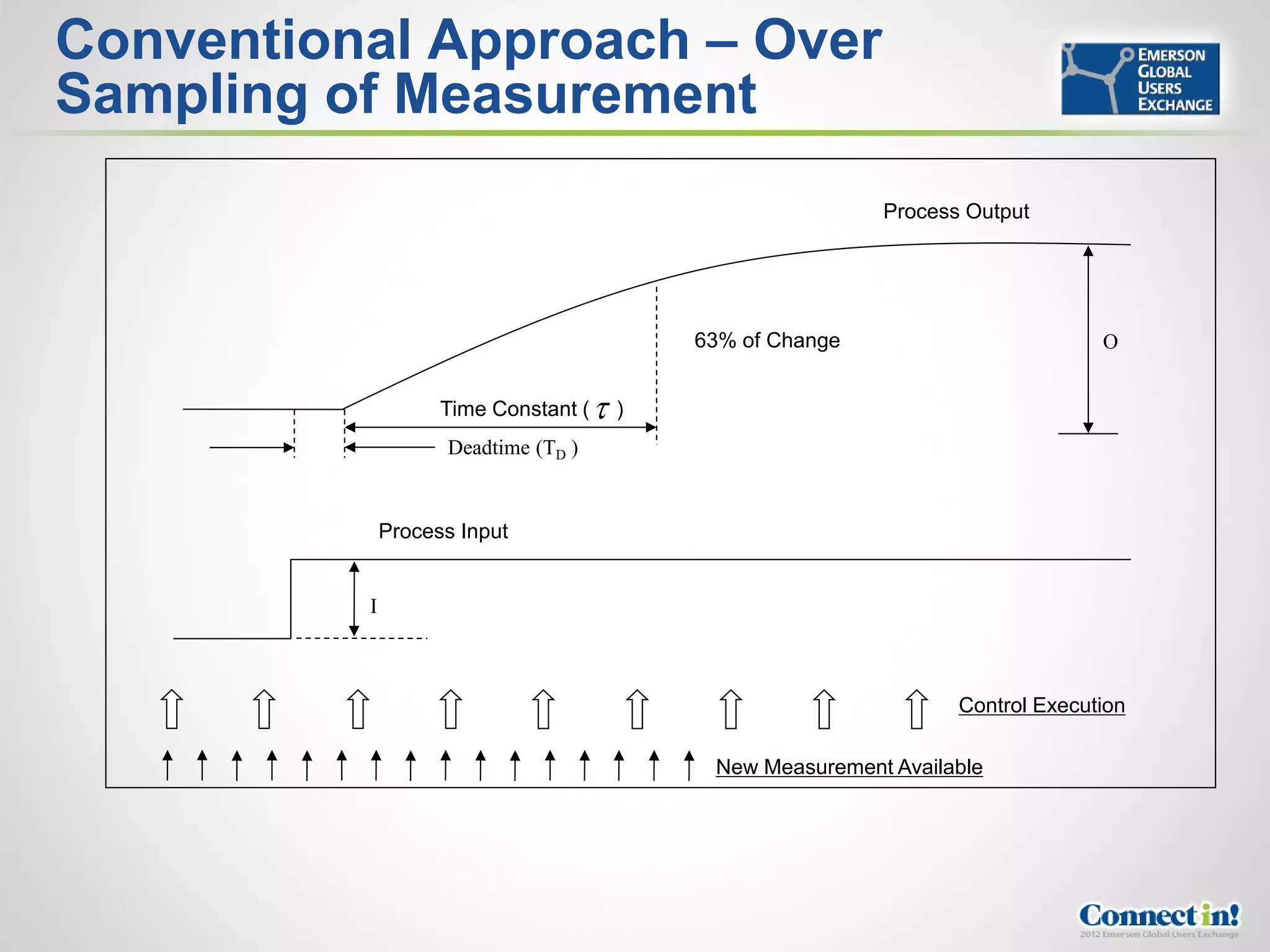

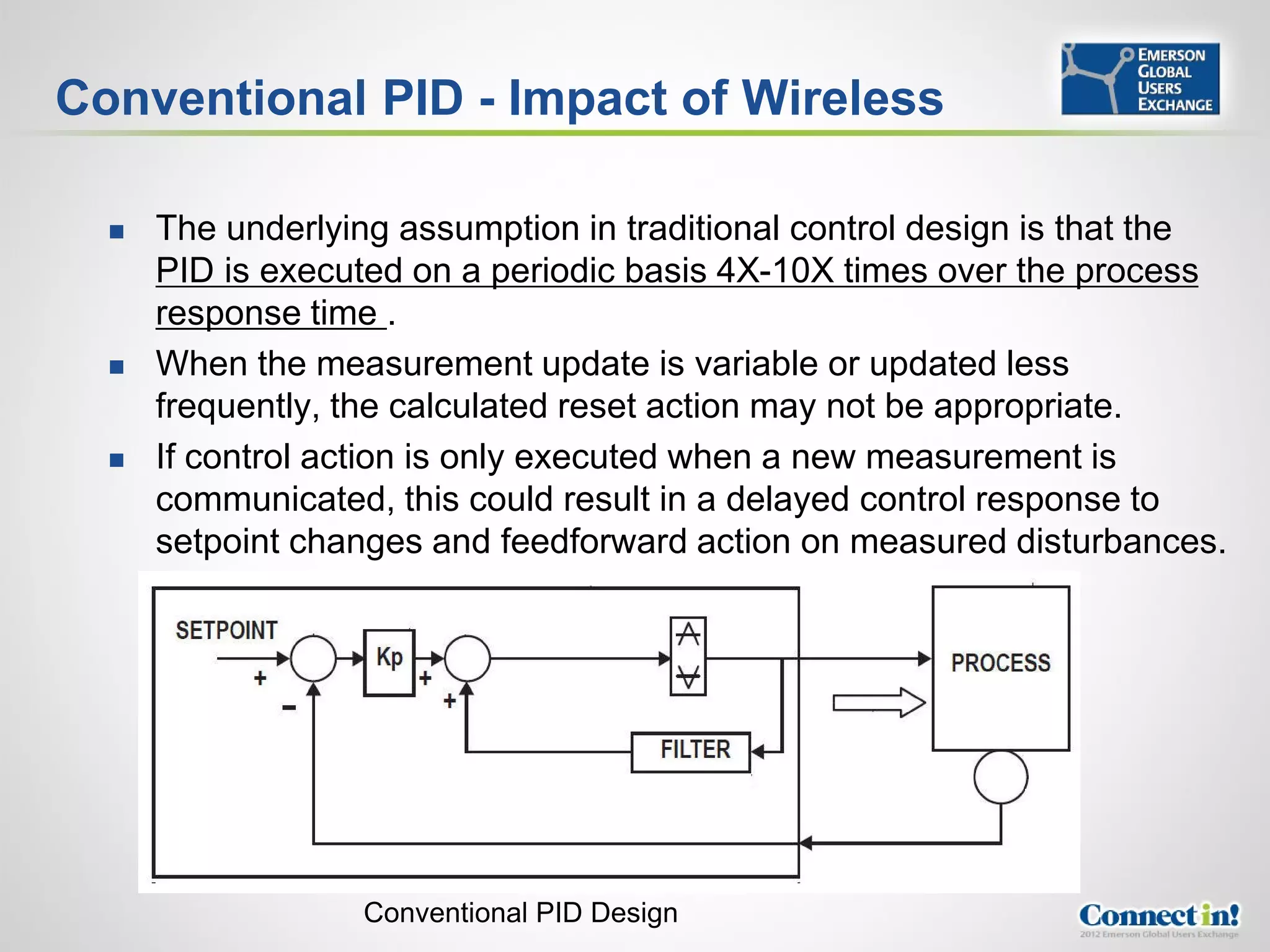

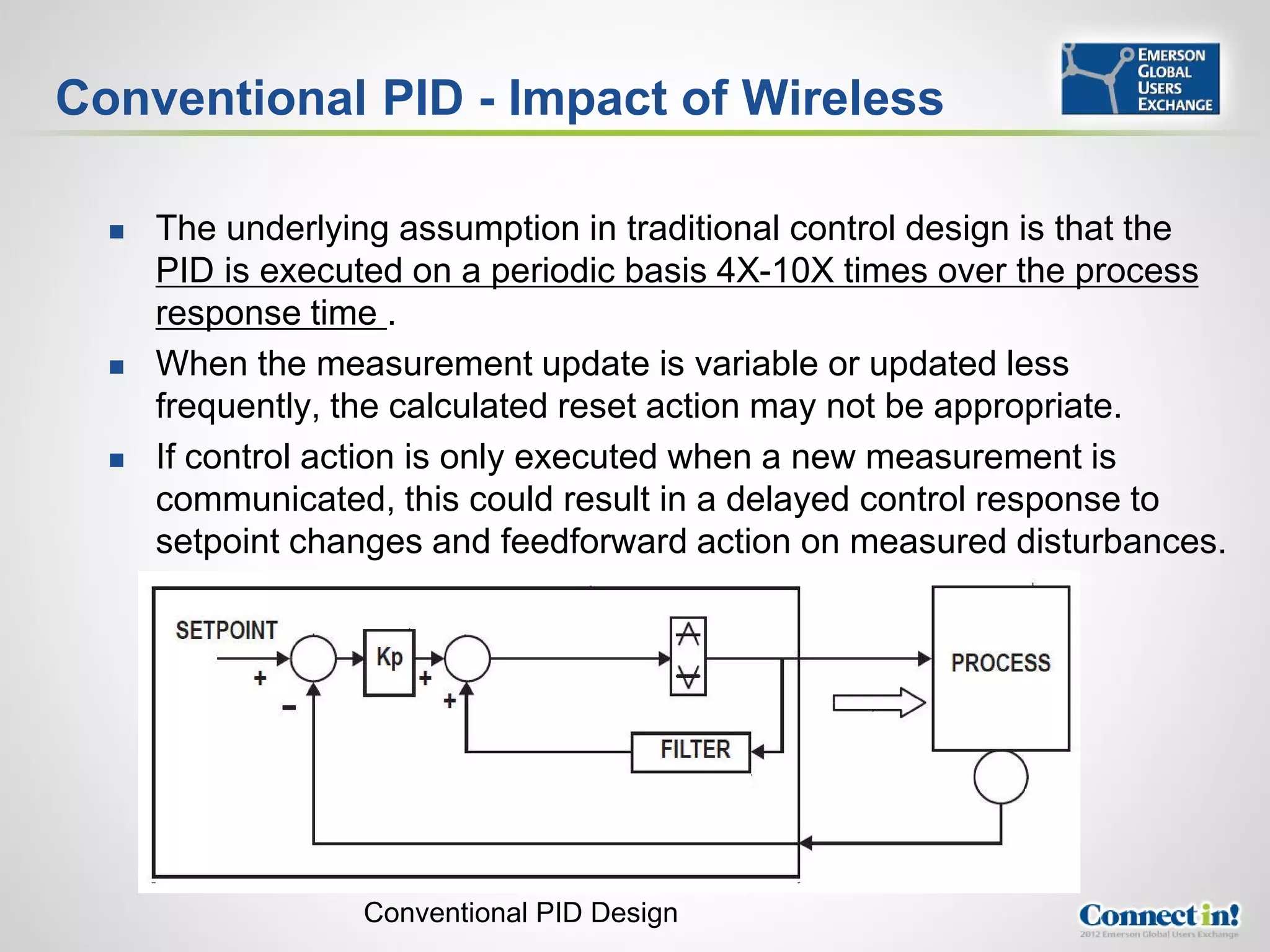

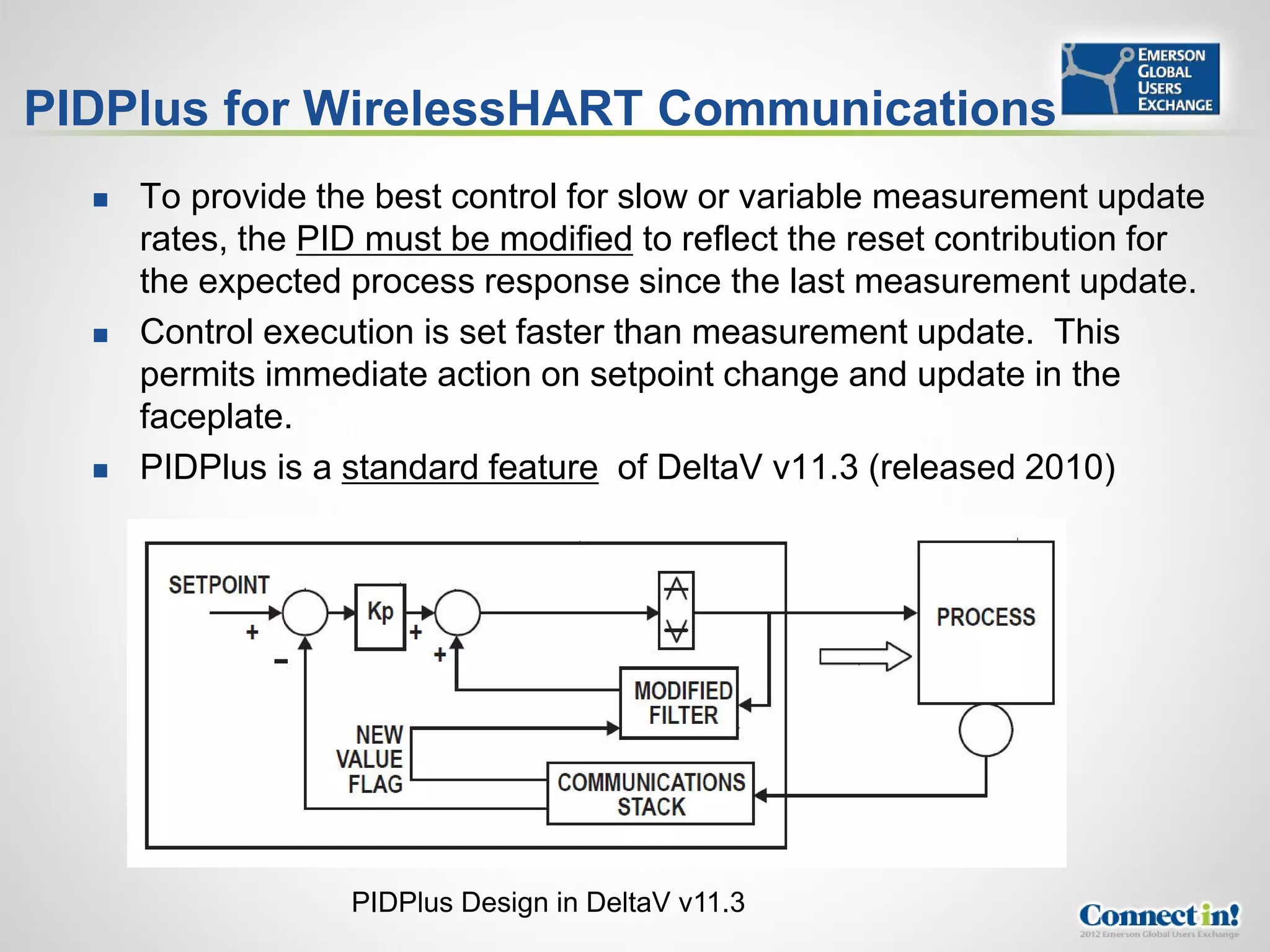

