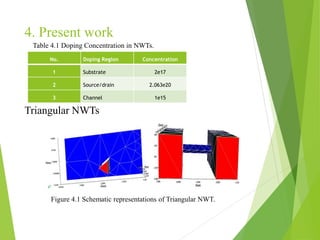

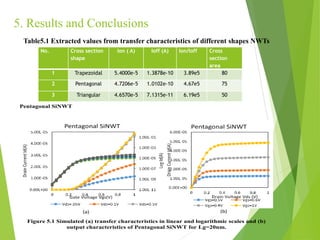

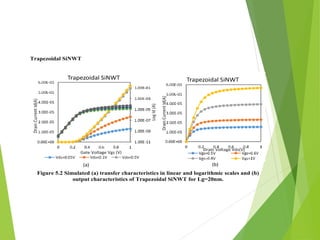

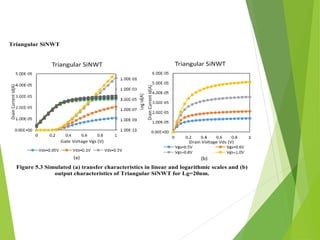

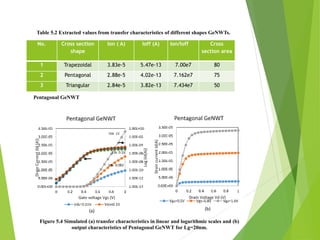

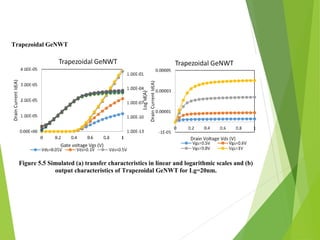

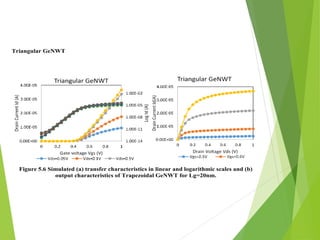

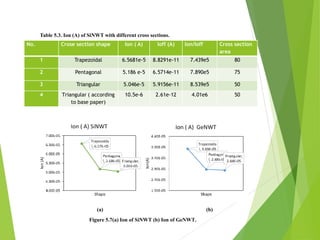

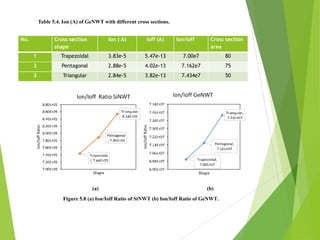

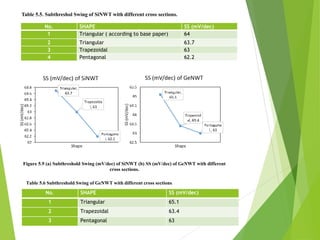

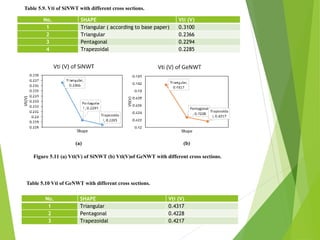

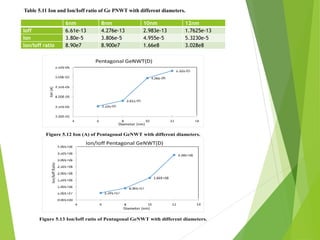

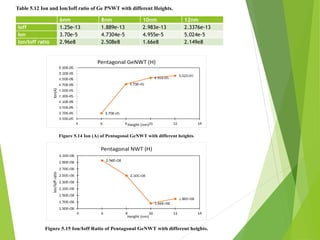

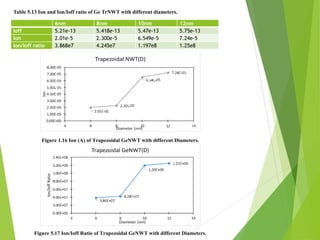

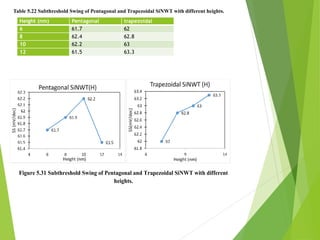

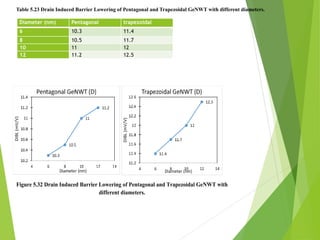

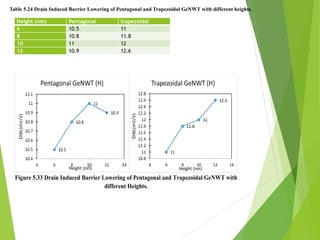

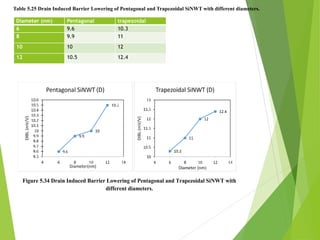

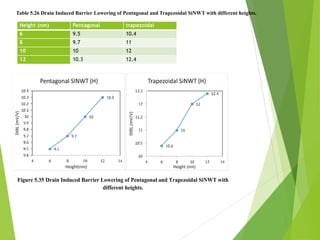

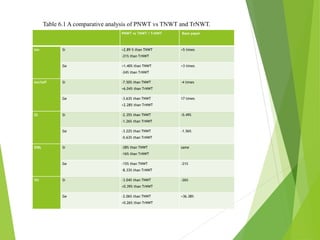

This document summarizes the design and performance analysis of 20nm silicon/germanium channel pentagonal and trapezoidal nanowire transistors. It presents the objectives of designing these nanowire transistors with different process parameters like diameter and height. The methodology involves using TCAD software to simulate the transfer characteristics, output characteristics, and short channel effects for different cross-sectional shapes and materials. The results show that pentagonal and trapezoidal nanowire transistors with germanium channels exhibit higher on-currents and on/off current ratios than triangular nanowire transistors. Key performance metrics like subthreshold swing and DIBL are also better for the pentagonal and trapezoidal nanowire transistors.

![2. Literature Review

H. Xuan et al. [2014] in the paper “Performance Studies in Nanowire

Field-Effect Transistors with Different Cross Sections” investigated

SNWTs with three different cross sections (triangular, circular and

square) and have simulated through TCAD and their performance

parameters are studied. The SNWT with triangular cross section exhibits

