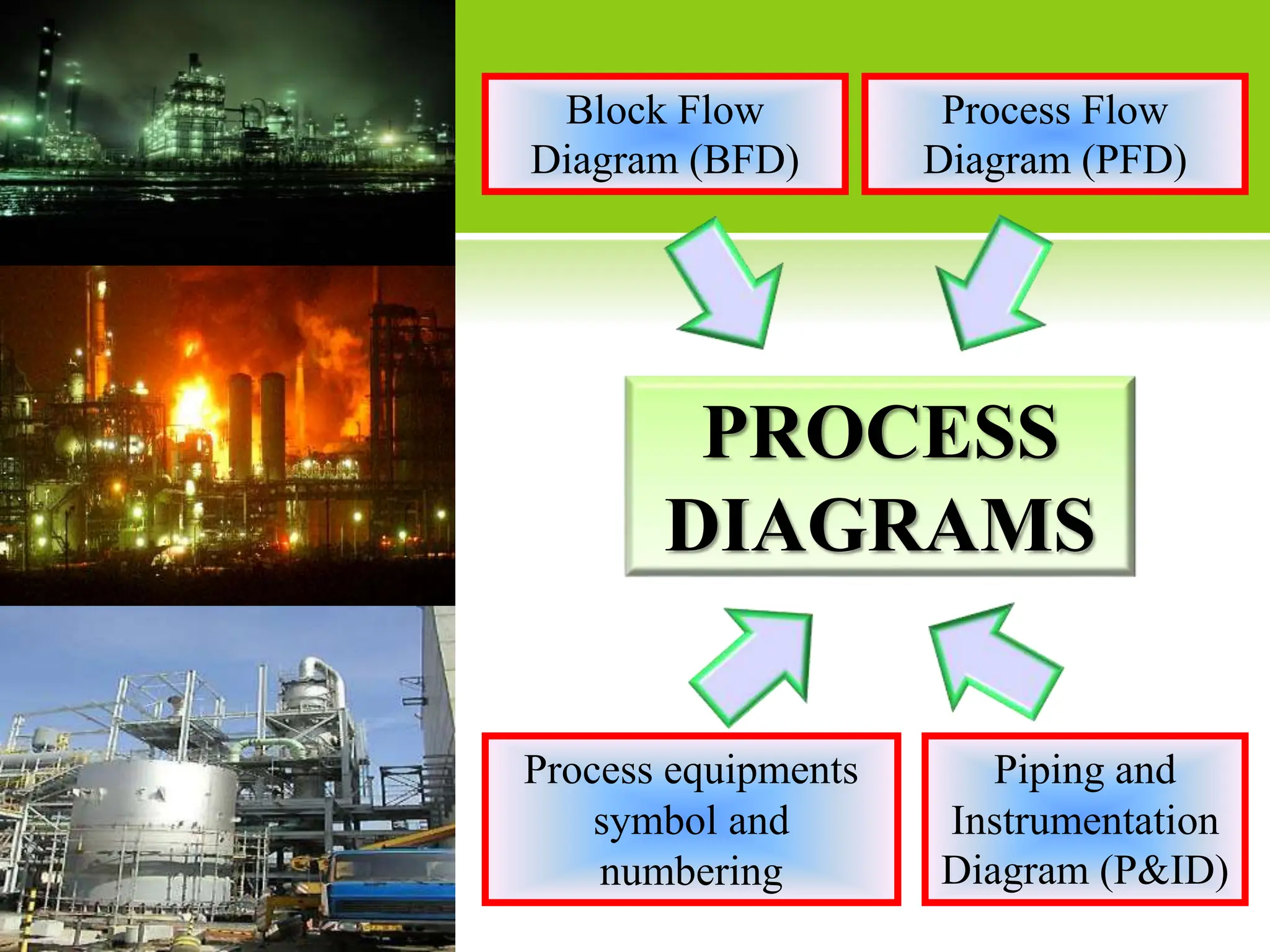

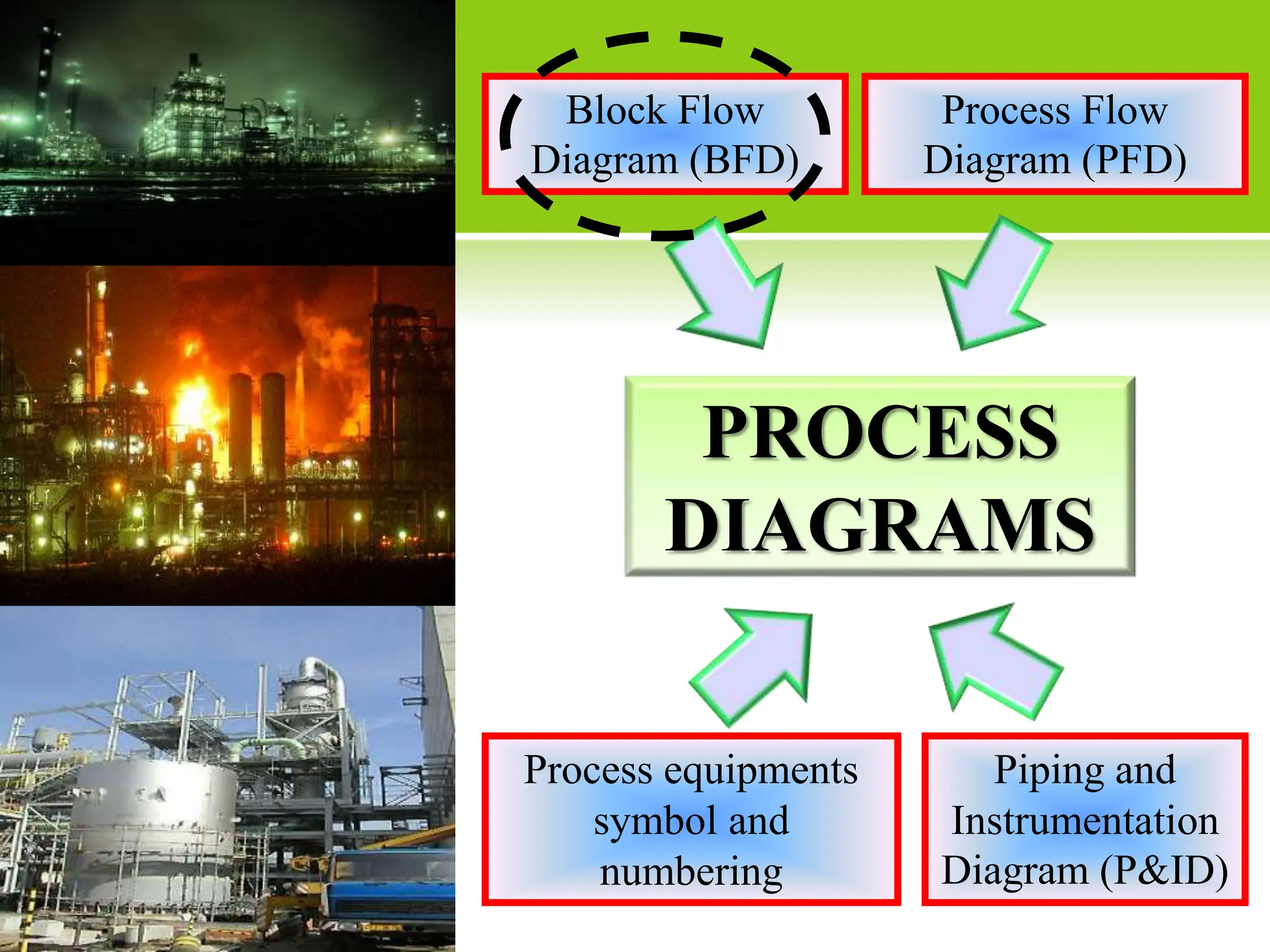

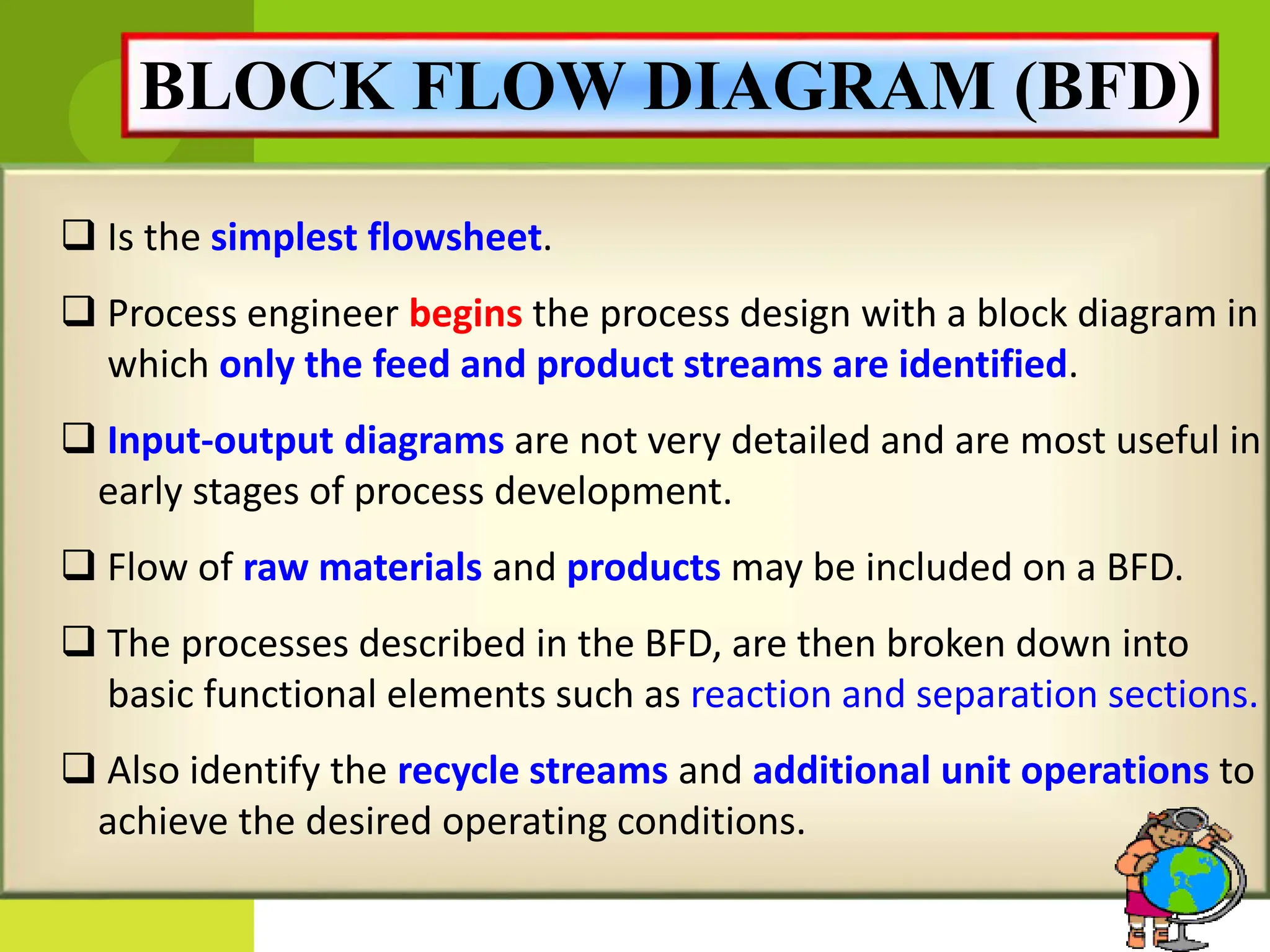

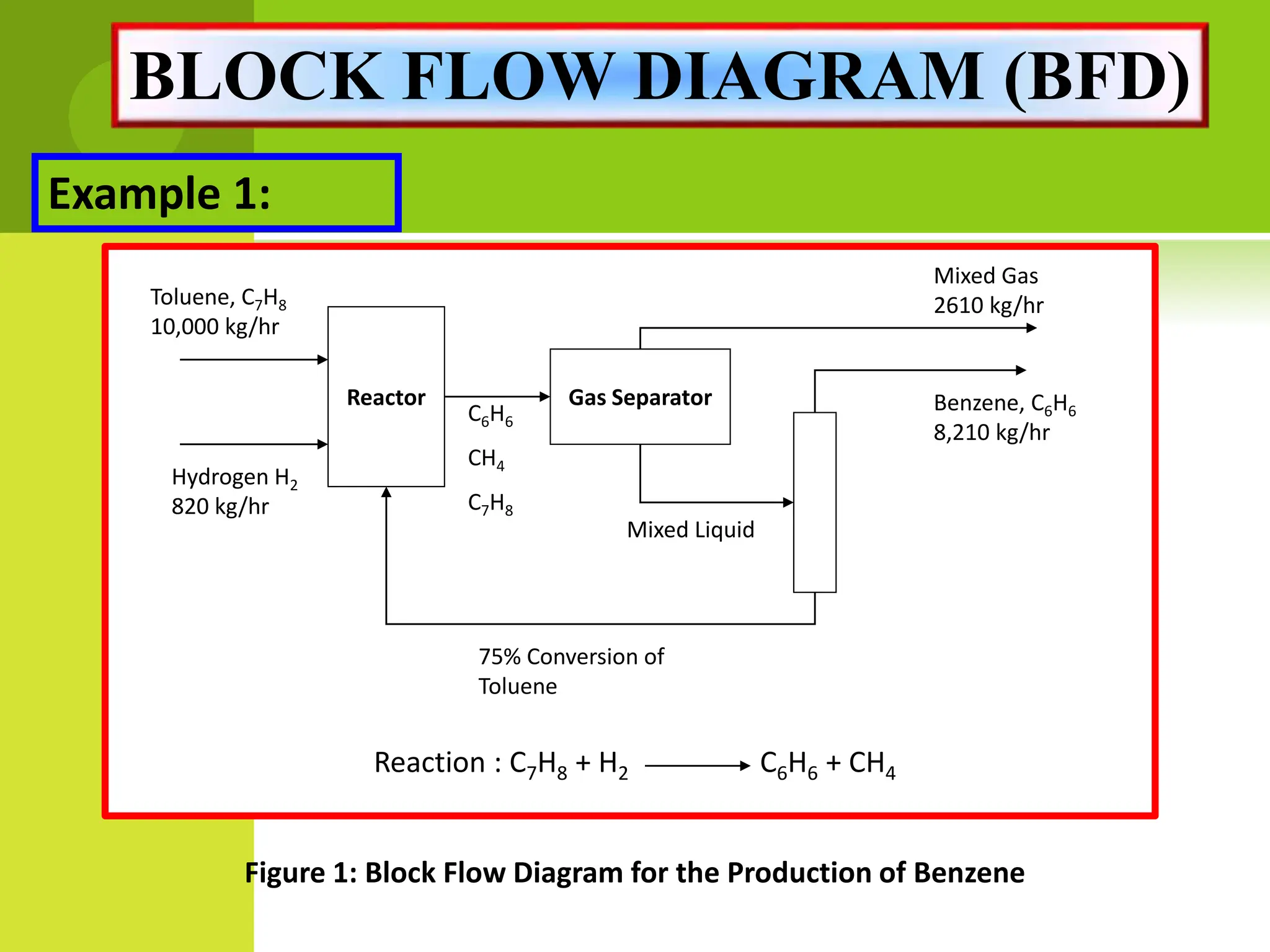

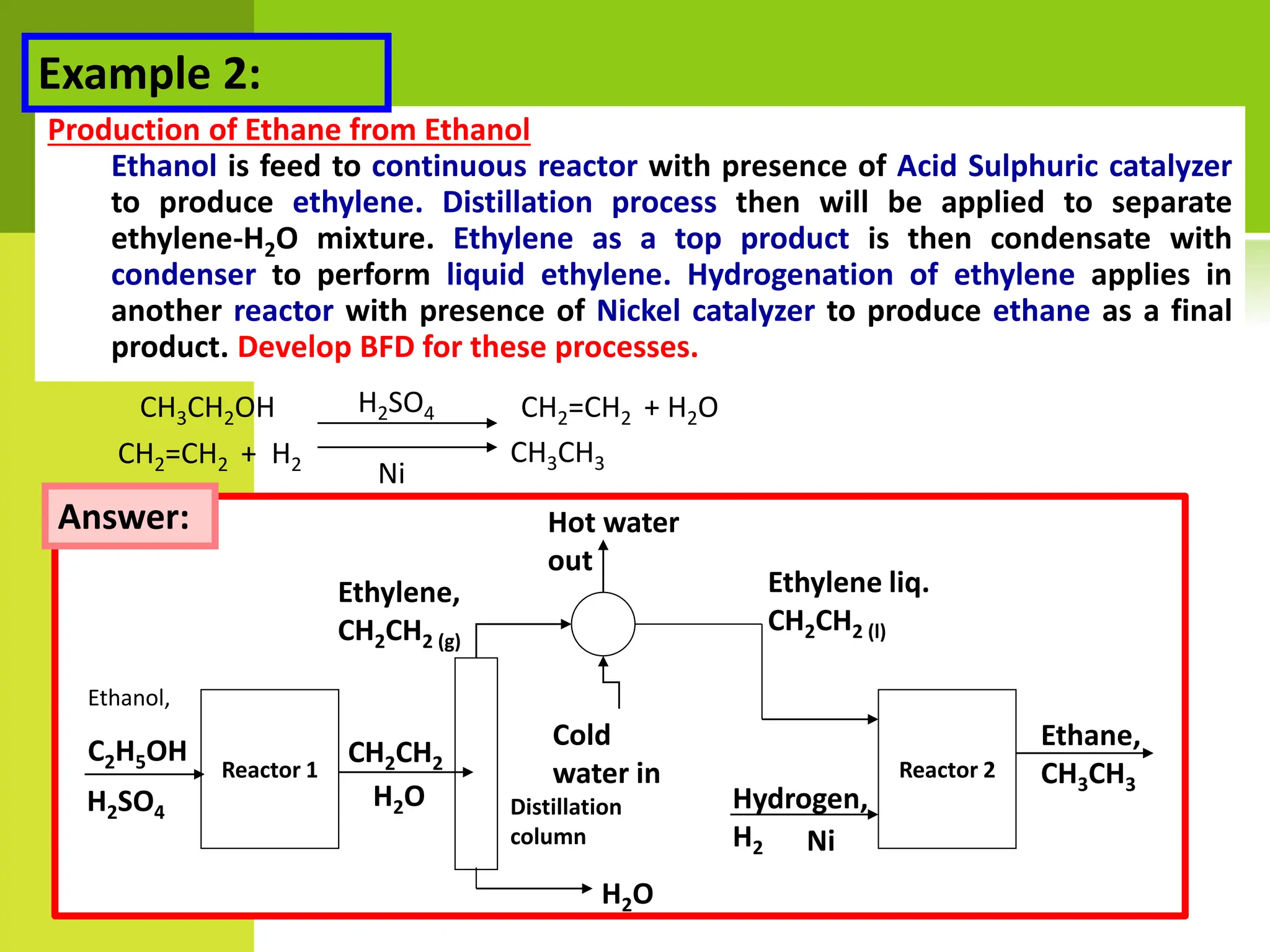

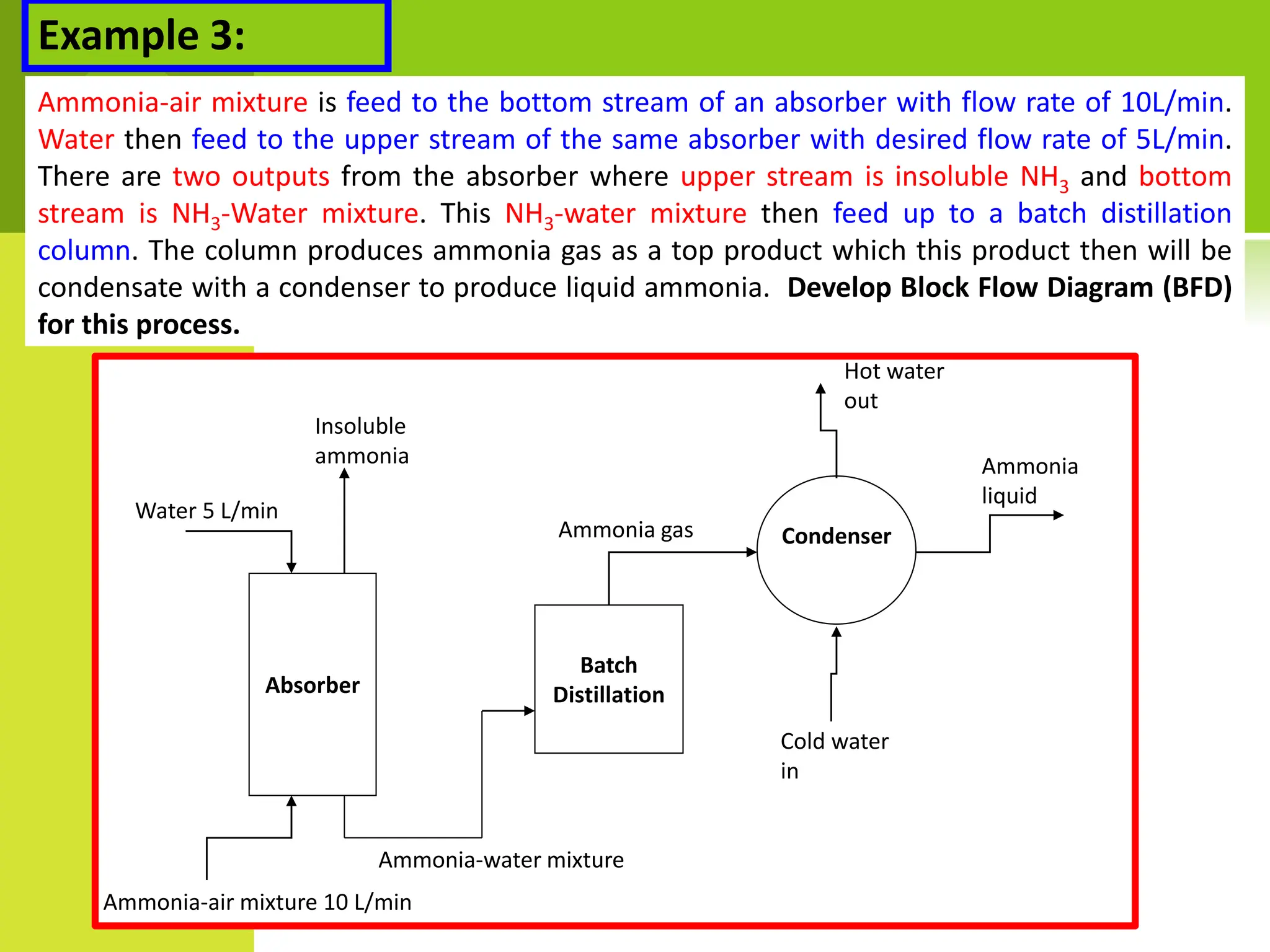

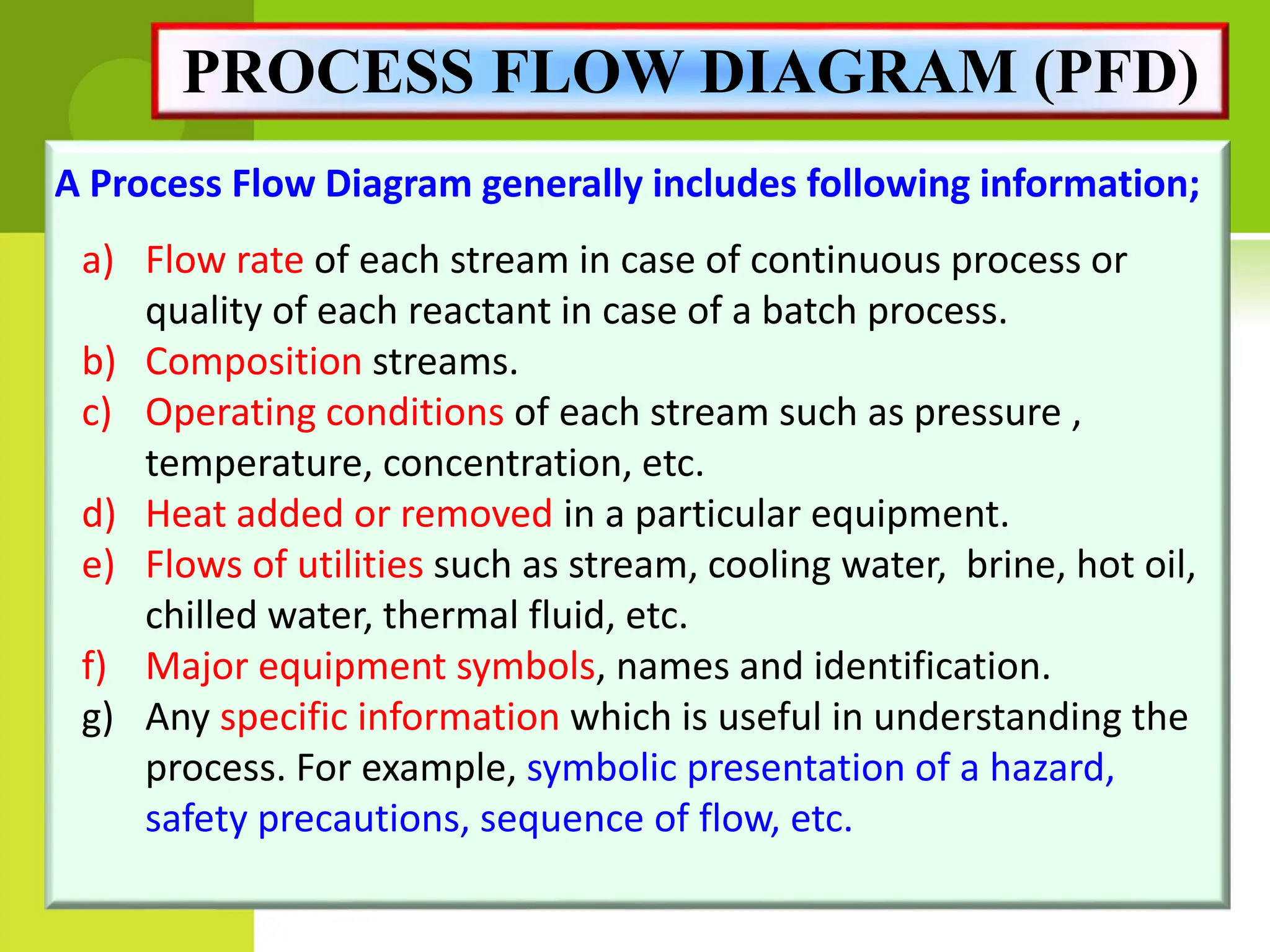

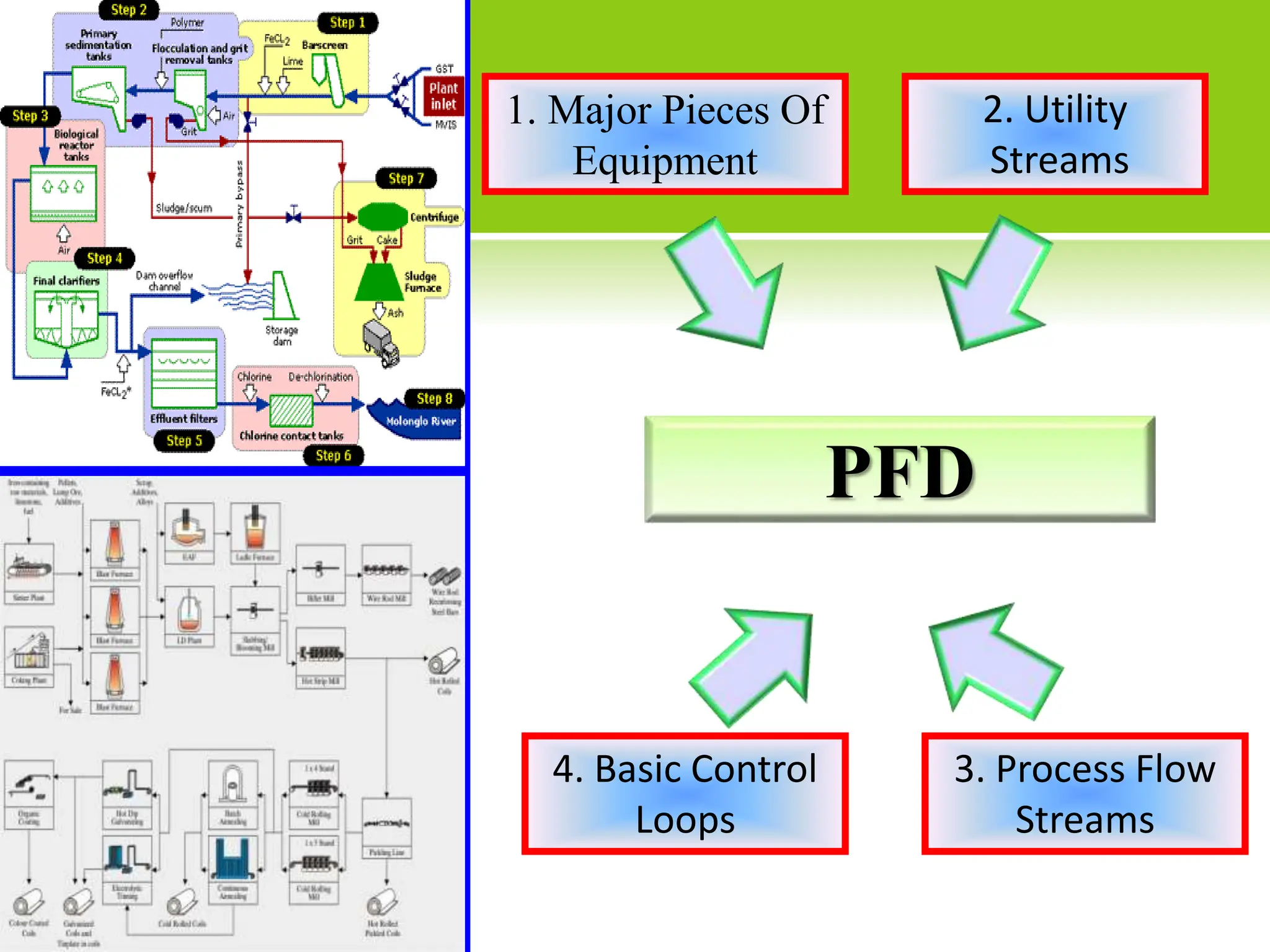