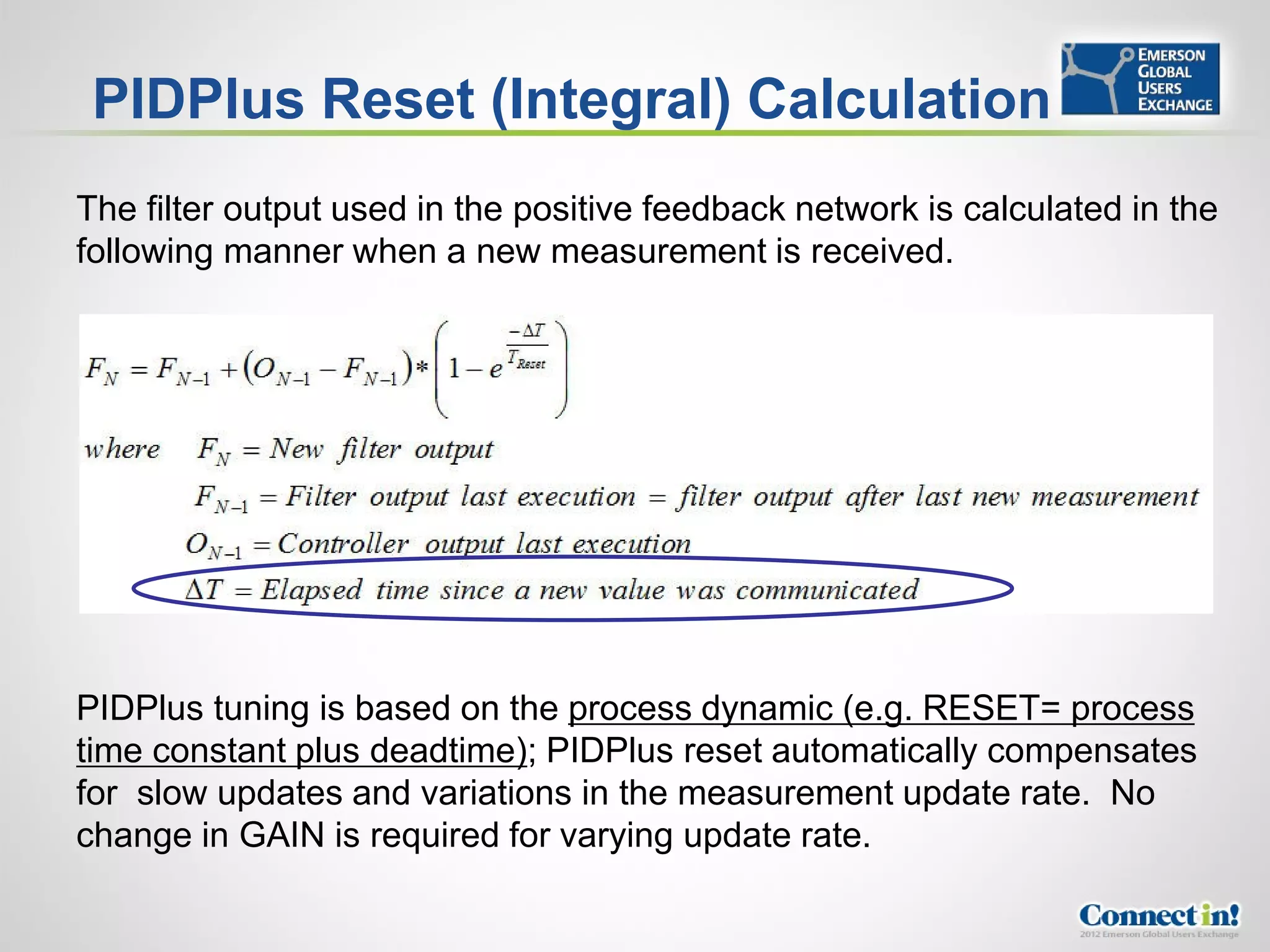

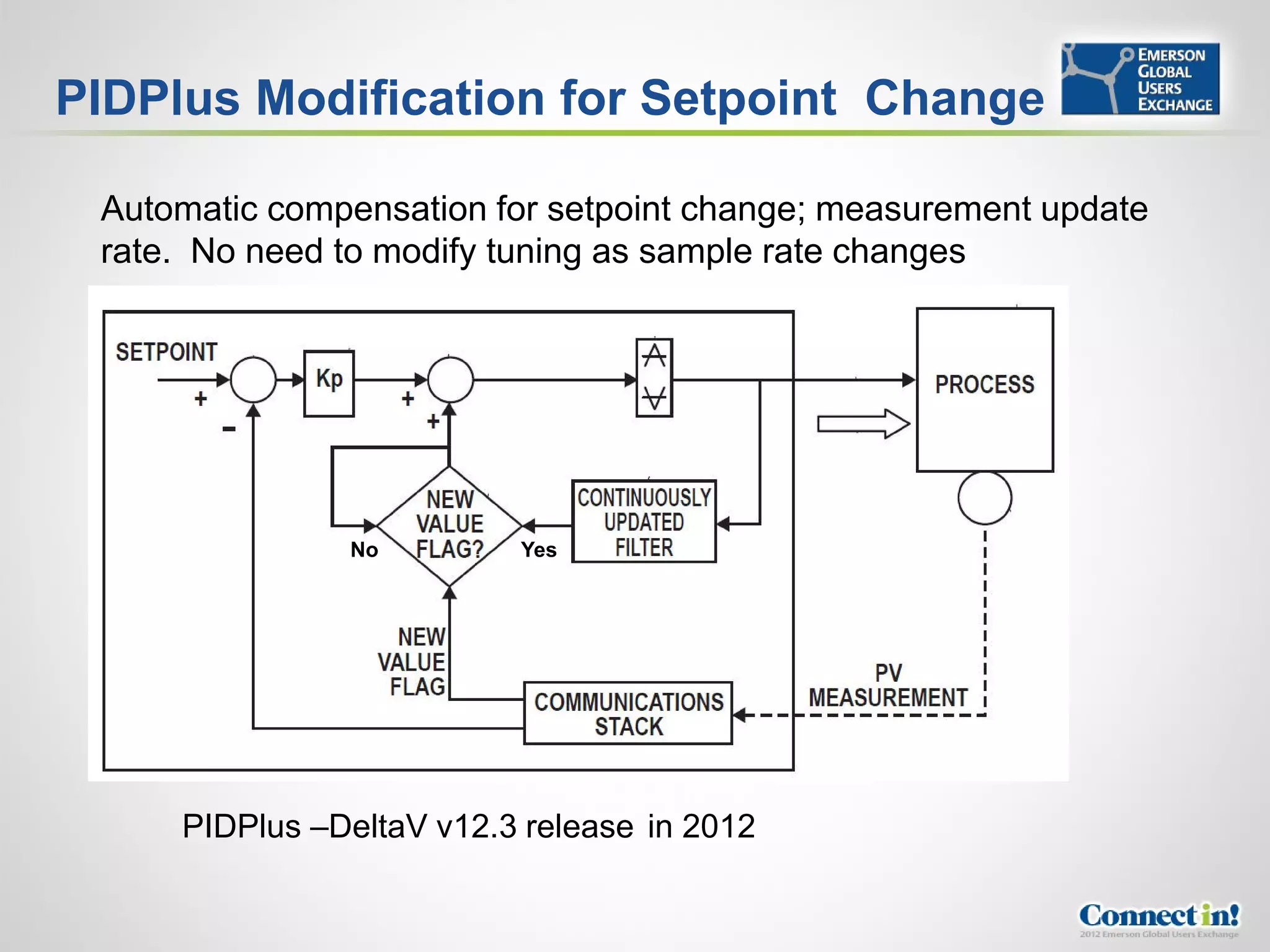

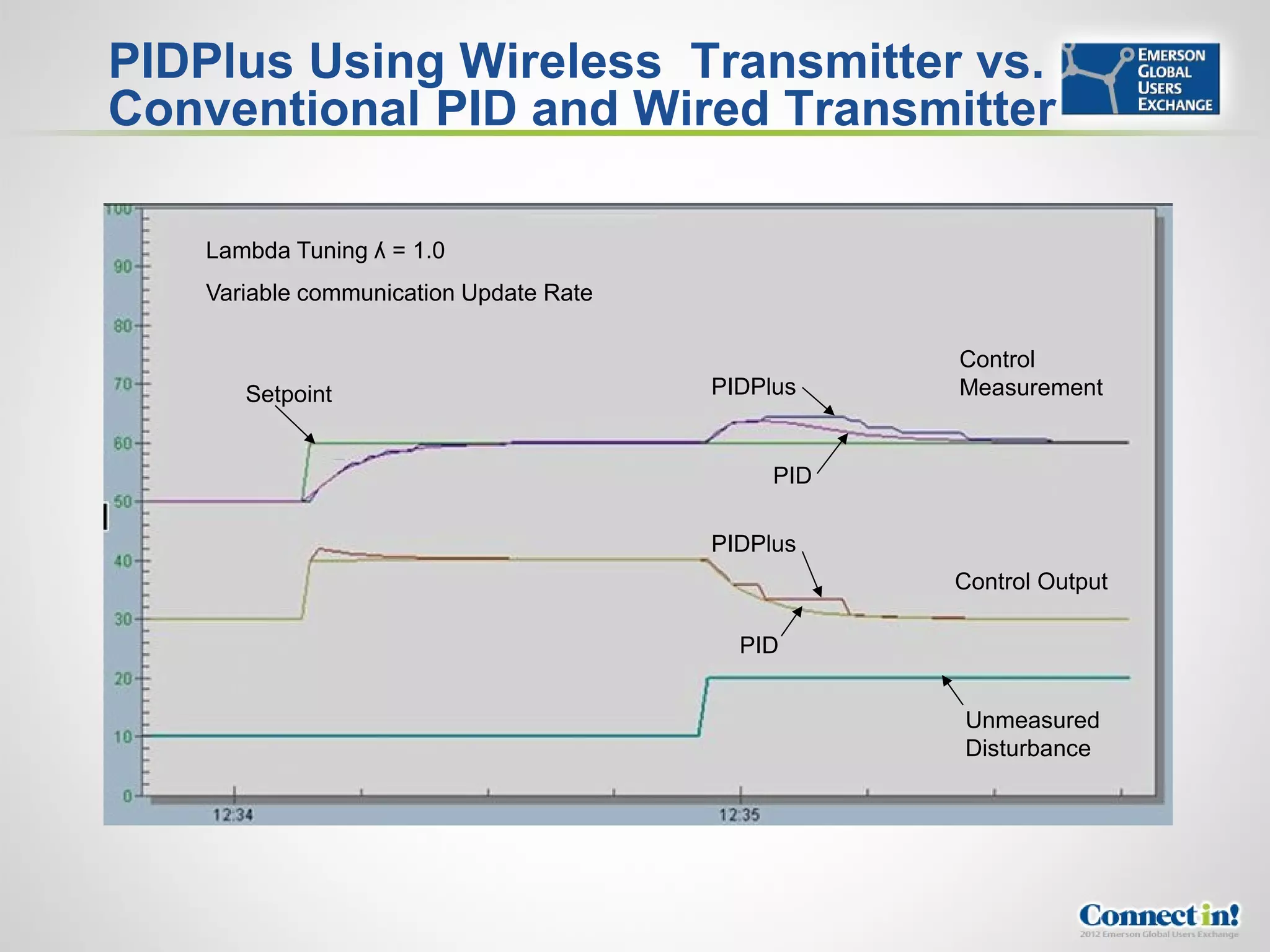

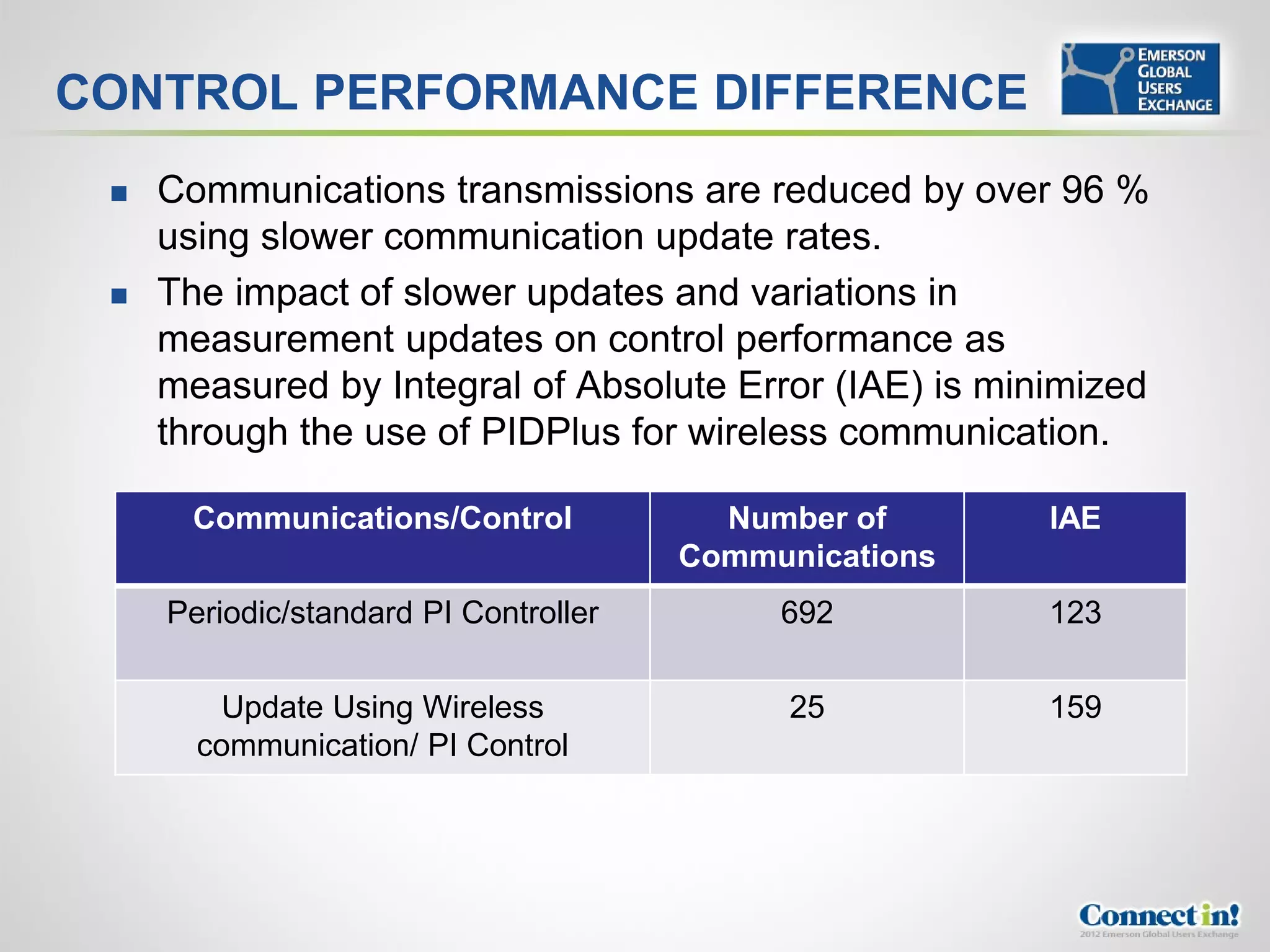

