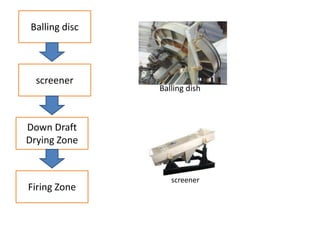

Pelletization is the process of making spheres of uniform quality iron ore with high carbon content. Iron ore is pelletized so that it can efficiently flow through a blast furnace for smelting. The process involves mixing iron ore fines with additives like limestone, dolomite, and bentonite. This mixture is then formed into balls on a balling disc and fired in a kiln to produce the iron ore pellets. The spherical shape of the pellets allows for better air flow through blast furnaces compared to finer iron ore particles. The pelletization process ultimately produces a product with higher efficiency as a raw material in blast furnaces.