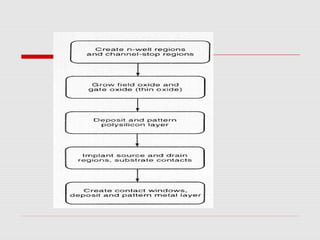

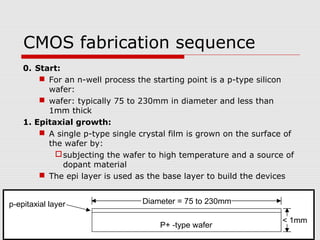

The document describes the key steps in CMOS fabrication:

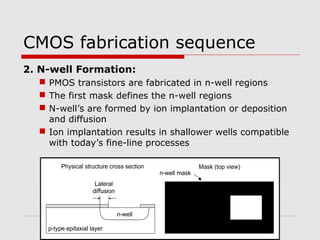

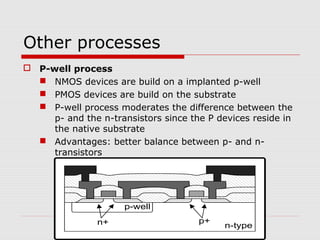

1. A p-type substrate is used, and n-well regions are defined through implantation to create isolation for p-MOSFETs.

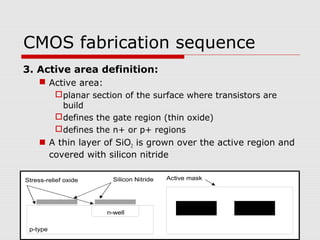

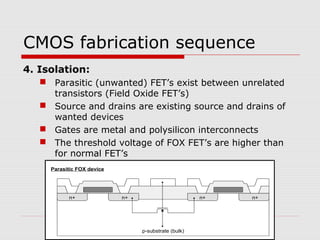

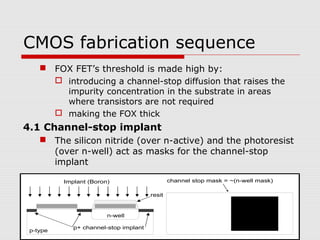

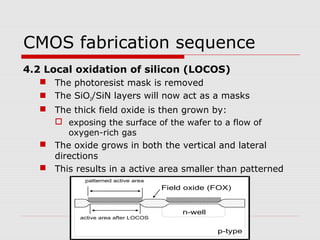

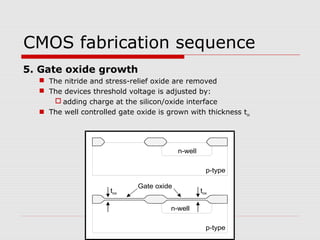

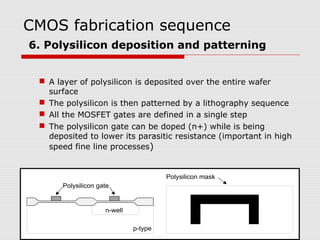

2. Active device regions and field oxide isolation are then patterned, followed by gate oxide growth and polysilicon deposition.

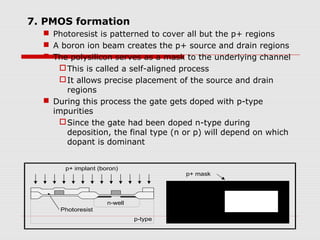

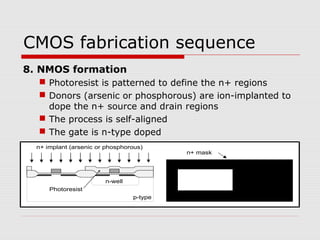

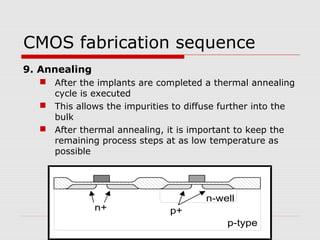

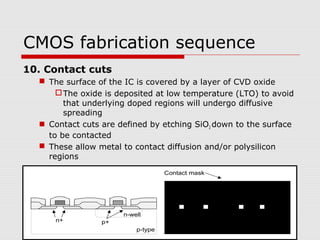

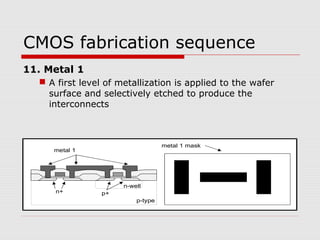

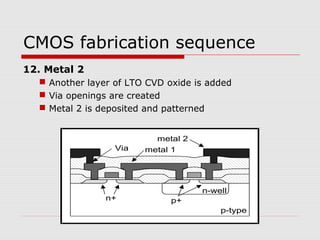

3. Self-aligned implantation creates n-type and p-type source/drain regions. Additional metallization layers connect the transistors.