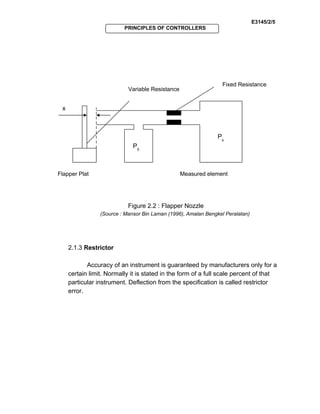

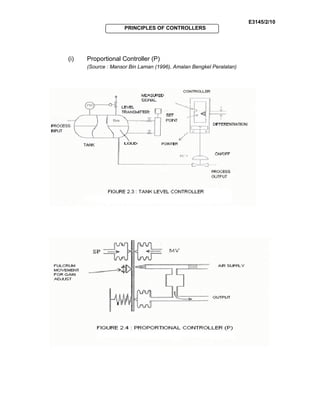

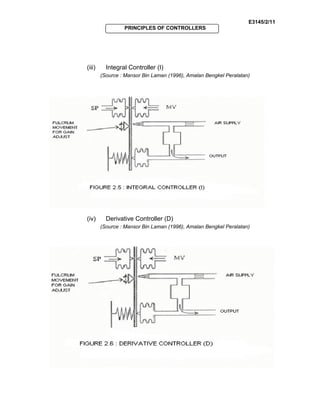

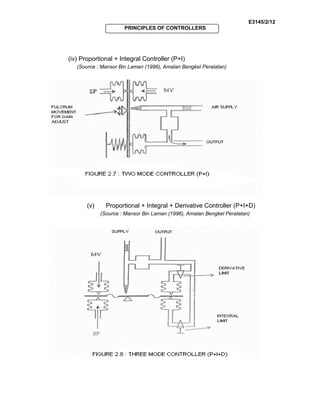

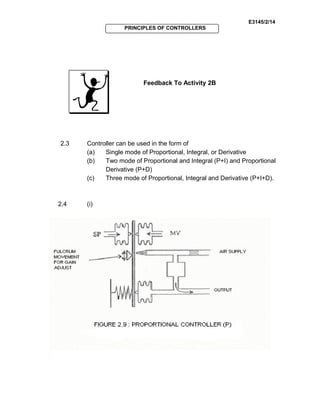

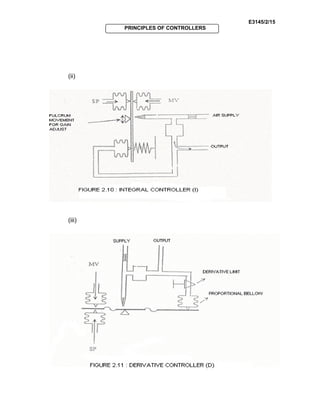

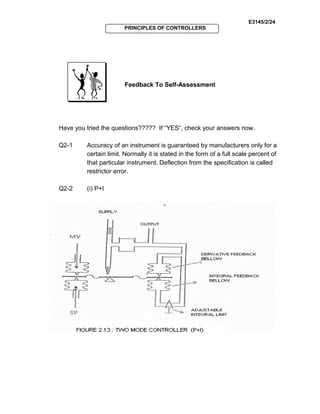

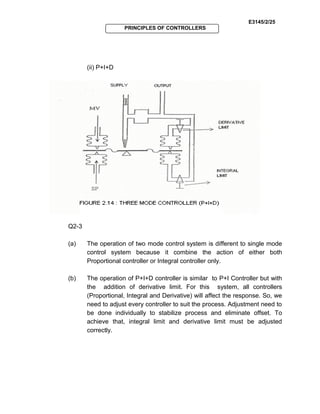

This document provides an overview of principles of controllers. It begins by stating the objectives of understanding basic controller concepts and components. It then defines controllers as devices that receive input from a transmitter and set point, and send output to control valves. The main controller components are identified as the comparator mechanism, controller, and feedback mechanism. Several types of controllers are described, including proportional, integral, derivative, and combinations of these. Schematics are provided to illustrate how different controller types operate based on error signals. Advantages and disadvantages of each controller type are also summarized.