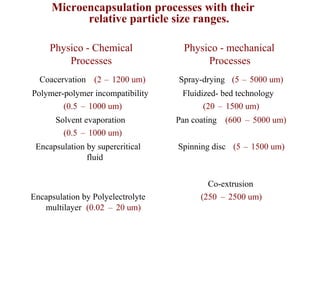

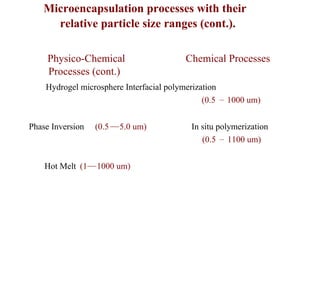

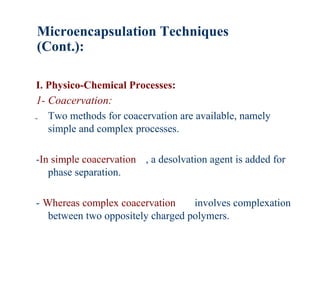

Microencapsulation is the process of coating solid or liquid particles with a polymeric shell to produce microcapsules in the micrometer to millimeter range. There are several morphologies of microcapsules depending on the core material and shell deposition process, including mononuclear, polynuclear, and matrix encapsulation. Microencapsulation provides benefits such as controlled release, protection from environmental factors, improved shelf life, and masking of tastes/odors. Common techniques for microencapsulation include coacervation, solvent evaporation, and rapid expansion of supercritical fluids.