This document discusses different types of instrumentation diagrams used in process instrumentation:

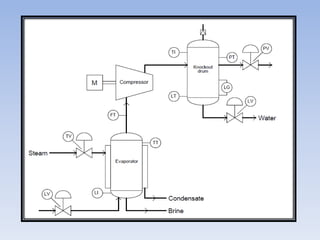

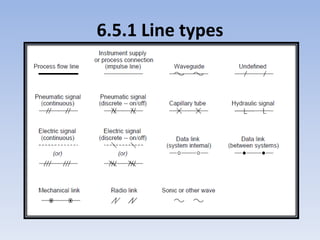

- Process Flow Diagrams (PFDs) show the overall process flow with minimal instrumentation details.

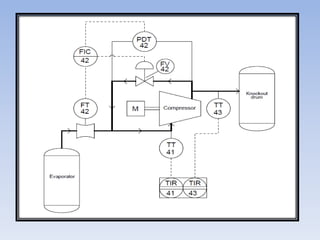

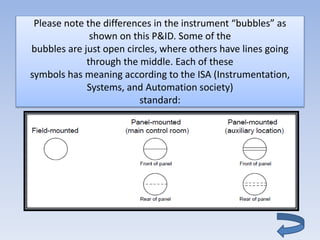

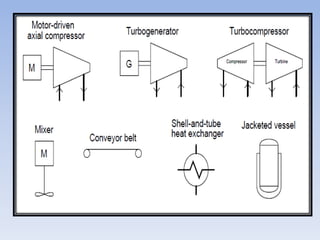

- Process and Instrument Diagrams (P&IDs) show both the process flow and instrumentation connections.

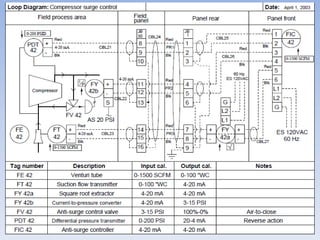

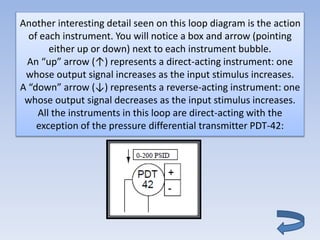

- Loop diagrams focus on instrumentation details like wire and terminal connections.

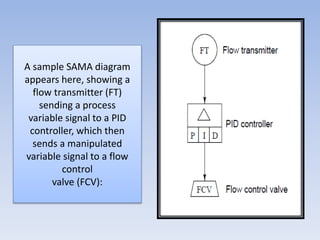

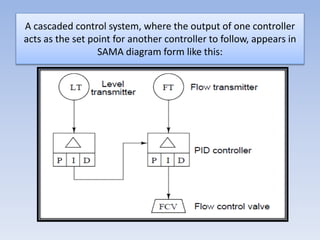

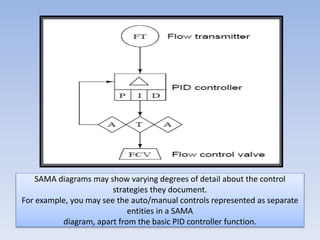

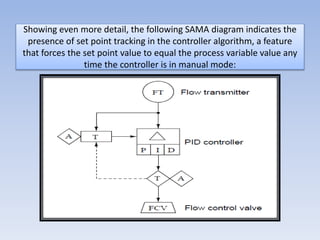

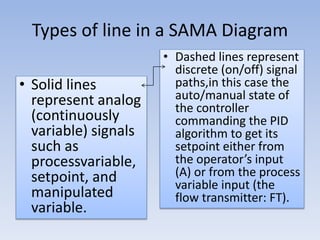

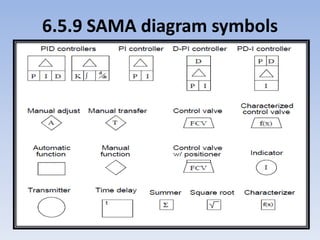

- SAMA diagrams focus on control strategies through information flow rather than physical connections.

The document explains key details depicted in each type of diagram through examples.