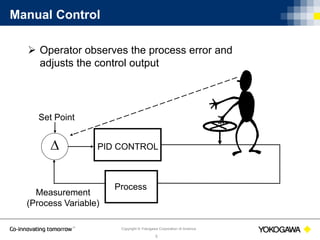

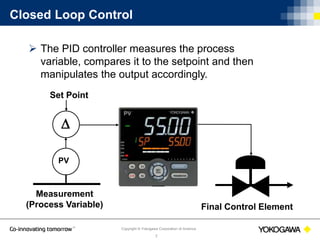

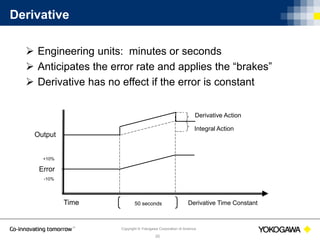

This document provides an overview of PID control basics and tuning. It begins with explaining why understanding PID is important and then covers common control techniques like manual, on/off, and closed loop control. It defines PID terms like proportional, integral, and derivative control and how they work together. The document discusses process dynamics around dead time and lag. It then provides guidance on manually tuning PID loops and using auto-tune functions. It concludes by listing some Yokogawa products that incorporate PID control capabilities.