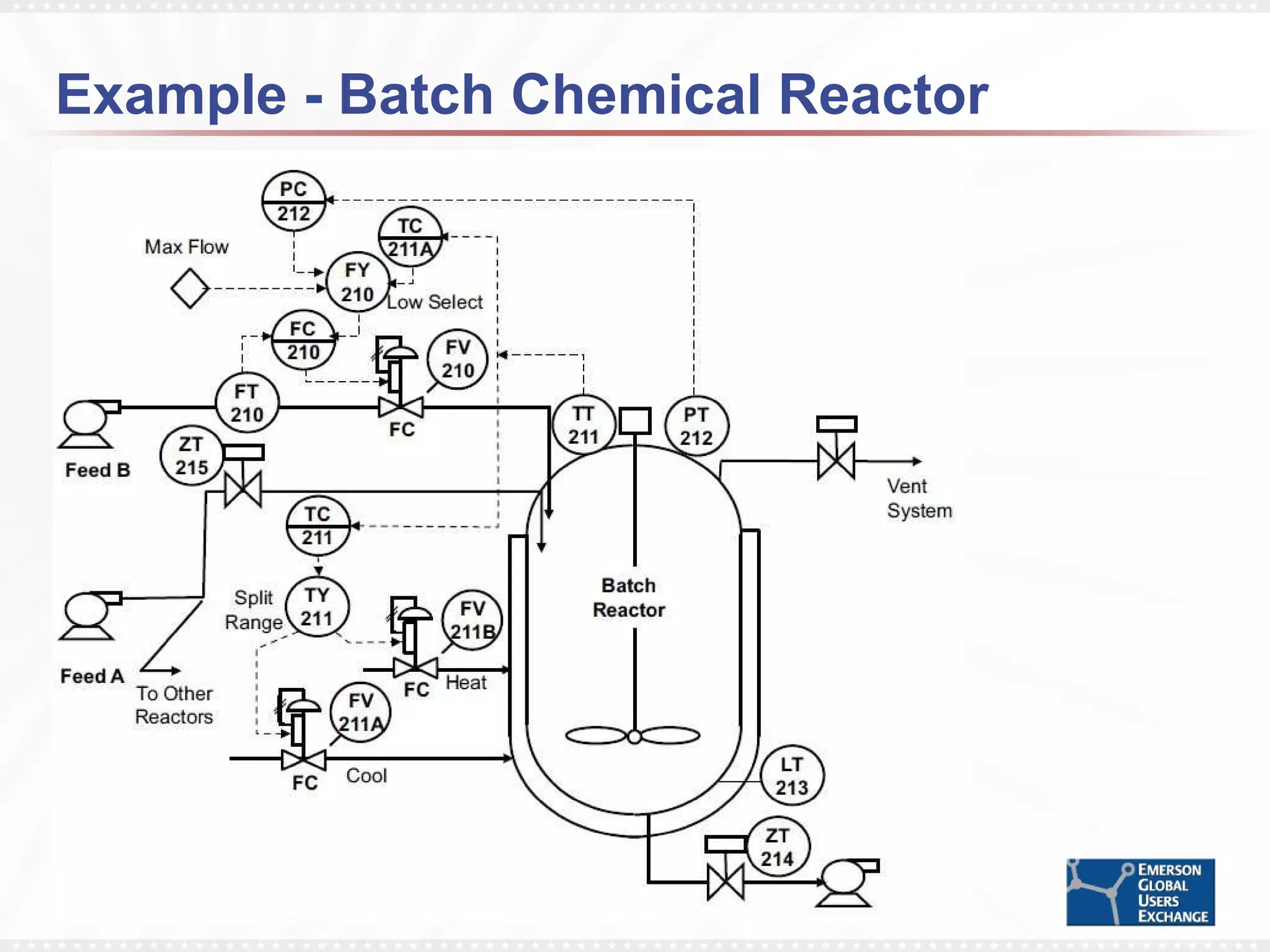

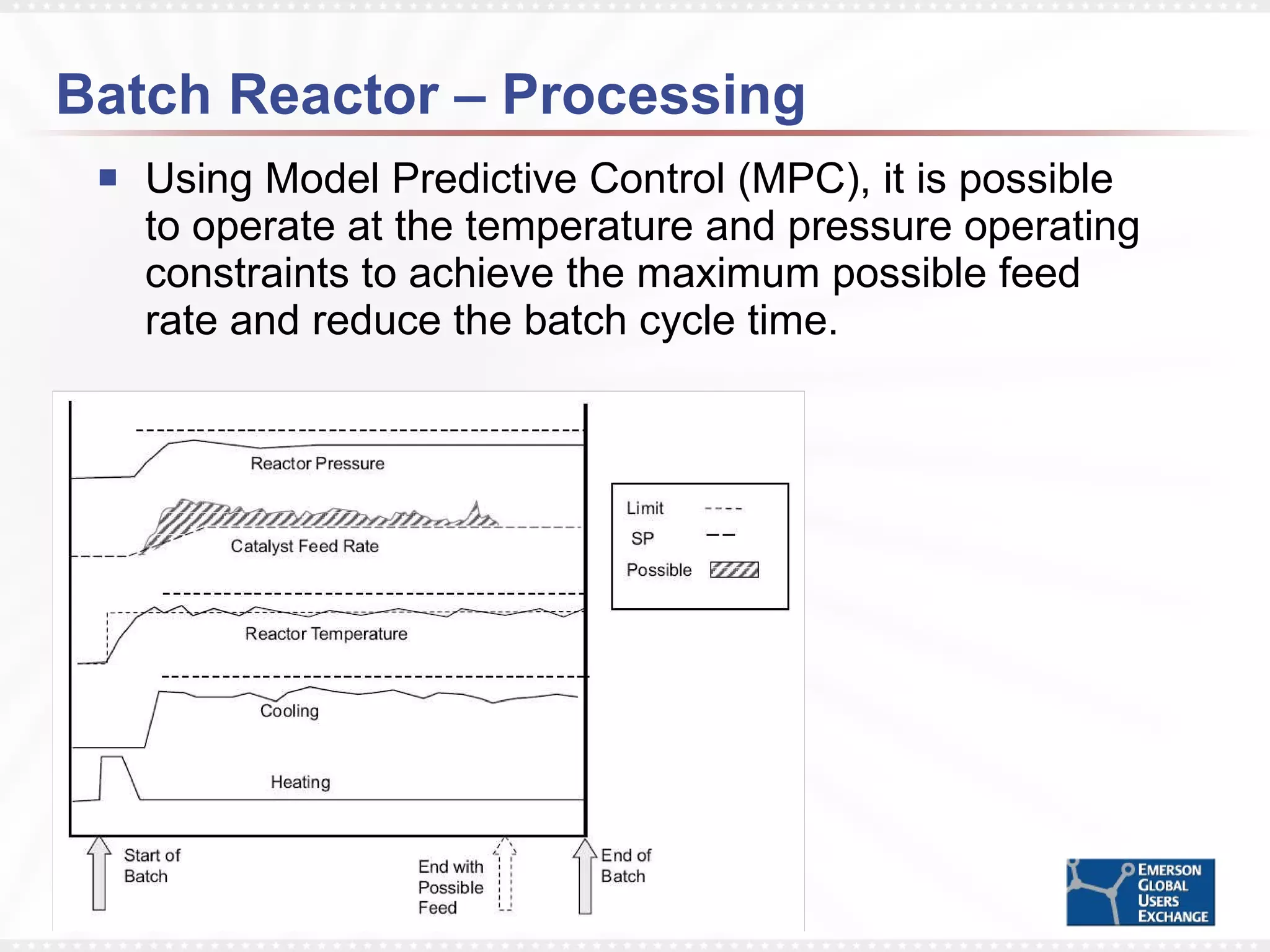

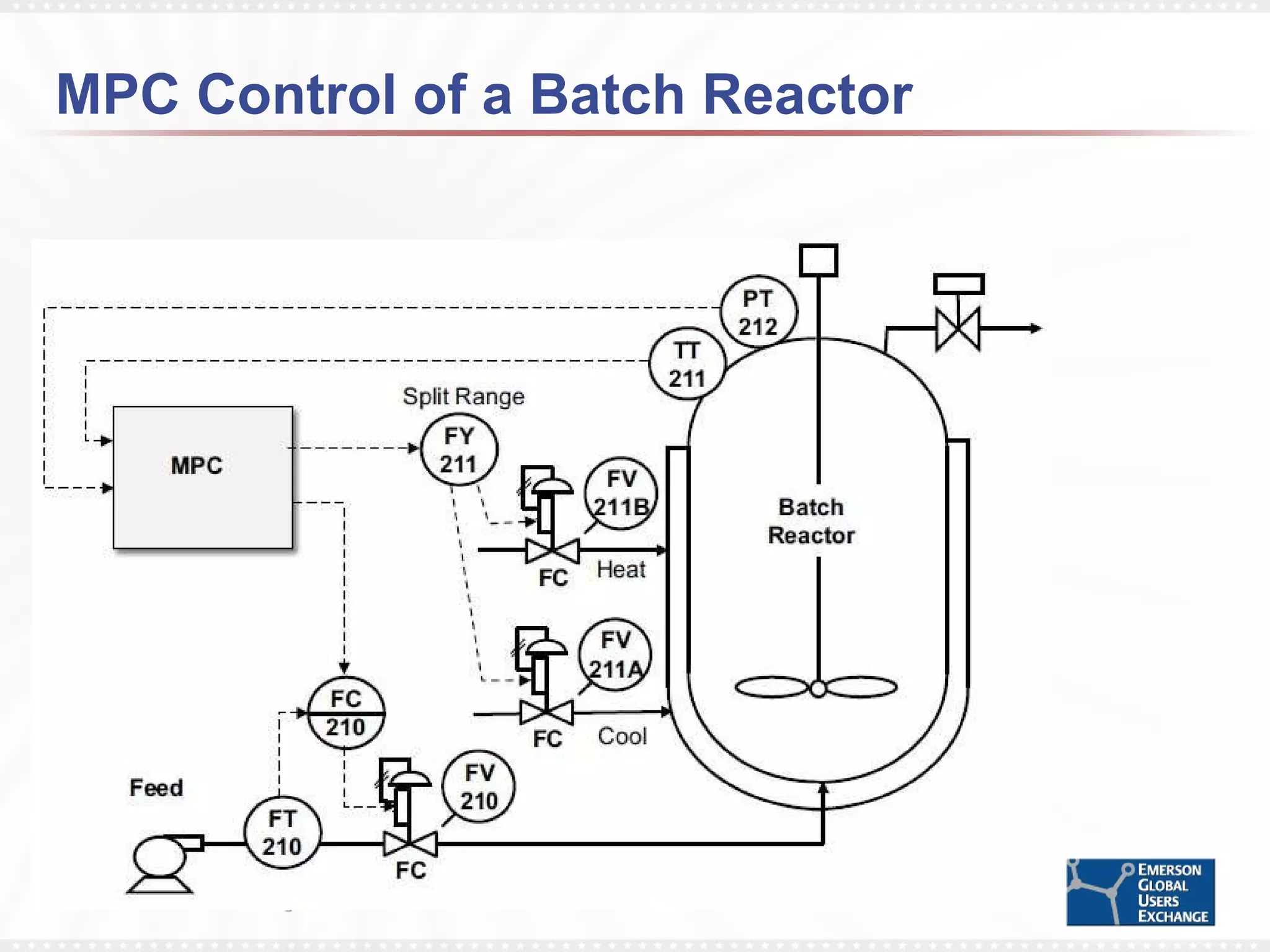

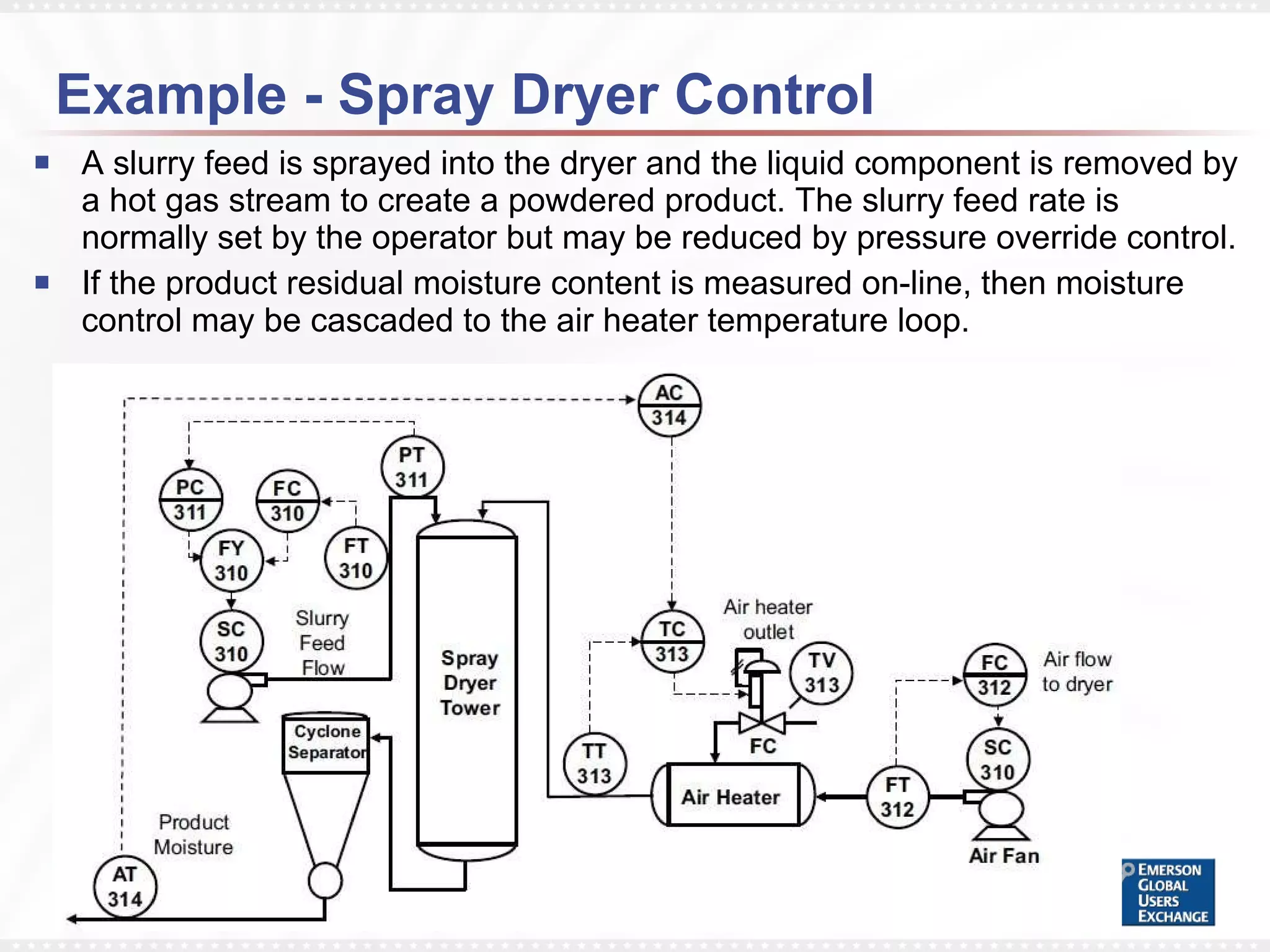

