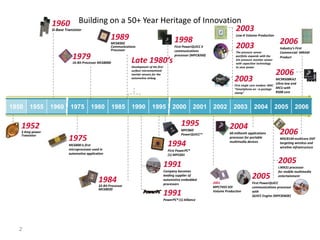

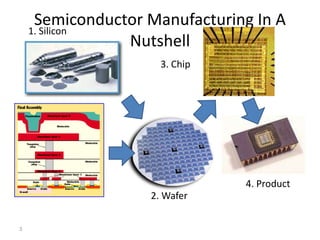

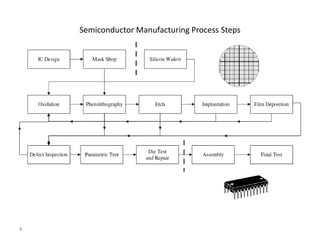

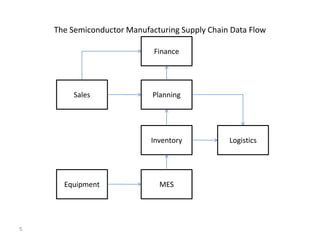

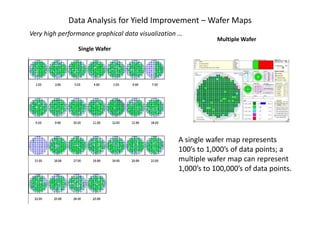

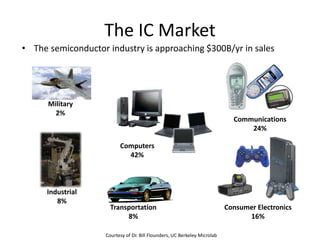

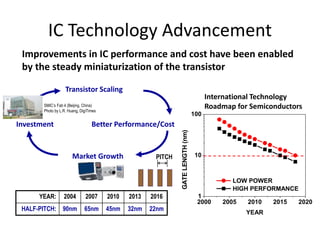

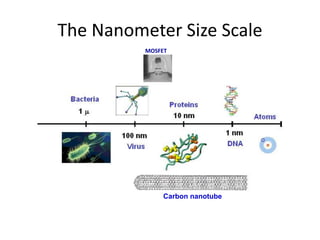

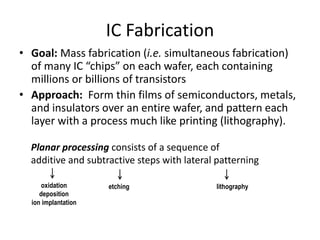

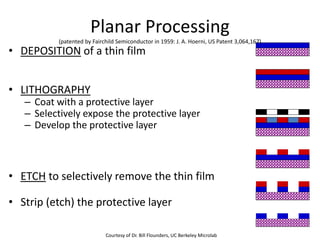

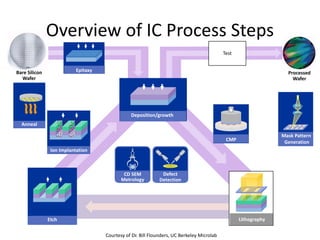

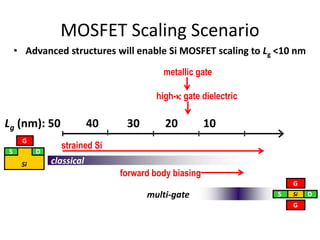

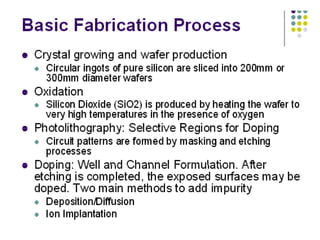

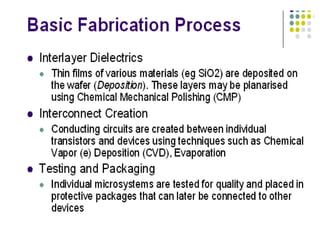

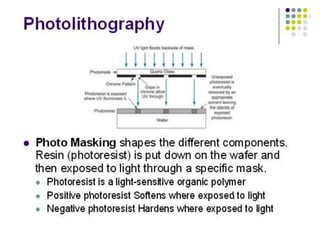

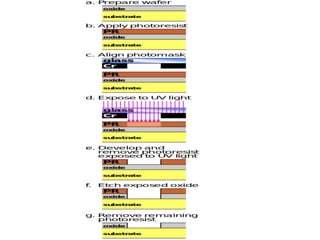

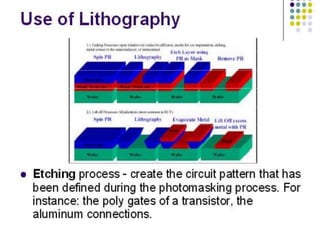

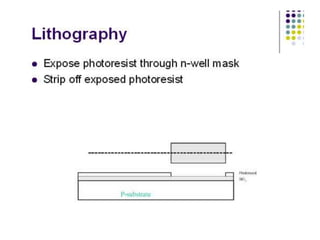

This document summarizes the history and development of semiconductor manufacturing and processing from the 1950s to the present. It outlines key milestones such as the first transistor in 1952, the first microprocessor in the 1970s, and advancements that enabled continued transistor scaling and integration through the 1980s-2000s. The document also provides overviews of the semiconductor manufacturing supply chain, fabrication process steps involving deposition, lithography, and etching, and factors that have driven the semiconductor industry market growth.