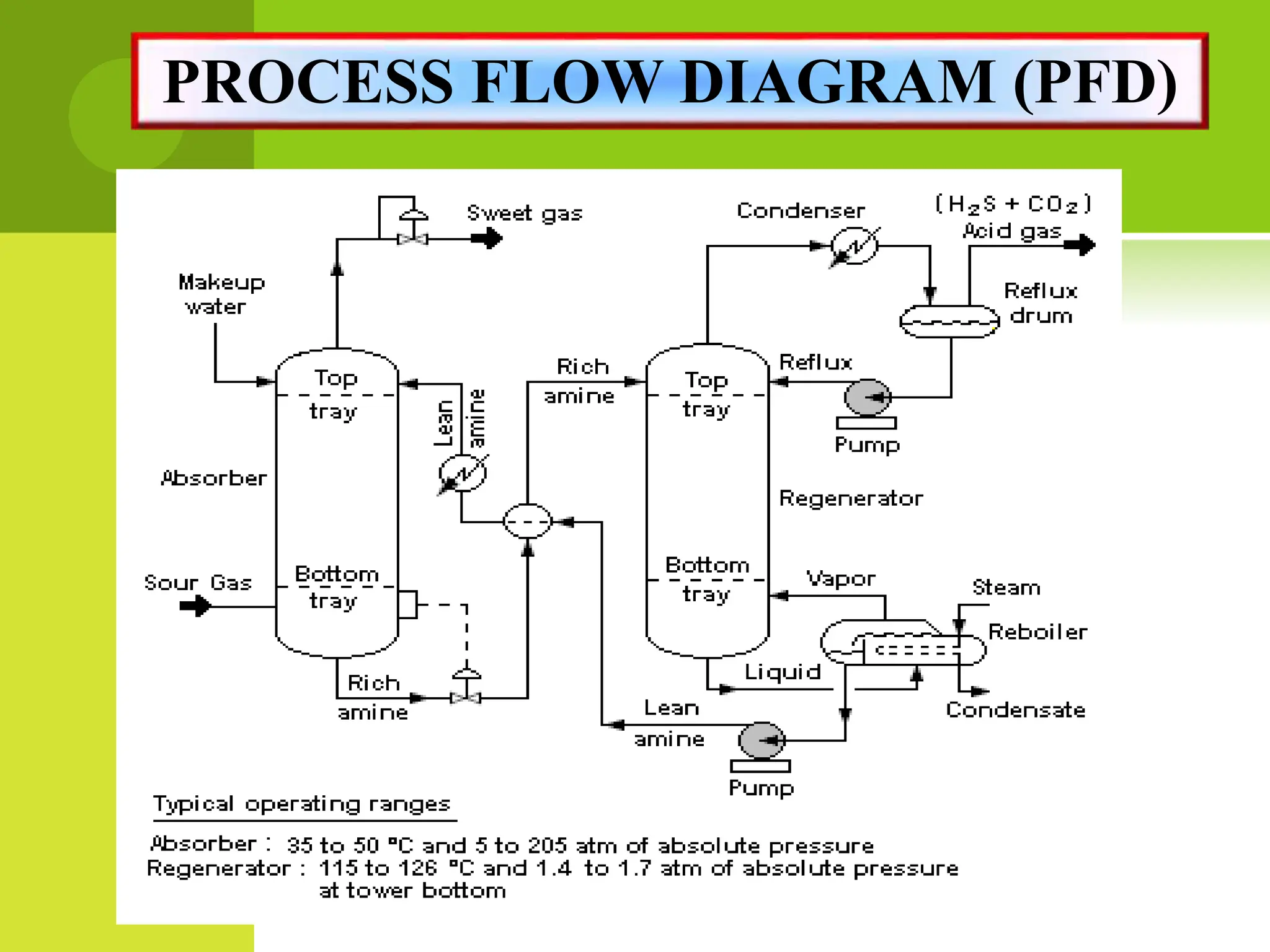

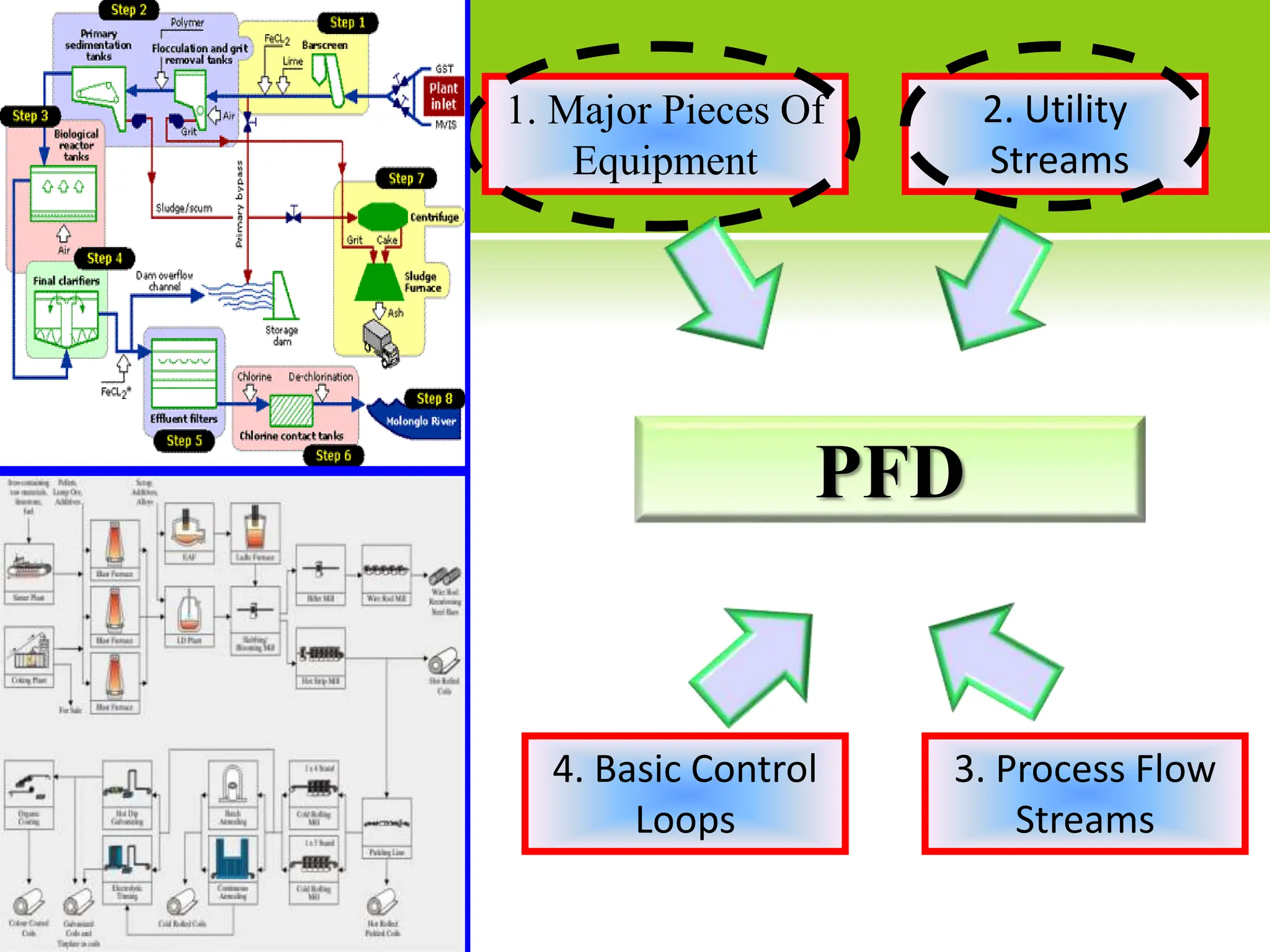

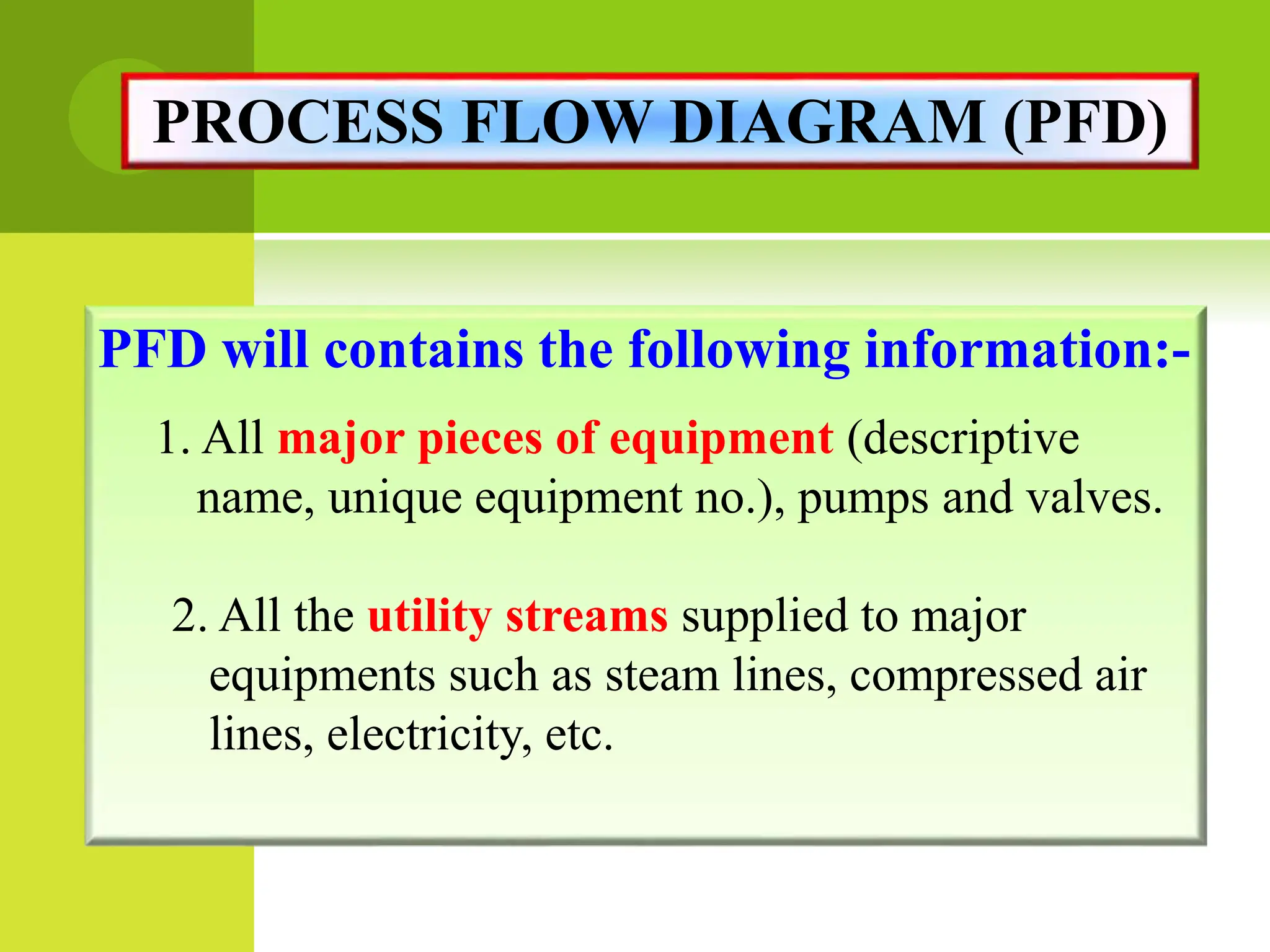

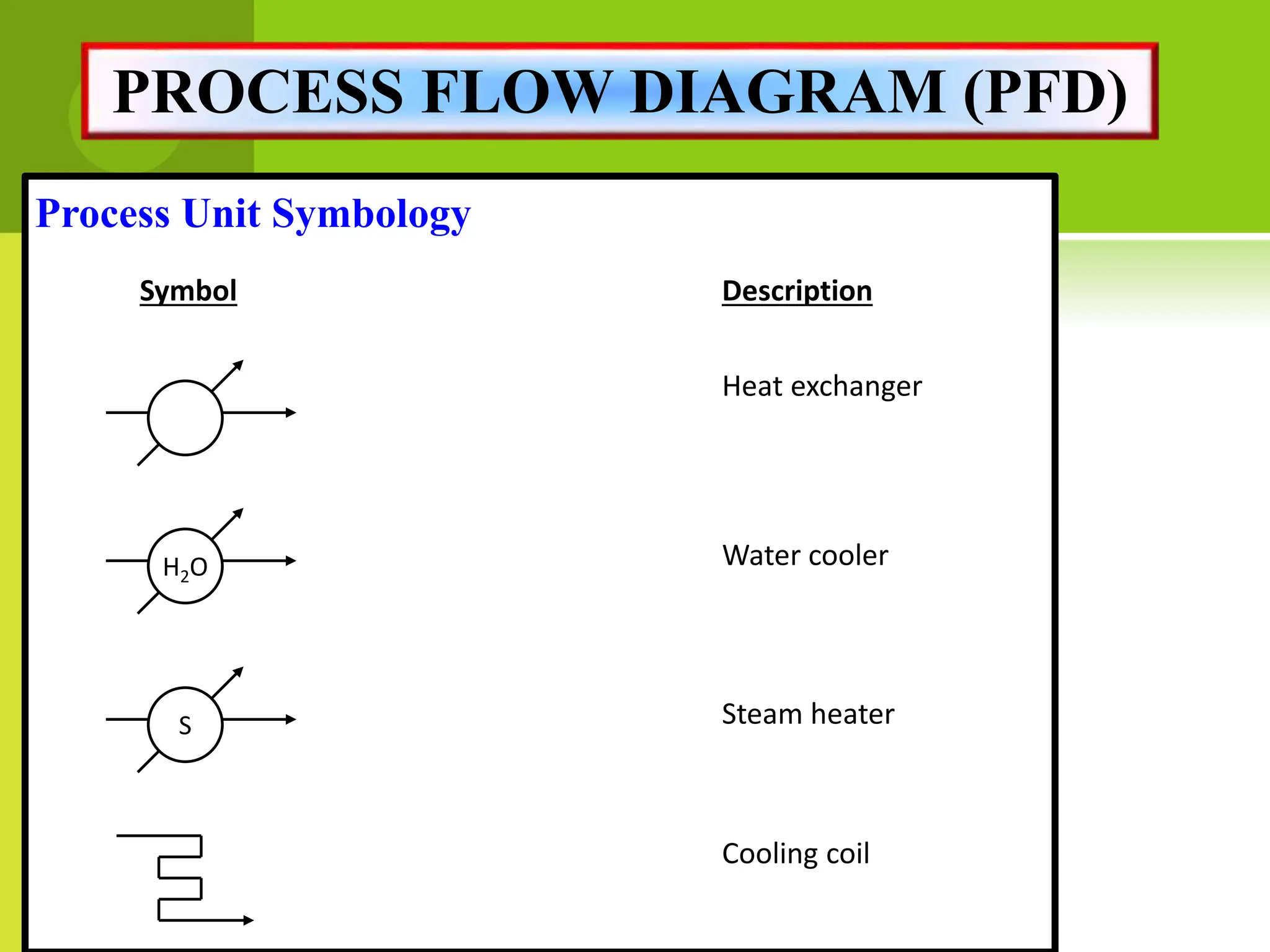

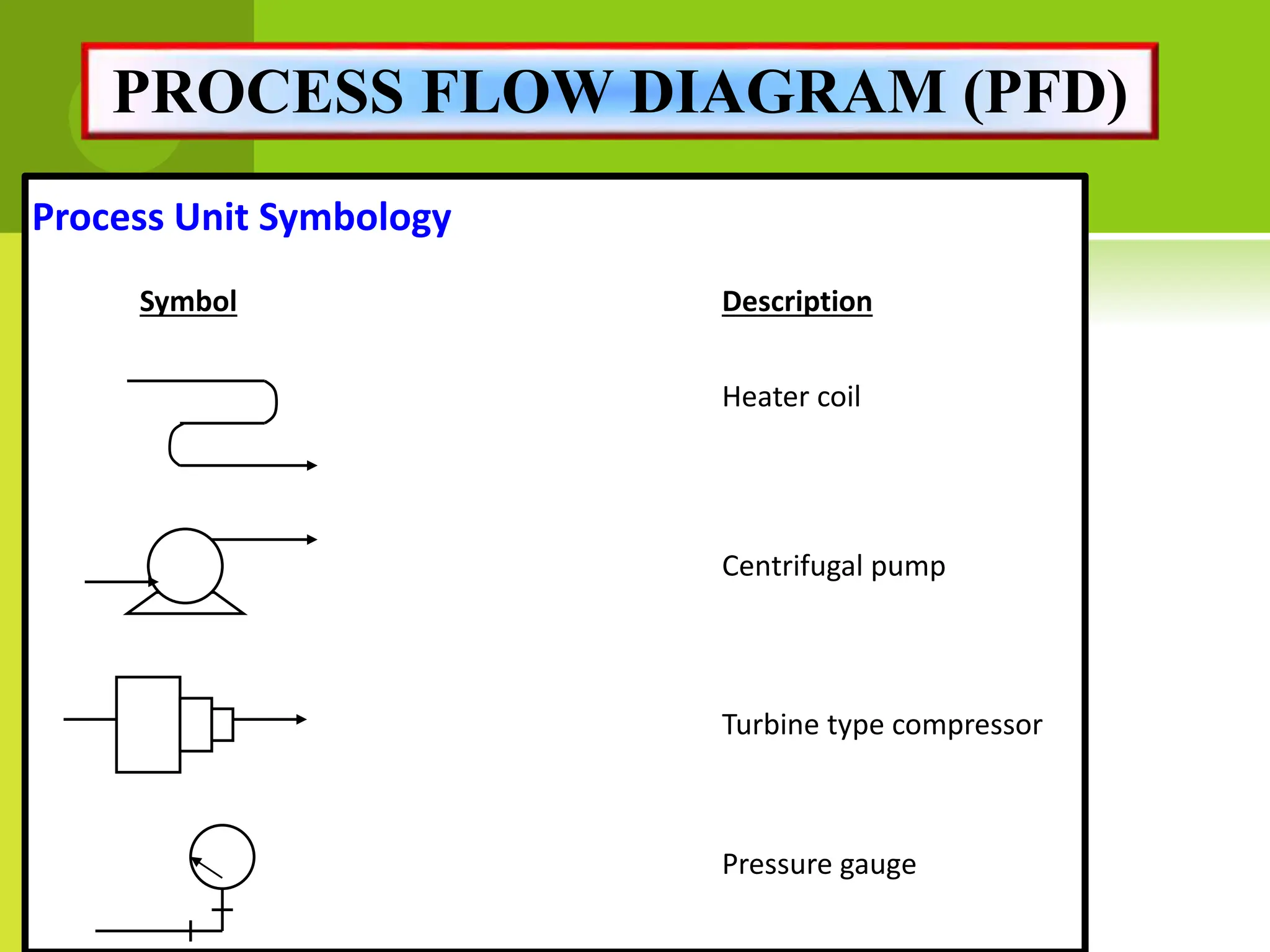

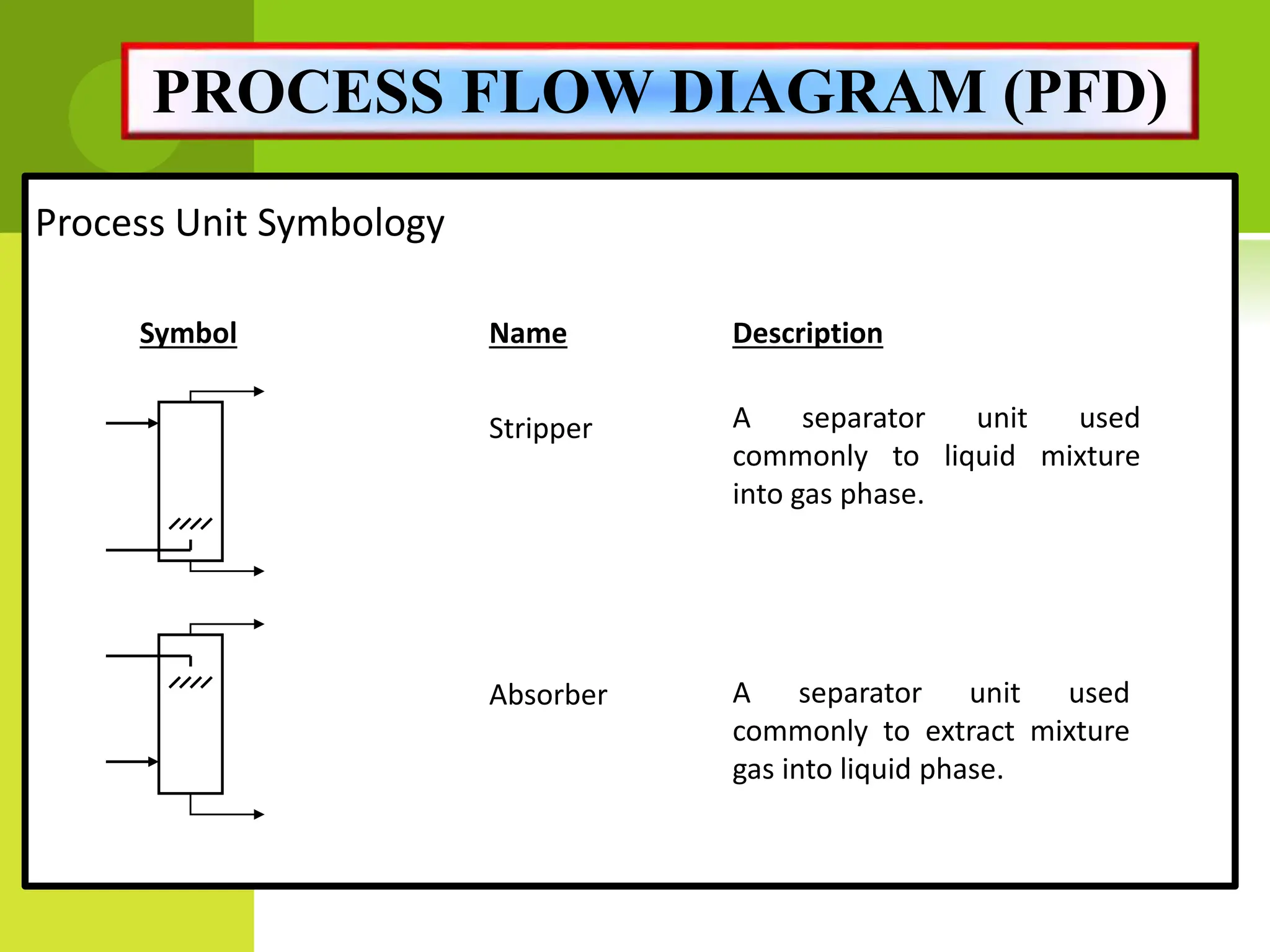

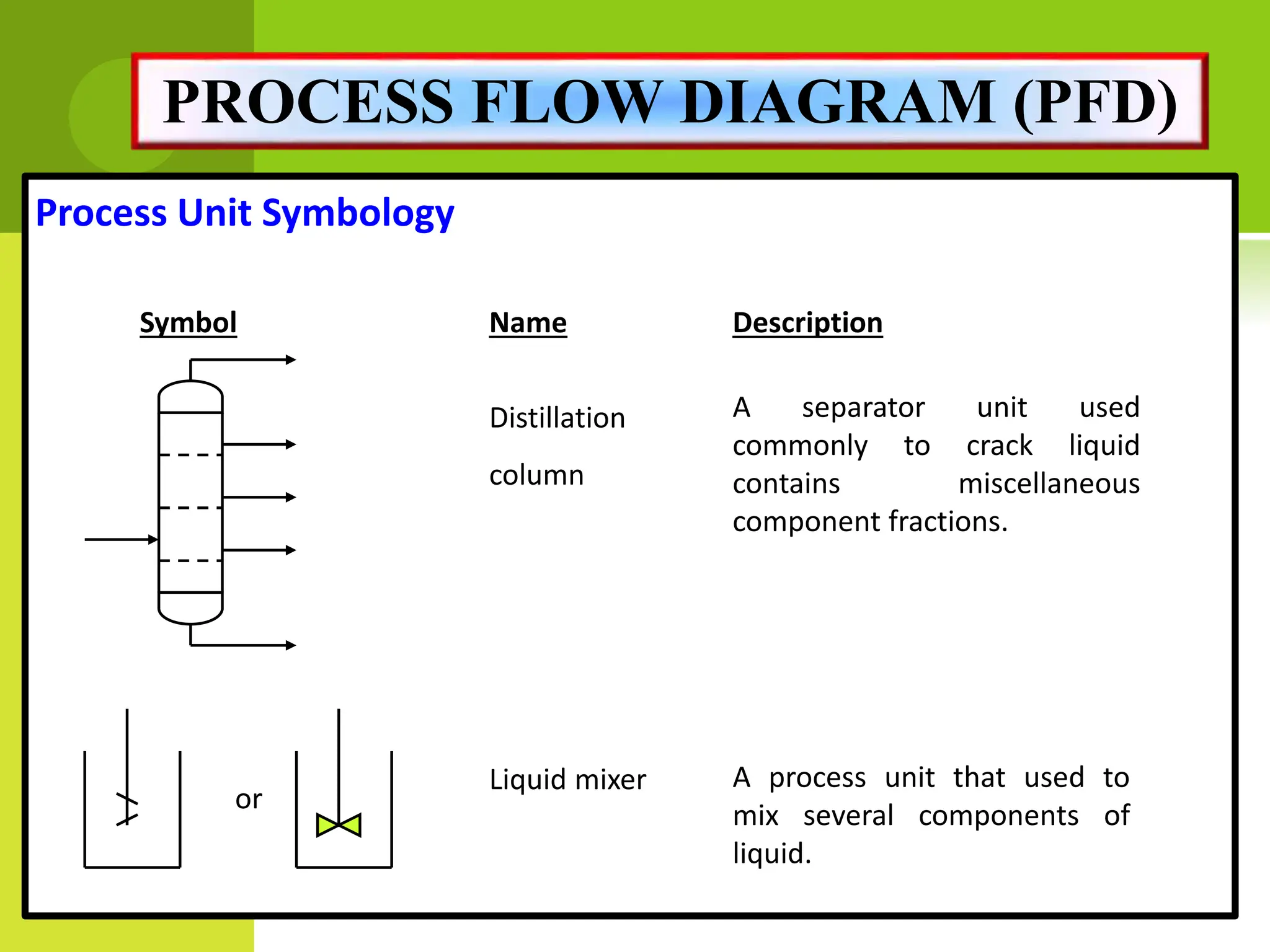

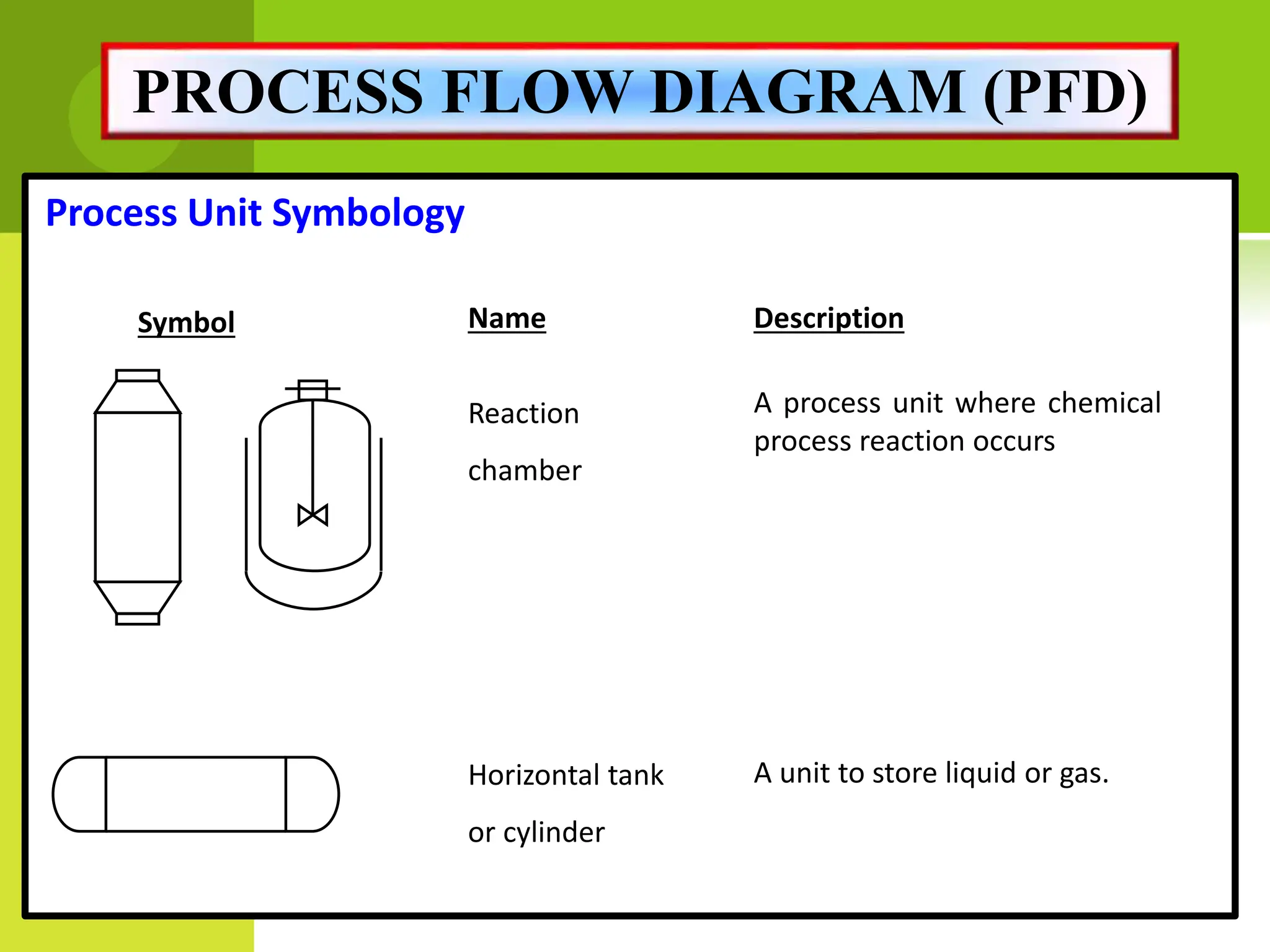

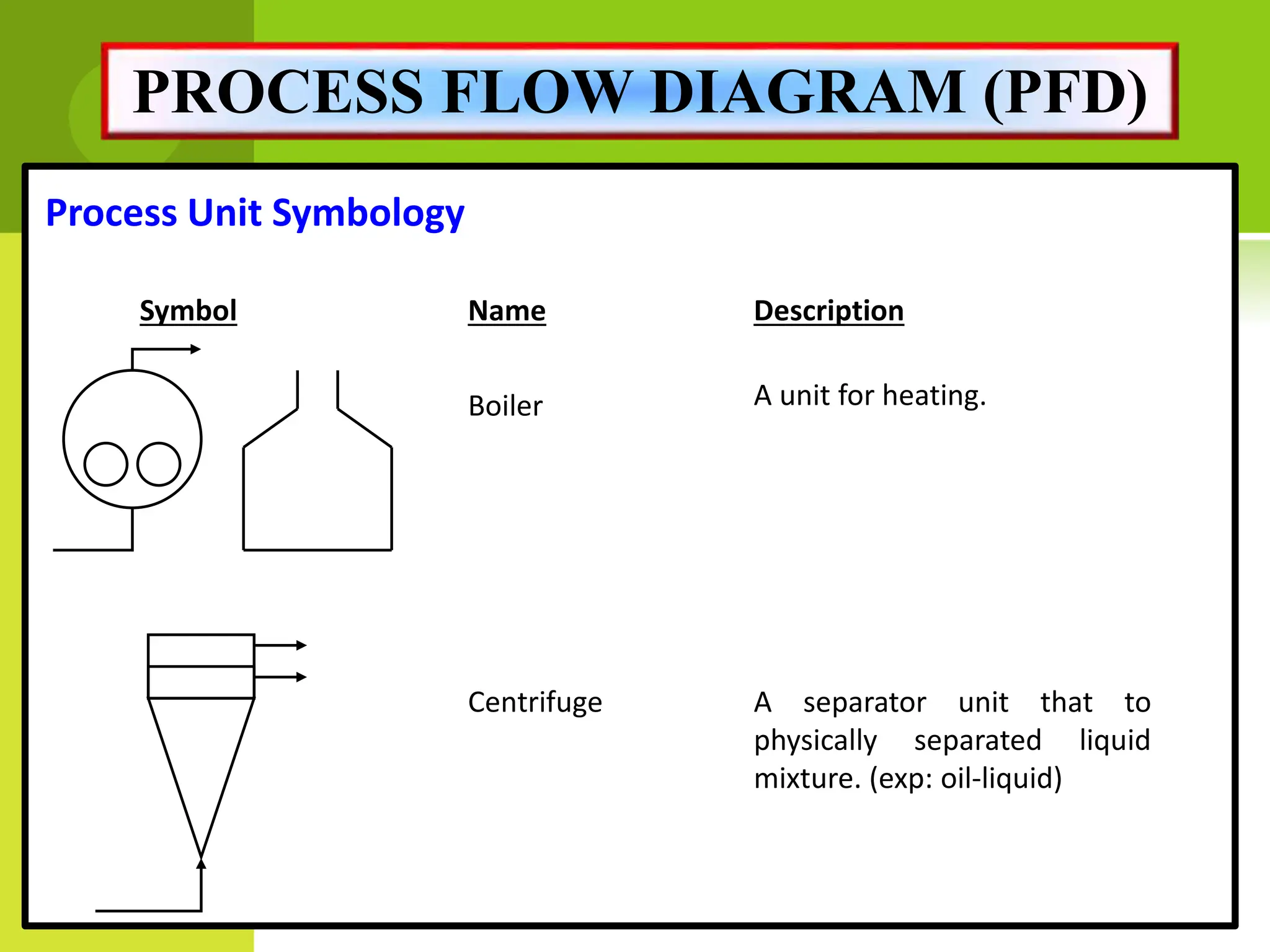

