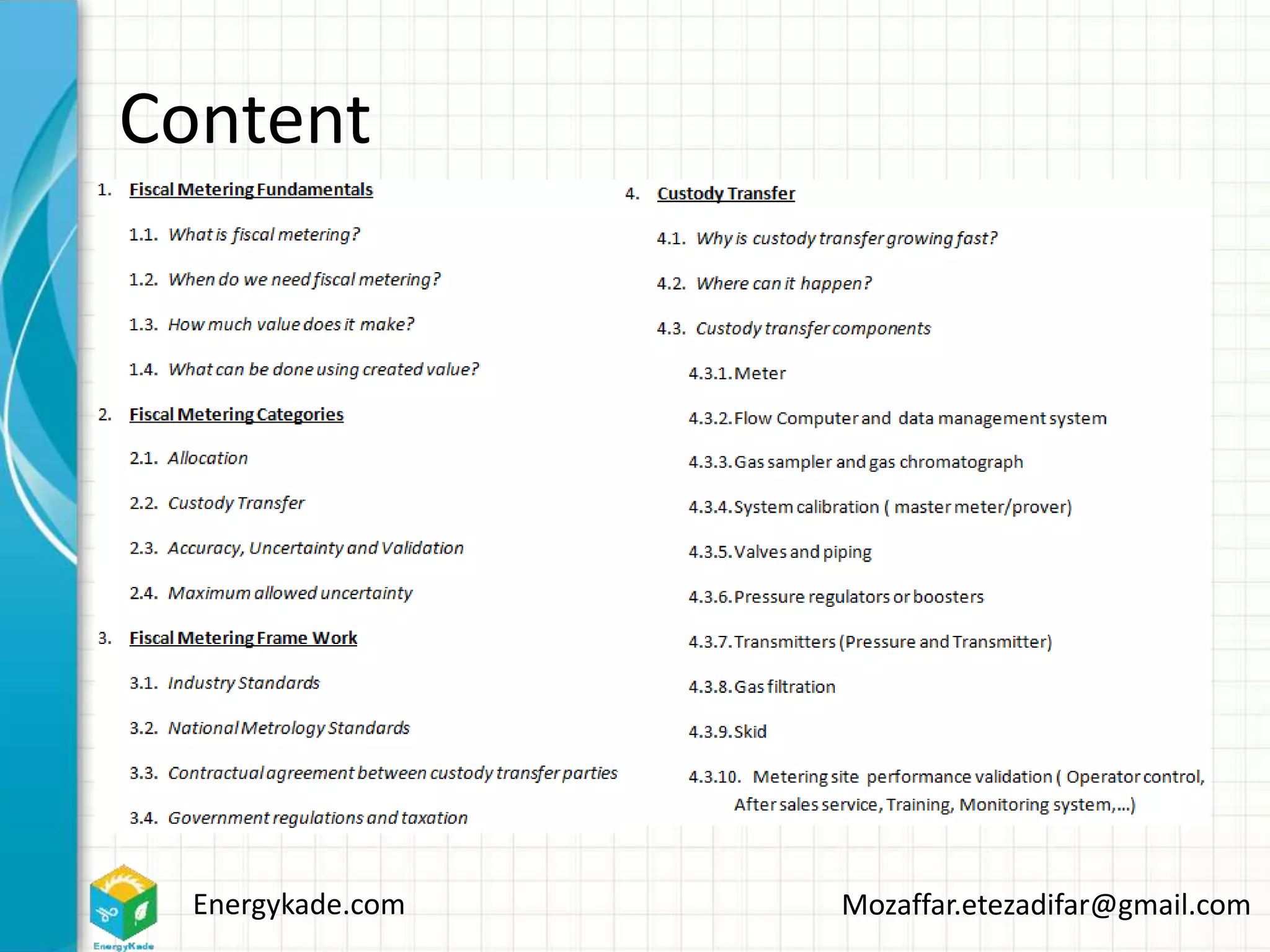

