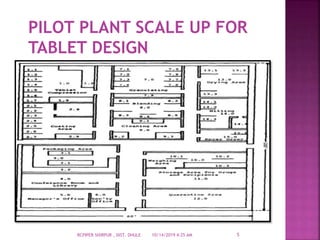

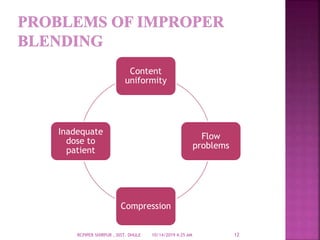

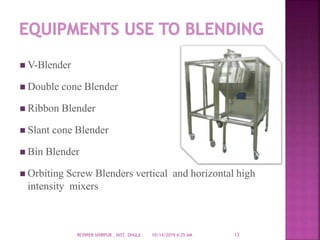

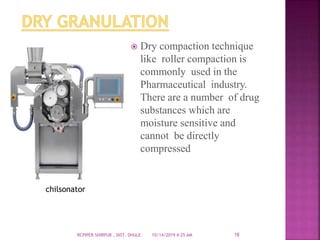

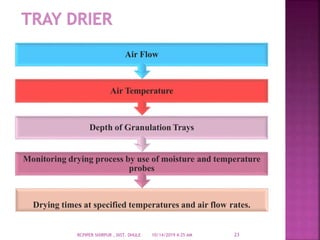

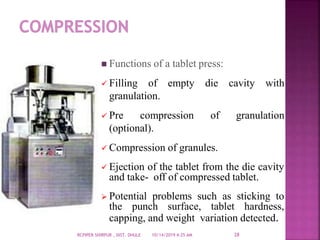

The document discusses the scale up of tablet production from the laboratory scale to the pilot plant scale. It describes the various stages involved in tablet production such as material handling, dry blending, granulation, drying, milling, blending, compression, and coating. Scaling up from the lab scale to pilot plant scale requires adjustments to processing equipment, material handling procedures, blending times and speeds, drying methods, and compression equipment to optimize tablet properties such as content uniformity and hardness for production. The goal of the scale up process is to develop a reliable manufacturing process for producing viable tablet products.