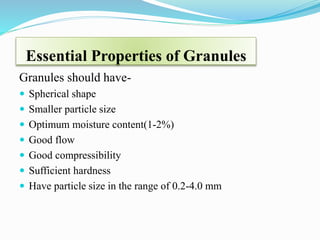

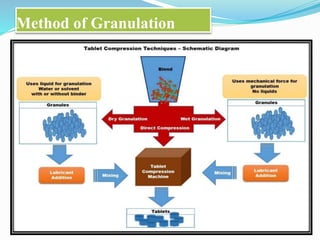

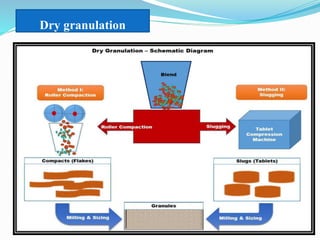

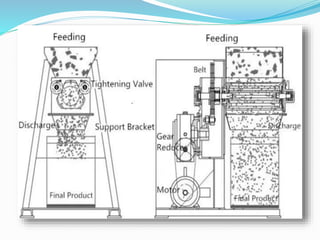

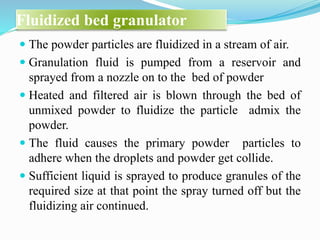

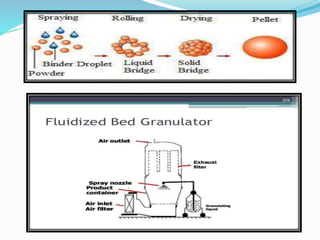

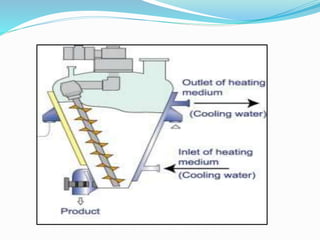

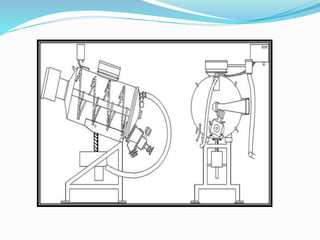

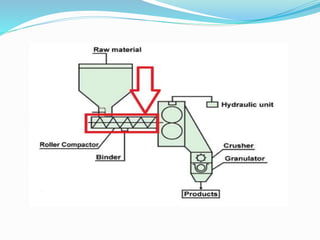

The document discusses granulation, a process used in the pharmaceutical industry to form grain-like agglomerates from powdered particles, facilitating the production of solid dosage forms. It outlines the objectives, essential properties, various methods of granulation, and modern equipment utilized for the granulation process. Equipment mentioned includes oscillating granulators, high shear granulators, fluidized bed granulators, and others, all designed to enhance the quality and efficiency of granules for pharmaceutical applications.