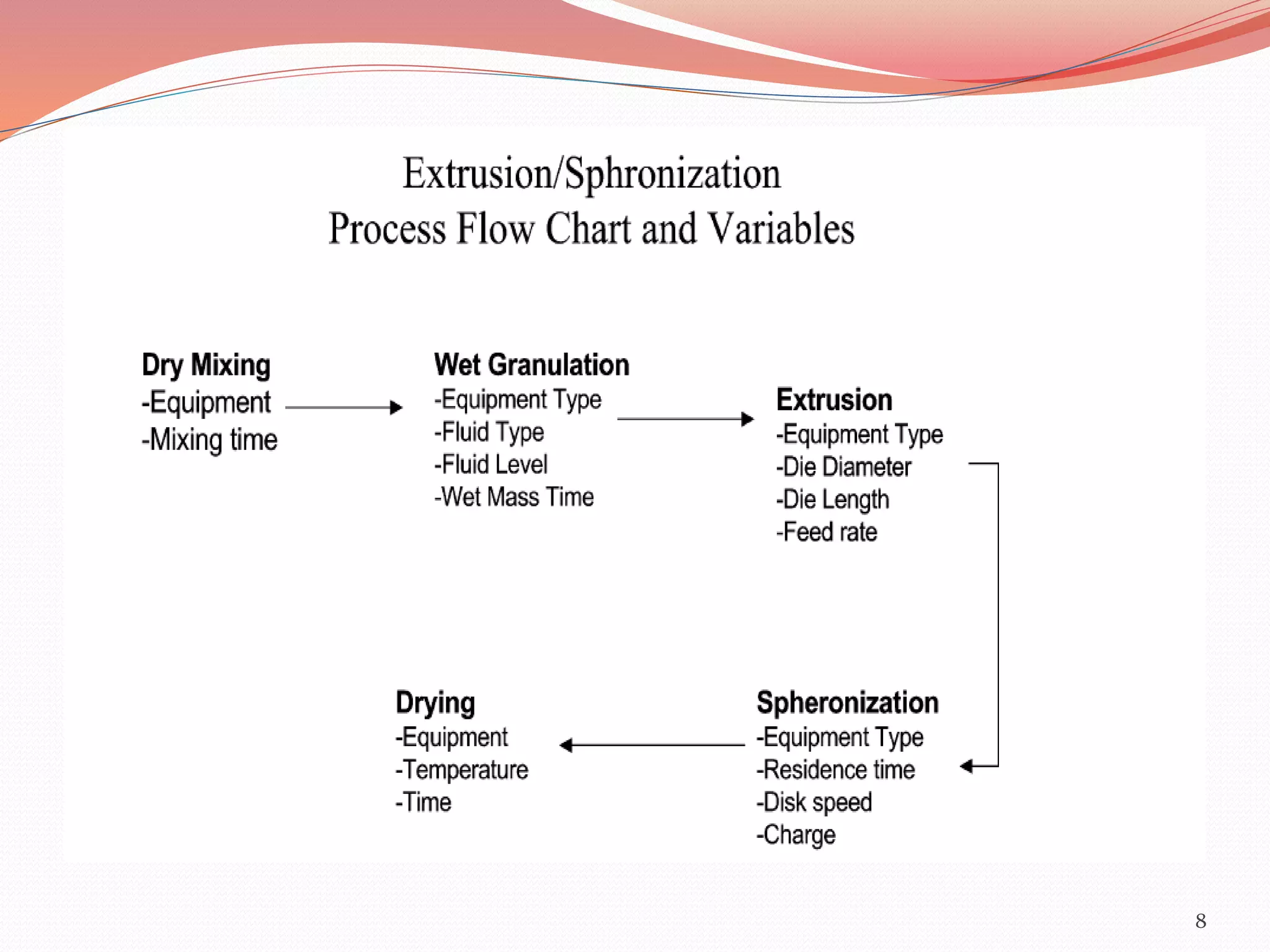

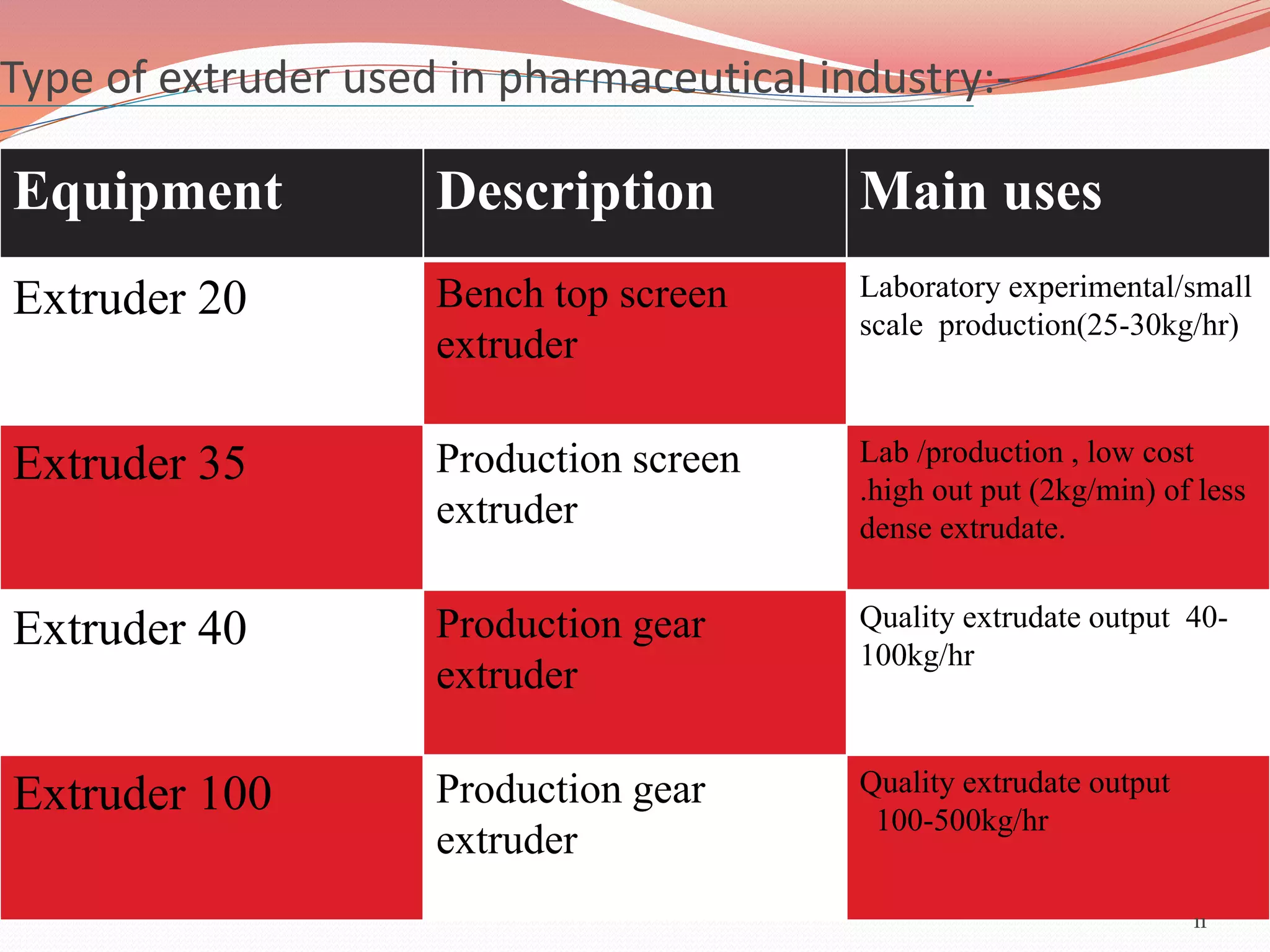

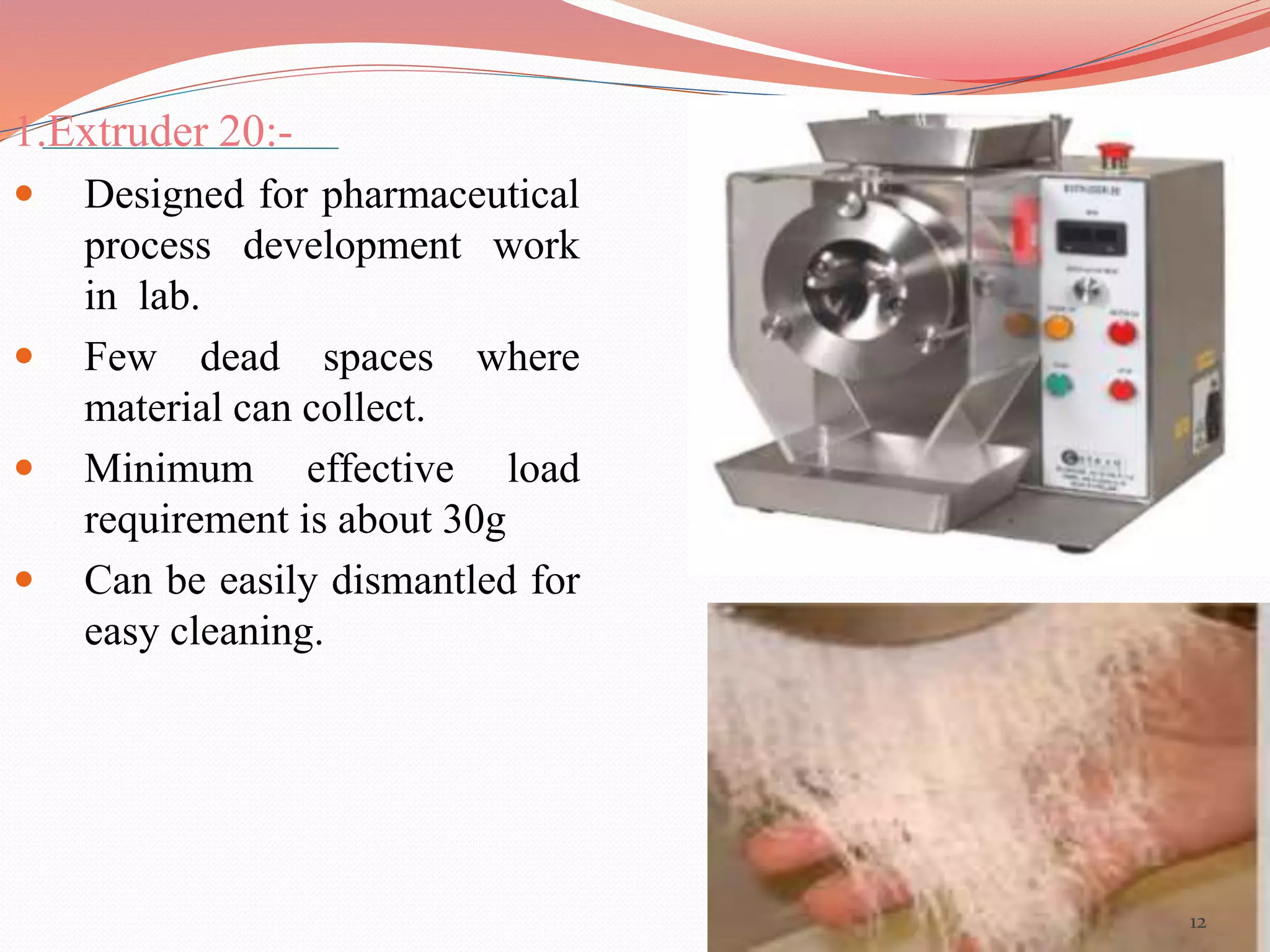

