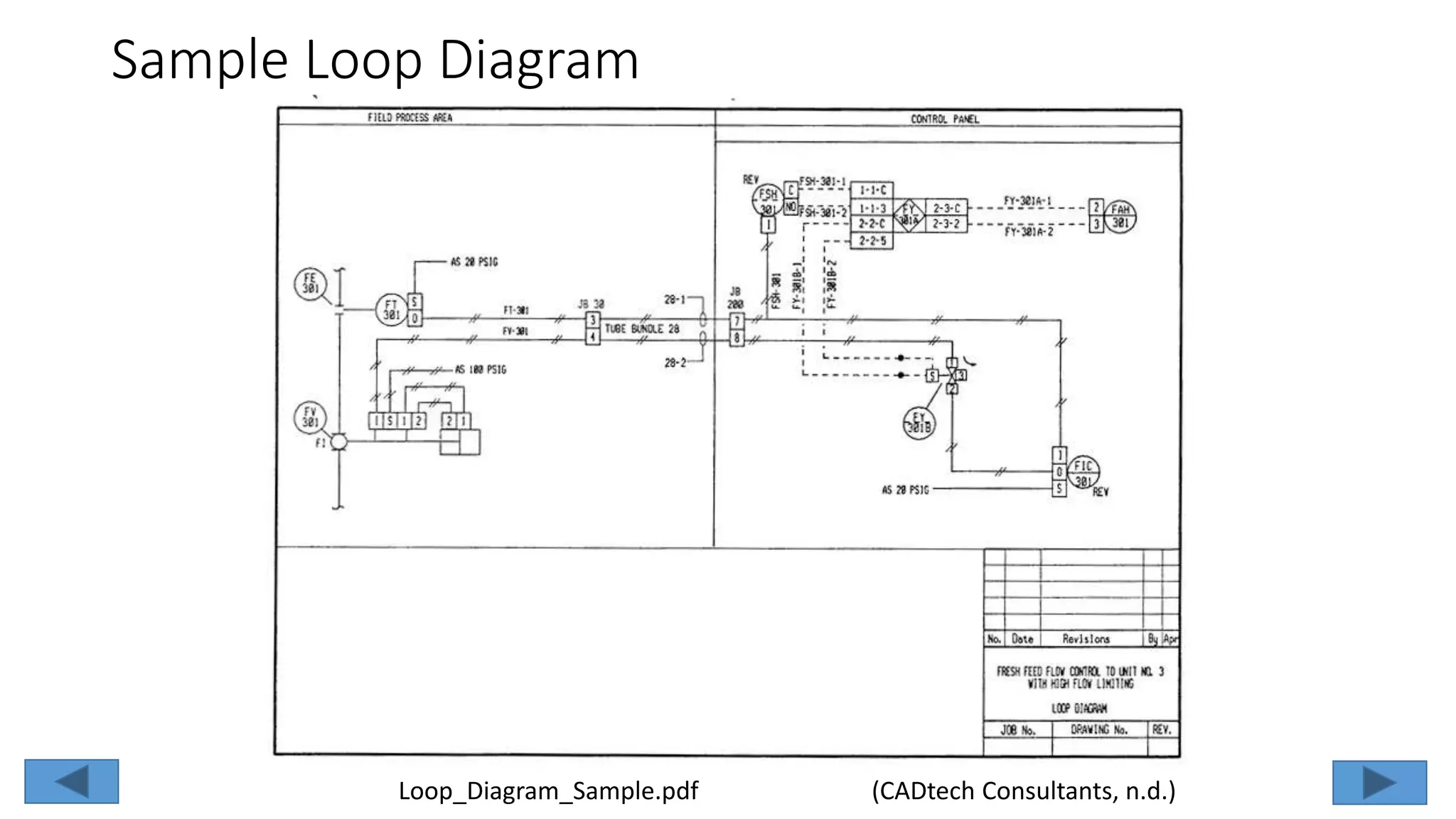

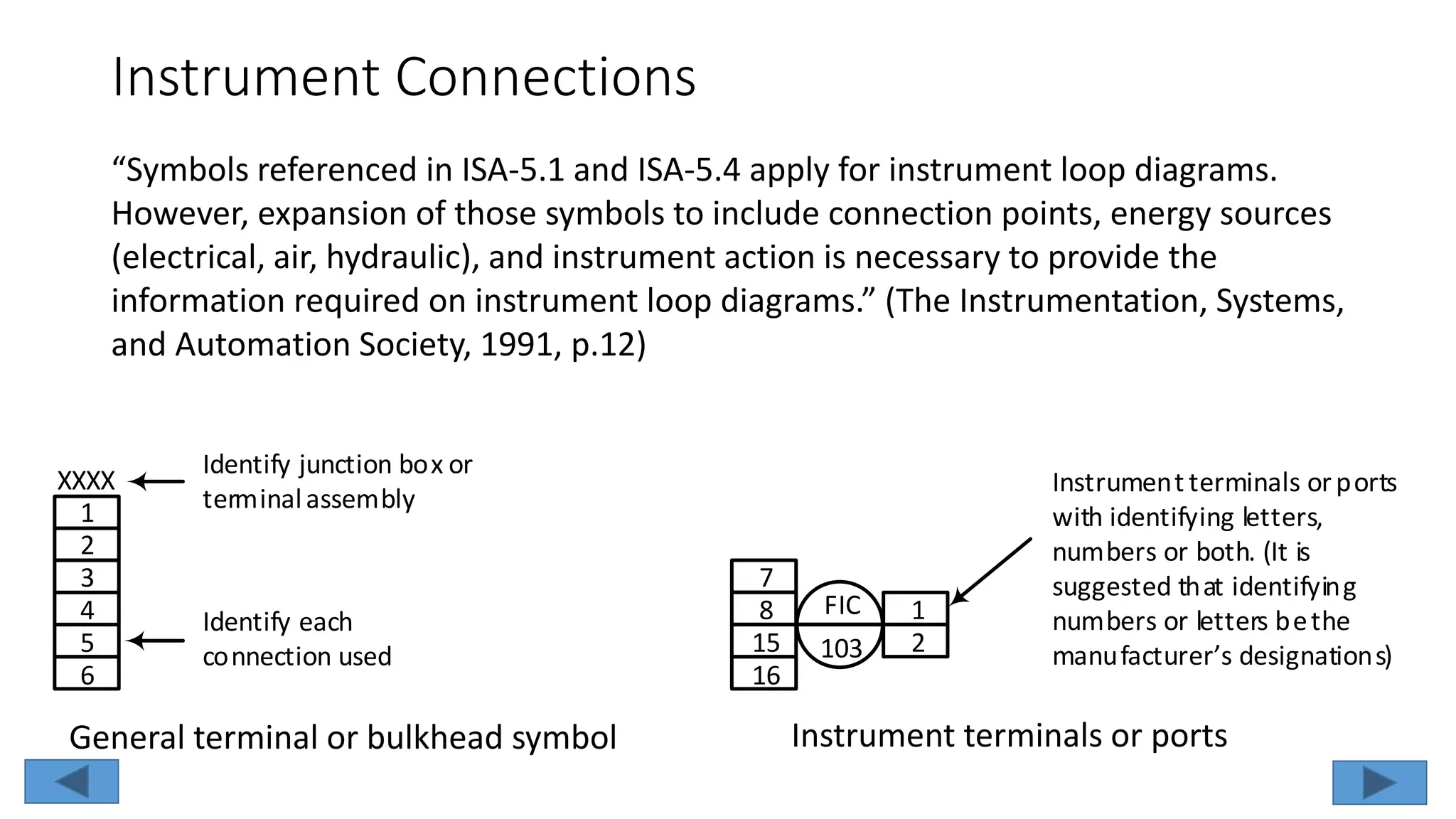

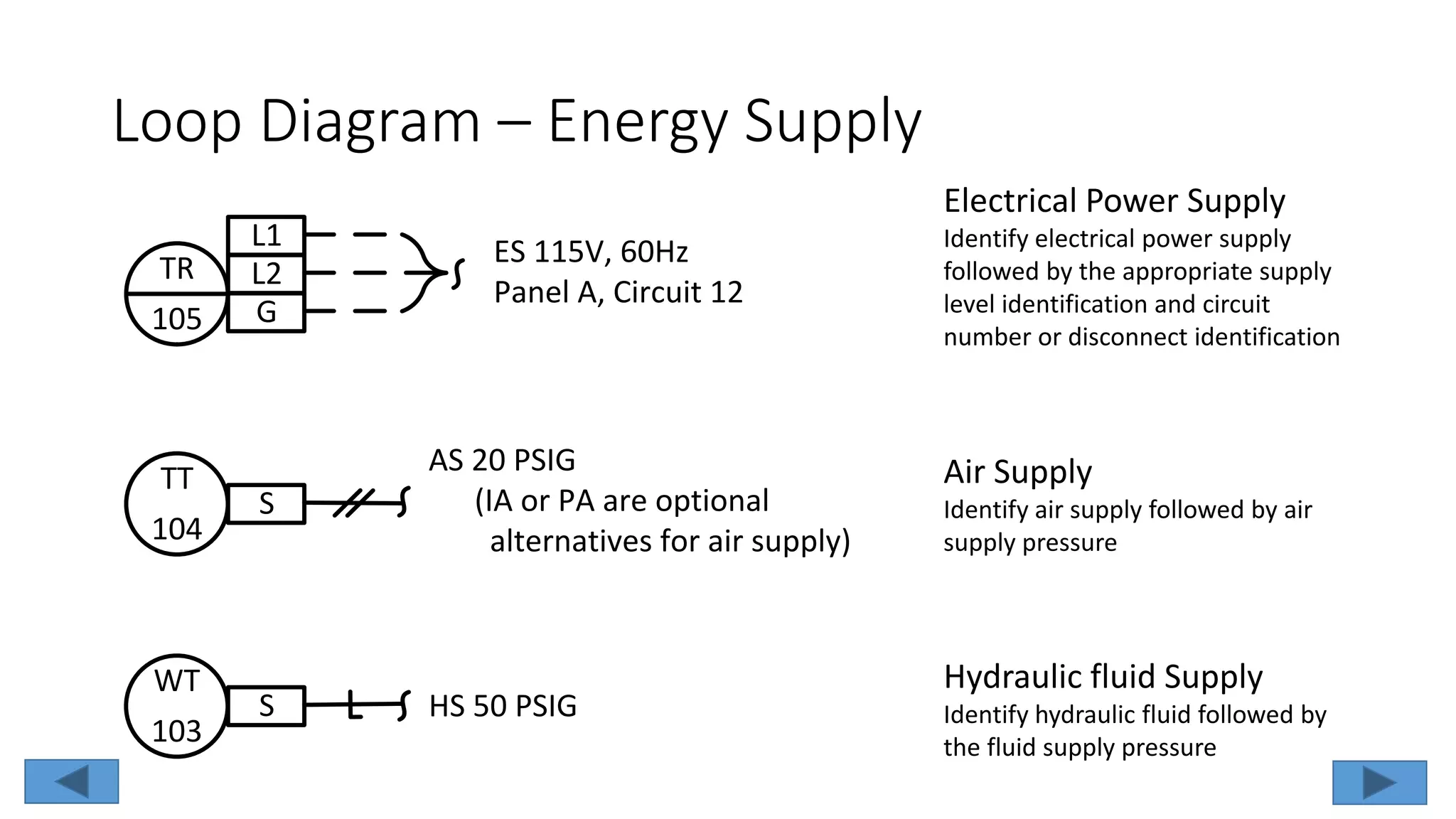

