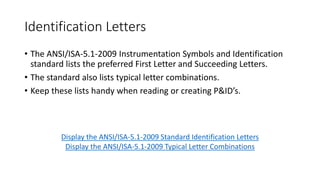

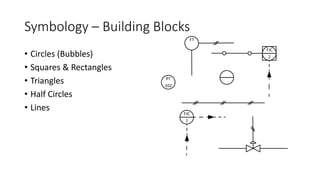

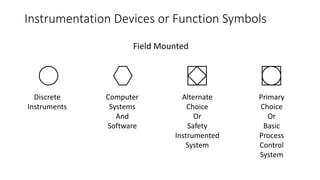

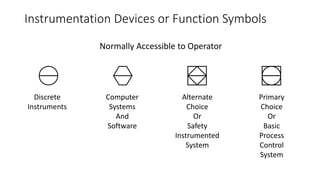

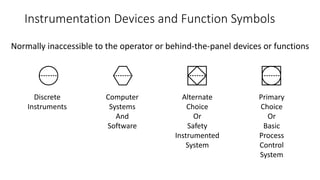

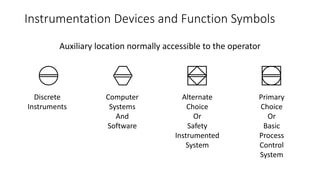

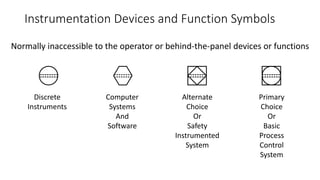

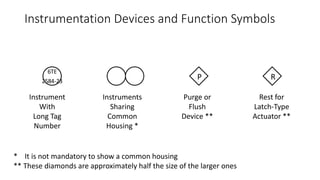

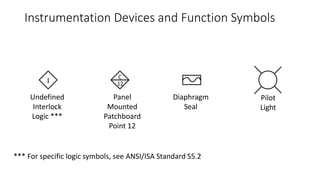

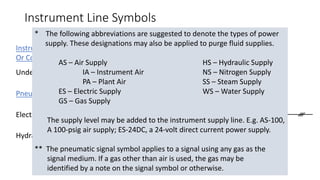

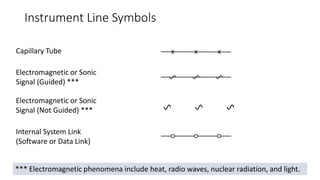

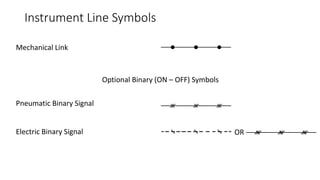

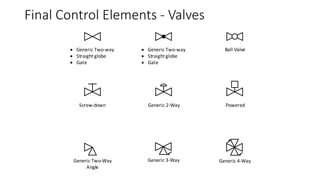

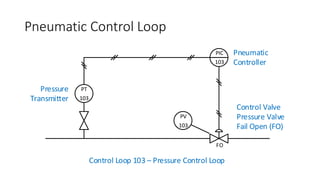

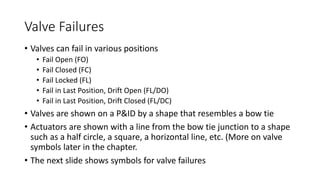

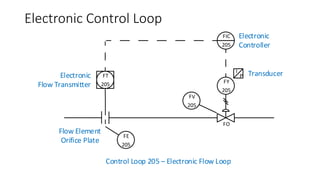

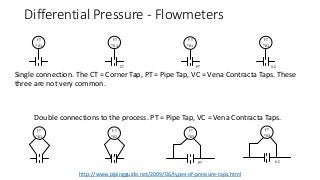

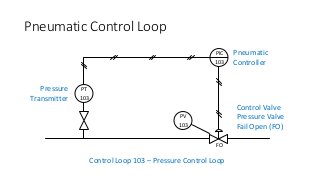

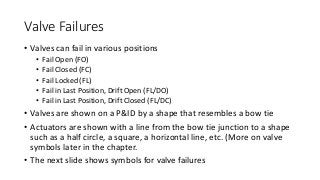

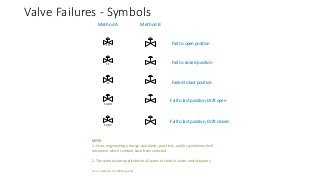

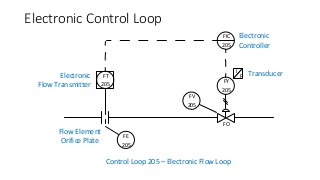

The document provides an overview of Piping and Instrumentation Diagrams (P&IDs) including their purpose, components, and standard symbols. It discusses that P&IDs are schematic diagrams that define process equipment and instrumentation using standardized symbols. While there is no single universal standard, the ISA 5.1 standard governs common symbols. P&IDs provide key information to support equipment specification and installation through lists generated from the diagrams. Control loops and instrumentation tags are also standardized.