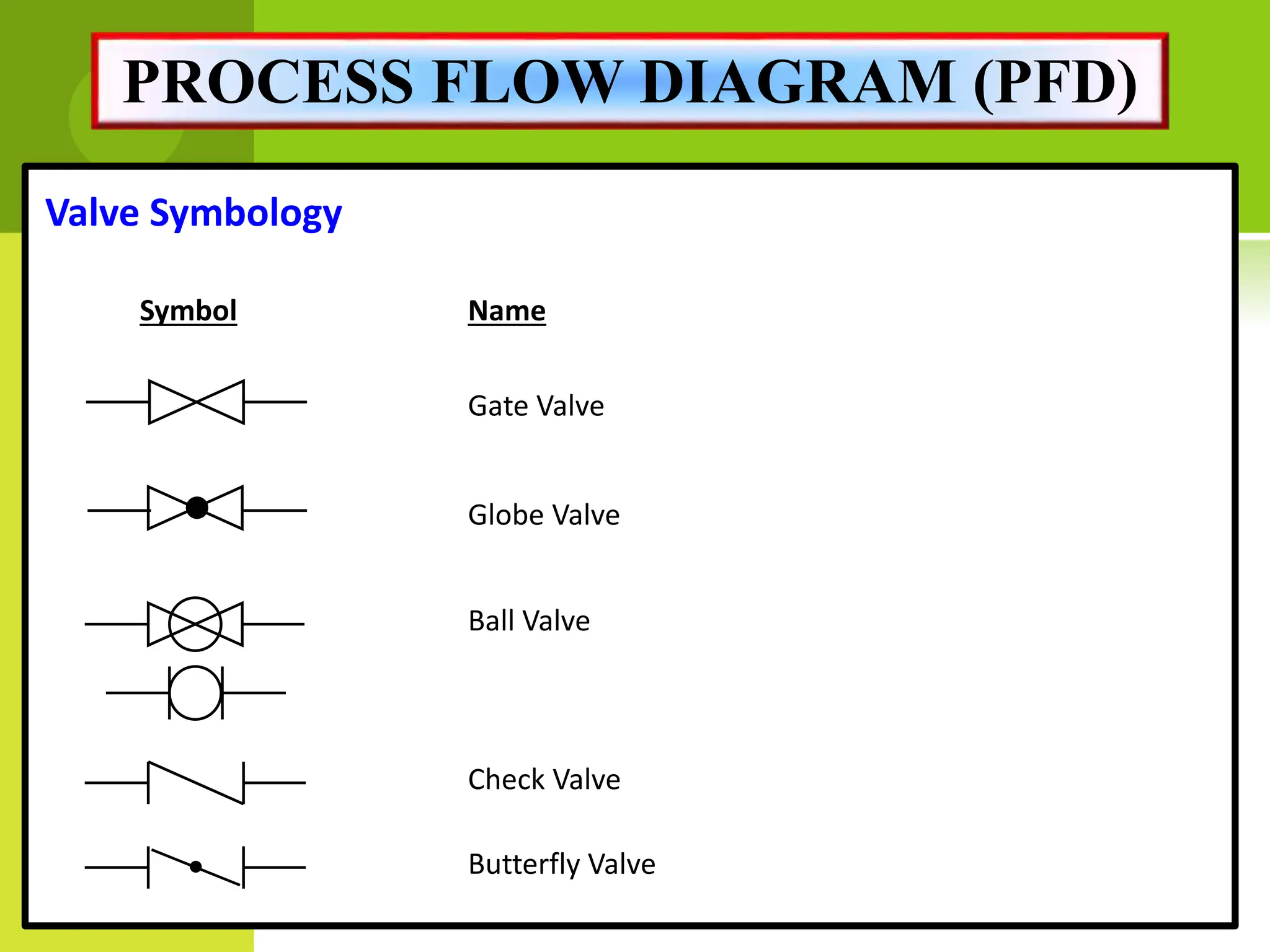

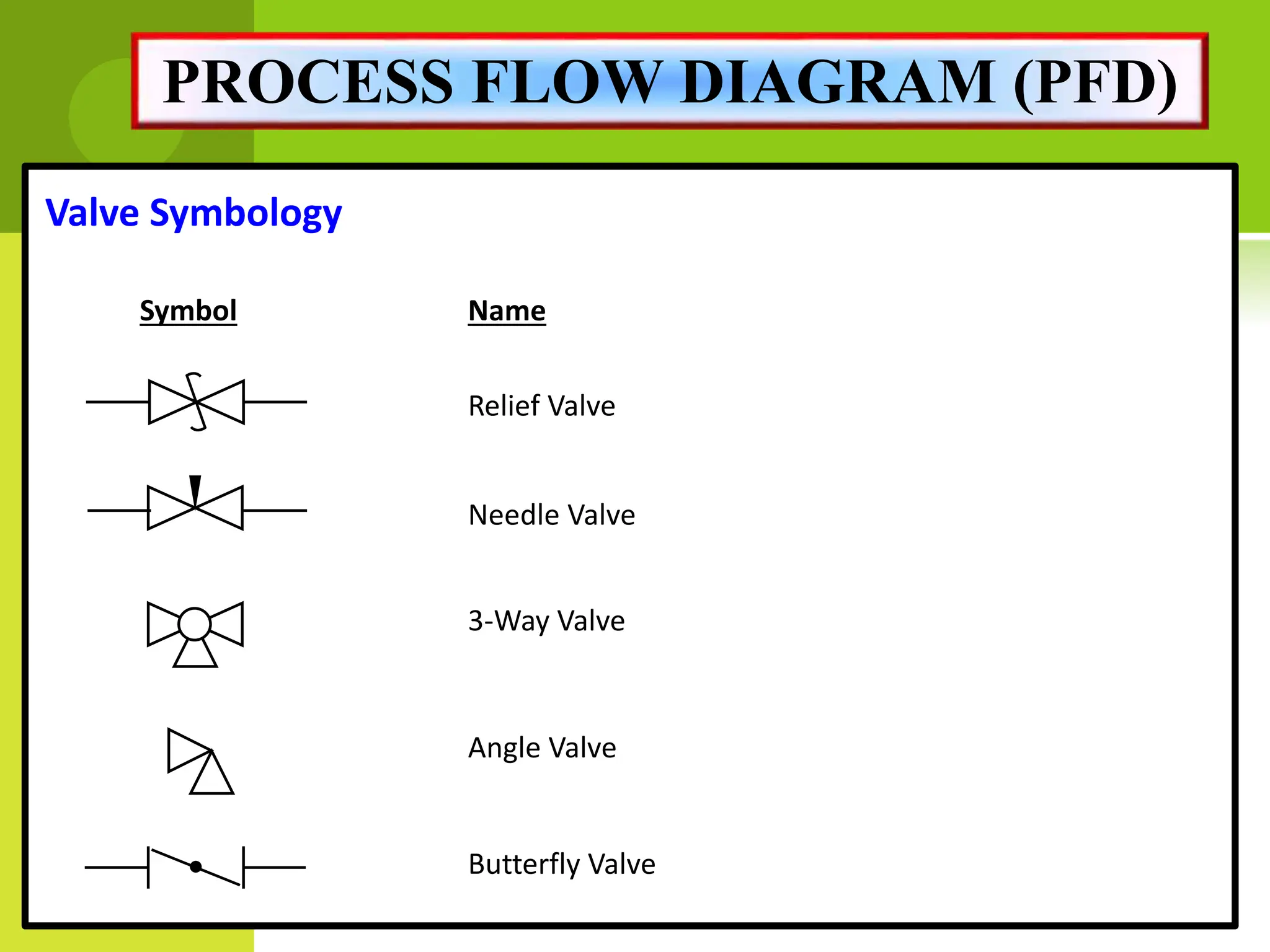

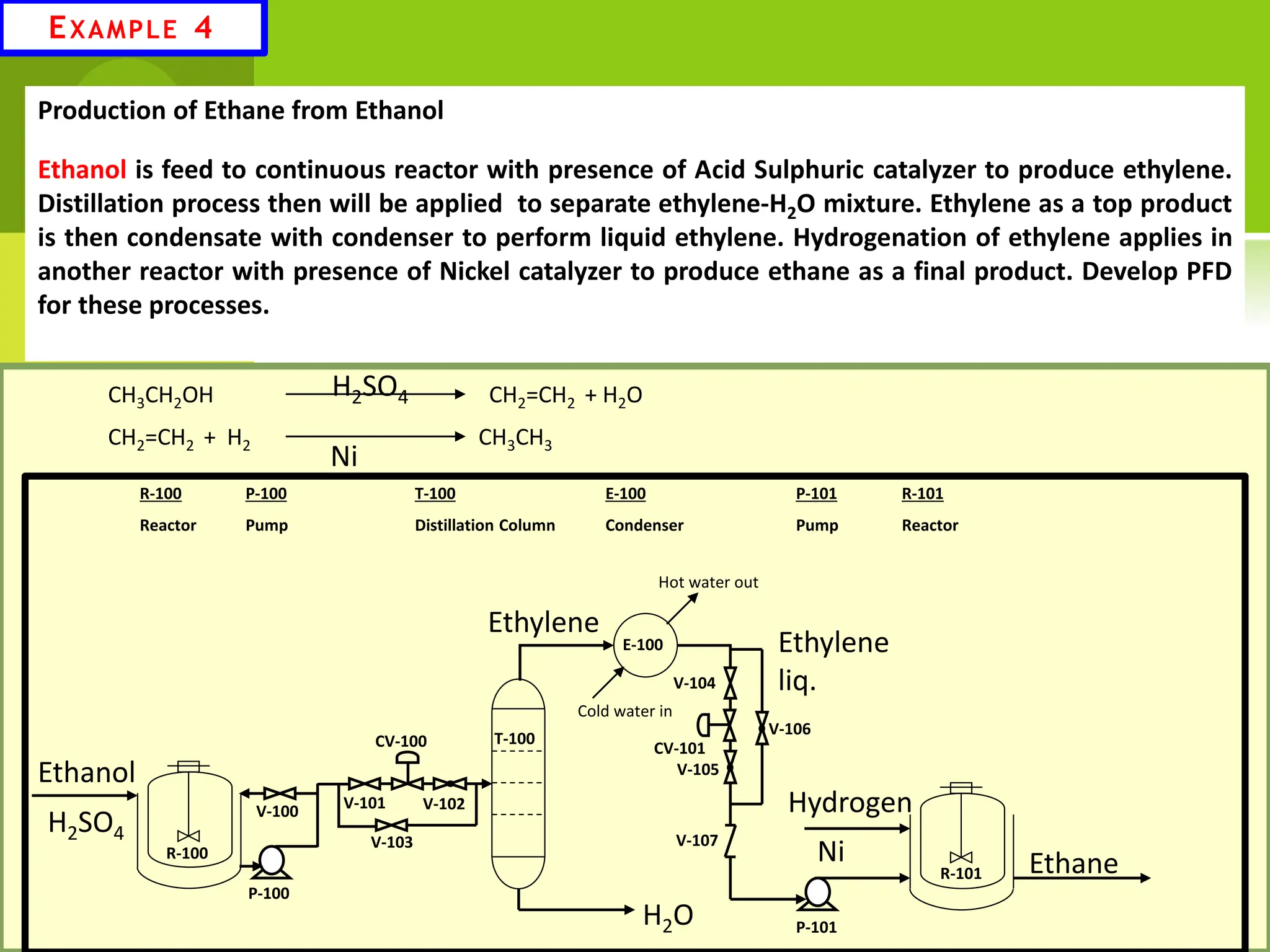

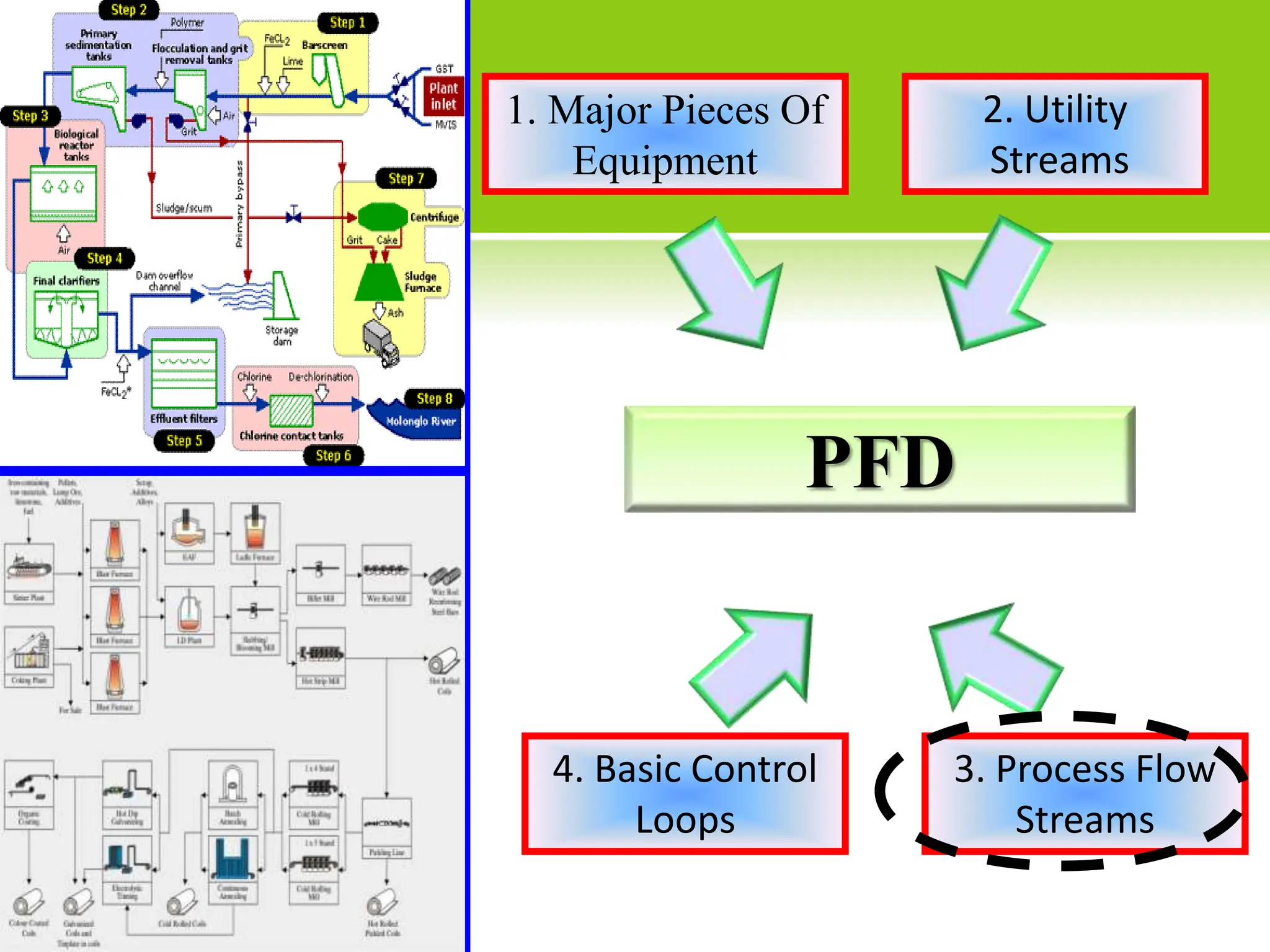

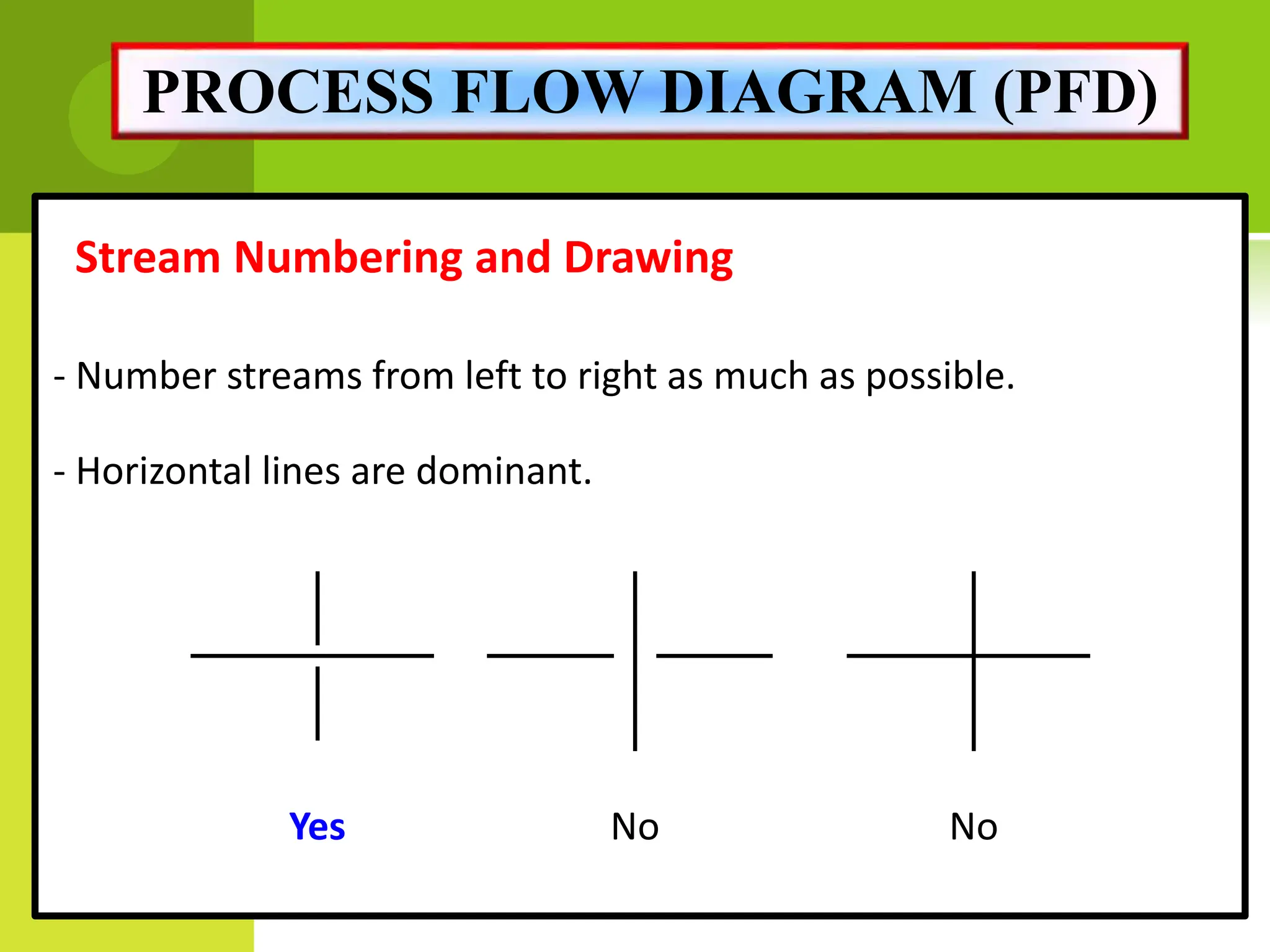

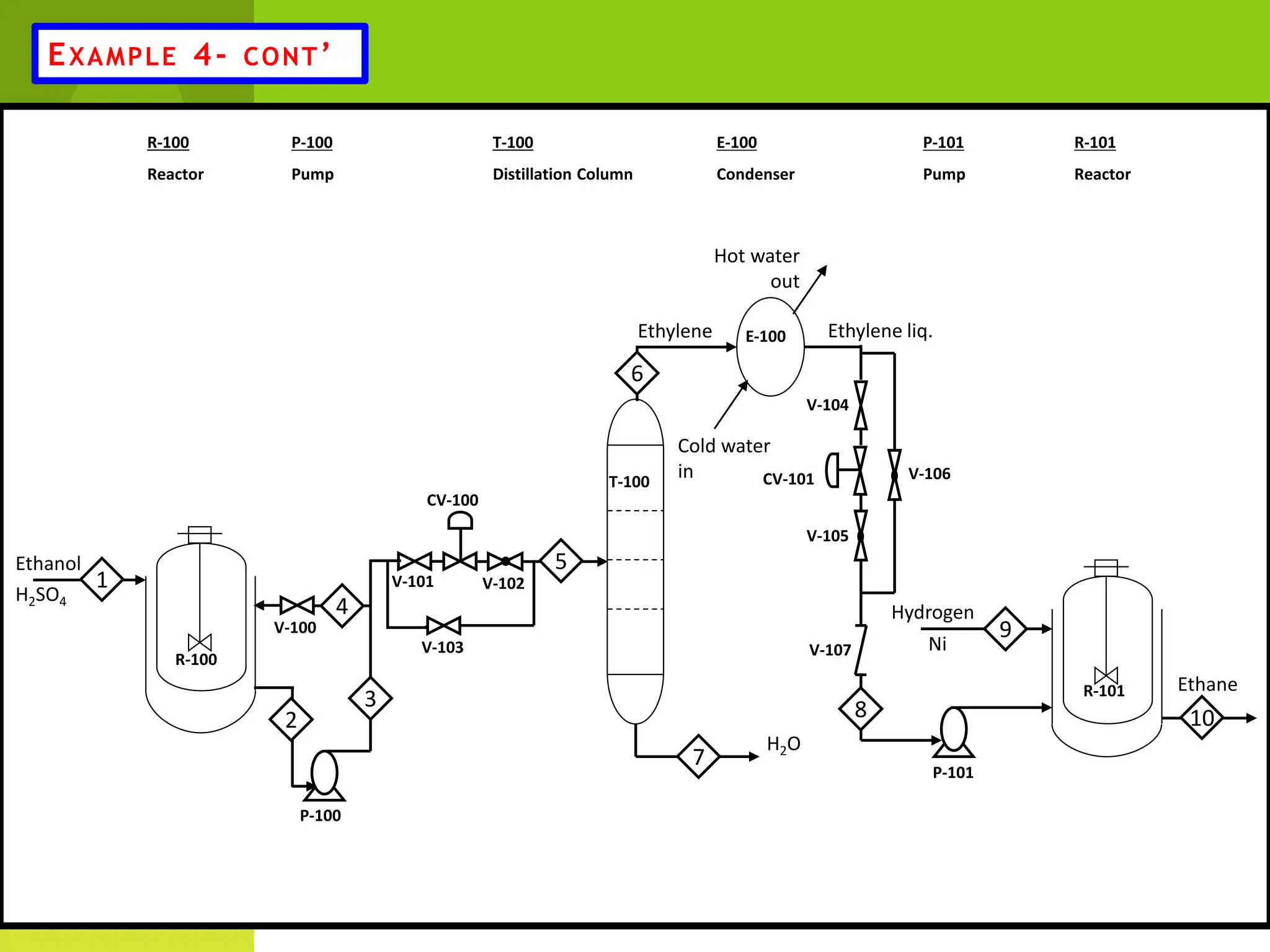

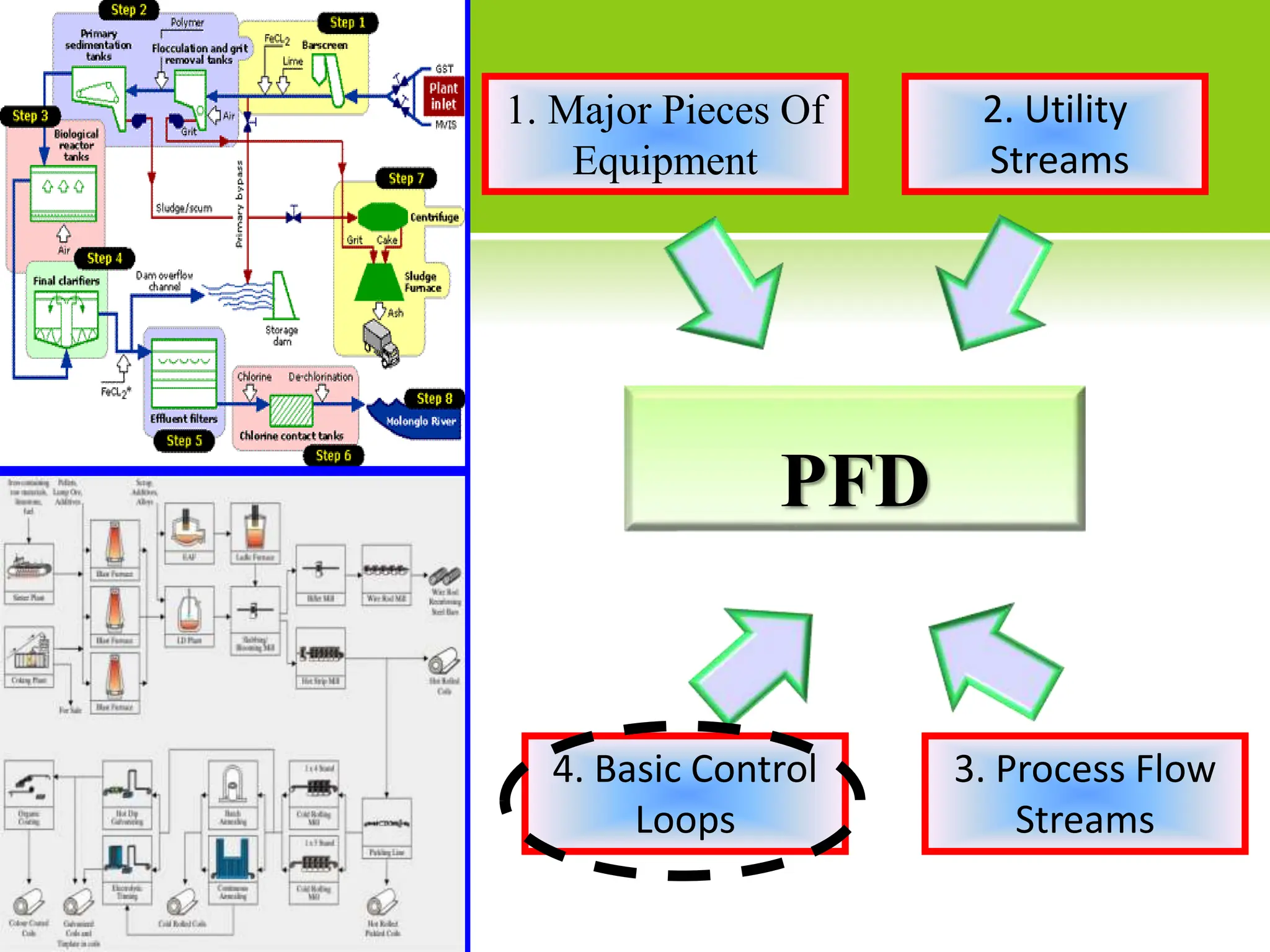

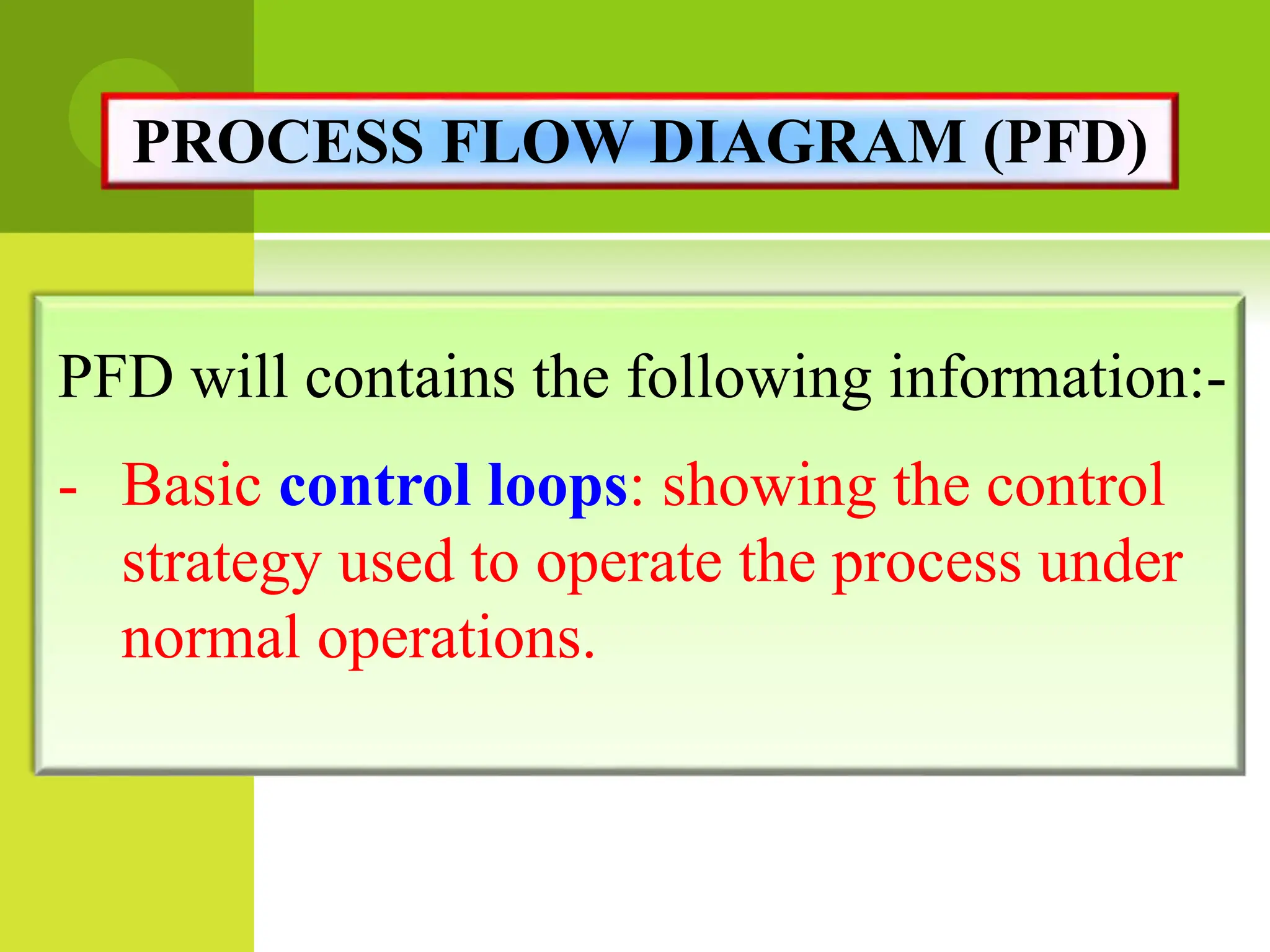