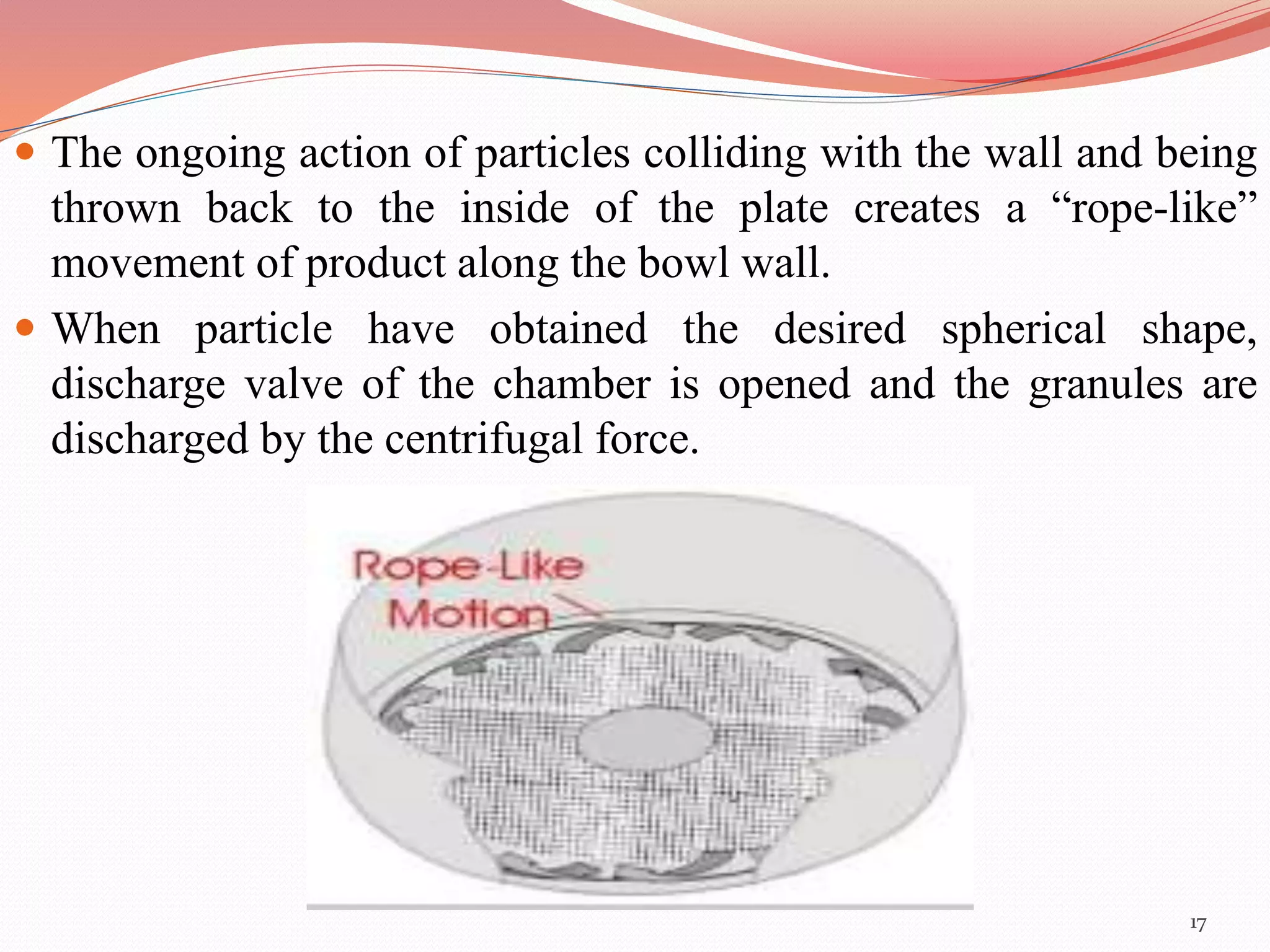

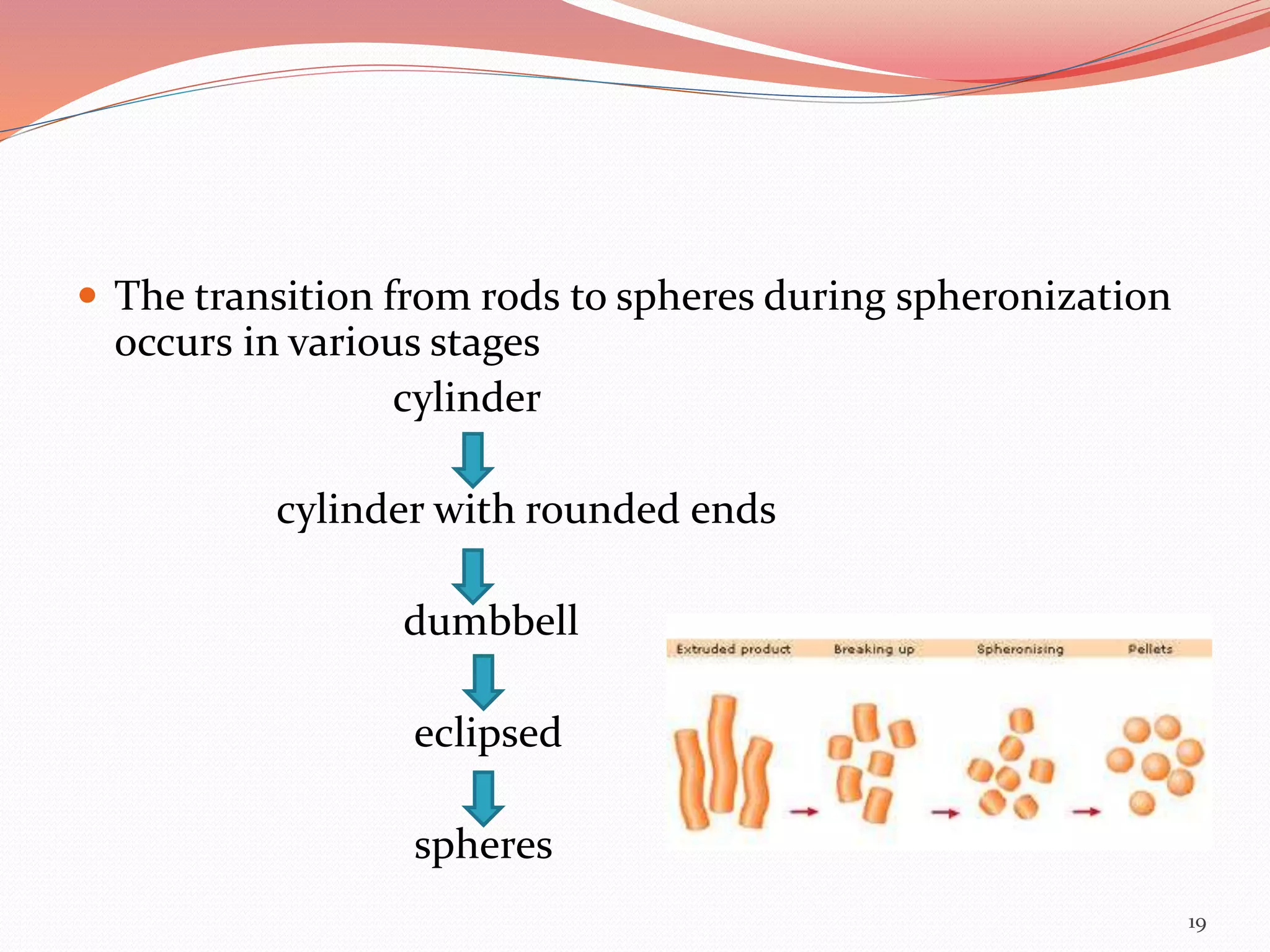

