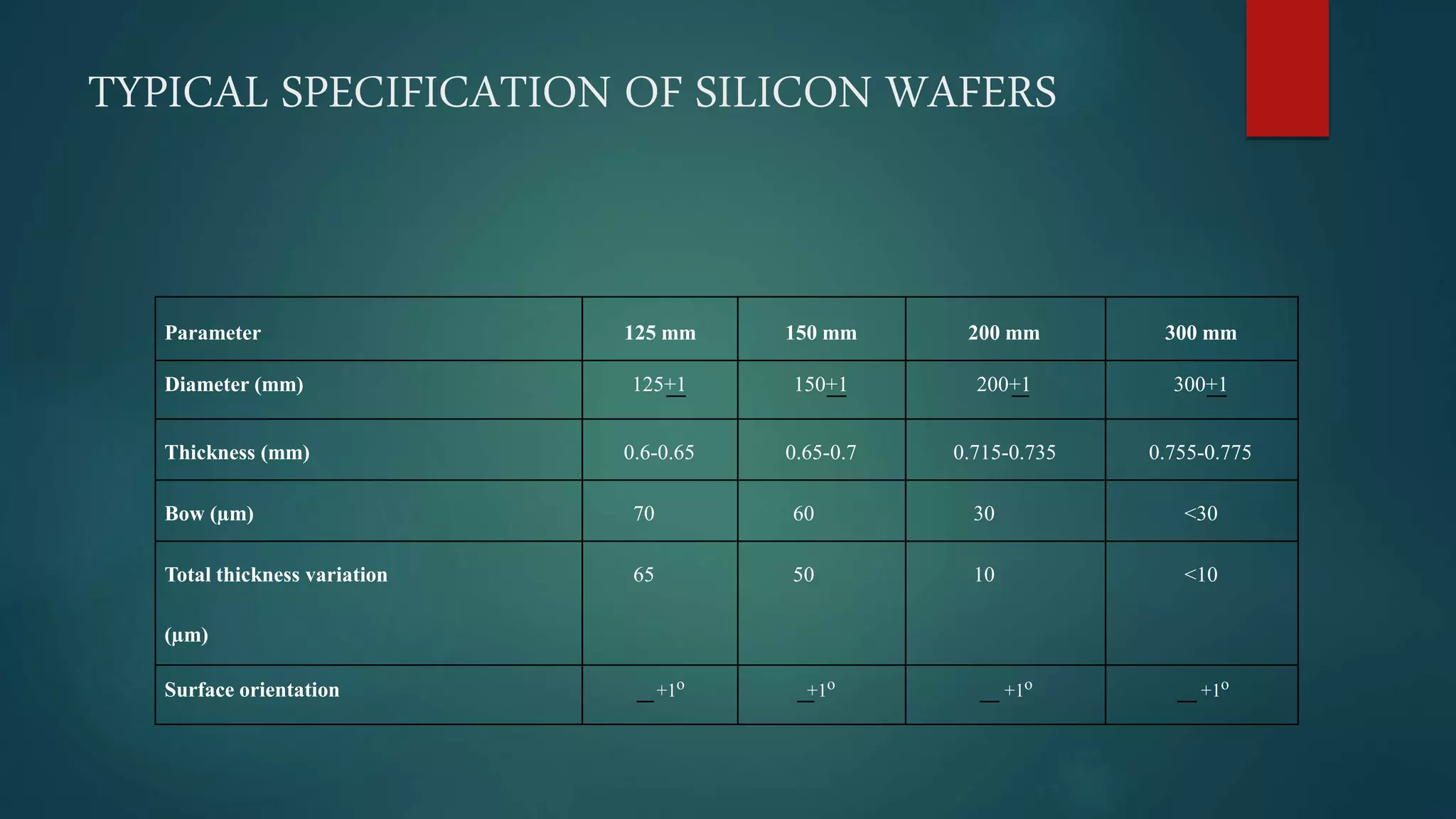

This document discusses the preparation process for silicon wafers used in integrated circuit manufacturing. It describes how a silicon crystal is grown and cut into wafers, which then undergo cleaning, etching, planarization, polishing, and inspection steps to produce a smooth, flat surface suitable for microfabrication. Key properties of wafers that are controlled include diameter, thickness, bow, thickness variation, and surface orientation. The presentation concludes that wafers serve as substrates for building microelectronic devices and undergo many process steps before individual circuits are separated and packaged.