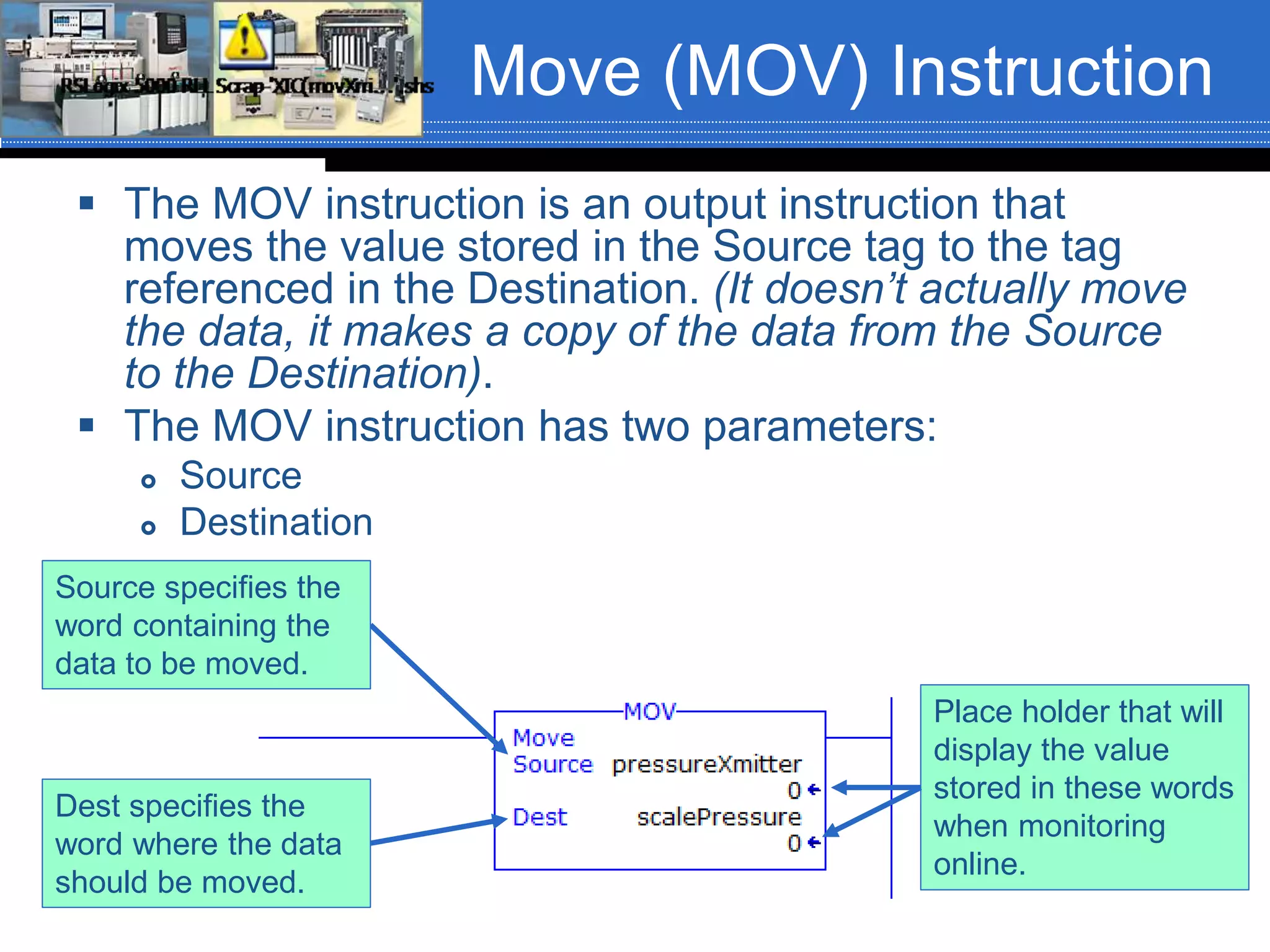

Chapter 06 covers data manipulation instructions for programmable controllers, highlighting their capability to transfer and operate on data. It explains data transfer and move (mov) instructions, detailing their parameters and practical applications, including a sample circuit for controlling pump operations. Additionally, it introduces the masked move (mvm) instruction, emphasizing its filtering mechanism for selectively moving data bits.