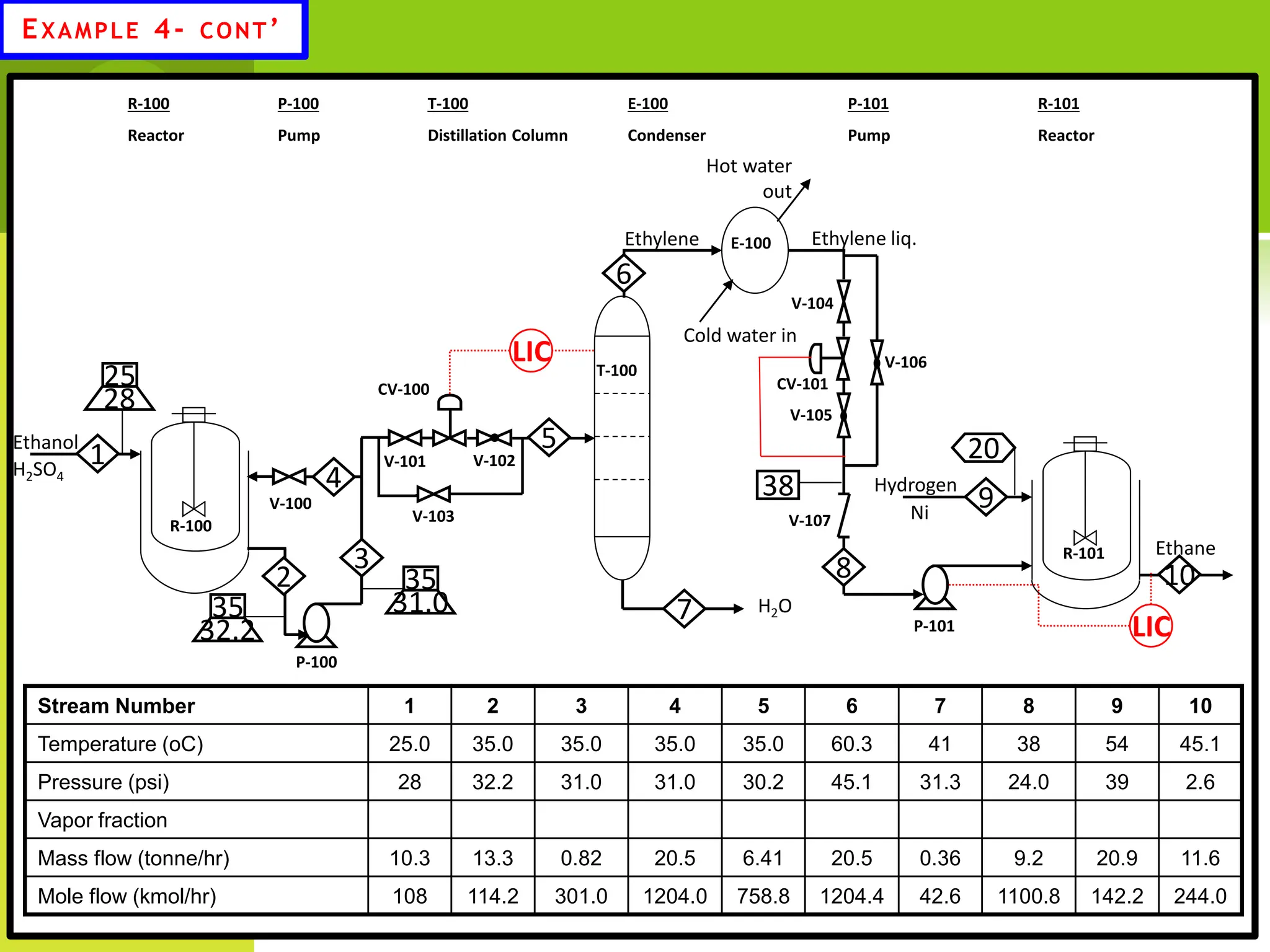

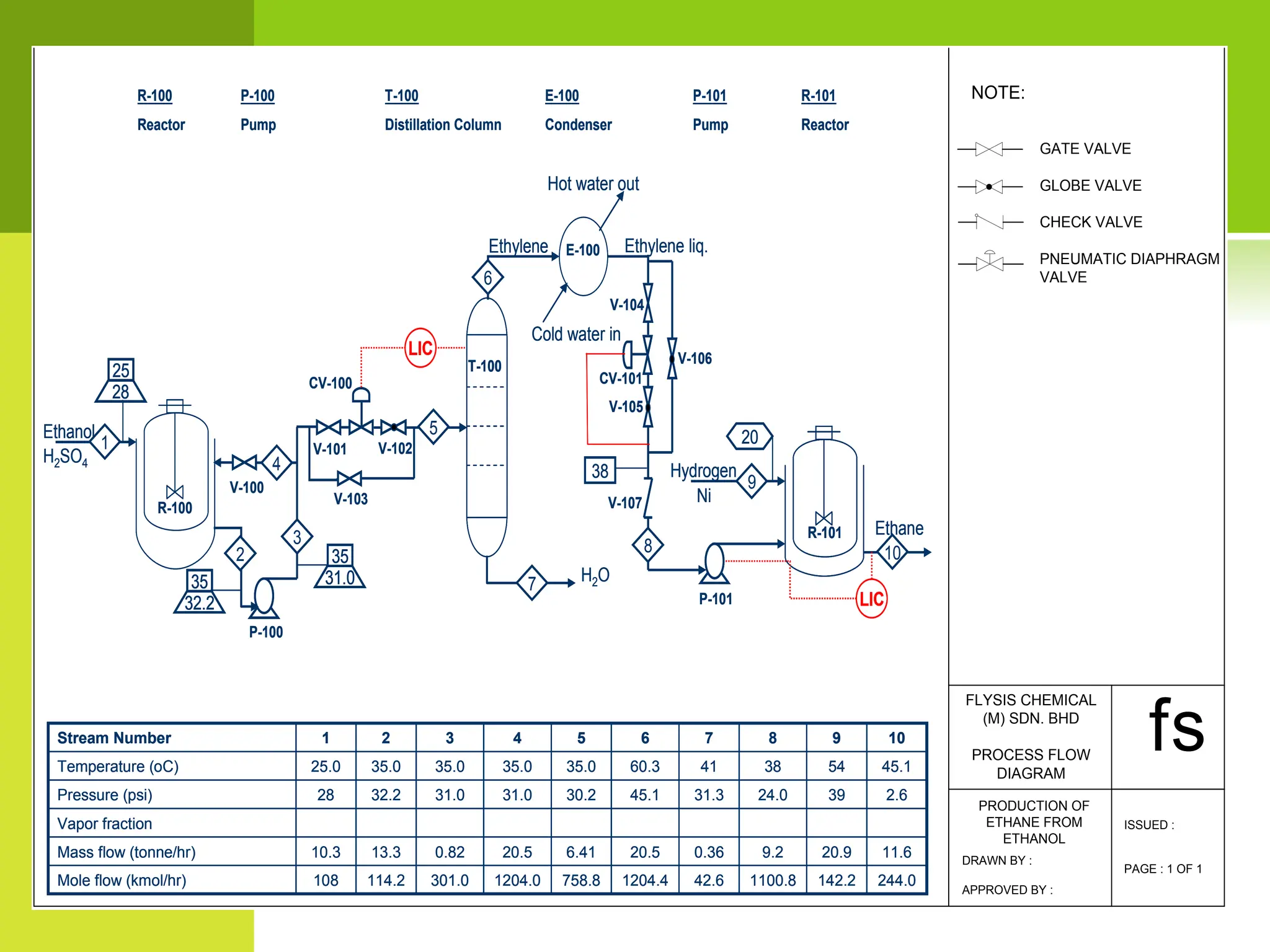

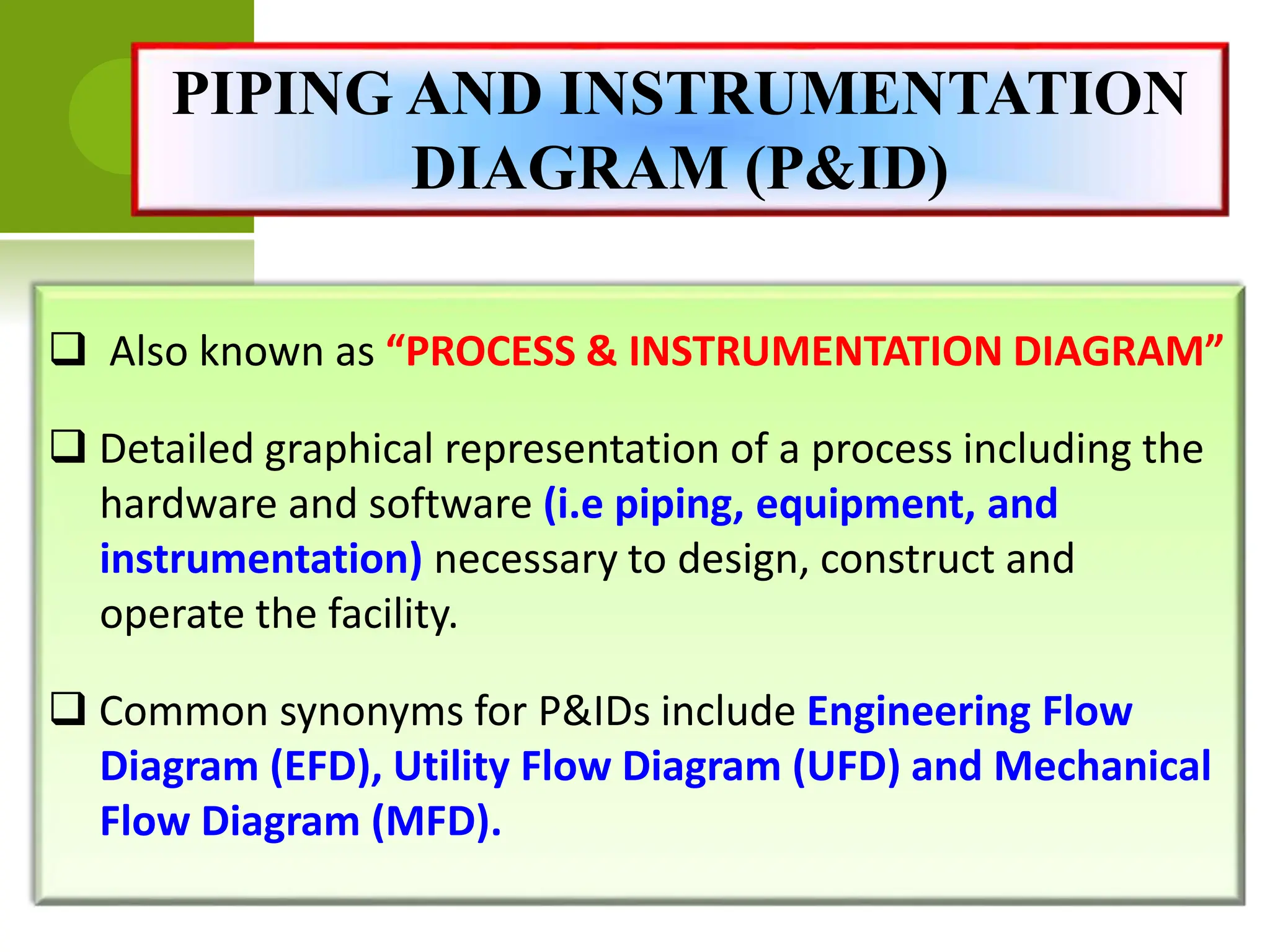

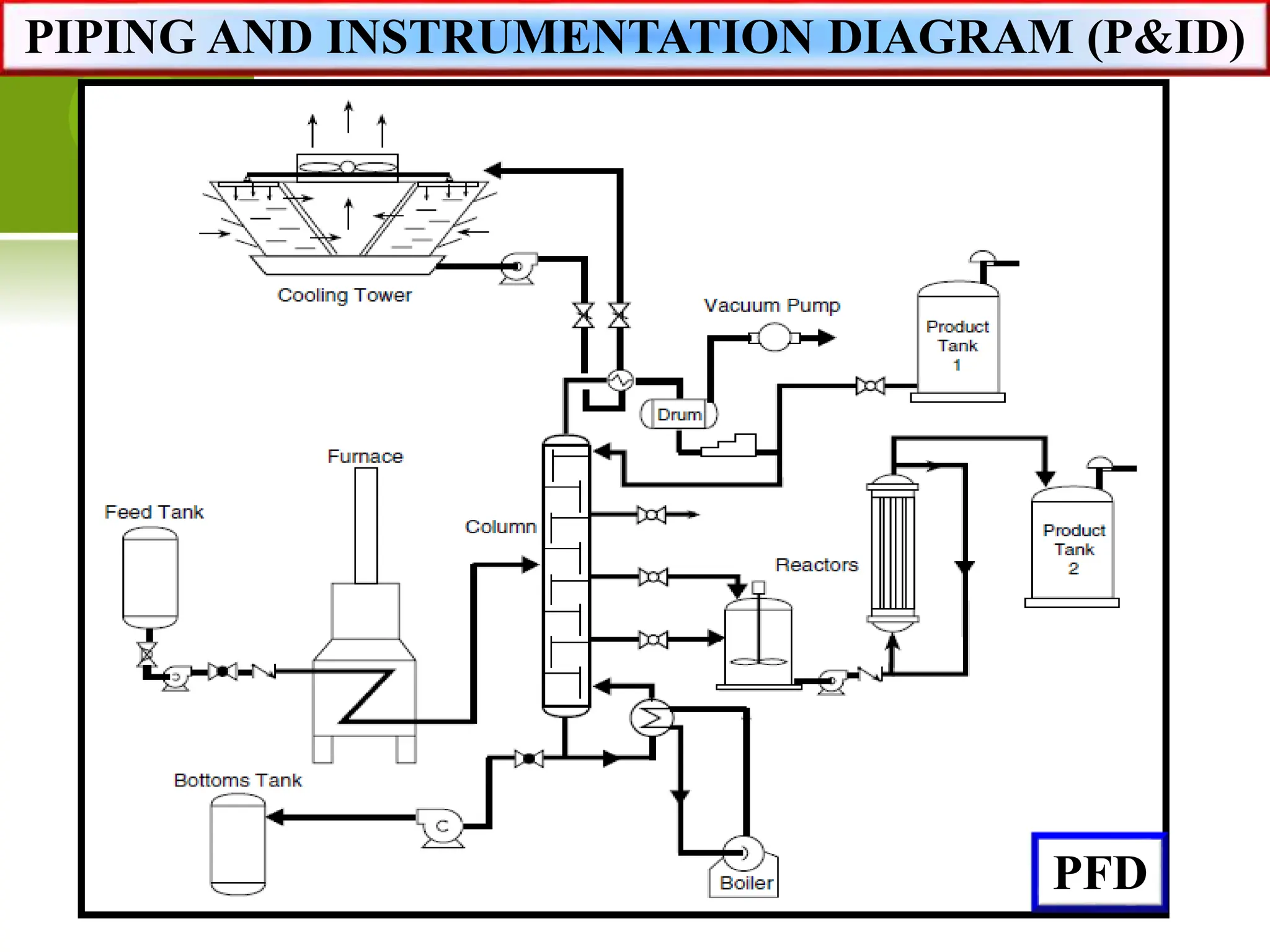

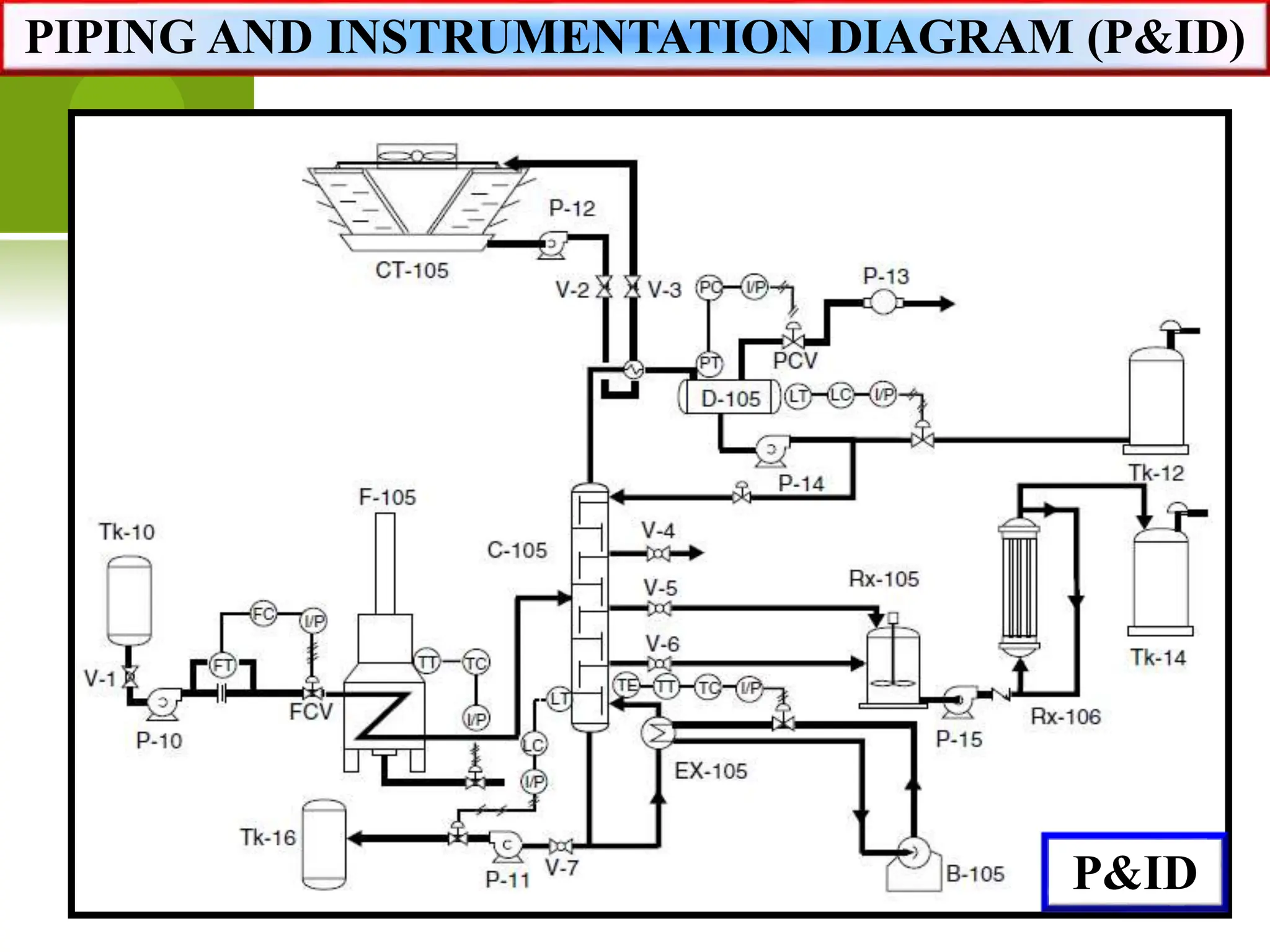

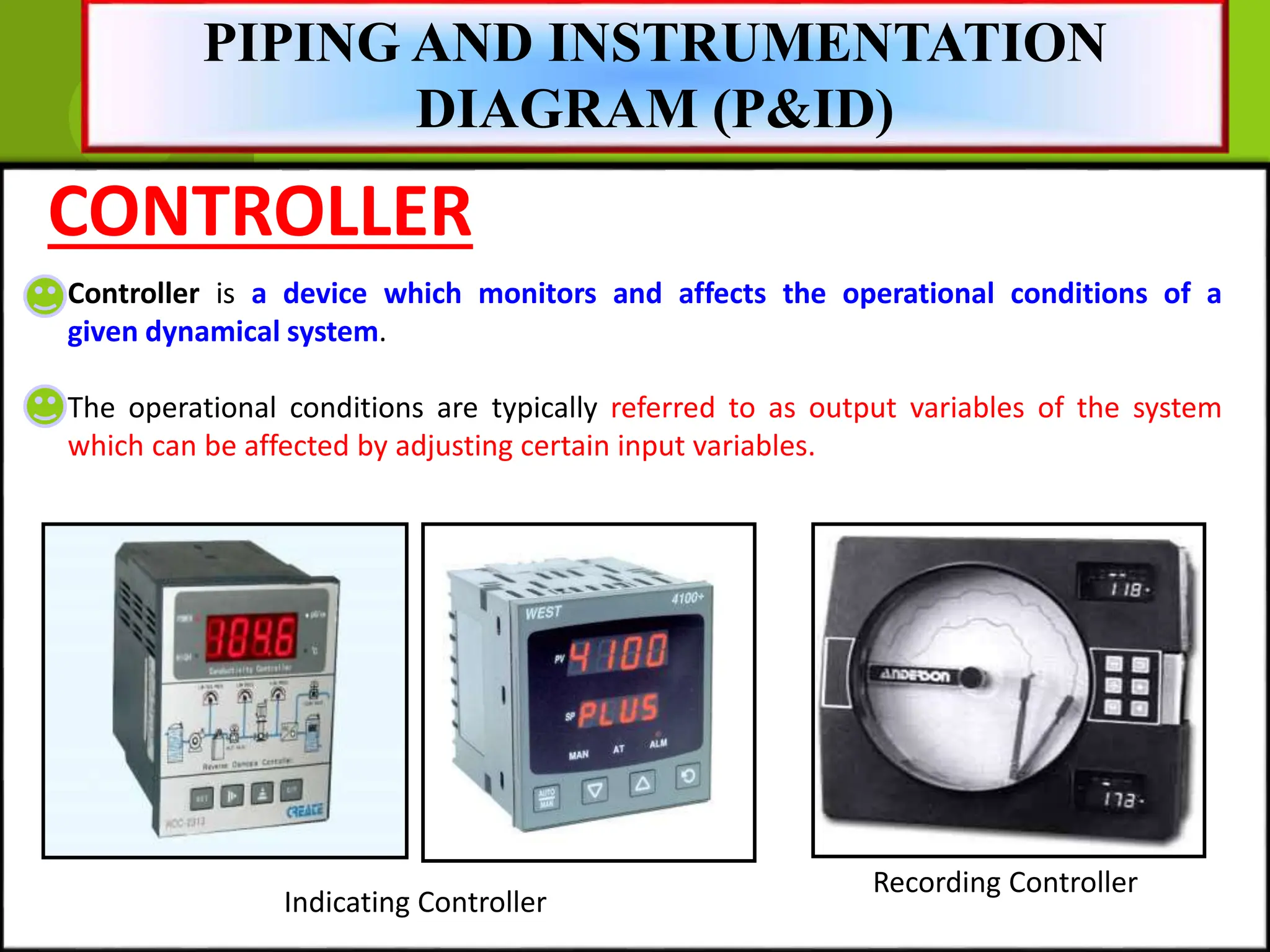

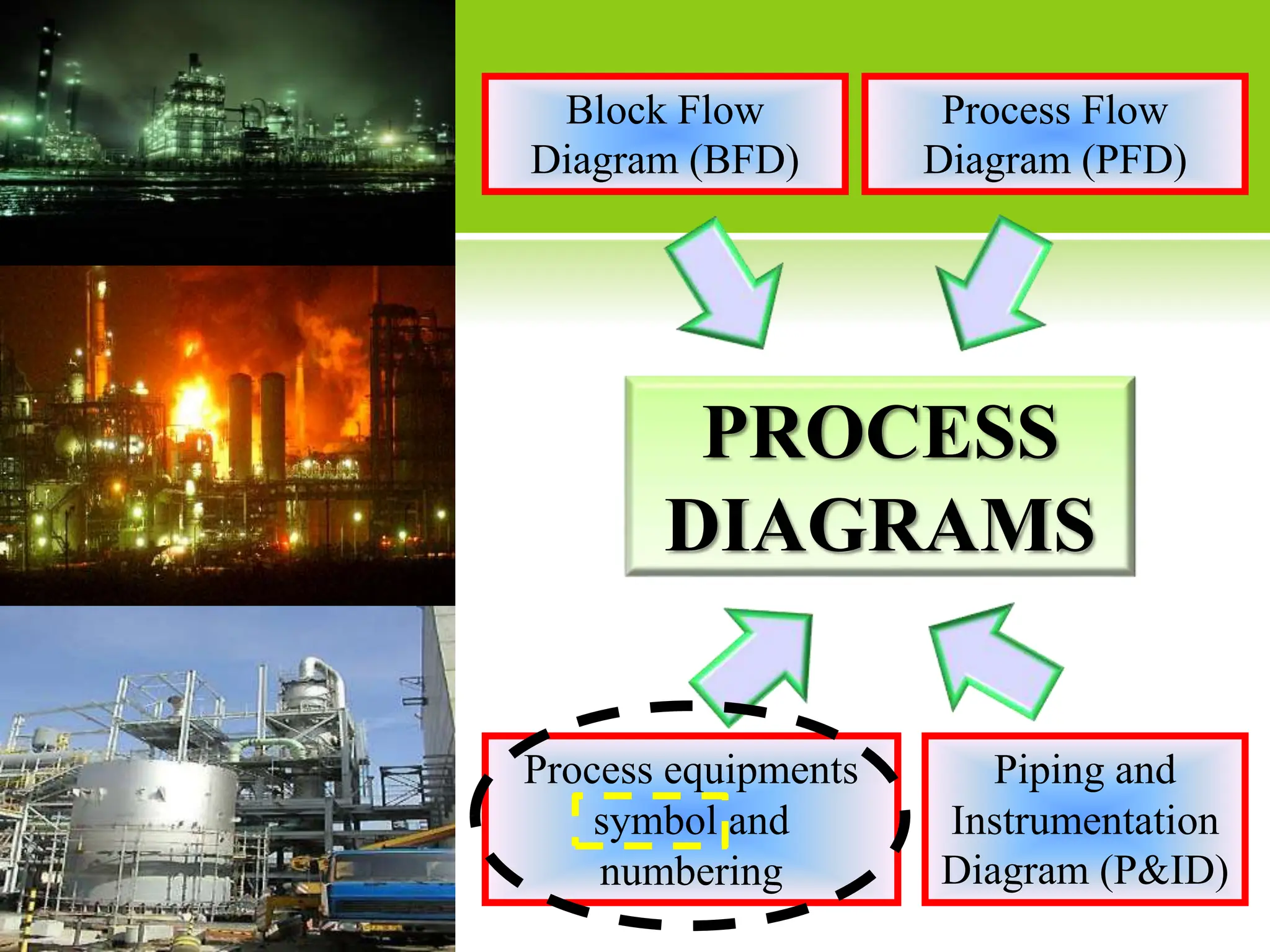

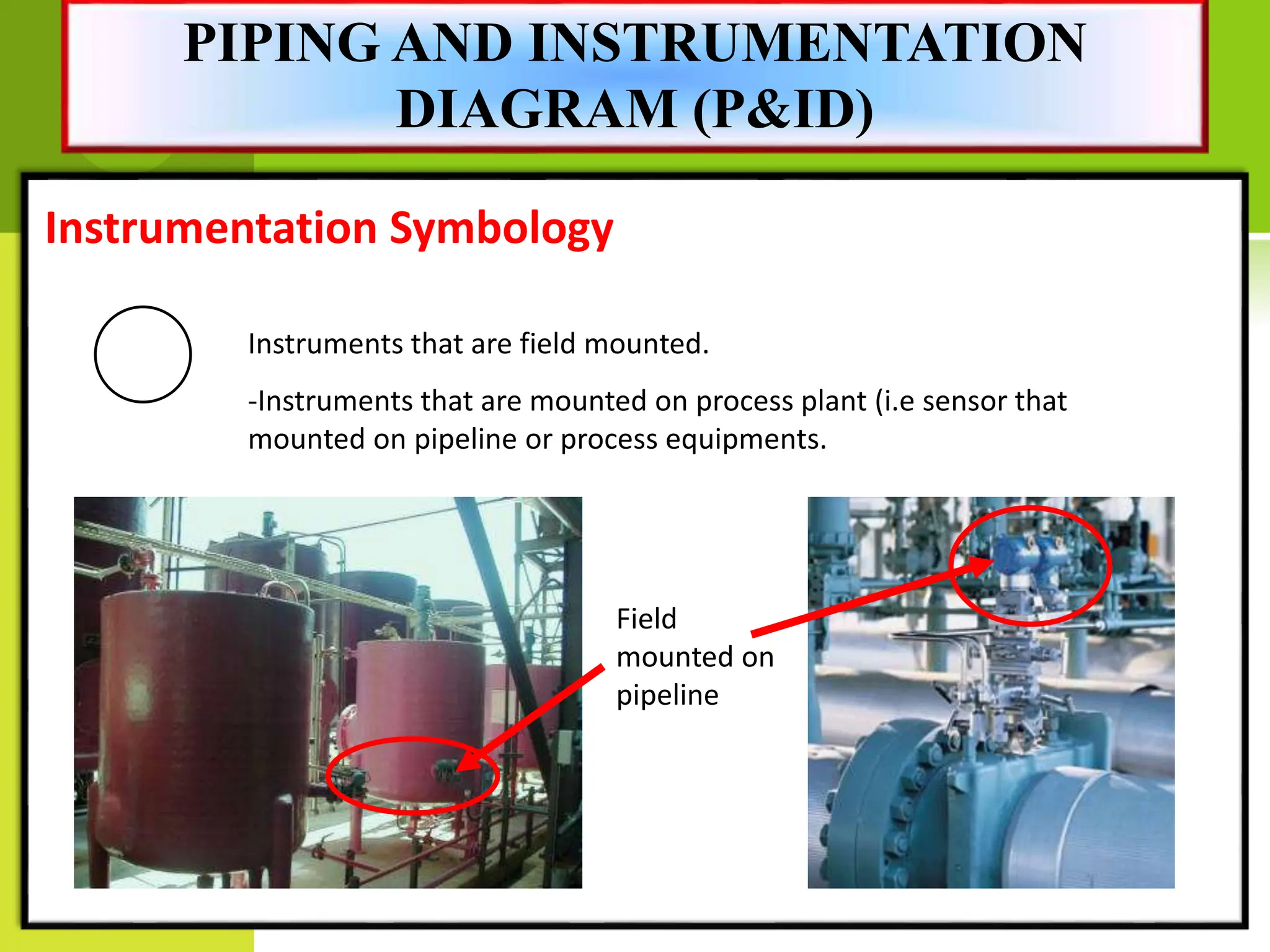

