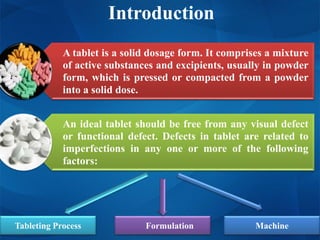

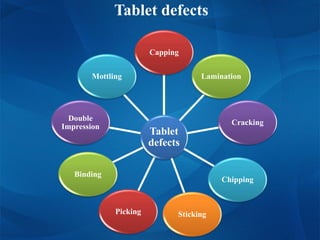

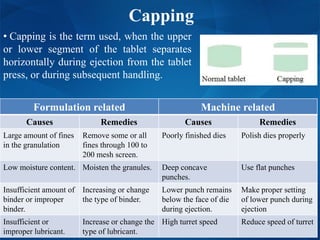

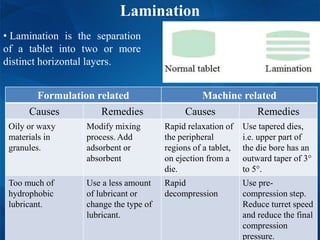

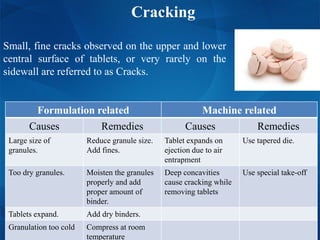

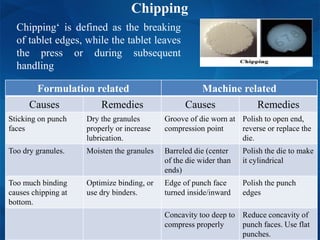

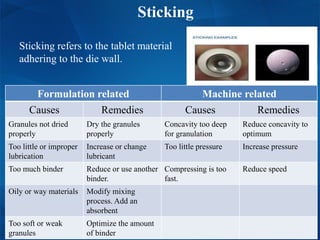

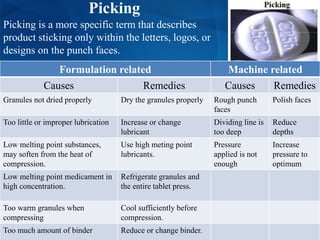

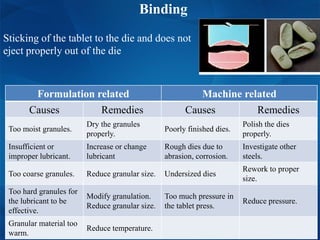

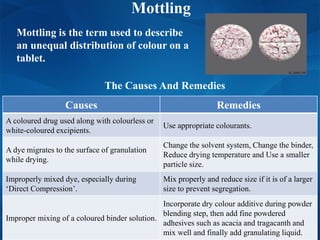

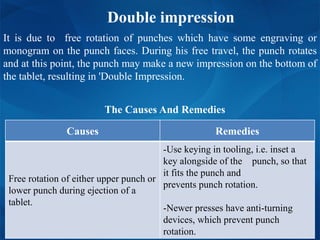

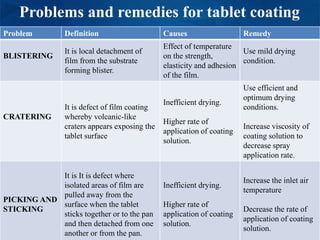

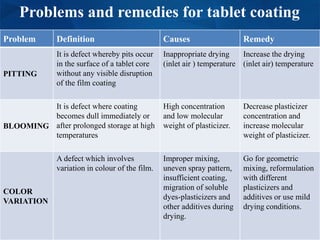

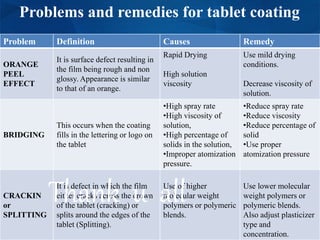

The document discusses various problems encountered in tablet processing, including defects like capping, lamination, cracking, chipping, sticking, picking, mottling, and double impressions, along with their causes and remedies. It also covers issues related to tablet coating, such as blistering, cratering, picking and sticking, pitting, blooming, color variation, orange peel effect, and bridging, providing potential solutions for each. Overall, the document serves as a comprehensive guide for identifying and remedying tablet and coating defects in pharmaceutical manufacturing.