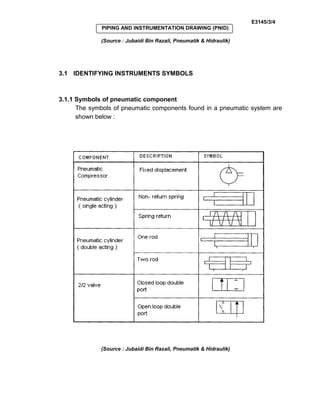

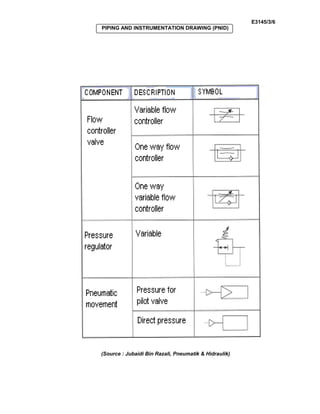

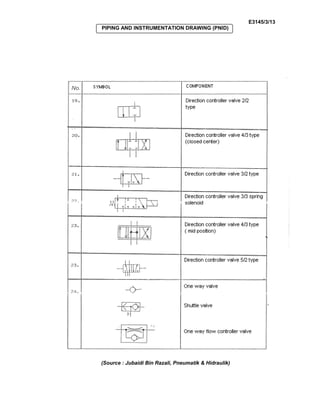

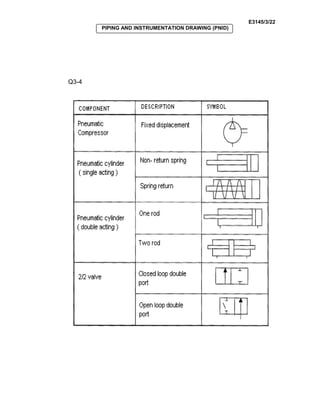

The document discusses piping and instrumentation drawings (PNIDs) which include components of pneumatic control systems and hydraulic control systems. It defines PNIDs and states their objectives. The basic components of pneumatic systems are compressors, air tanks, air dryers, regulators, directional control valves, and actuators. Basic hydraulic system components are pumps, motors or cylinders, oil tanks, and valves. It also compares the advantages of pneumatic and hydraulic systems and provides their symbols.