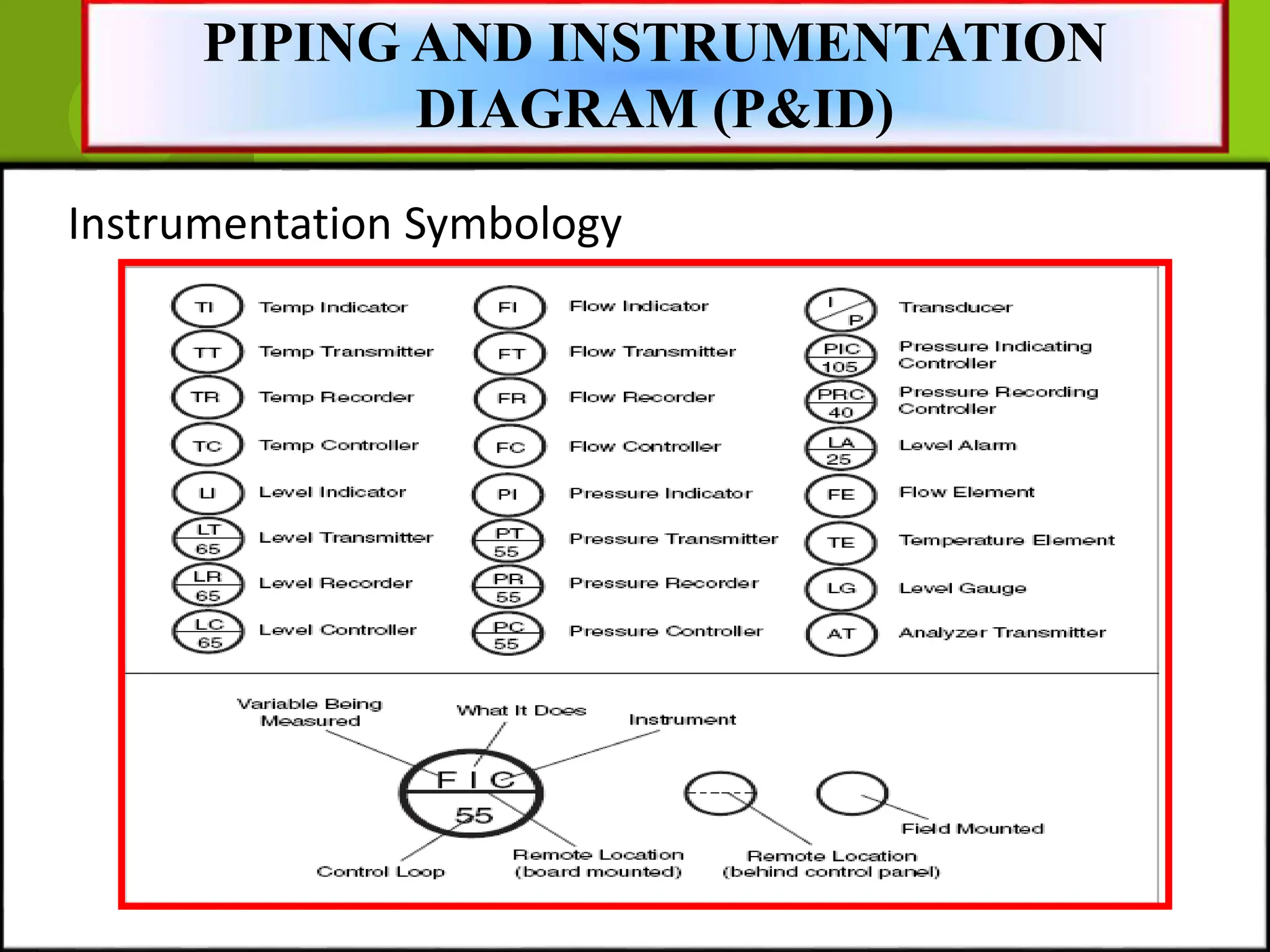

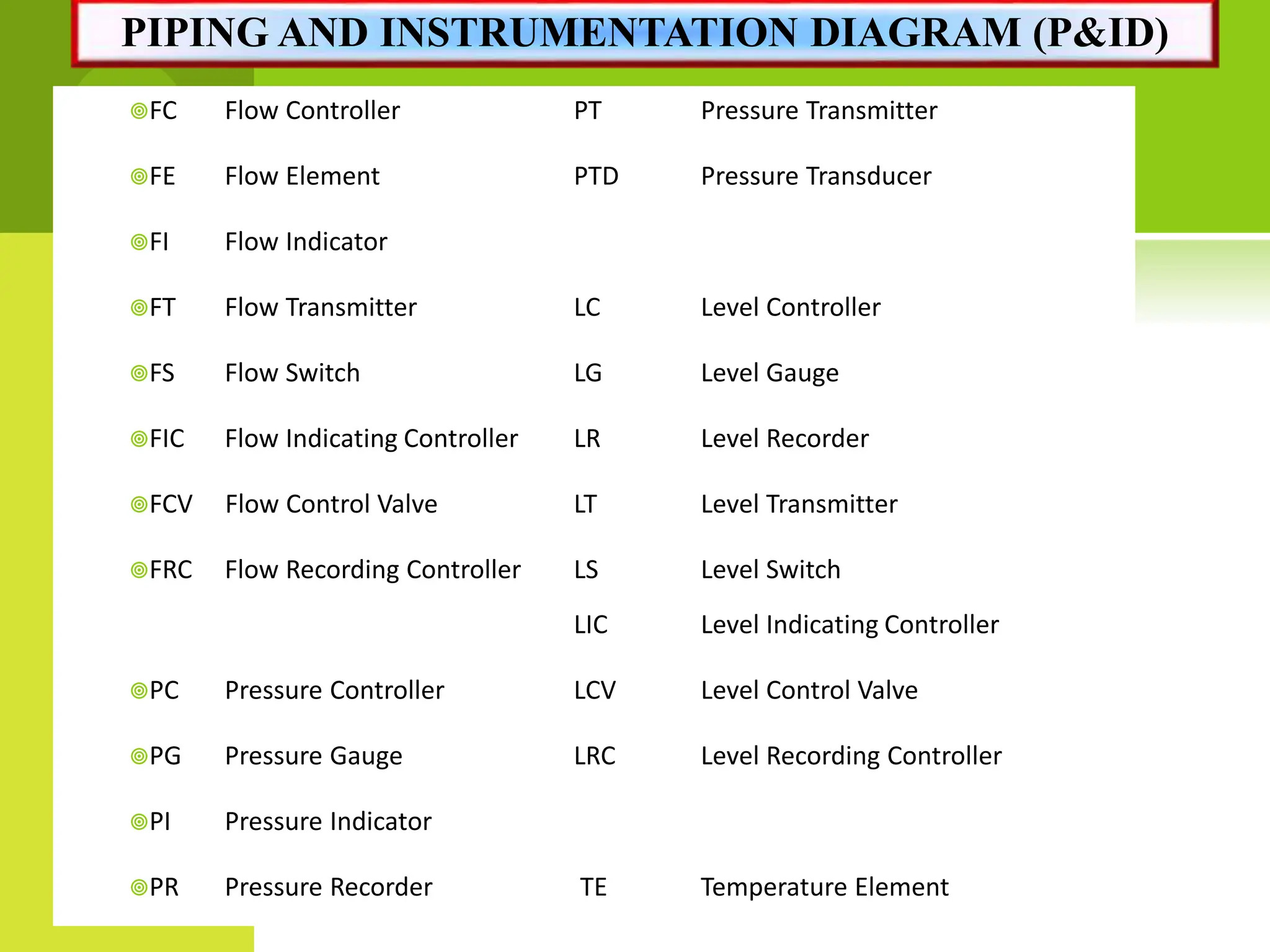

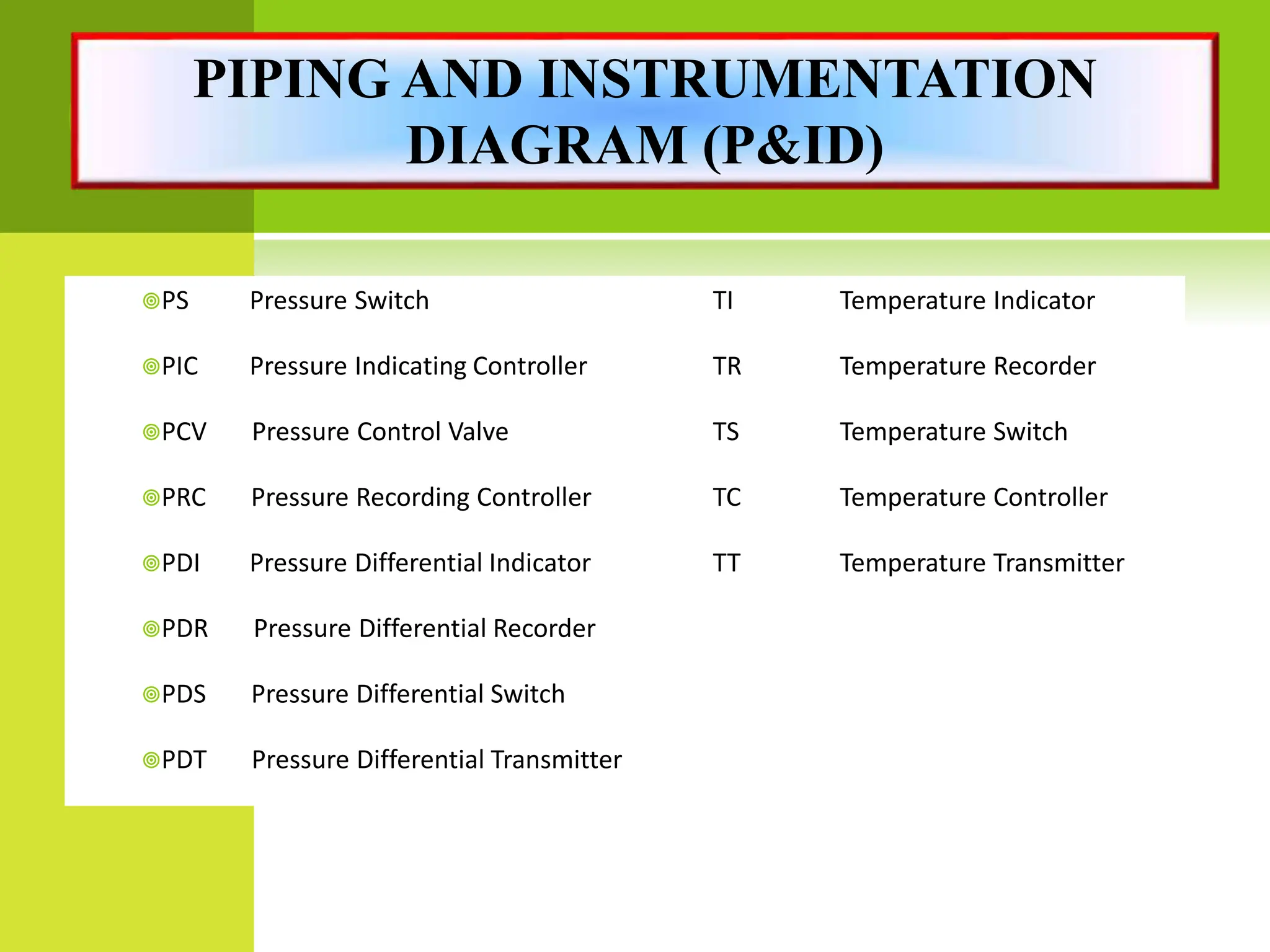

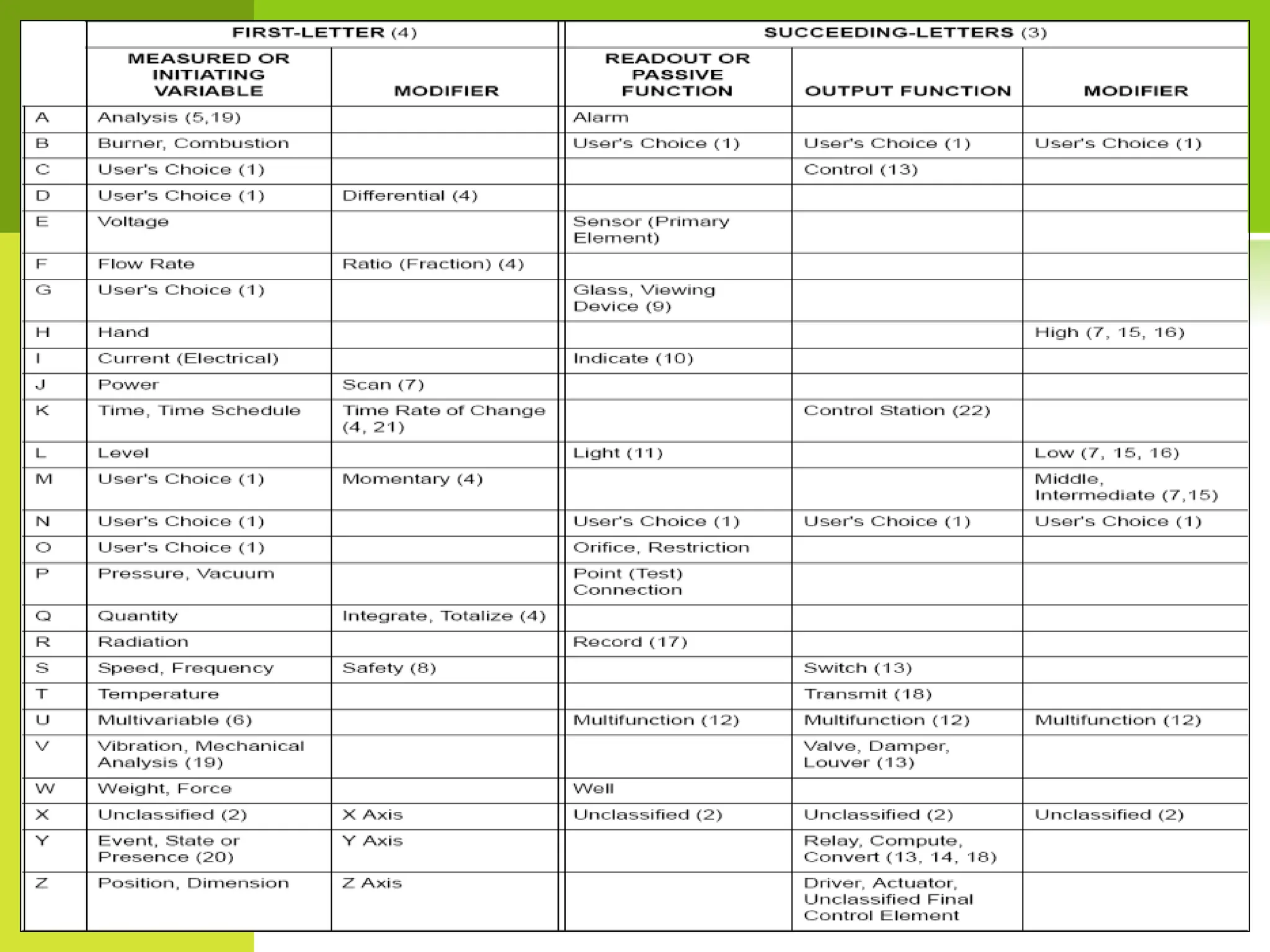

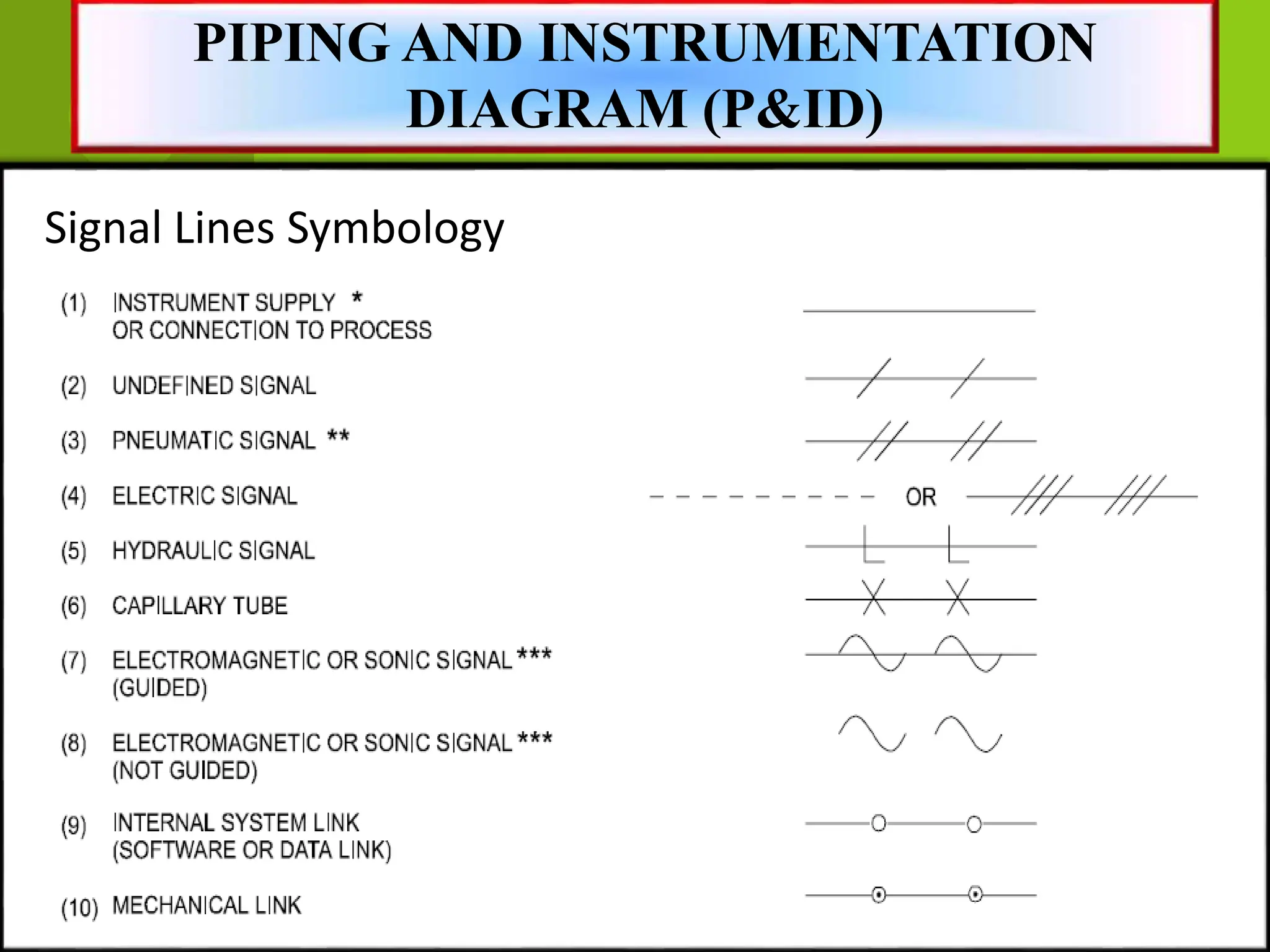

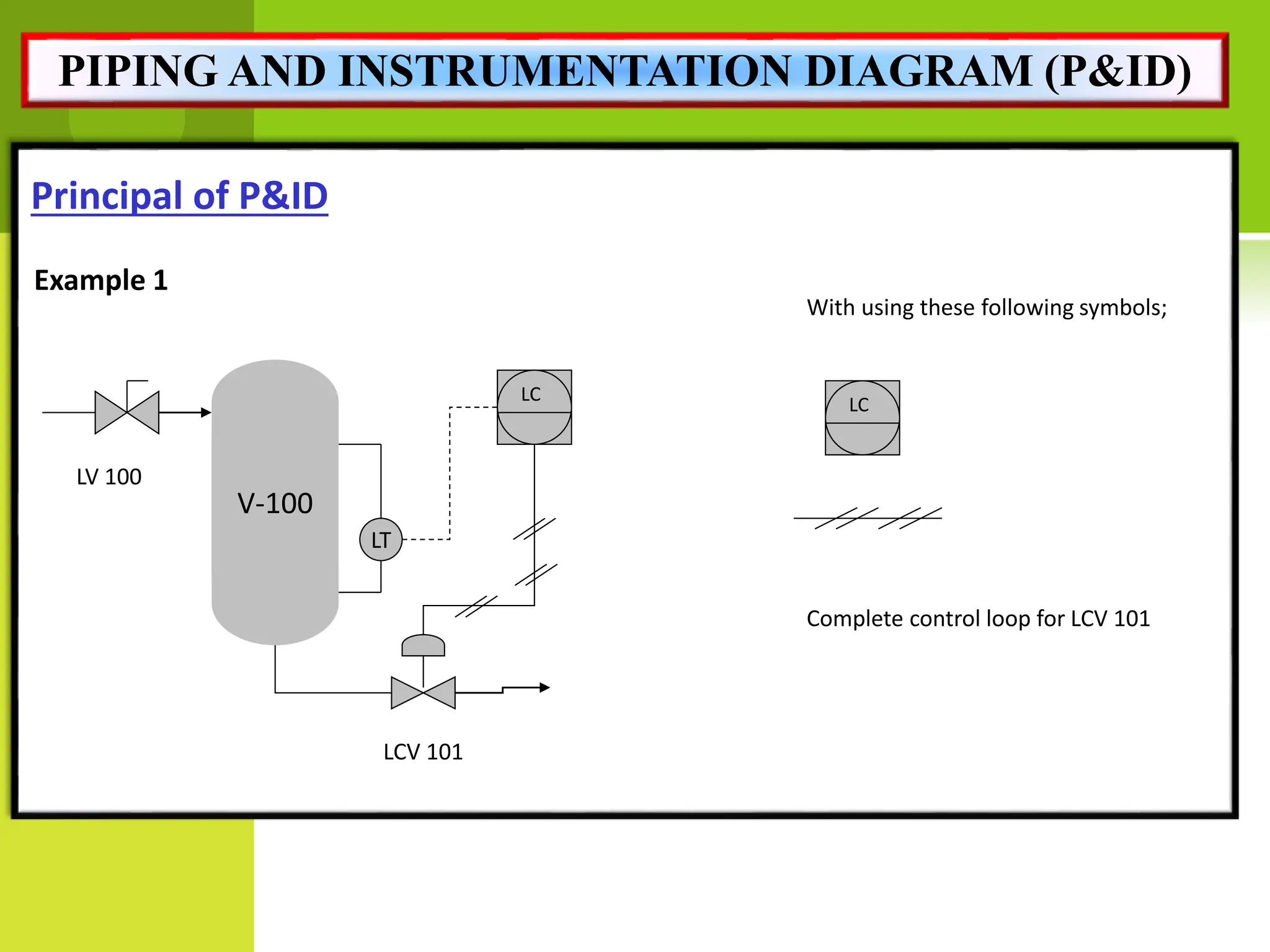

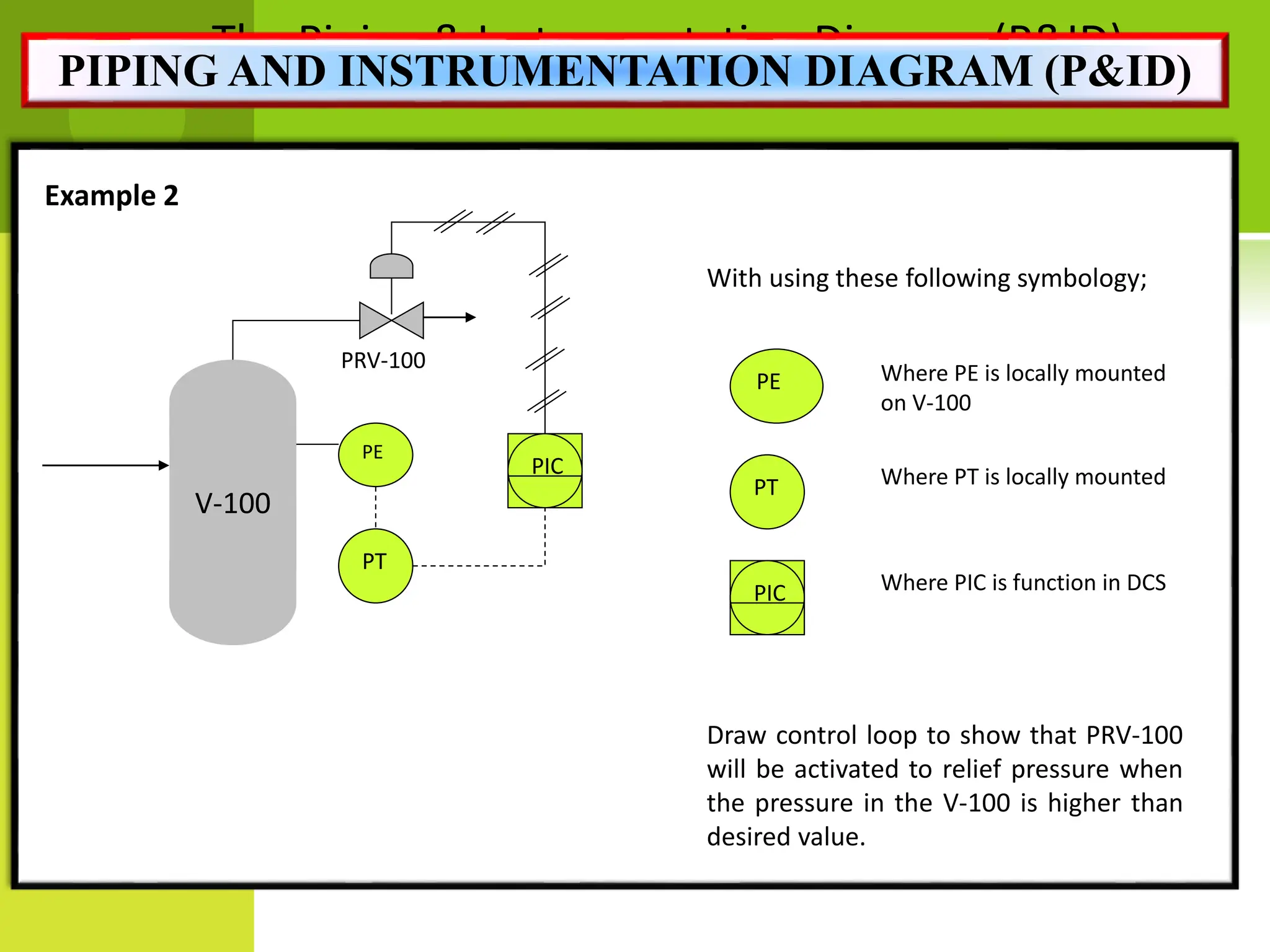

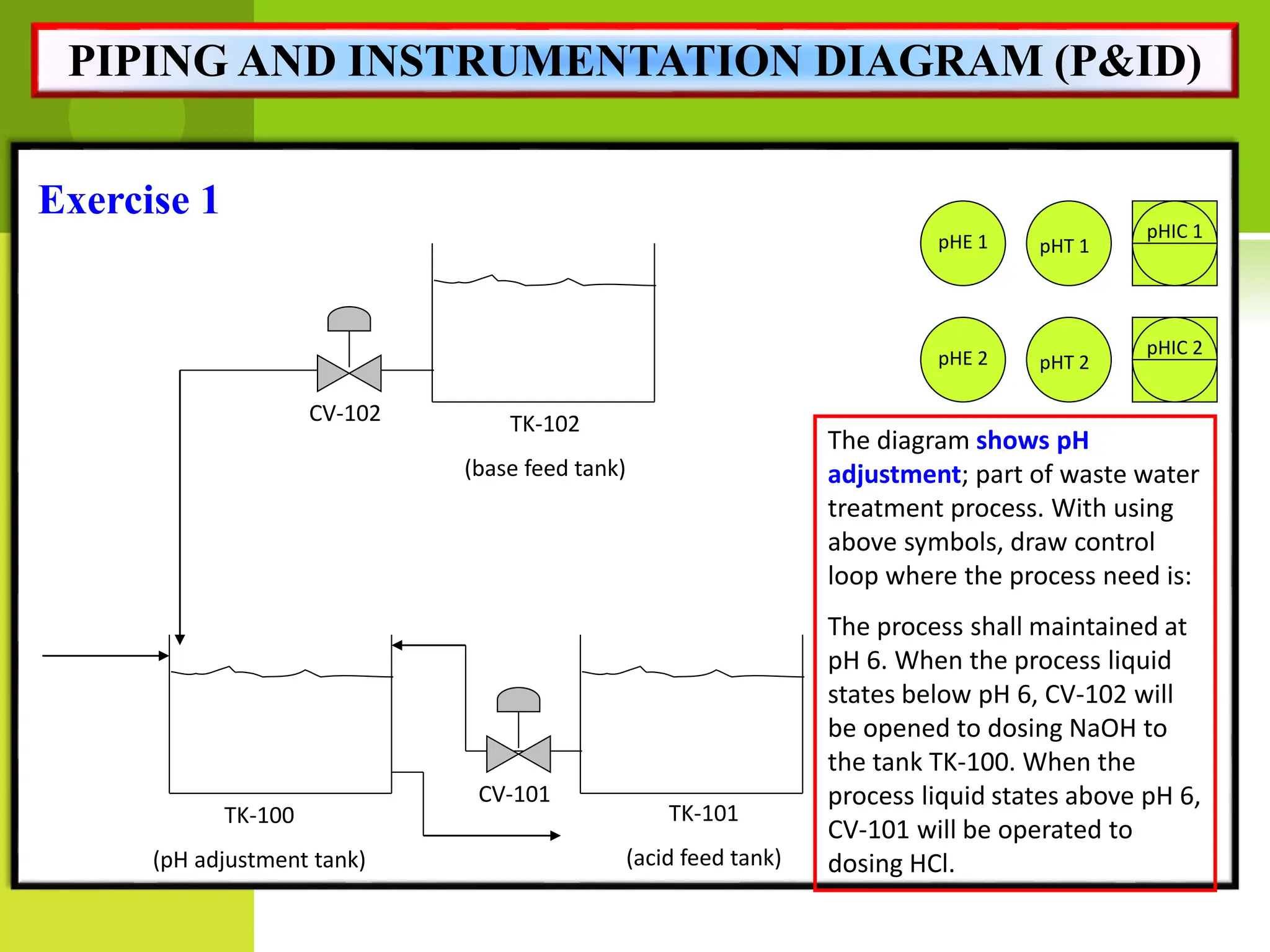

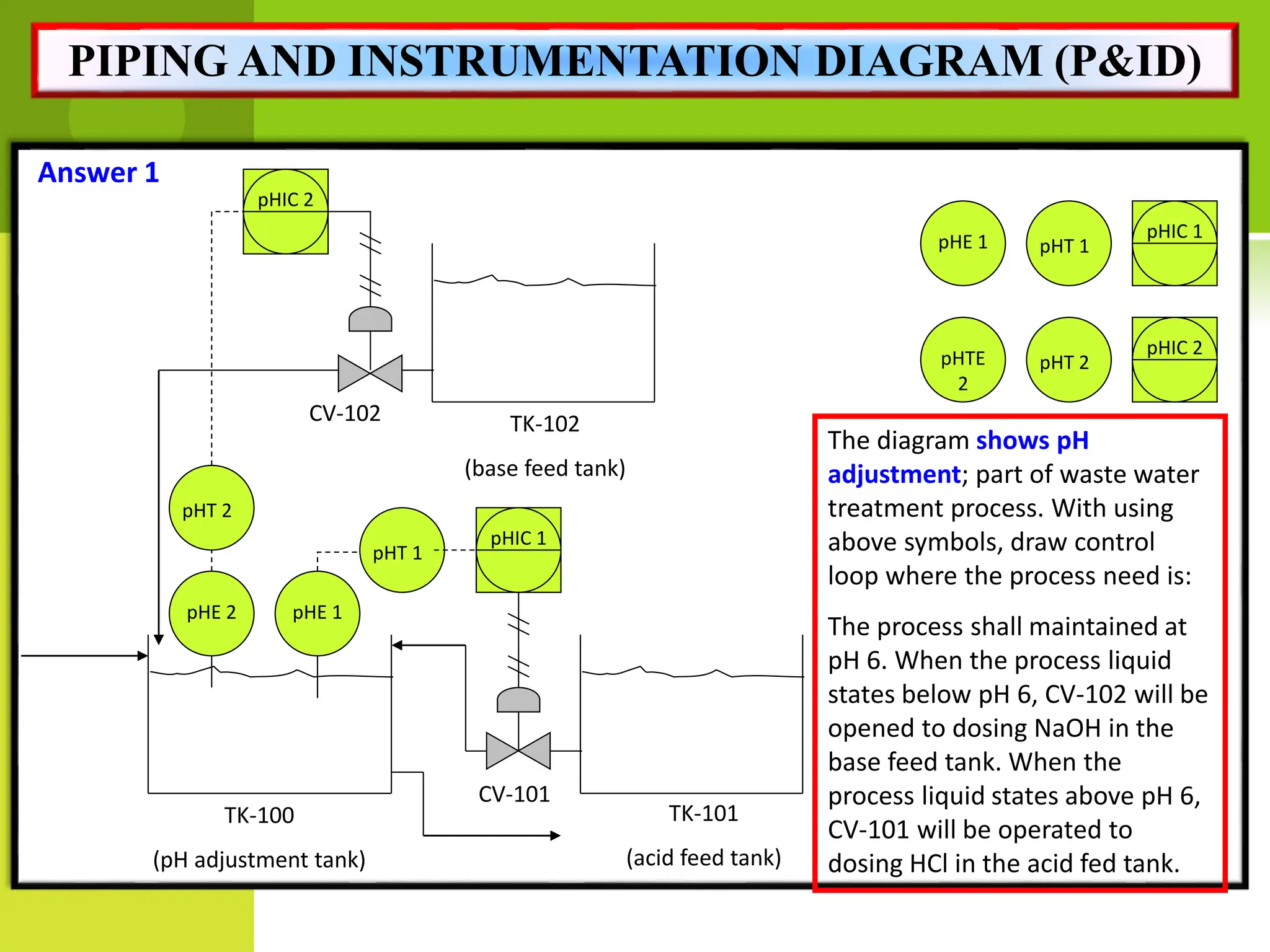

