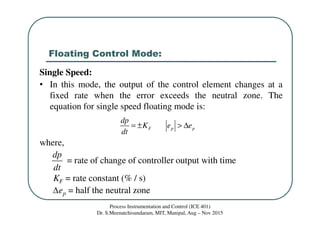

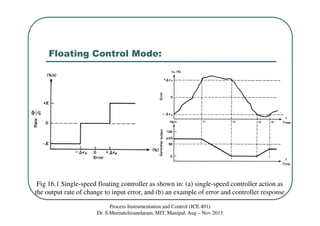

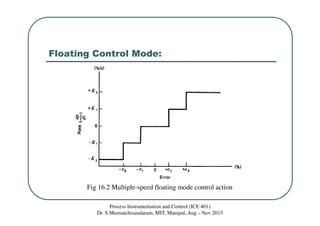

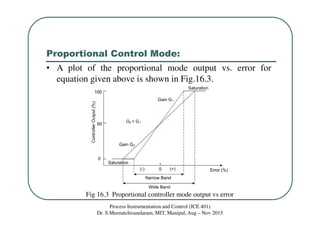

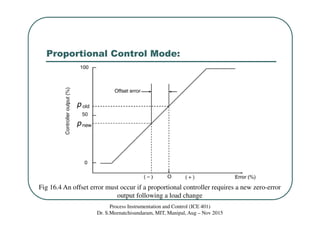

This document discusses floating and proportional control modes. It describes floating control as having a neutral zone where the controller output does not change with error. There are single-speed and multiple-speed floating modes. Proportional control provides a linear relationship between controller output and error over the proportional band. Proportional control results in an offset error due to its inability to achieve a new zero-error output with a load change. Examples are provided to illustrate concepts.

![Proportional Control Mode:

Process Instrumentation and Control (ICE 401)

Dr. S.Meenatchisundaram, MIT, Manipal, Aug – Nov 2015

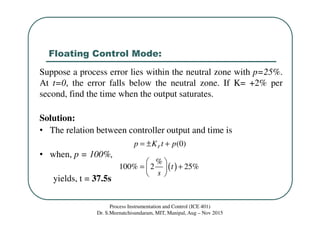

Solution:

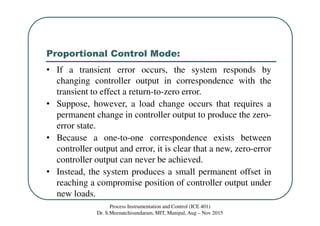

Given data:

Temperature Range = 50 to 130 oC

Setpoint = 73.5 oC

P0 = 50%

P = 55%

ep = ?

Offset error = ? for Kp = 0.1, 0.7, 2.0 & 5.0

For proportional controller: P = Kpep + P0

ep = [P - P0] / Kp = [55 – 50] / Kp = 5 / Kp %](https://image.slidesharecdn.com/class16-floatingandproportionalcontrolmode-150910092807-lva1-app6891/85/Class-16-floating-and-proportional-control-mode-17-320.jpg)

![Proportional Control Mode:

Process Instrumentation and Control (ICE 401)

Dr. S.Meenatchisundaram, MIT, Manipal, Aug – Nov 2015

Solution:

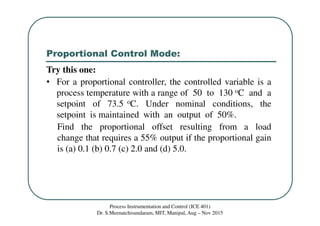

(a) when Kp = 0.1 Offset error, ep = 5/0.1 = 50%

(b) when Kp = 0.7 Offset error, ep = 5/0.7 = 7.1%

(c) when Kp = 2.0 Offset error, ep = 5/2.0 = 2.5%

(d) when Kp = 5.0 Offset error, ep = 5/5.0 = 1%

[It can be observed from the results that as proportional gain

Kp increases the offset error decreases.]](https://image.slidesharecdn.com/class16-floatingandproportionalcontrolmode-150910092807-lva1-app6891/85/Class-16-floating-and-proportional-control-mode-18-320.jpg)