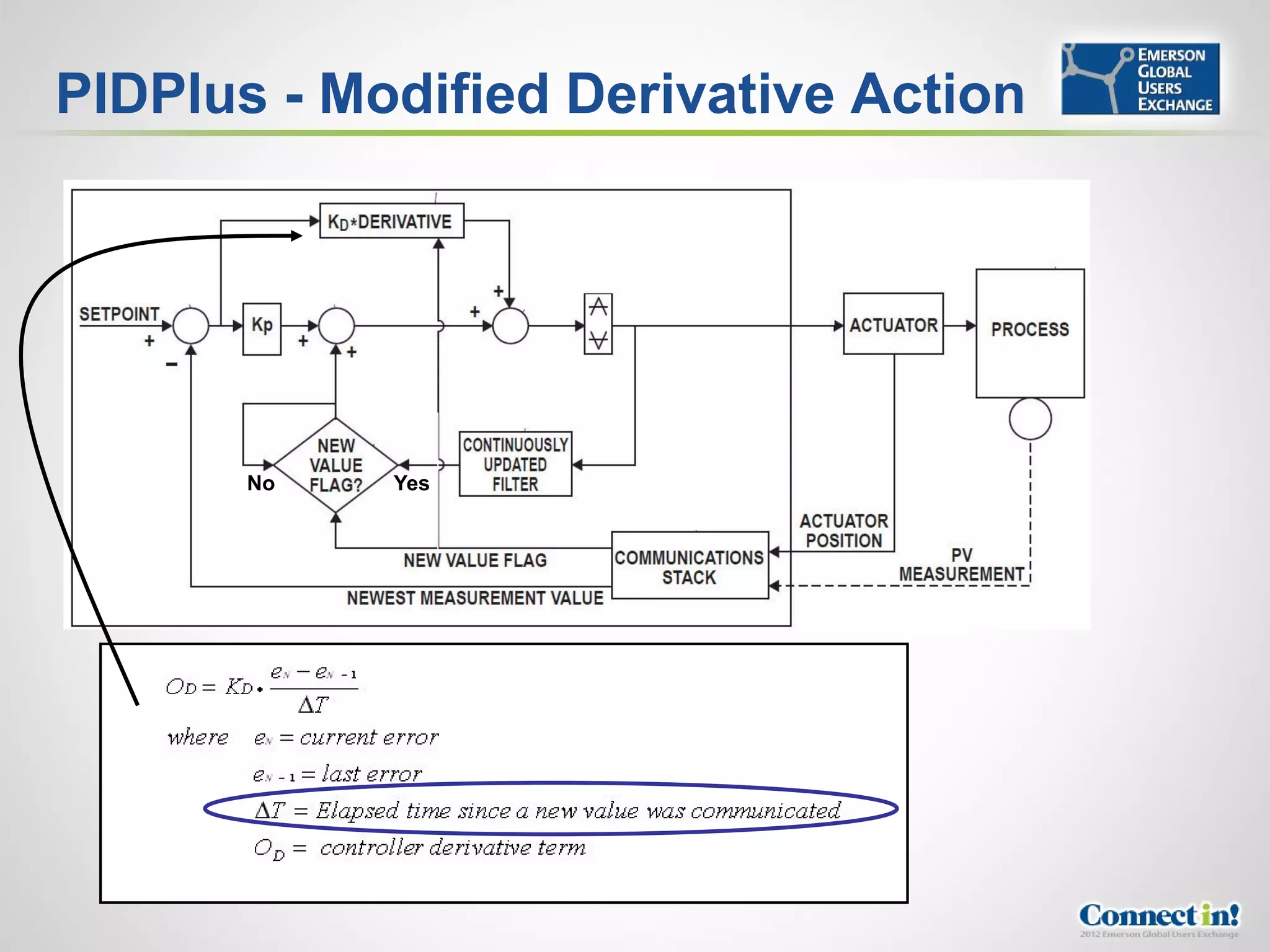

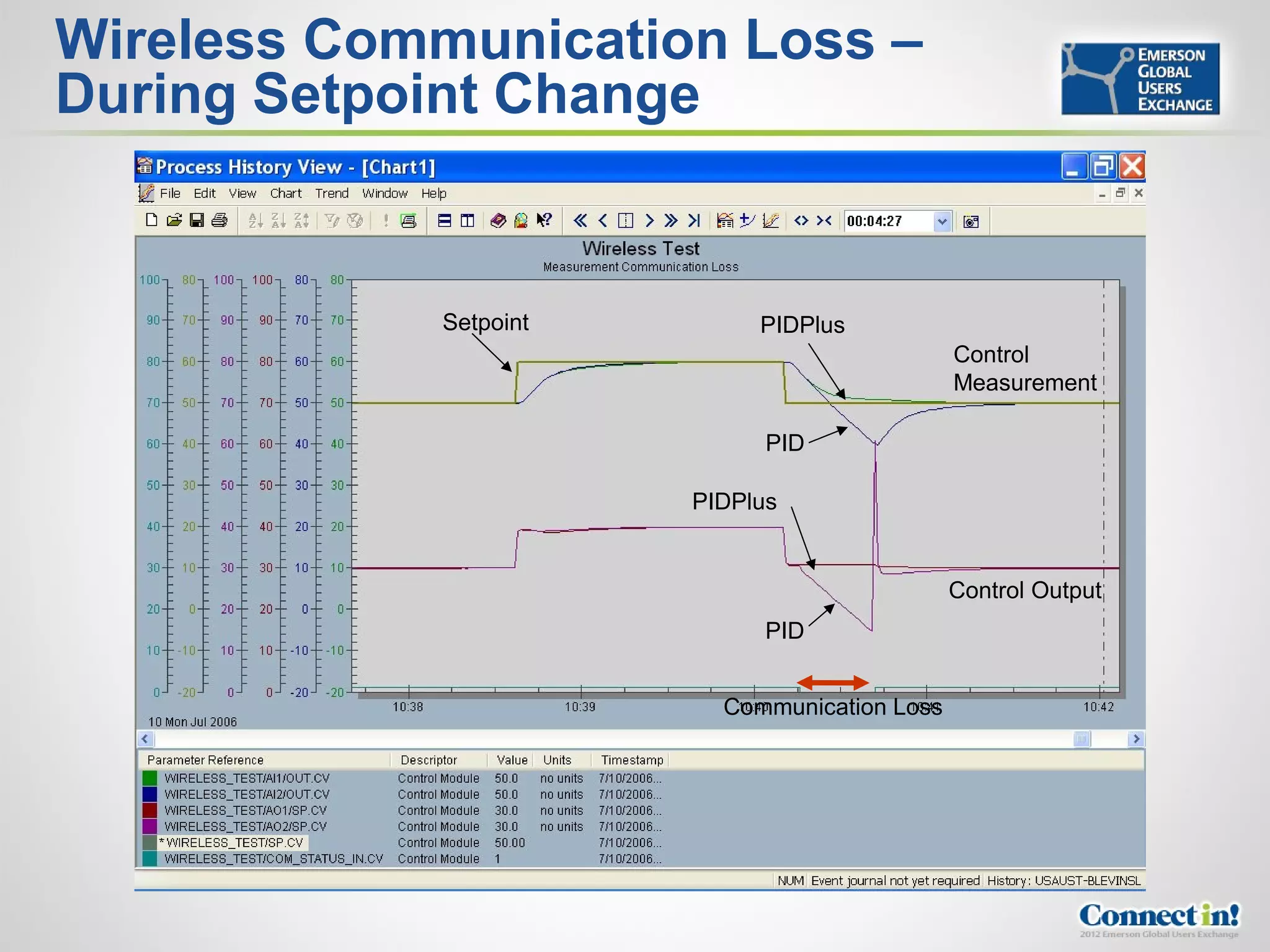

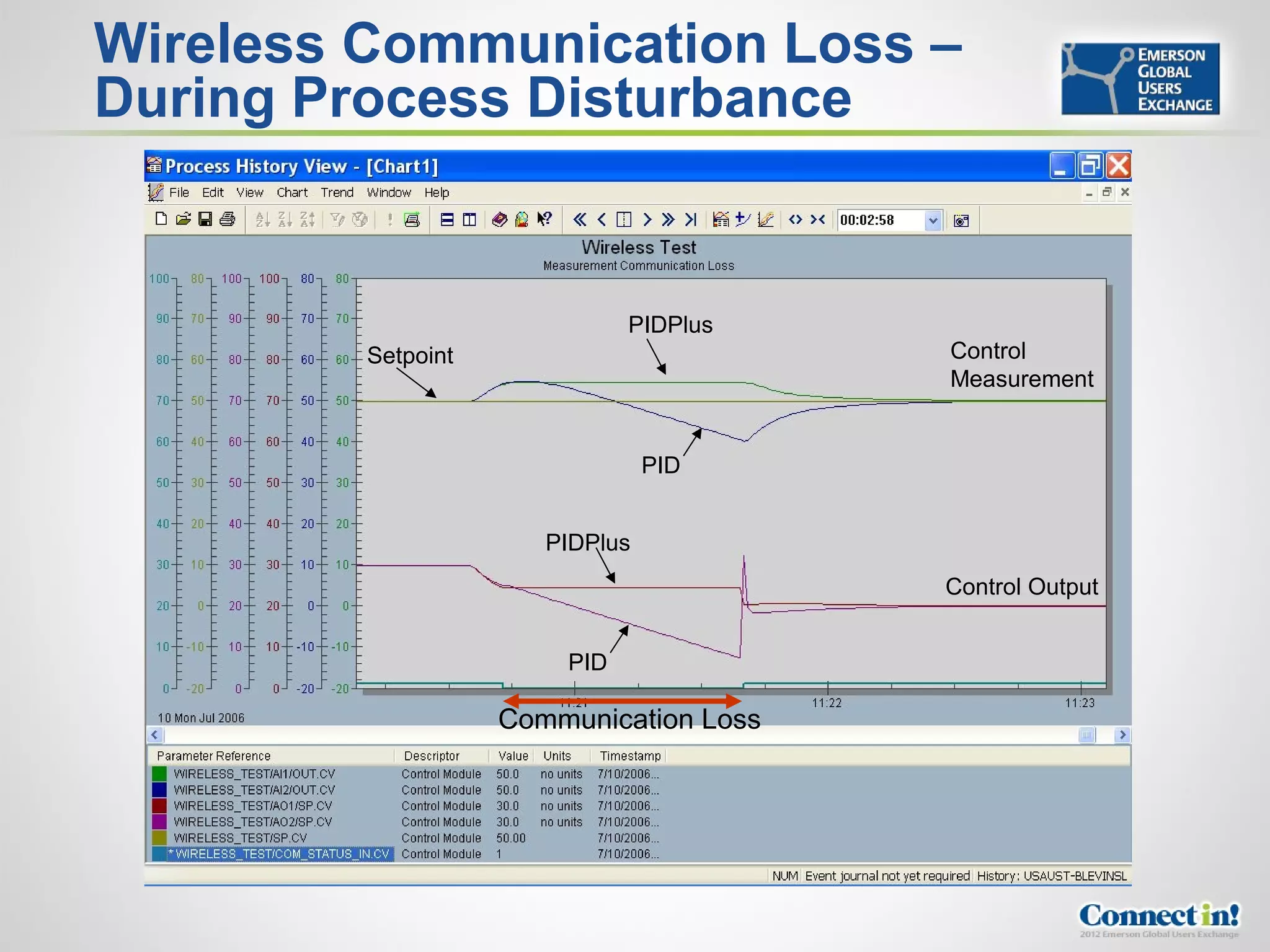

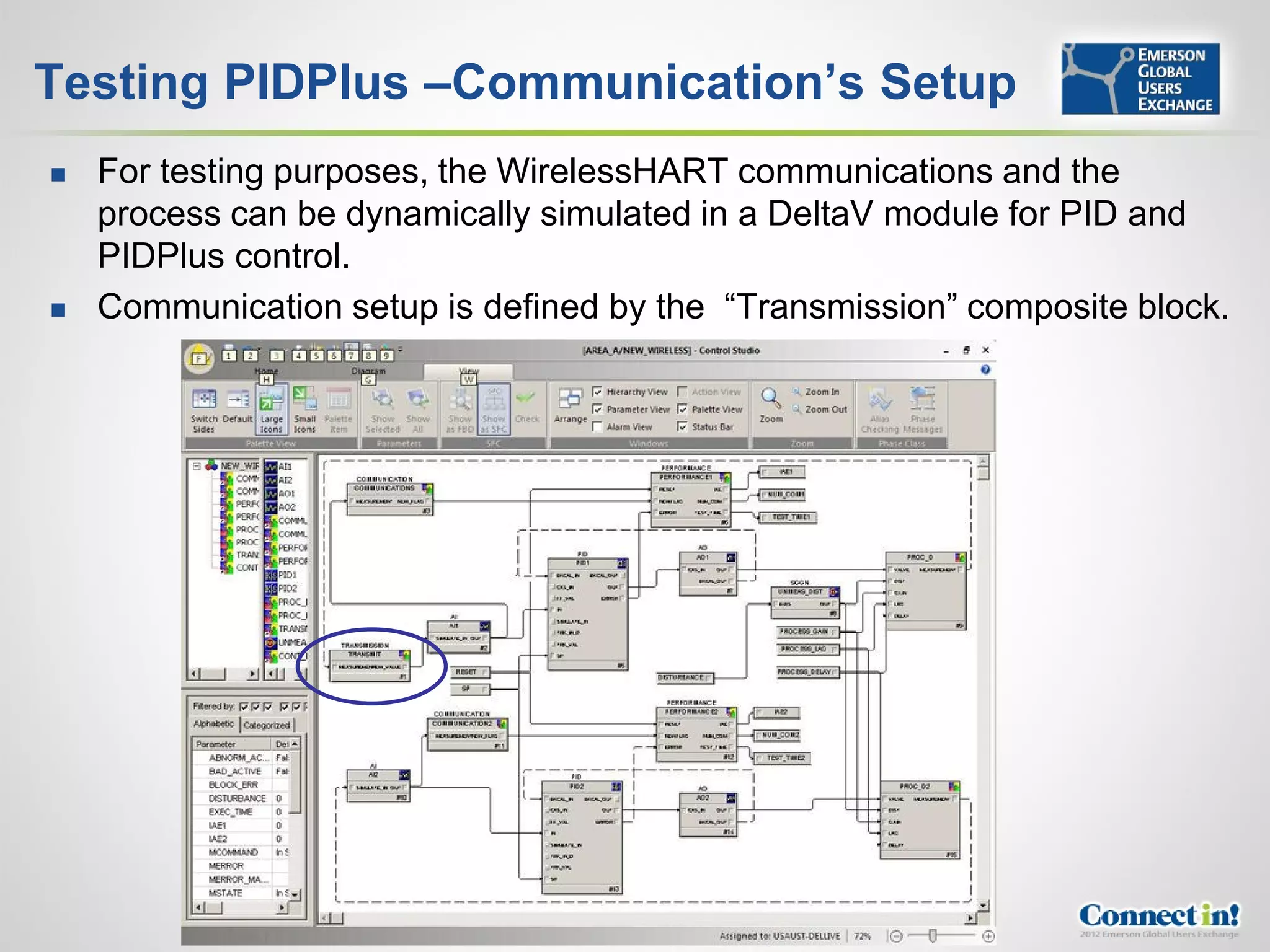