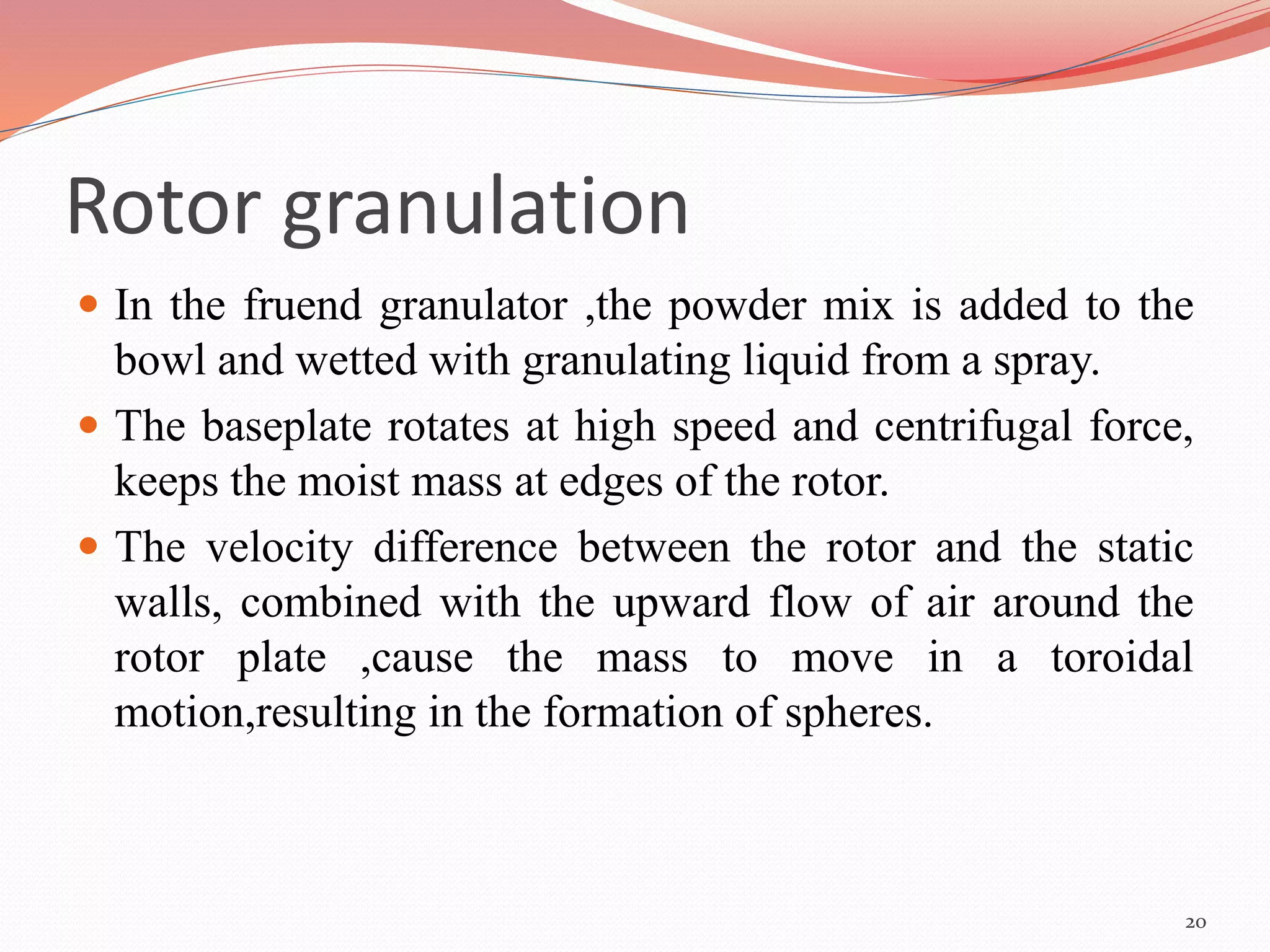

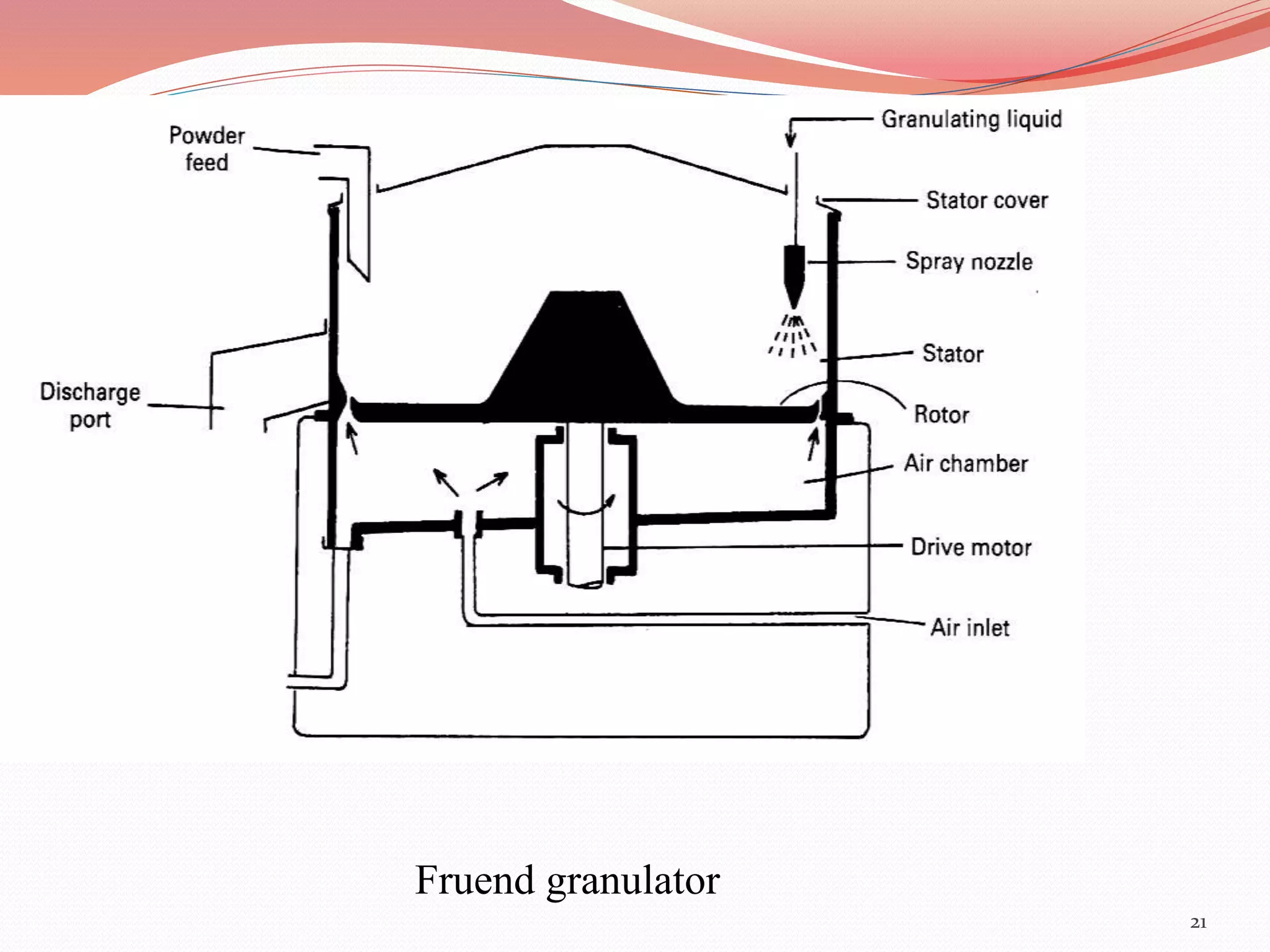

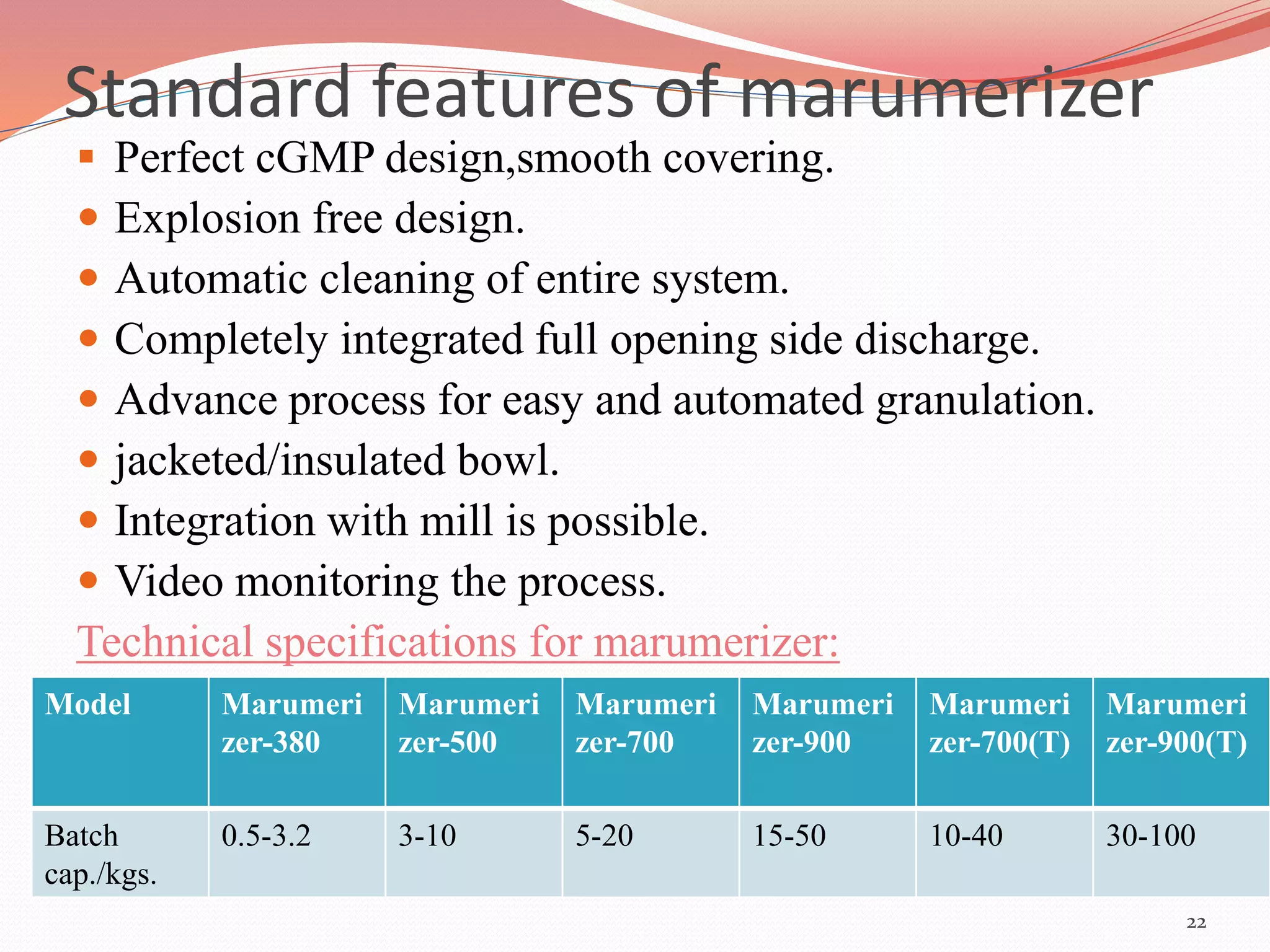

