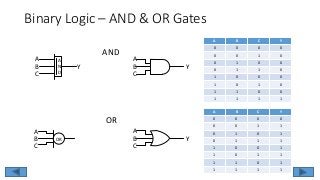

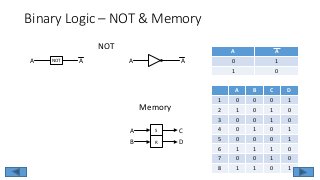

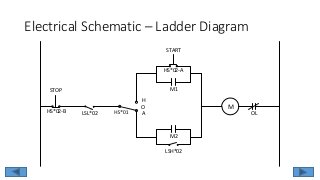

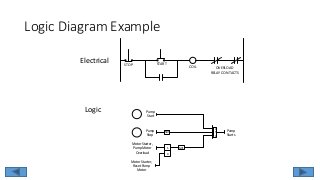

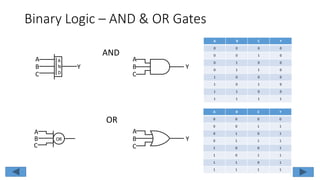

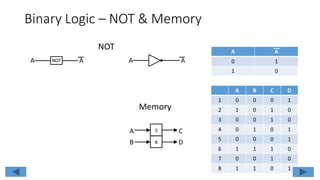

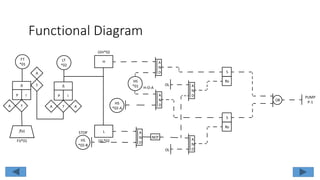

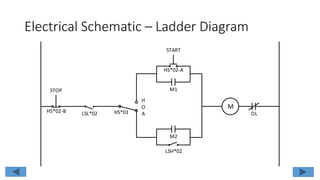

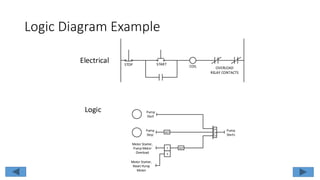

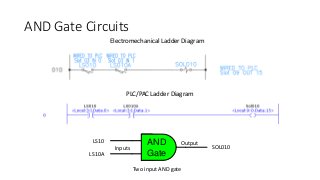

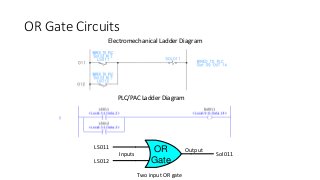

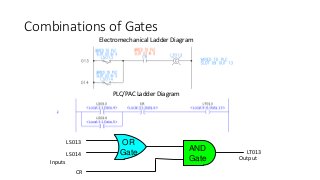

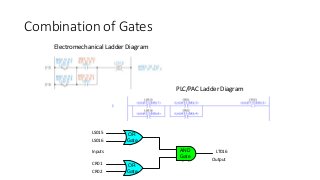

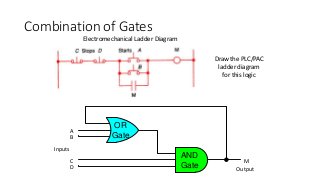

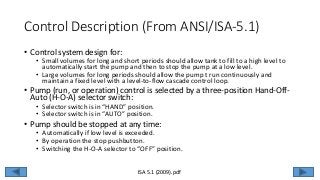

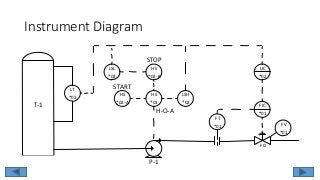

This chapter covers binary logic systems in process control, emphasizing the importance of understanding documentation for various professionals in the field. It includes definitions of key terms, explanations of binary logic operations such as AND, OR, and NOT gates, and discusses their applications in control systems. The chapter also highlights the use of logic diagrams and functional symbols to aid in the design and understanding of safety instrumented systems.

![Terms You Should Know Before Proceeding

• Discrete Control

• “On/off control. One of the two output values is equal to zero.” (International

Society of Automation, 2003, p. 150)

• A better definition would be: A signal that is either fully ON or fully OFF with

no values in-between.

• Binary

• “1. A term applied to a signal or device that has only two discrete positions or

states. When used in its simplest form, as in “binary signal” (as opposed to

“analog signal”), the term denotes an “on-off” or “high-low” state, that is, one

that does not represent continuously varying quantities. [ANSI-ISA-5.1-1984

(R1992)].” (International Society of Automation, 2003, p. 49).](https://image.slidesharecdn.com/06chapter06binarylogicsystems-160811205502/85/06-chapter06-binary_logic_systems_Rev02-4-320.jpg)

![Terms You Should Know Before Proceeding

• Process Variable

• “1. Any variable property of a process. The term process variable is used in

the relevant standard to apply to all variables other than instrument signals

[ANSI/ISA-5.1-1984 (R1992)]. 2. In the treatment of material, any

characteristic or measurable attribute whose value changes with changes in

prevailing conditions. Common variables are flow, level, pressure and

temperature.” (International Society of Automation, 2003, p. 392).

• Control Variable (Controlled Variable)

• “1. The variable that the control system attempts to keep at the set point

value. The set point may be constant or variable. 2. The part of a process to

be controlled (flow, level, temperature, pressure, etc.).” (International Society

of Automation, 2003, p. 109).](https://image.slidesharecdn.com/06chapter06binarylogicsystems-160811205502/85/06-chapter06-binary_logic_systems_Rev02-6-320.jpg)

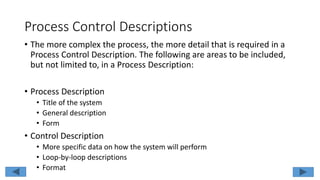

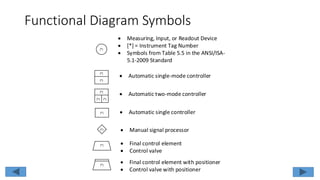

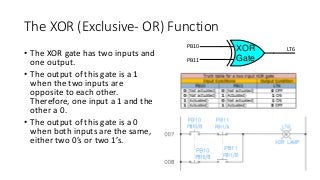

![Functional Diagram Symbols

(*)

Measuring, Input, or Readout Device

[*] = Instrument Tag Number

Symbols from Table 5.5 in the ANSI/ISA-

5.1-2009 Standard

(*)

(*)

Automatic single-mode controller

(*)

(*) (*)

Automatic two-mode controller

(*) Automatic single controller

(*) Manual signal processor

(*) Final control element

Control valve

(*)

Final control element with positioner

Control valve with positioner](https://image.slidesharecdn.com/06chapter06binarylogicsystems-160811205502/85/06-chapter06-binary_logic_systems_Rev02-32-320.jpg)