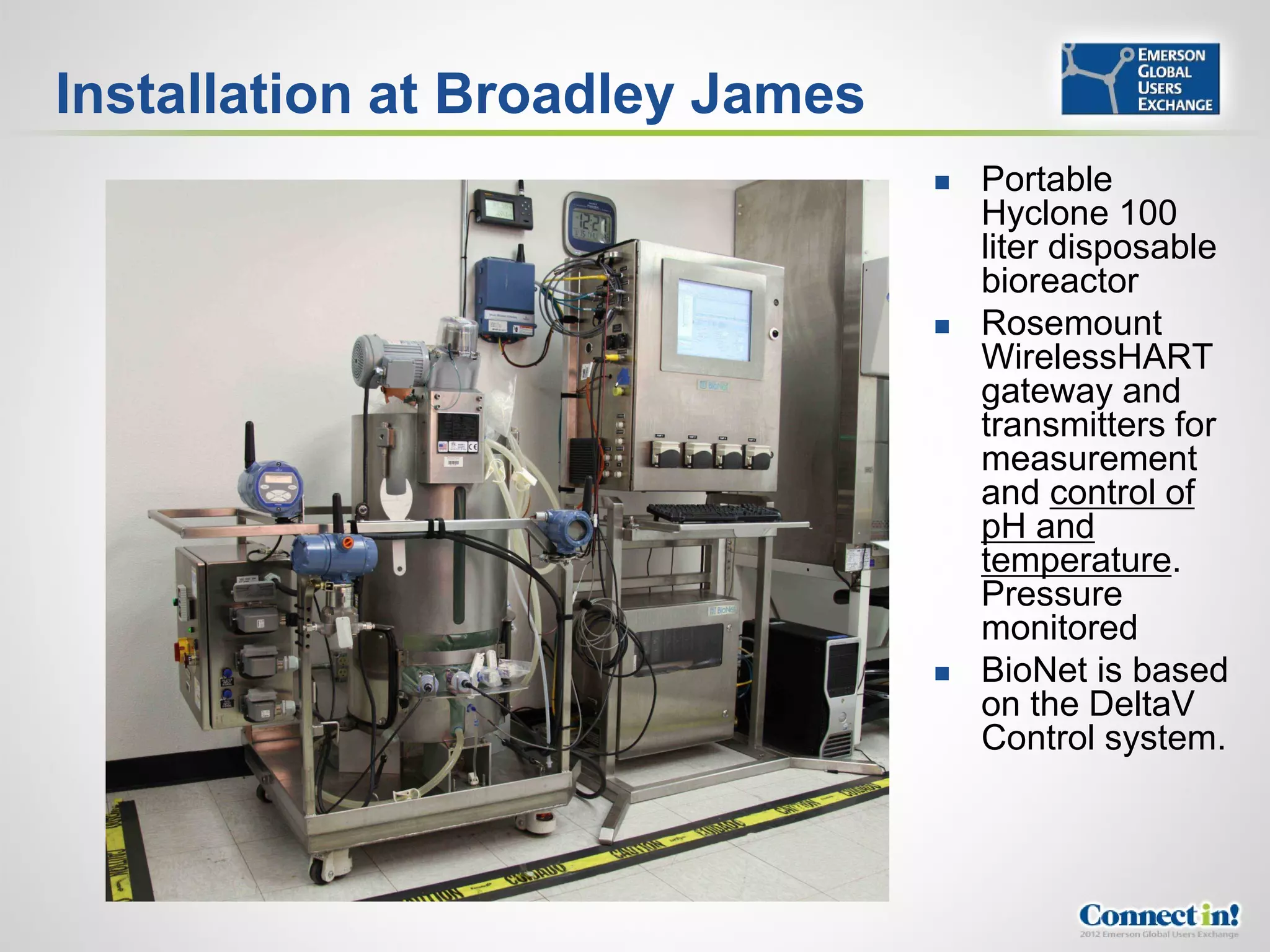

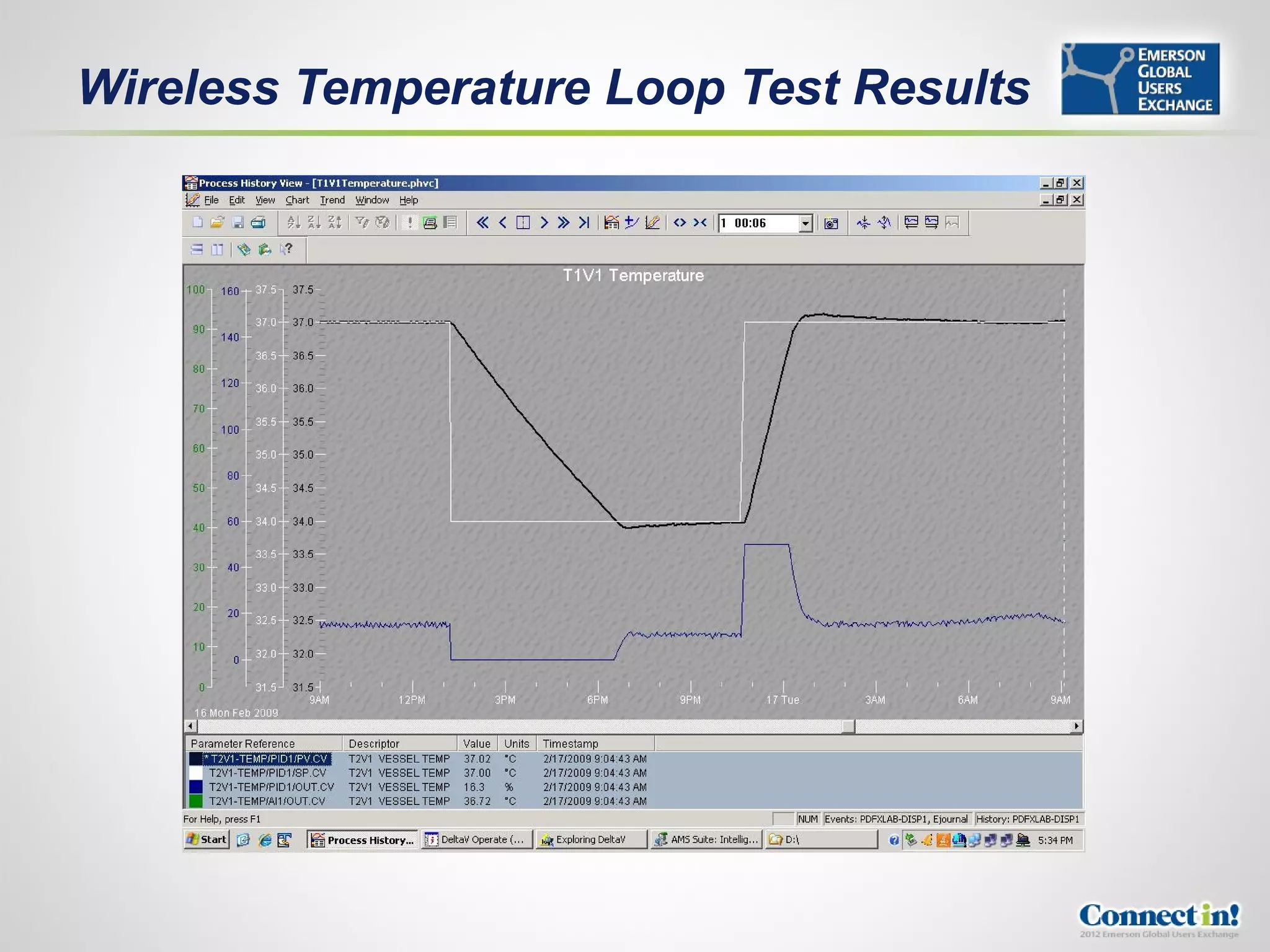

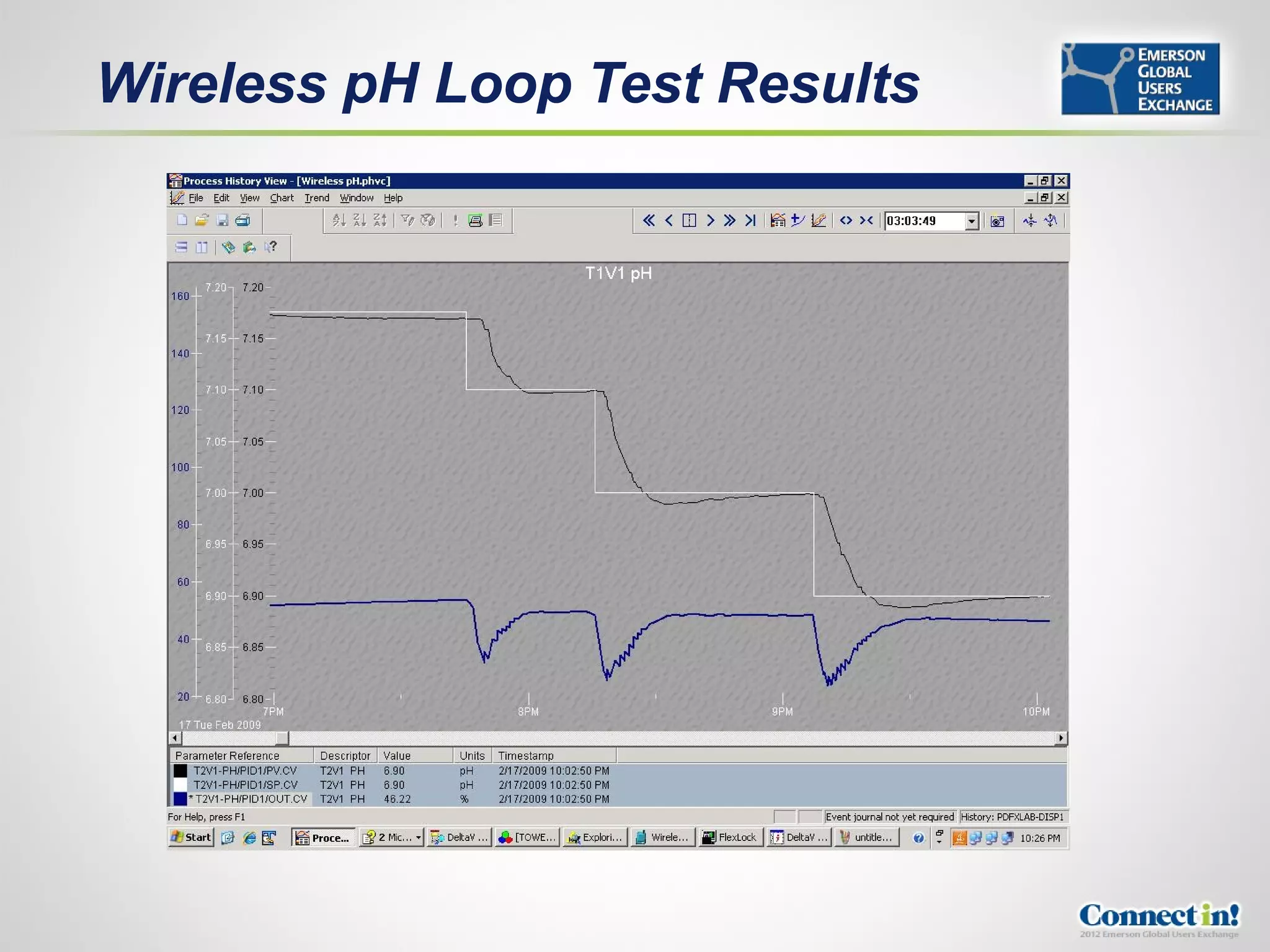

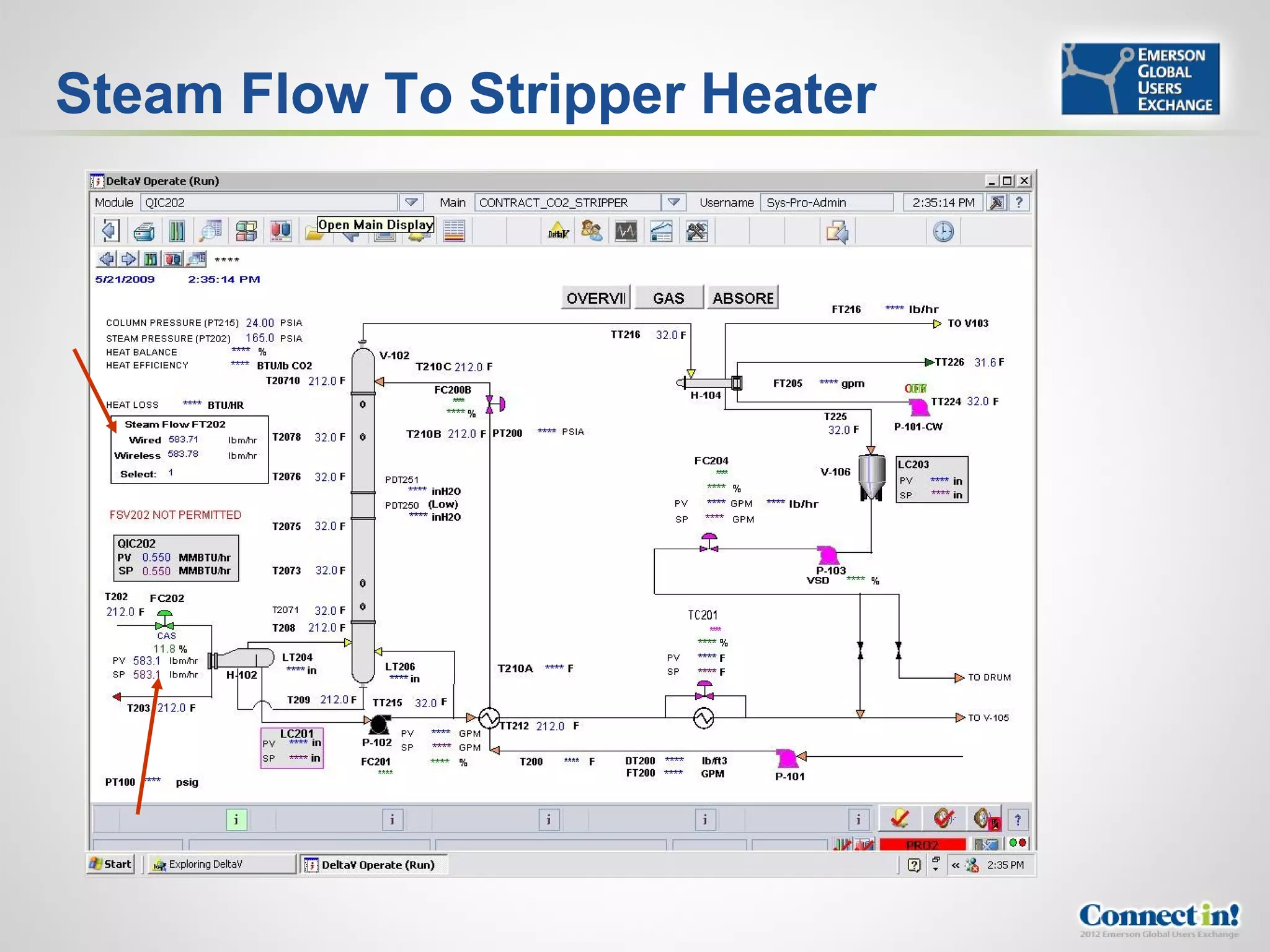

