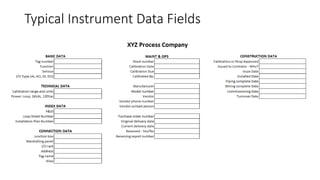

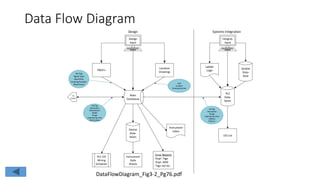

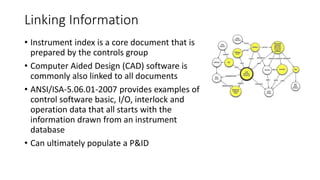

The document outlines the evolution and importance of lists, indexes, and databases in managing mechanical equipment and control systems in process plants. It emphasizes the necessity for accurate, consistent, and up-to-date data entry, as well as the integration of information across various departments and software tools. The ANSI/ISA standards and the significance of maintaining an instrument index are highlighted as crucial for effective plant operations.