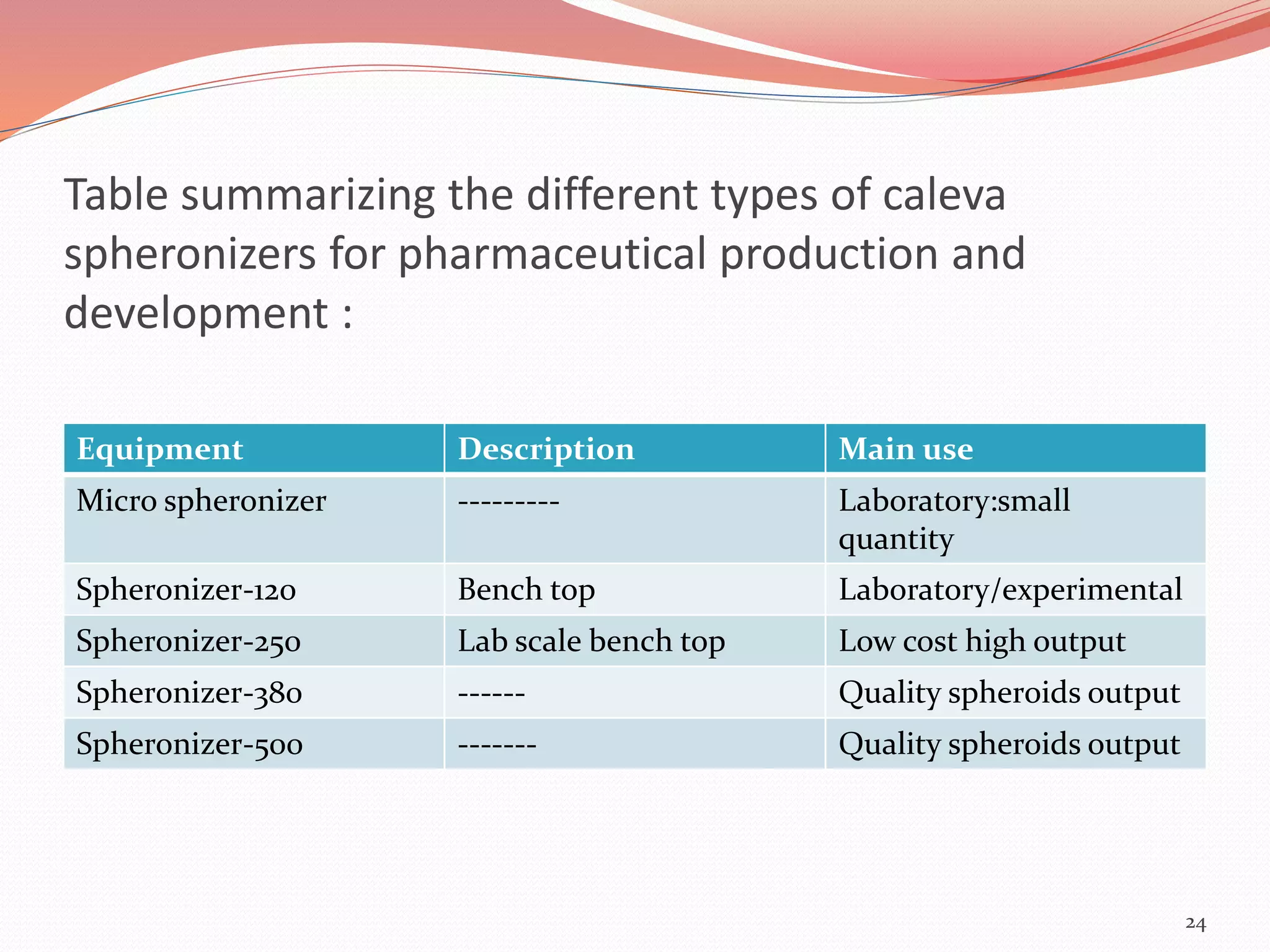

This document provides an overview of spheronization as a process for producing spherical pharmaceutical granules. It defines spheronization and discusses the key advantages such as improved flow properties and uniform packing. The document describes the basic spheronization process which involves extrusion to form rods followed by spheronization to round the rods into spheres. It also outlines important machine parameters that influence the process like disc speed and pattern, as well as product parameters related to granule rheology.