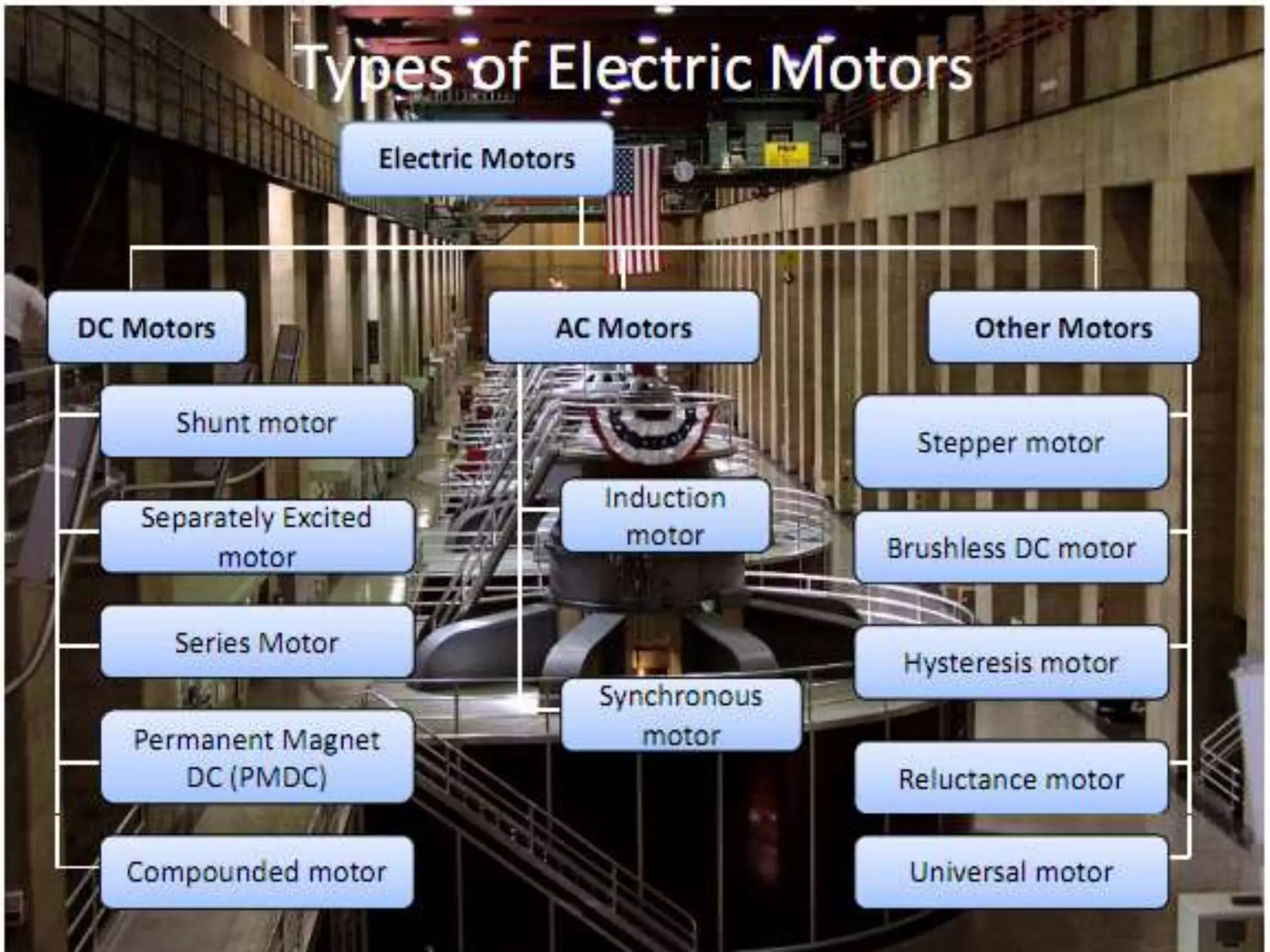

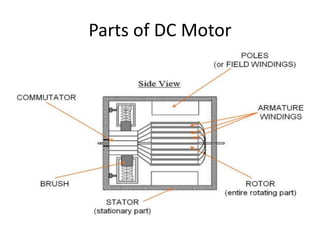

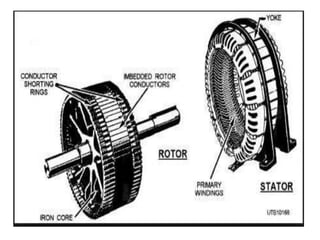

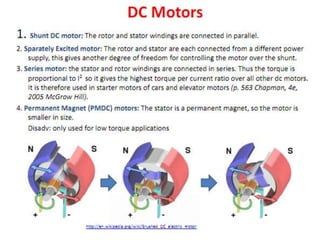

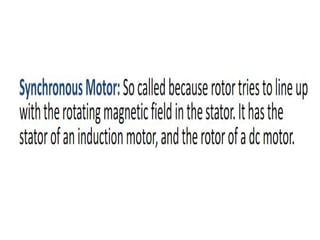

This document discusses different types of electric motors. It describes the basic components of a DC motor including the rotor, stator, and air gap. It then discusses advantages of series and permanent magnet DC motors. Permanent magnet DC motors have higher efficiency and power density. Synchronous motors require supplemental mechanisms to start but provide precise speed control. Induction motors are the most common type due to their simple and rugged design, and can operate at constant speed from no load to full load. However, variable speed control requires a variable frequency drive.