higher Ion/Ioff ratio, better subthreshold characteristics and have been

compared with other transistors. In addition, an equivalent model have

been proposed to accurately estimate the performance of different

shaped SNWTs with the same channel cross-section area to simplify the

device model for future circuit simulation](https://image.slidesharecdn.com/20nmnwt1312088-160804141816/85/GAA-nano-wire-FET-8-320.jpg)

![Zang et al. [2014] in the paper entitled “Comparative study of silicon

nanowire transistors with triangular-shaped cross sections” presented

Nanowire transistors with triangular cross sections (TNWTs) are

proposed and studied. Working mechanisms of TNWTs and impacts of

physical parameters are investigated with technology computer aided

design (TCAD) tools. It is found that TNWT’s current mostly

concentrates in channel center, and expands to corners of the triangle at

a higher gate voltage. TNWTs with a longer channel length show better

subthreshold slope and lower drain-induced barrier lowering (DIBL),

which allows low gate work function to be maintained.](https://image.slidesharecdn.com/20nmnwt1312088-160804141816/85/GAA-nano-wire-FET-9-320.jpg)

![R. Gupta et al. [2014] in the paper “Study of Gate all around lnAs/Si

based Nanowire FETs using Simulation Approach,” presented a GAA

Si Nanowire FET (SNWFET) and InAs NWFET and compared it with

respect to various performance parameters. The device metrics

considered at the nanometer scale are transfer characteristics,

transconductance, output characteristics, drive and leakage current,

switching speed (Ion/Ioft), conduction band profile, subthreshold

swing and DlBL. It is shown that InAs channelled NWFET have

higher mobility and hence higher transconductance, whereas Si

NWFET shows better immunity towards SCE with lower leakage

current, lower subthreshold slope, lower DlBL.](https://image.slidesharecdn.com/20nmnwt1312088-160804141816/85/GAA-nano-wire-FET-10-320.jpg)