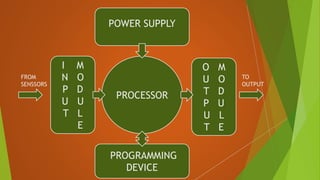

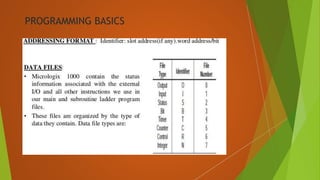

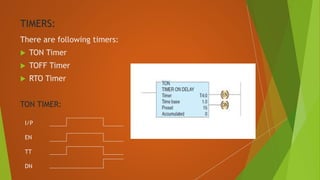

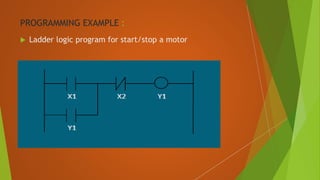

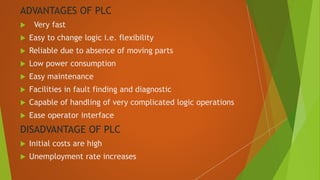

This document provides an overview of PLC and SCADA systems. It defines PLC as an industrial computer that monitors inputs, makes decisions based on its program, and controls outputs to automate processes. The history and components of PLCs are described, including the power supply, I/O modules, processor, and programming devices. Programming languages for PLCs include ladder logic, functional block diagrams, and sequential function charts. SCADA is defined as software used for process control that allows users to monitor, control, generate alarms and acquire data from remote facilities. The document discusses the composition, advantages, and applications of SCADA systems.