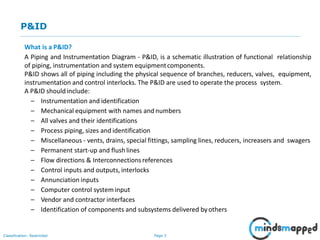

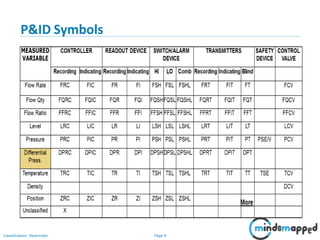

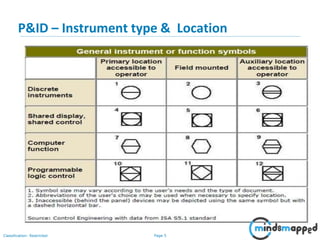

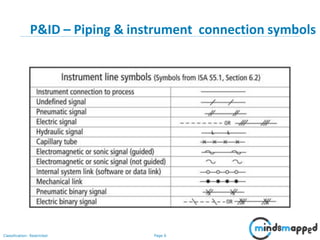

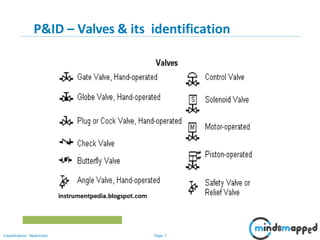

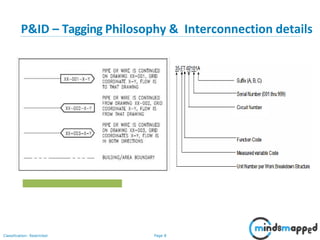

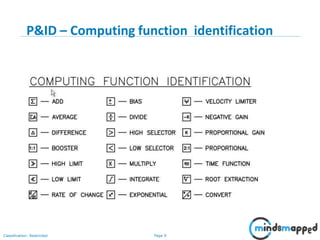

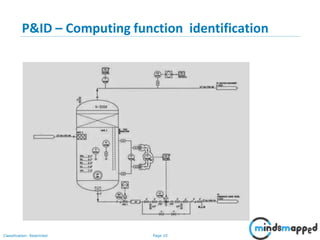

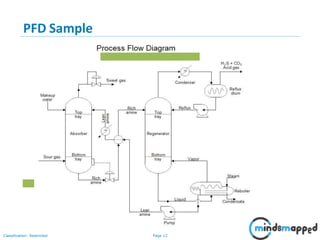

The document provides training content on Piping and Instrumentation Diagrams (P&ID) and Process Flow Diagrams (PFD), detailing their purpose, components, and symbols. P&IDs are schematic illustrations that depict the functional relationships of piping, instrumentation, and equipment within process systems, while PFDs illustrate relationships between major system components and process design values. Various aspects, such as identification, tagging, and operational details, are emphasized to facilitate understanding and operation of these diagrams.