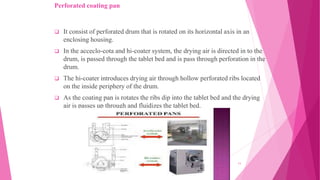

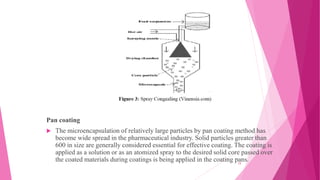

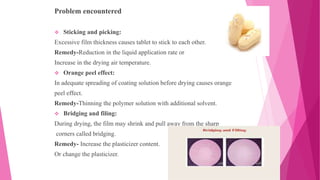

This document provides information about coating technology. It discusses various coating principles, processes, equipment, and applications. Specifically, it describes sugar coating and film coating processes, common coating equipment like standard coating pans and fluidized bed coaters, and particle coating techniques like microencapsulation and spray drying. It aims to explain how coating is used to modify drug release profiles and protect pharmaceutical products.