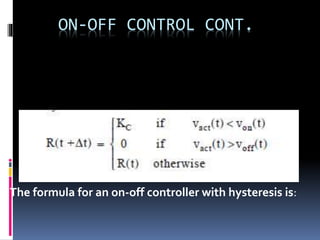

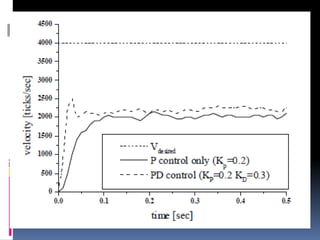

This document discusses various types of motor control, including on-off control and PID control. It begins with an overview of closed-loop control using motor feedback via encoders for velocity and position control. The main focus is on introducing PID control in a step-wise manner, first explaining on-off control and then proportional, integral and derivative controllers. It provides the mathematical formulas for these controller types and discusses implementing them in software and tuning the PID parameters.

![2.2 INTEGRAL CONTROLLER CONT.

When using e(t) as the error function, the

formula for the PI controller is:

R(t) = KP · [ e(t) + 1/TI · 0∫ t e(t)dt ]

We rewrite this formula by substituting

QI = KP/TI, so we receive independent

additive terms for P and I:

R(t) = KP · e(t) + QI · 0∫ t e(t)dt](https://image.slidesharecdn.com/5-140709124838-phpapp01/85/Control-28-320.jpg)

![2.3 DERIVATIVE CONTROLLER

CONT.

When using e(t) as the error function, the formula for

a combined PD controller

is:

R(t) = KP · [ e(t) +TD · de(t)/dt]

The formula for the full PID controller is:

R(t) = KP · [ e(t) + 1/TI · 0 ∫ t e(t)dt +TD · de(t)/dt ]](https://image.slidesharecdn.com/5-140709124838-phpapp01/85/Control-36-320.jpg)

![2.4 PID PARAMETER TUNING

The tuning of the three PID parameters KP, KI, and KD is

an important issue.The following guidelines can be used

for experimentally finding suitable values (adapted after

[Williams 2006]):

1. Select a typical operating setting for the desired

speed, turn off integral and derivative parts, then

increase KP to maximum or until oscillation occurs.](https://image.slidesharecdn.com/5-140709124838-phpapp01/85/Control-38-320.jpg)

![4- MULTIPLE MOTORS – DRIVING

STRAIGHT CONT.

There are a number of different approaches for driving

straight.The idea presented in the following is from

[Jones, Flynn, Seiger 1999]. Figure 5.14

shows the first try for a differential drive vehicle to drive

in a straight line.There are two separate control loops

for the left and the right motor, each

involving feedback control via a P controller. The

desired forward speed is supplied to both controllers .

Unfortunately, this design will not produce a nice

straight line of driving.](https://image.slidesharecdn.com/5-140709124838-phpapp01/85/Control-53-320.jpg)