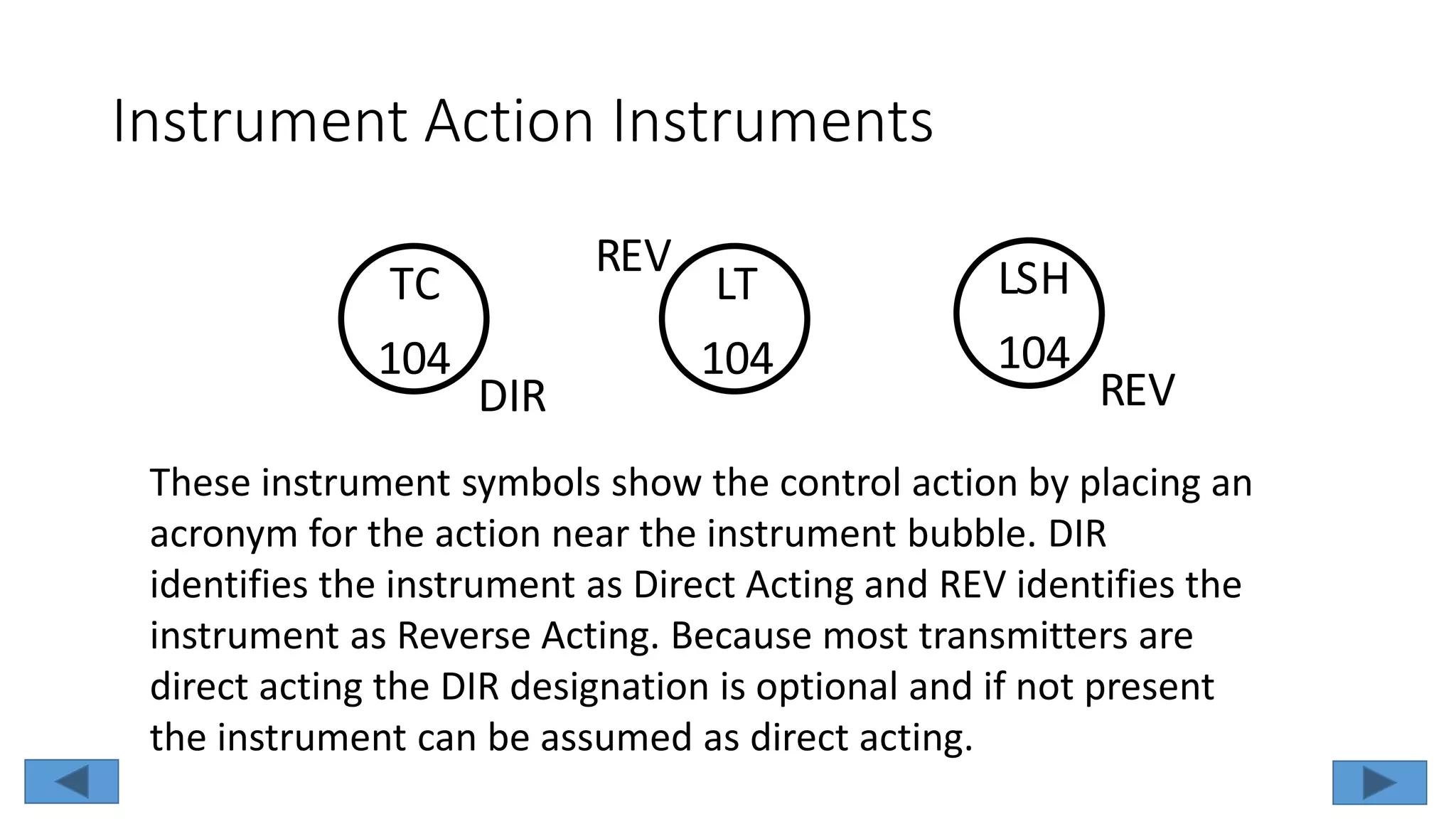

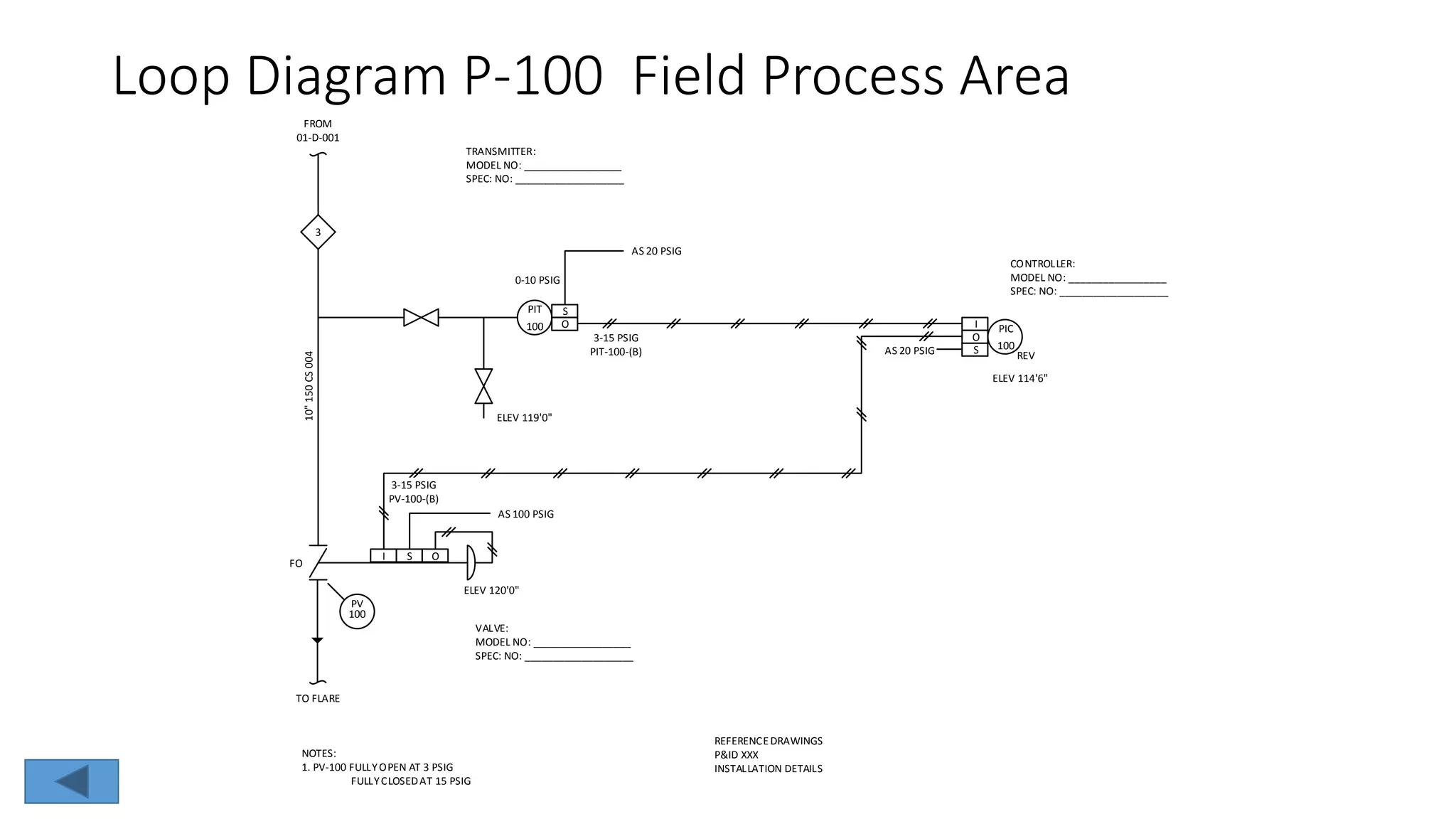

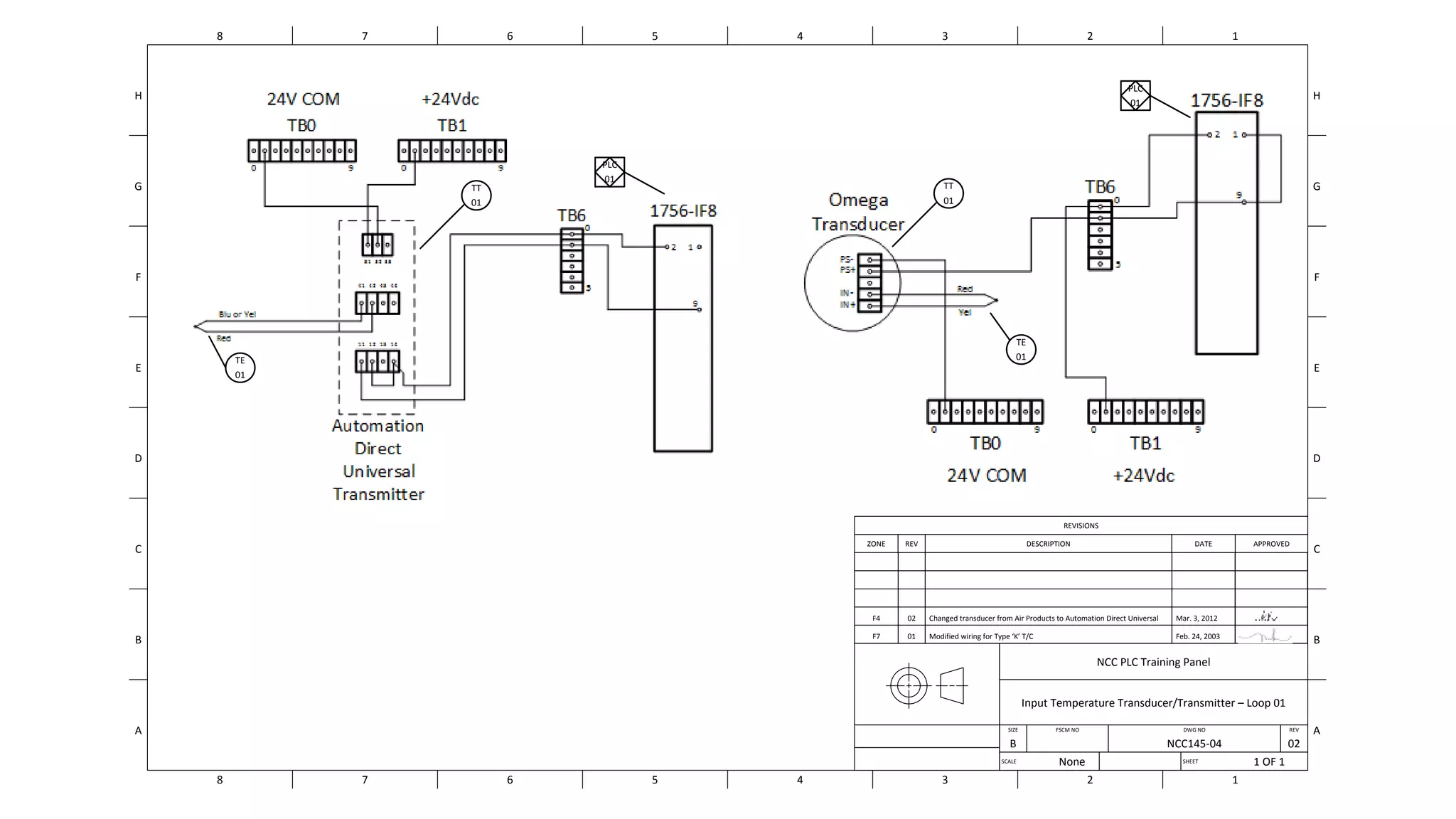

Loop diagrams are schematic representations of instrumentation and control circuits used in process control systems. They show all electrical, pneumatic and physical connections for a loop including signal, power and utility connections. Key elements shown are field devices, control panels, junction boxes and terminal identification. Instrument action (direct or reverse) and energy supplies such as air, power and hydraulic are also identified. Guidelines specify that one loop should be depicted per drawing and that standard symbols are used to represent components and connections.