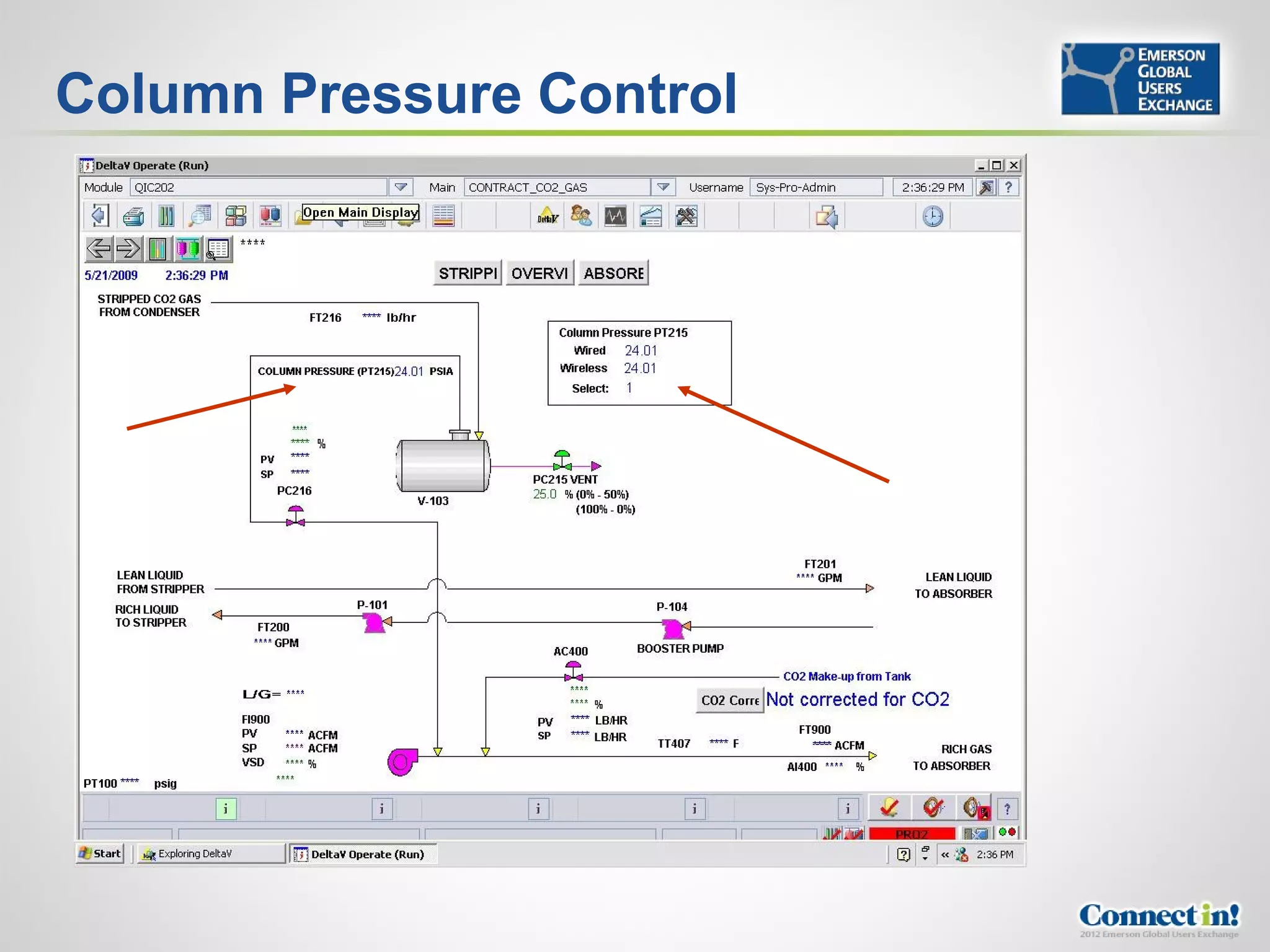

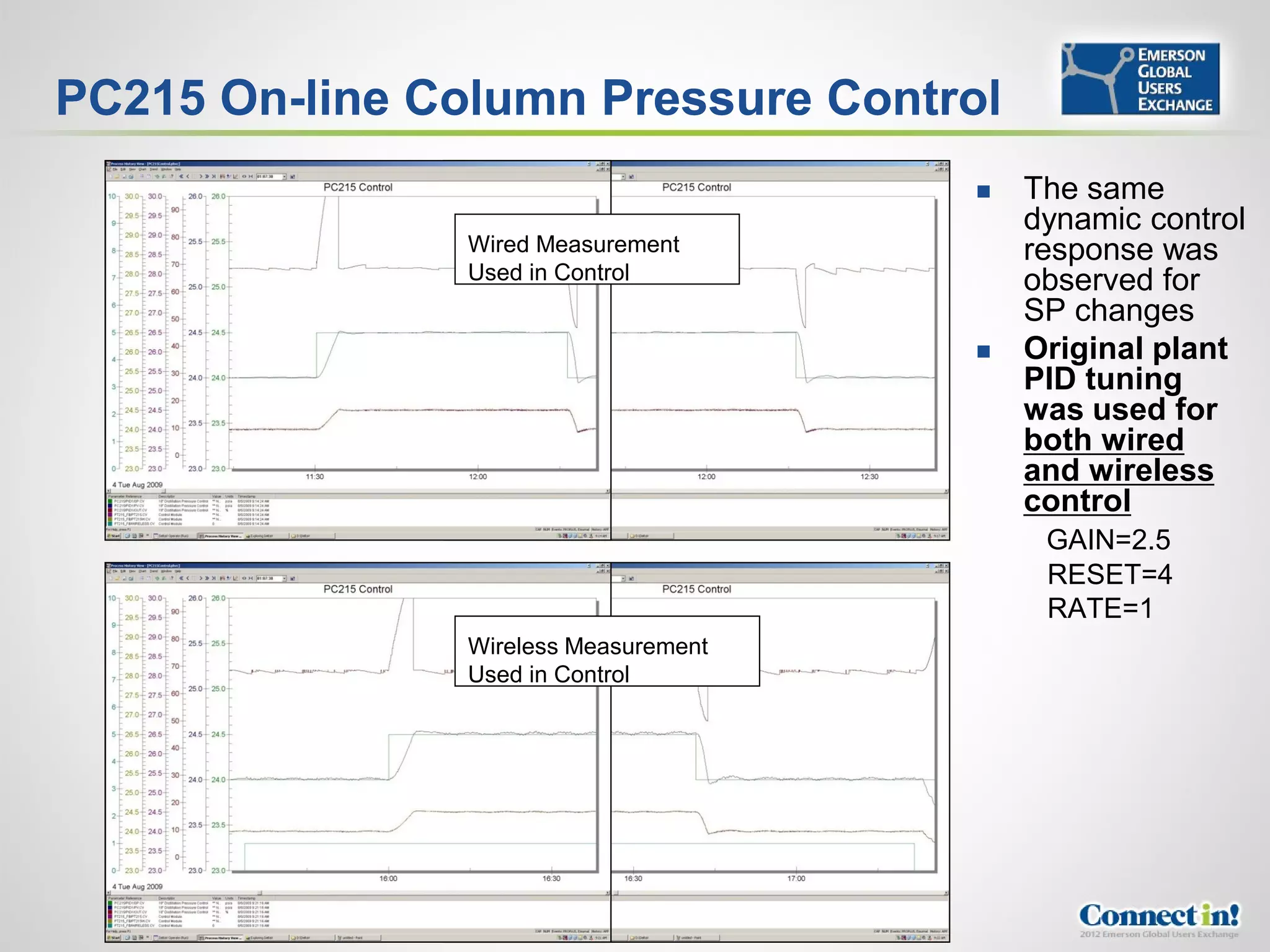

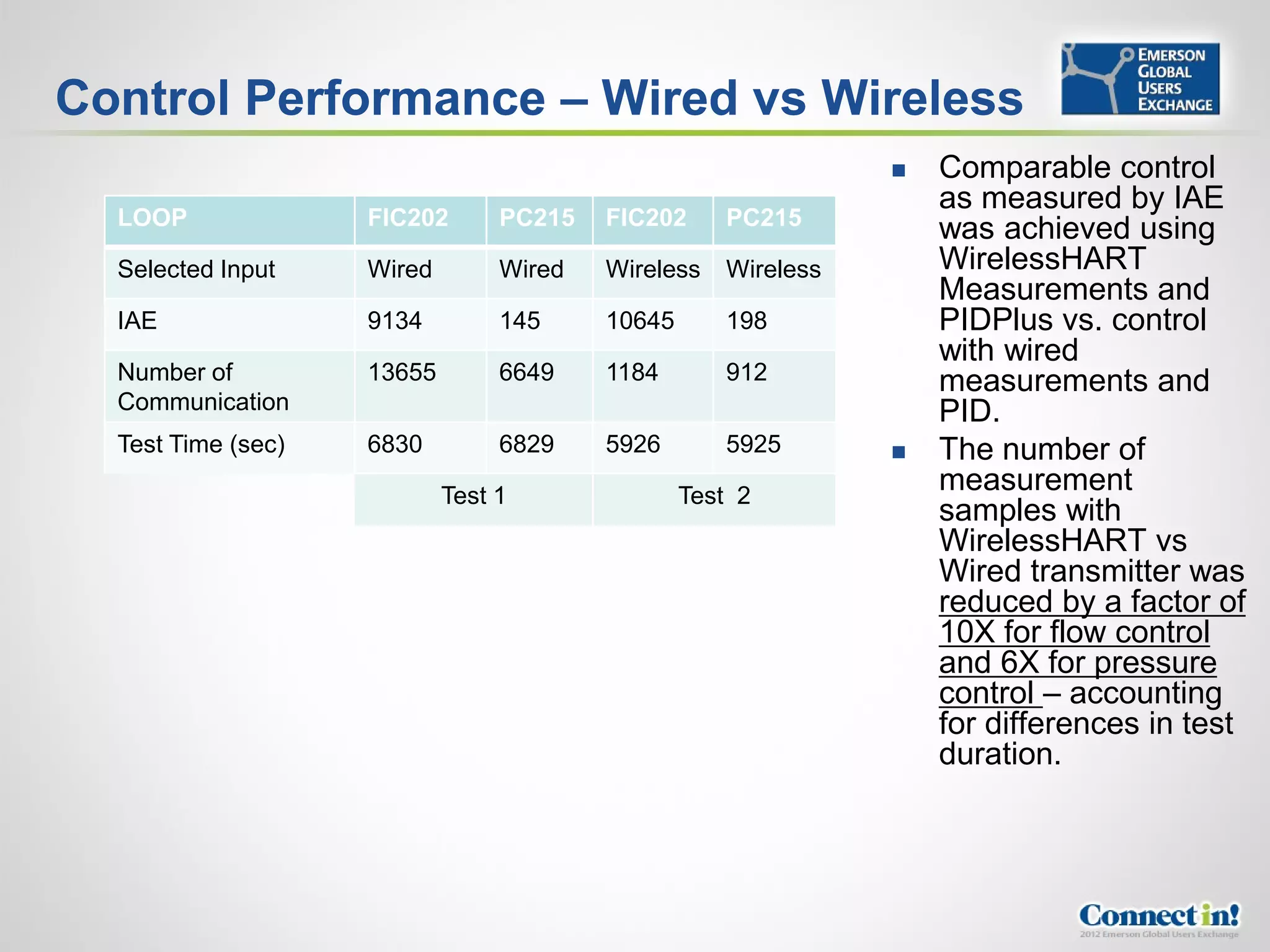

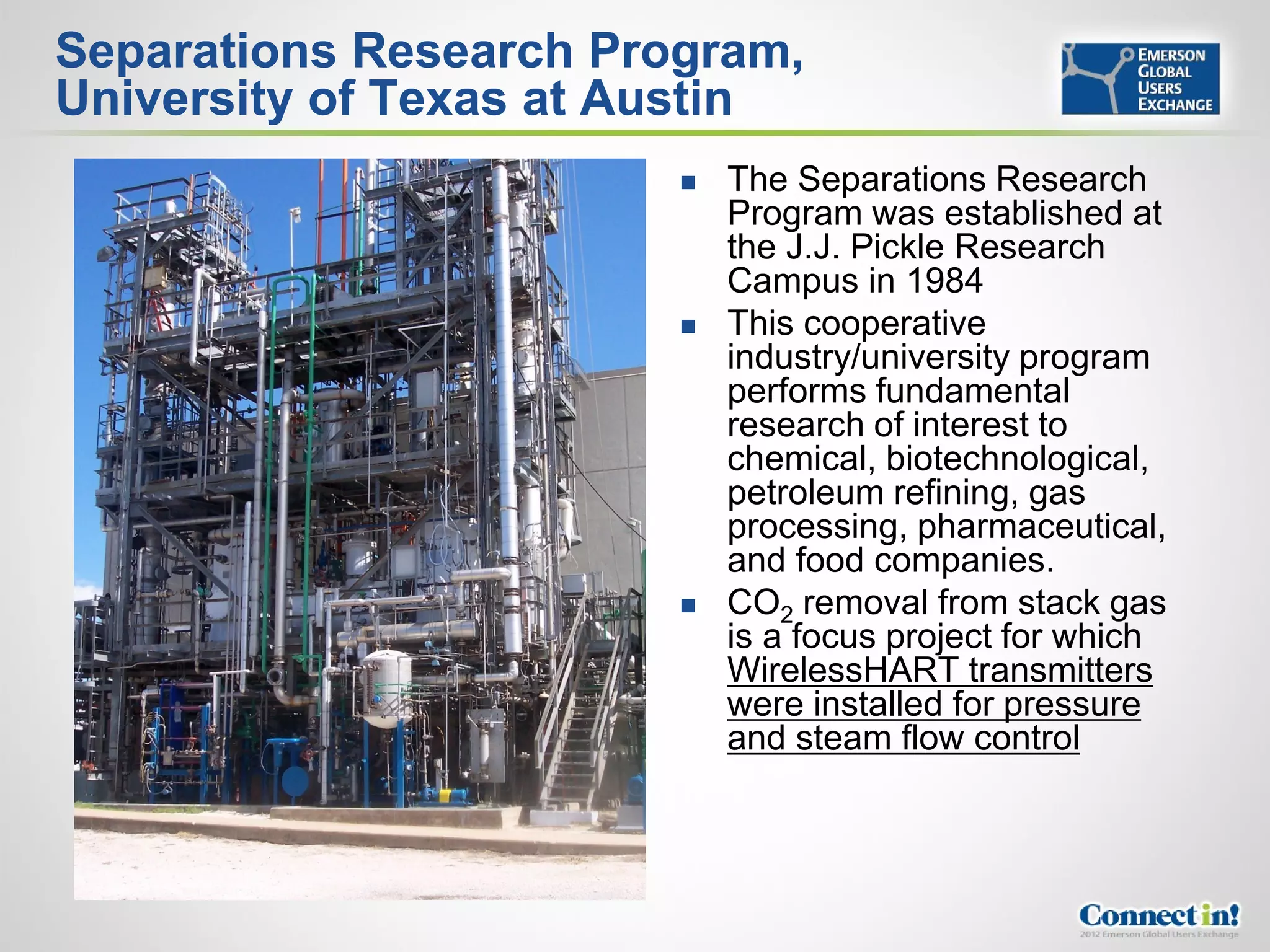

The document discusses the implementation of closed-loop control using WirelessHART devices through the PIDPlus capability in DeltaV, highlighting its advantages over traditional wired systems. It details how PIDPlus handles variable communication updates and lost communications more effectively, reducing power consumption and ensuring stable control performance in various applications. Additionally, the document provides test results demonstrating comparable performance between wireless and wired controls in industrial settings.