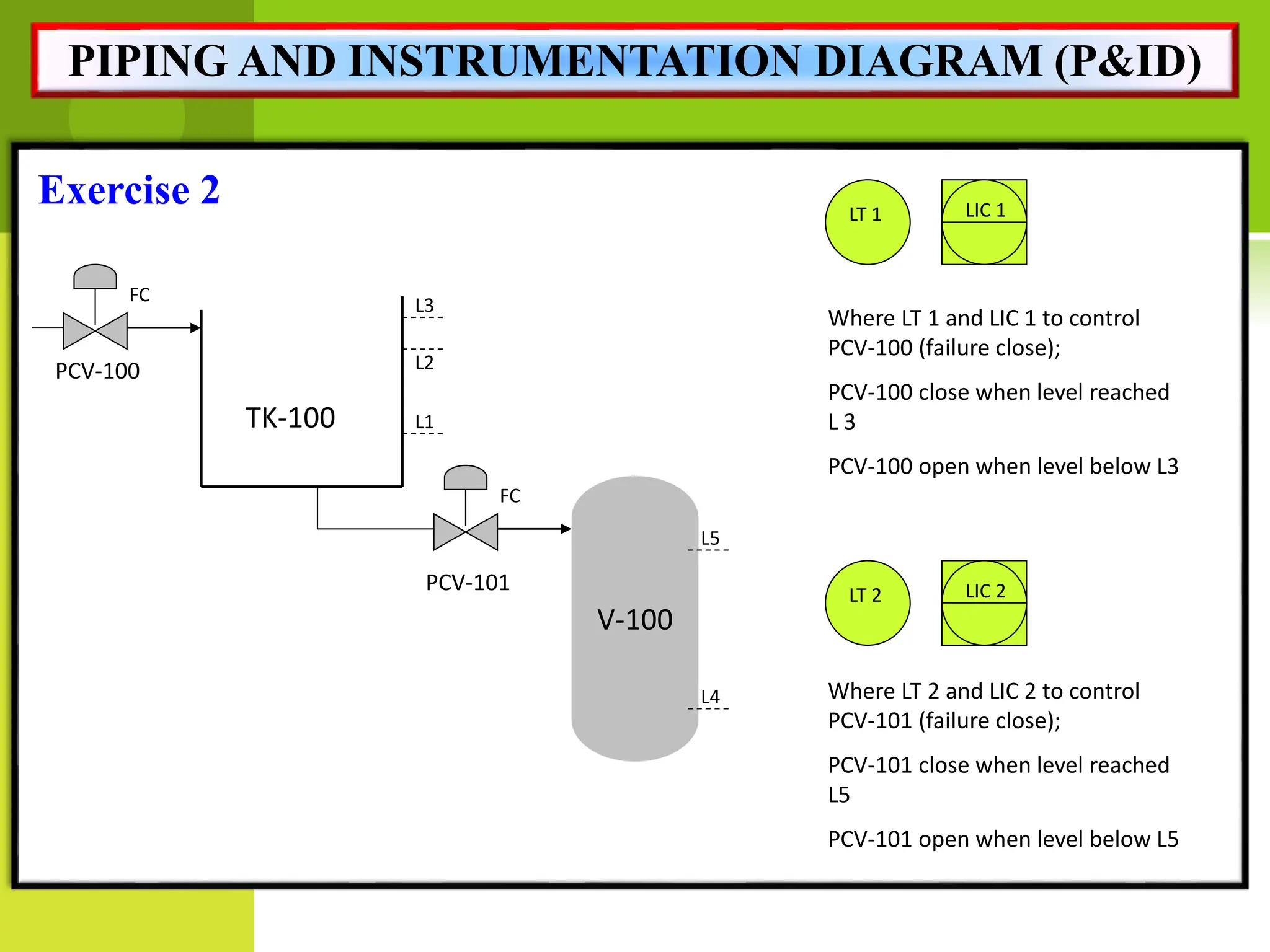

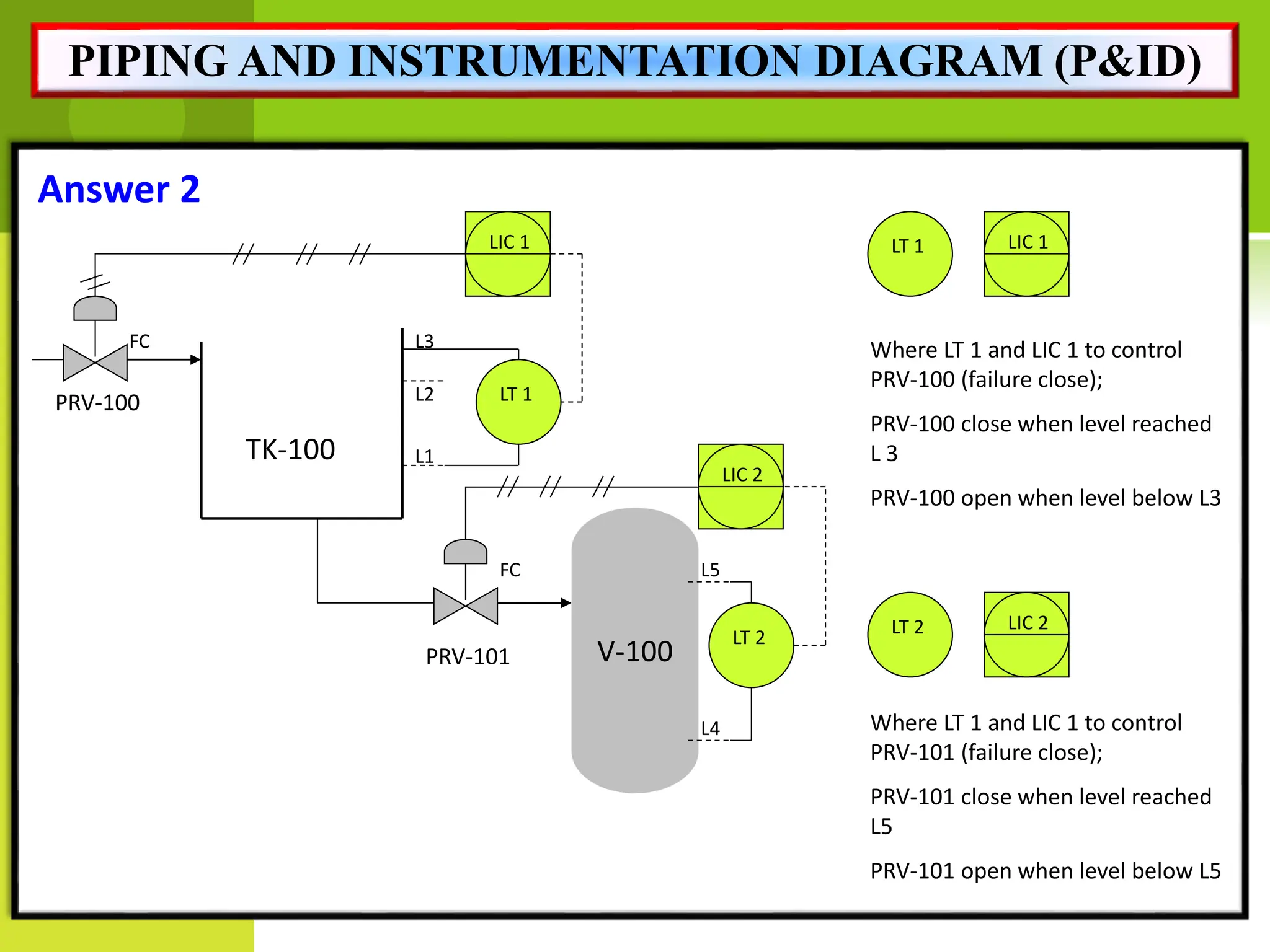

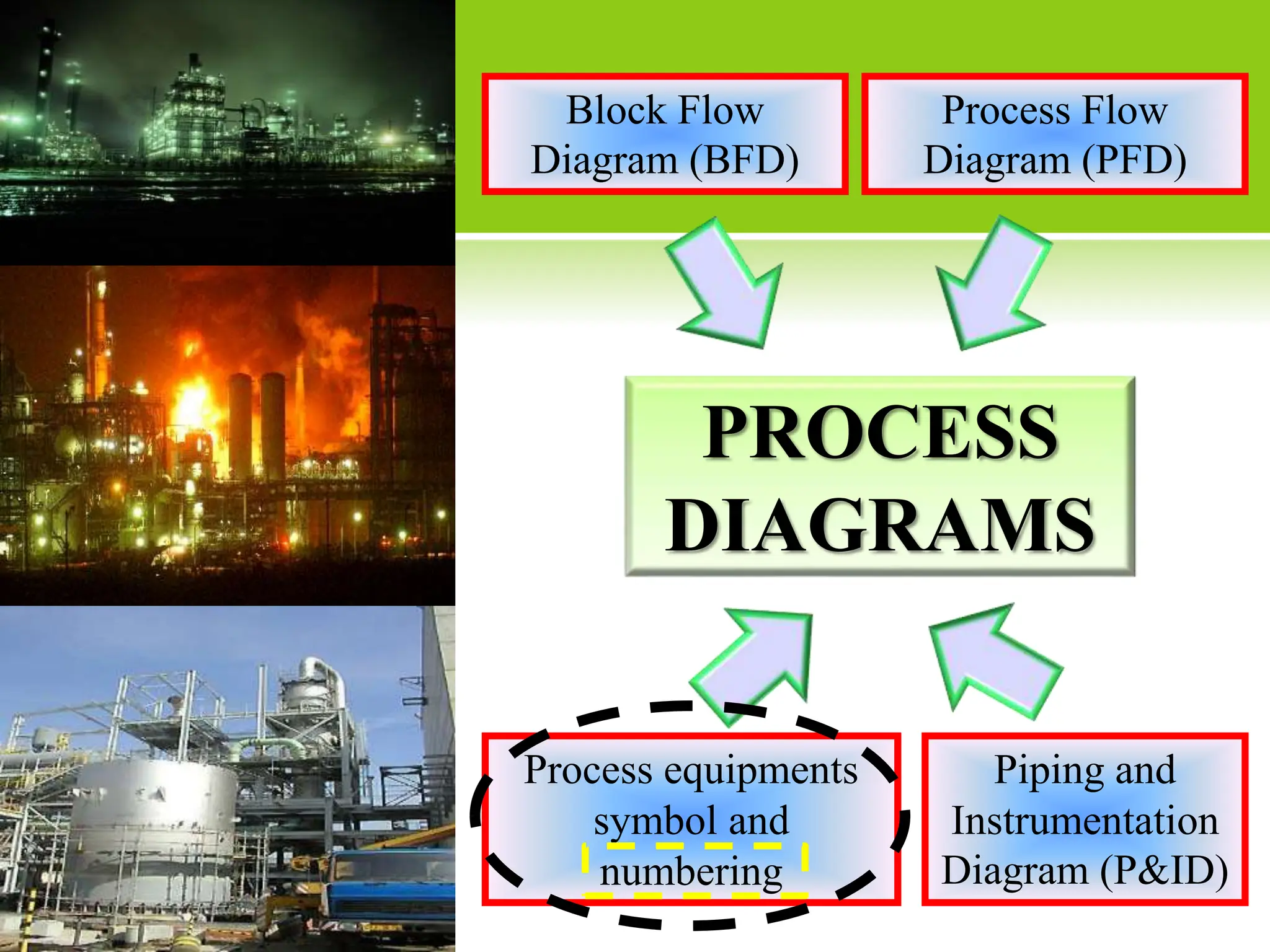

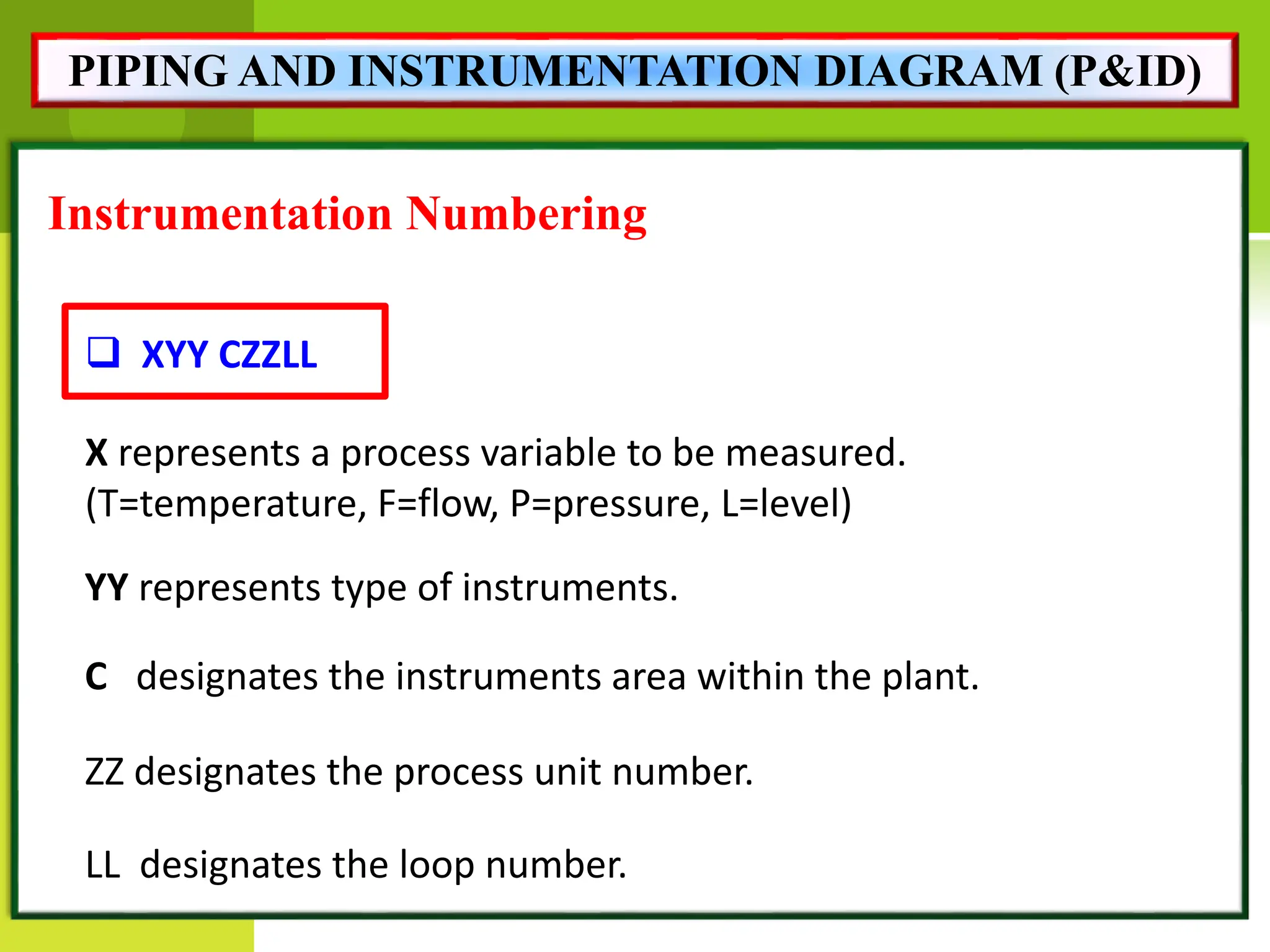

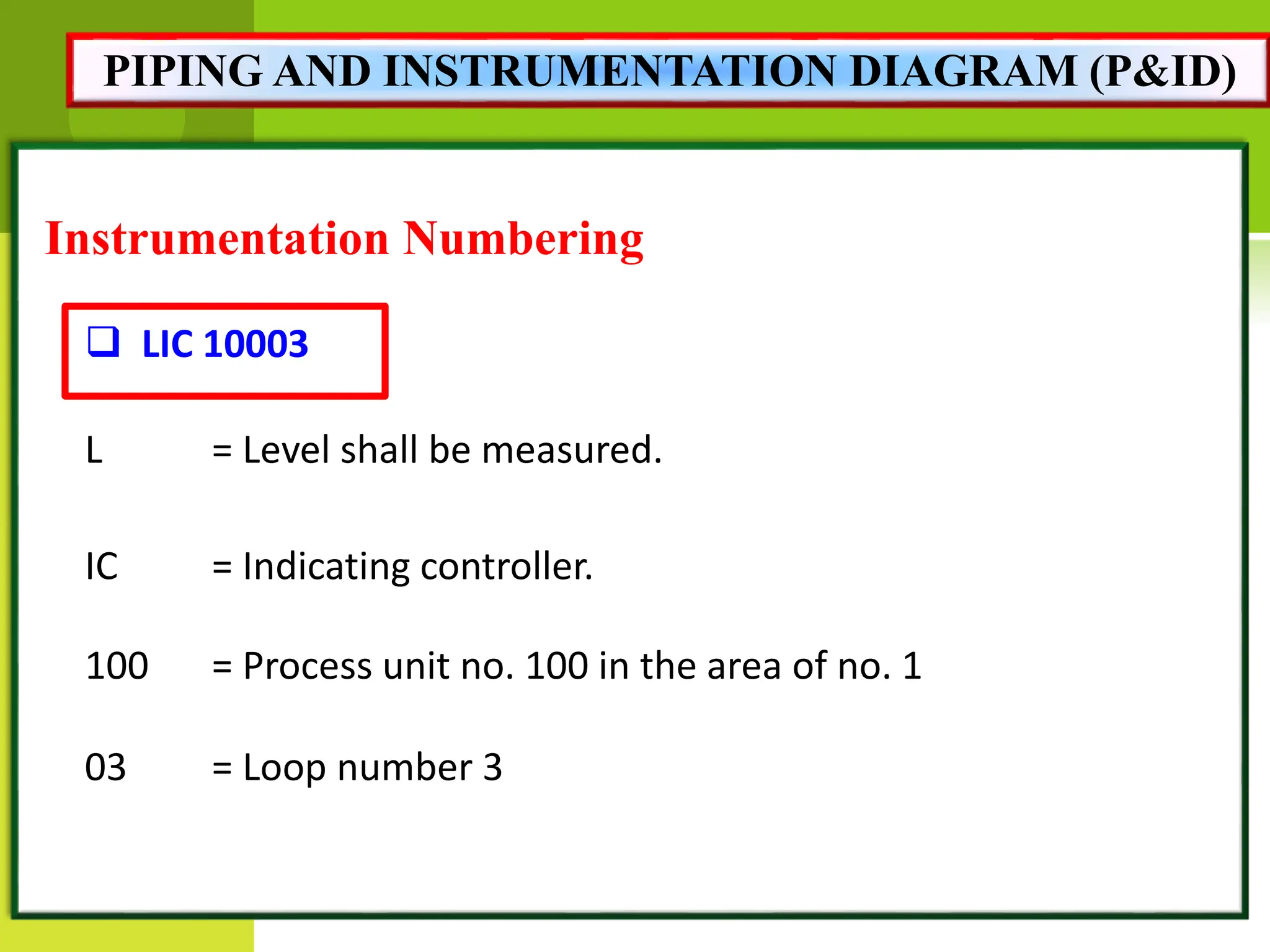

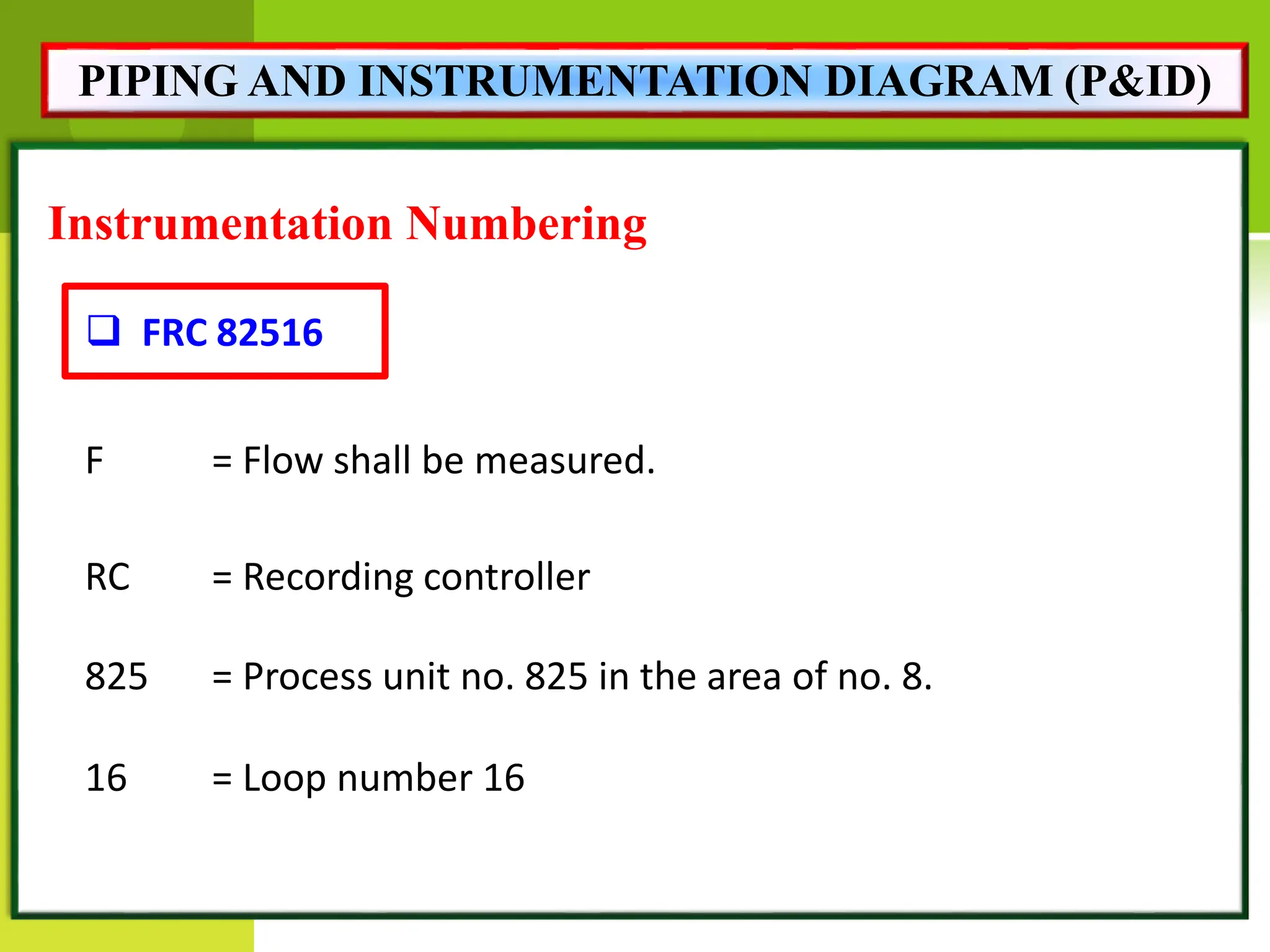

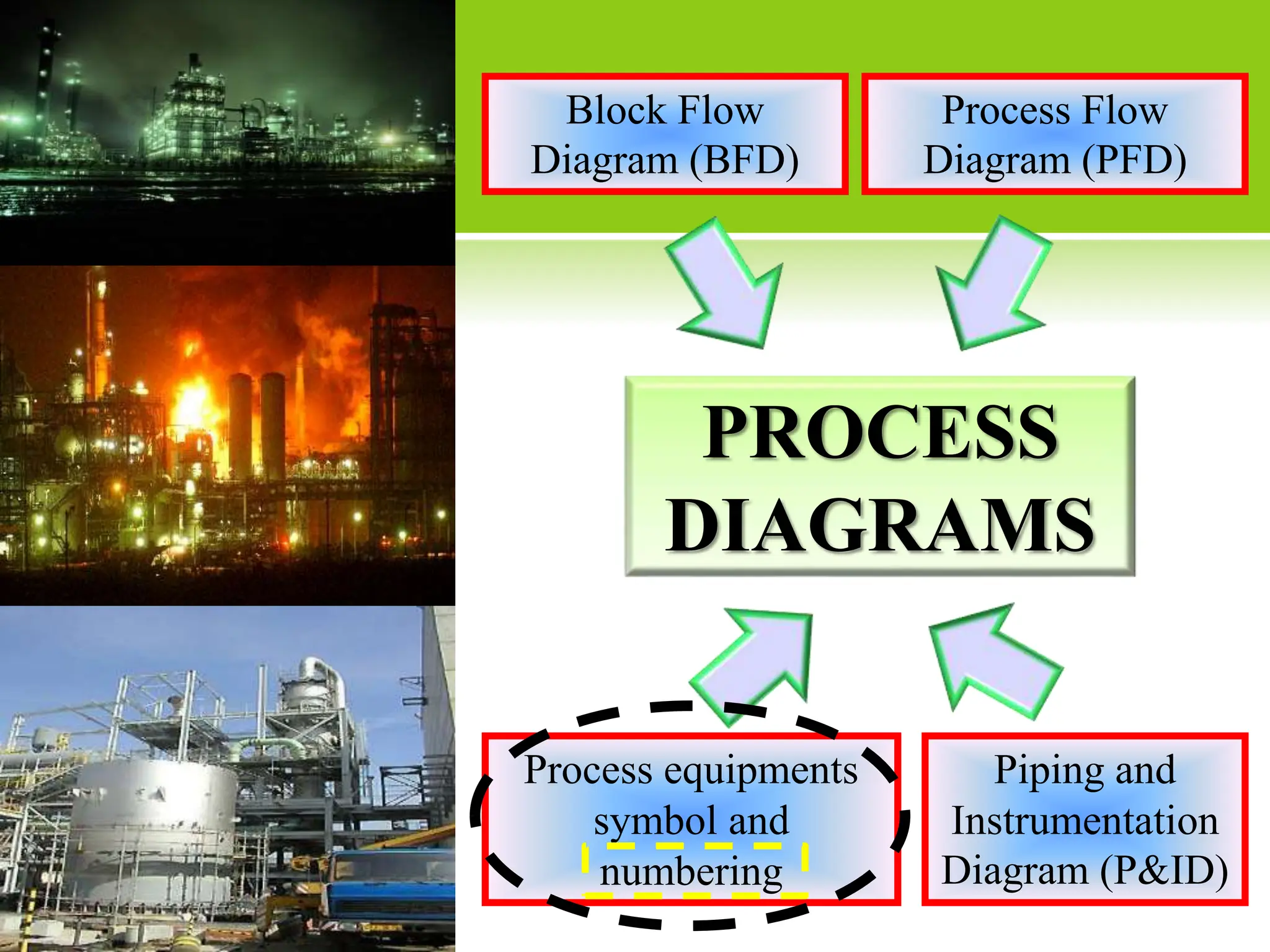

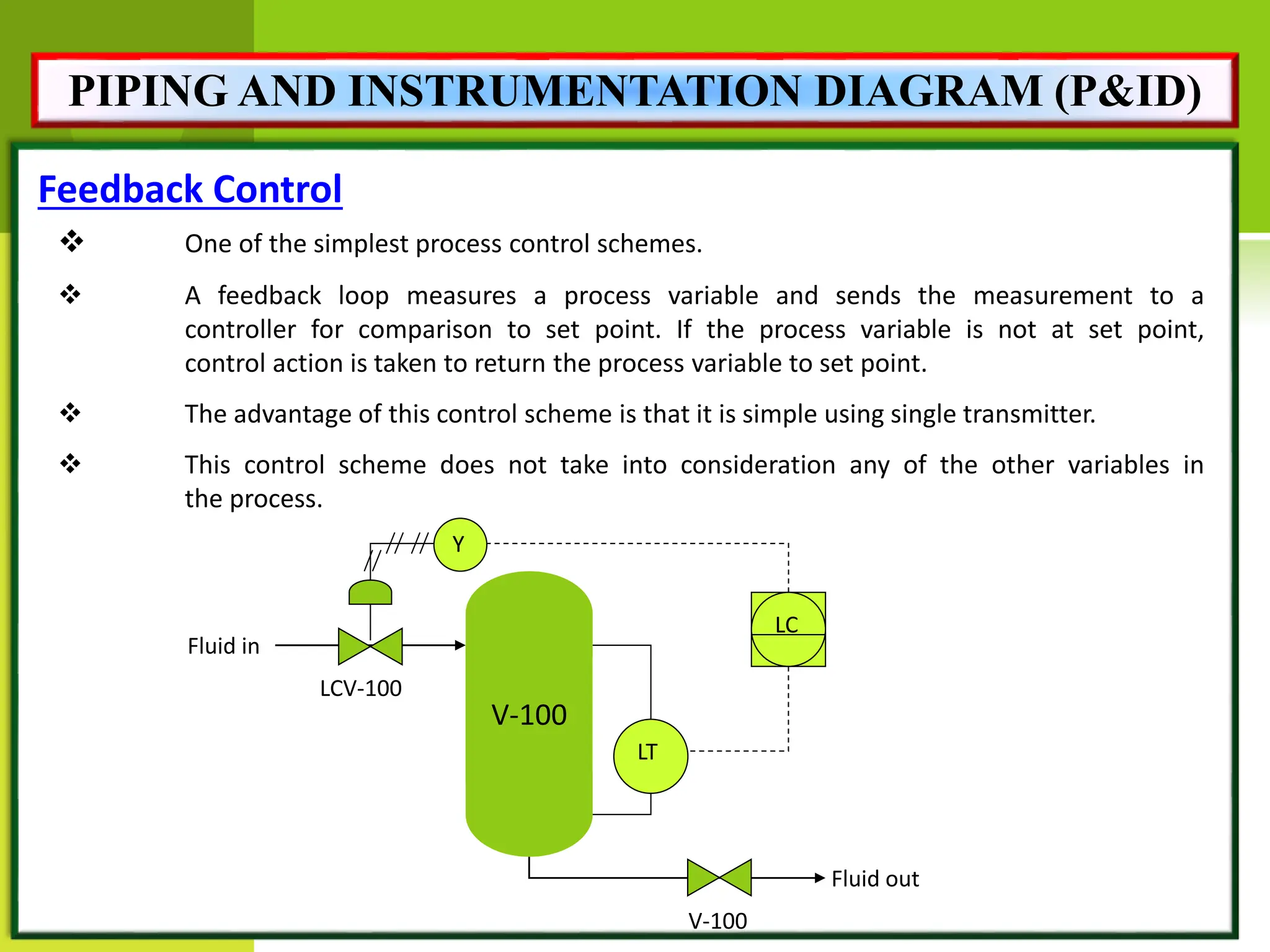

