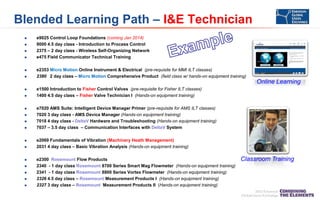

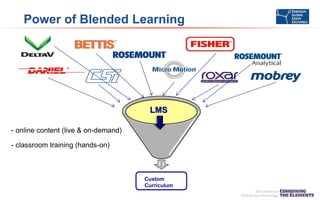

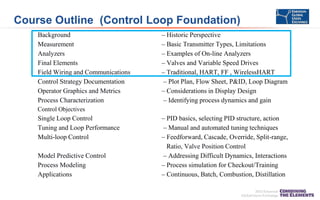

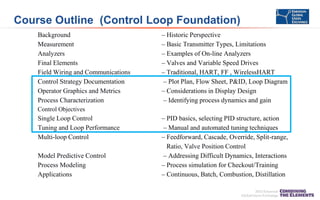

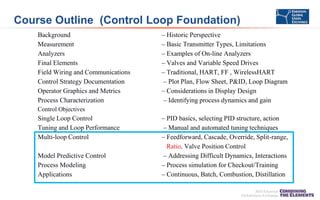

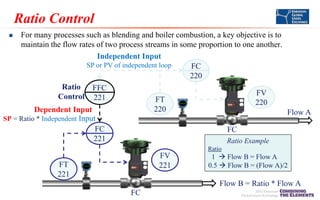

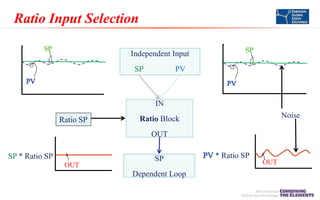

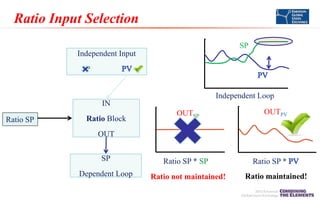

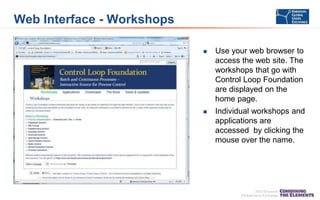

The document outlines a workshop focused on online educational services offering flexible, 24/7 access to customizable training for process control technologies, including blended learning options. Key topics include the upcoming e9025 course on control loop foundations, various online and classroom training programs, and strategies to improve customer learning experiences. It emphasizes the importance of high-quality content and supports personalized learning tailored to demographic and technological changes.