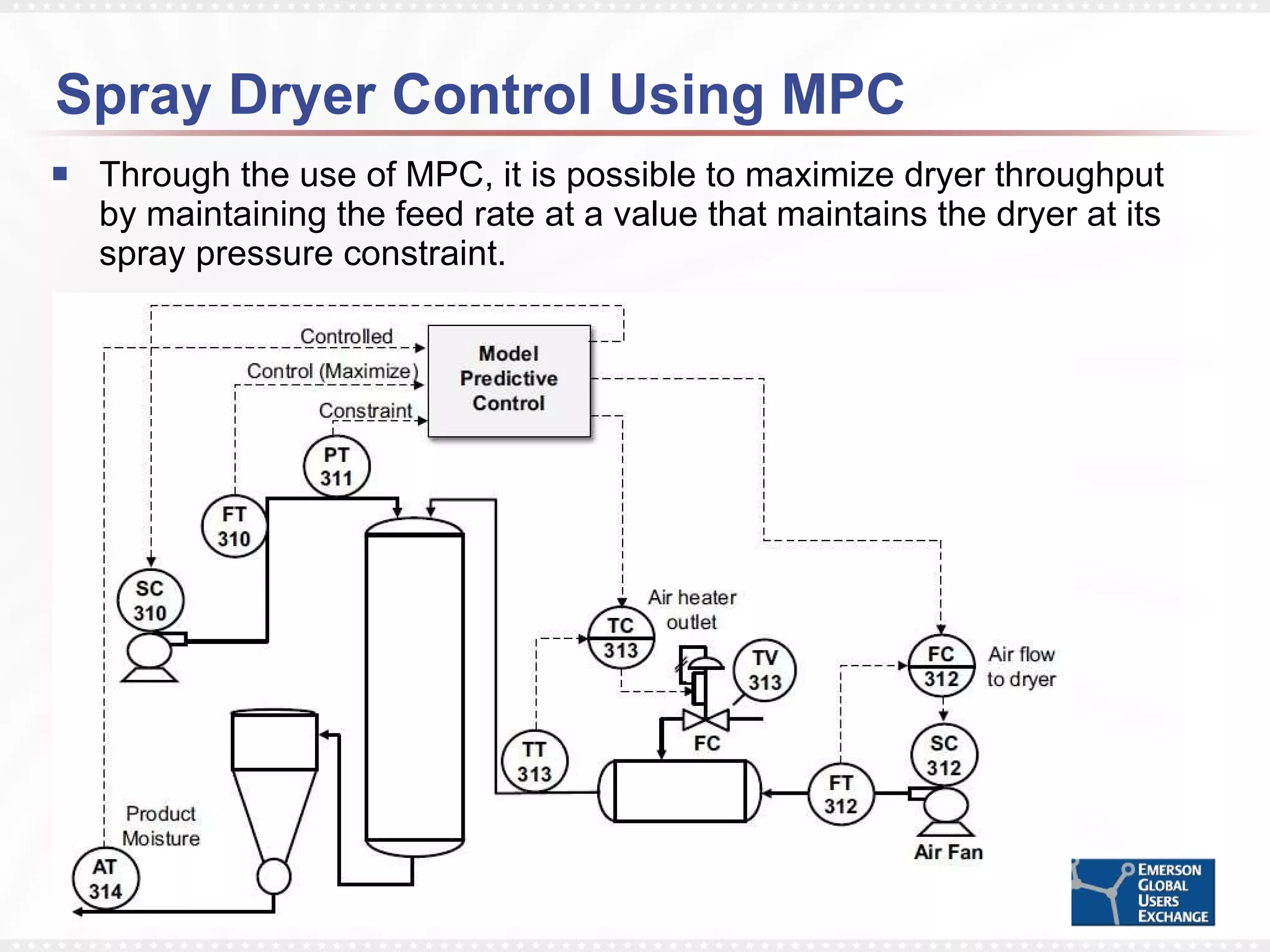

This document discusses when and why advanced control techniques beyond single-loop PID control may be needed. It describes economic incentive, safety/compliance, and equipment protection as key objectives that can require reduced variability. Multi-loop techniques like feedforward, cascade, and override control are introduced to improve control in cases where single PID loops are insufficient. Model predictive control is also presented as an option for addressing difficult dynamics or process interactions. Examples of ammonia plants, spray dryers, and batch reactors are provided.