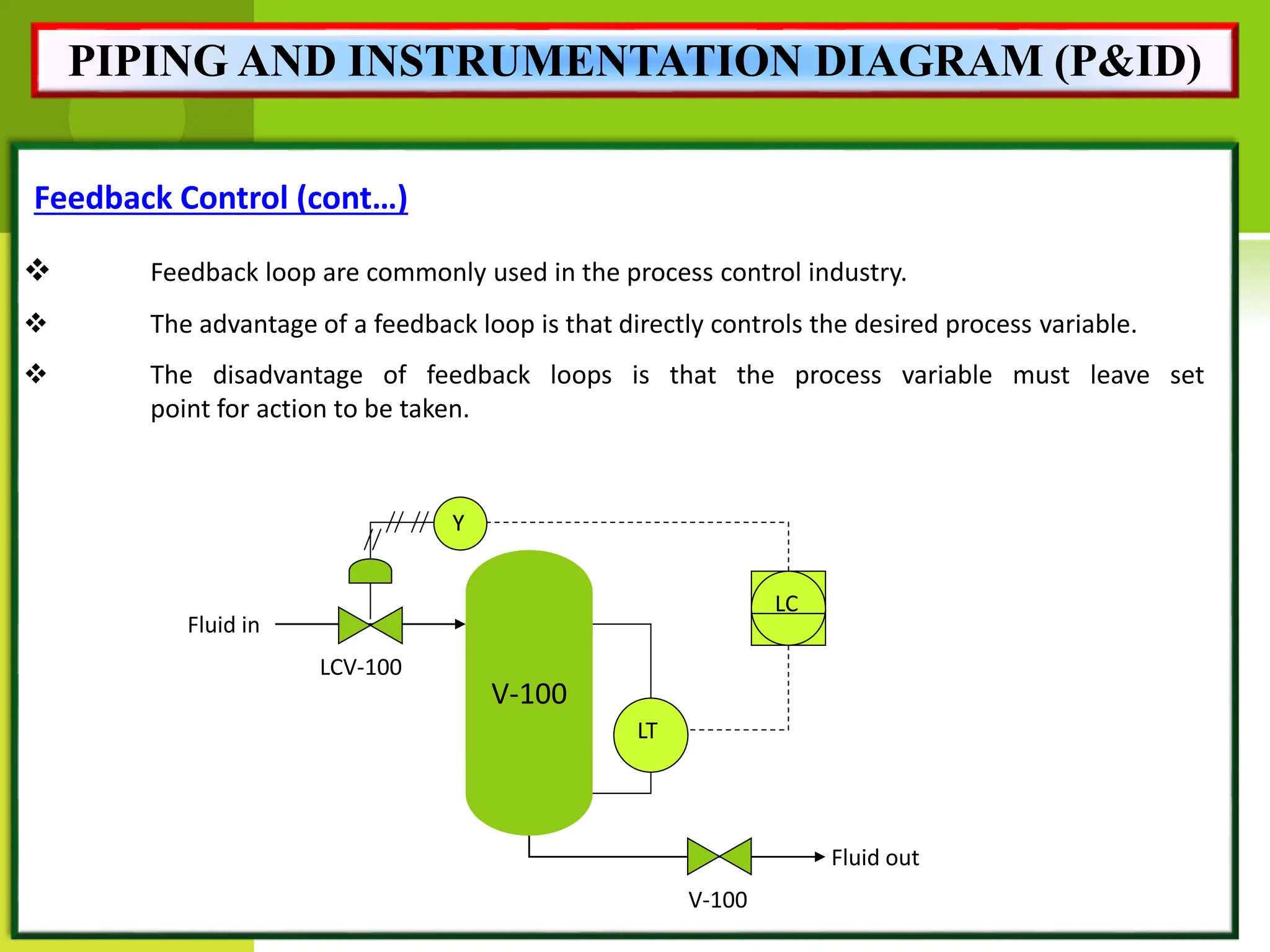

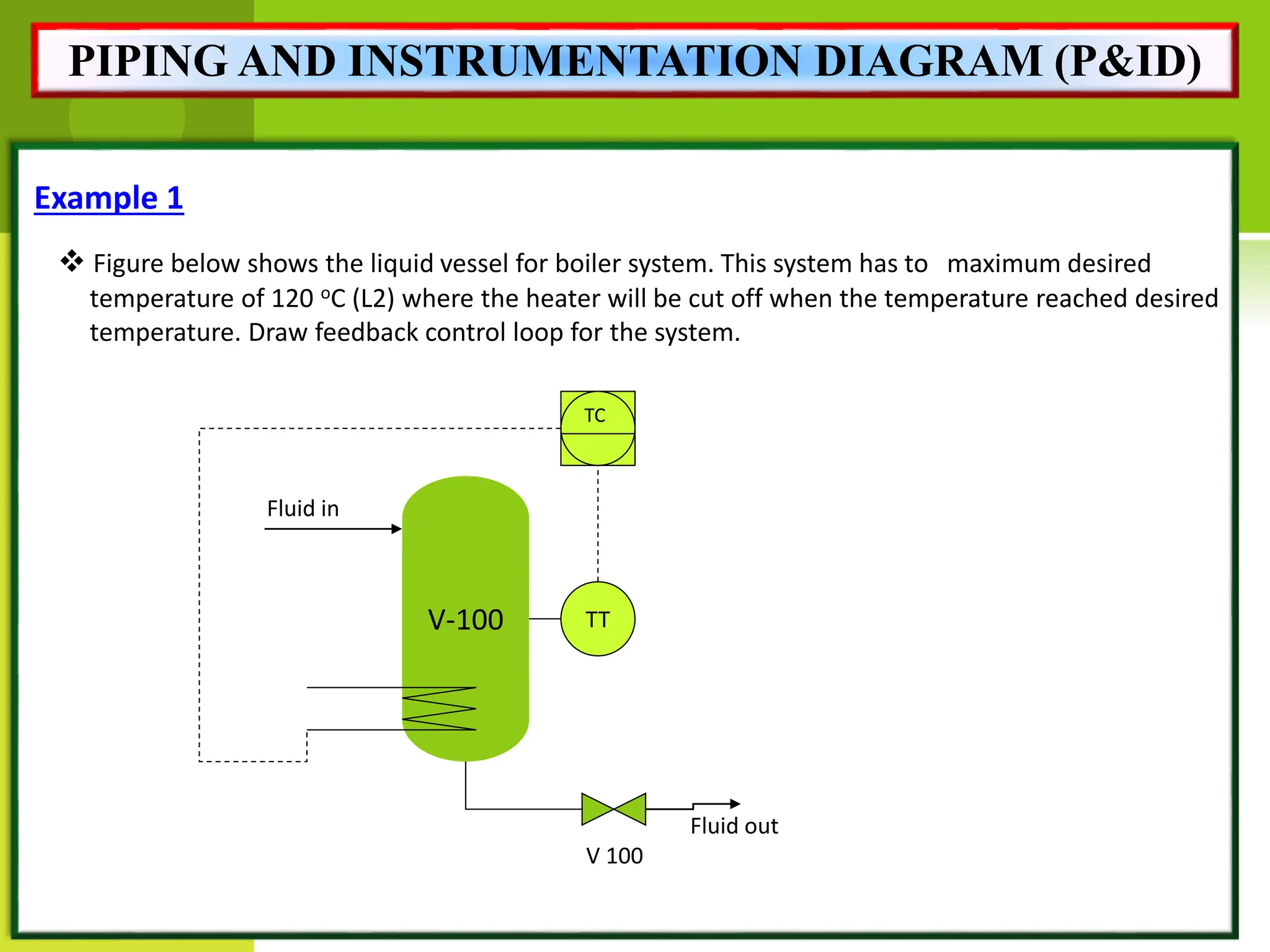

The document discusses the key aspects of a piping and instrumentation diagram (P&ID) course. The course aims to teach students to recognize piping and instrumentation symbols, choose suitable symbols for control systems, and develop piping systems and specifications for process instrumentation, equipment, piping, valves, and fittings in P&IDs for bioprocess plant design. It outlines topics that will be covered, including types of symbols, arrangement of components in P&IDs, and developing piping systems and specifications. Process diagrams like block flow diagrams, process flow diagrams, and P&IDs are also introduced.