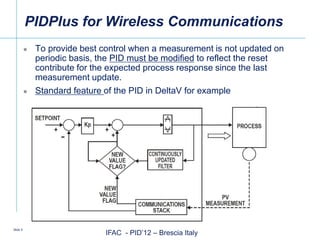

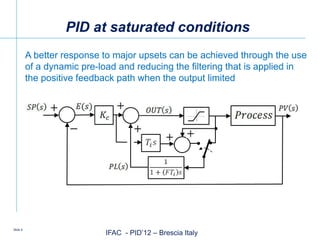

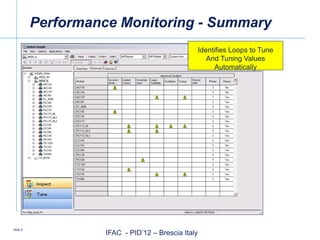

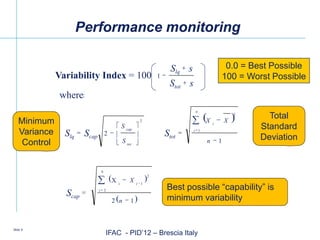

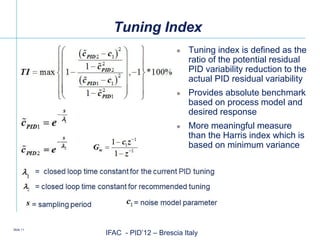

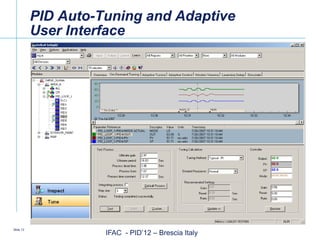

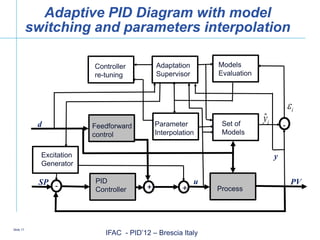

The document discusses advancements in intelligent PID (Proportional-Integral-Derivative) control systems presented at the IFAC conference in Brescia, Italy. It outlines features such as automatic performance improvement, fault detection, and an adaptive user interface that enhance control effectiveness. Key topics include PID tuning techniques, adaptive modeling, and the significance of robust process model identification for user acceptance.