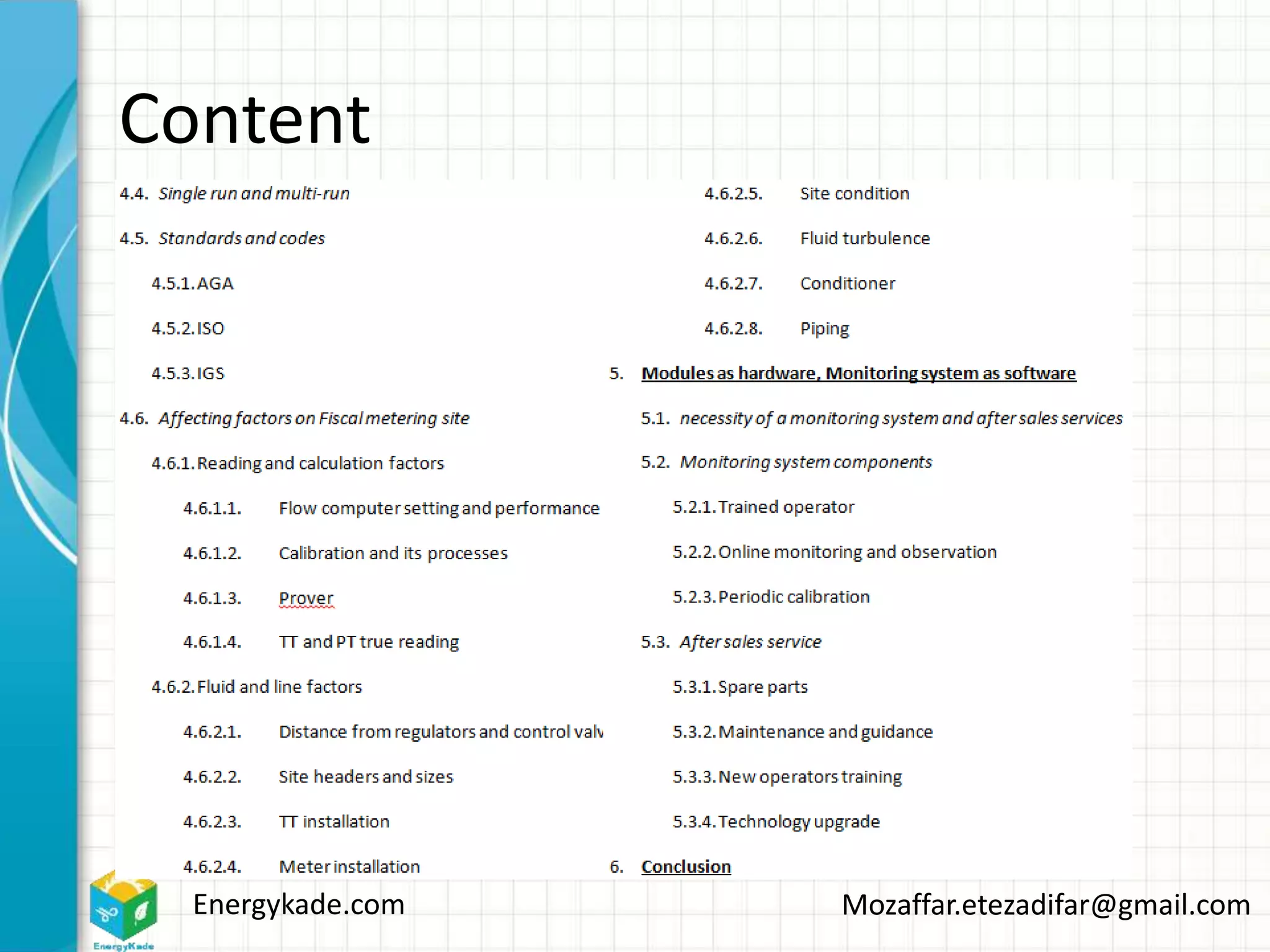

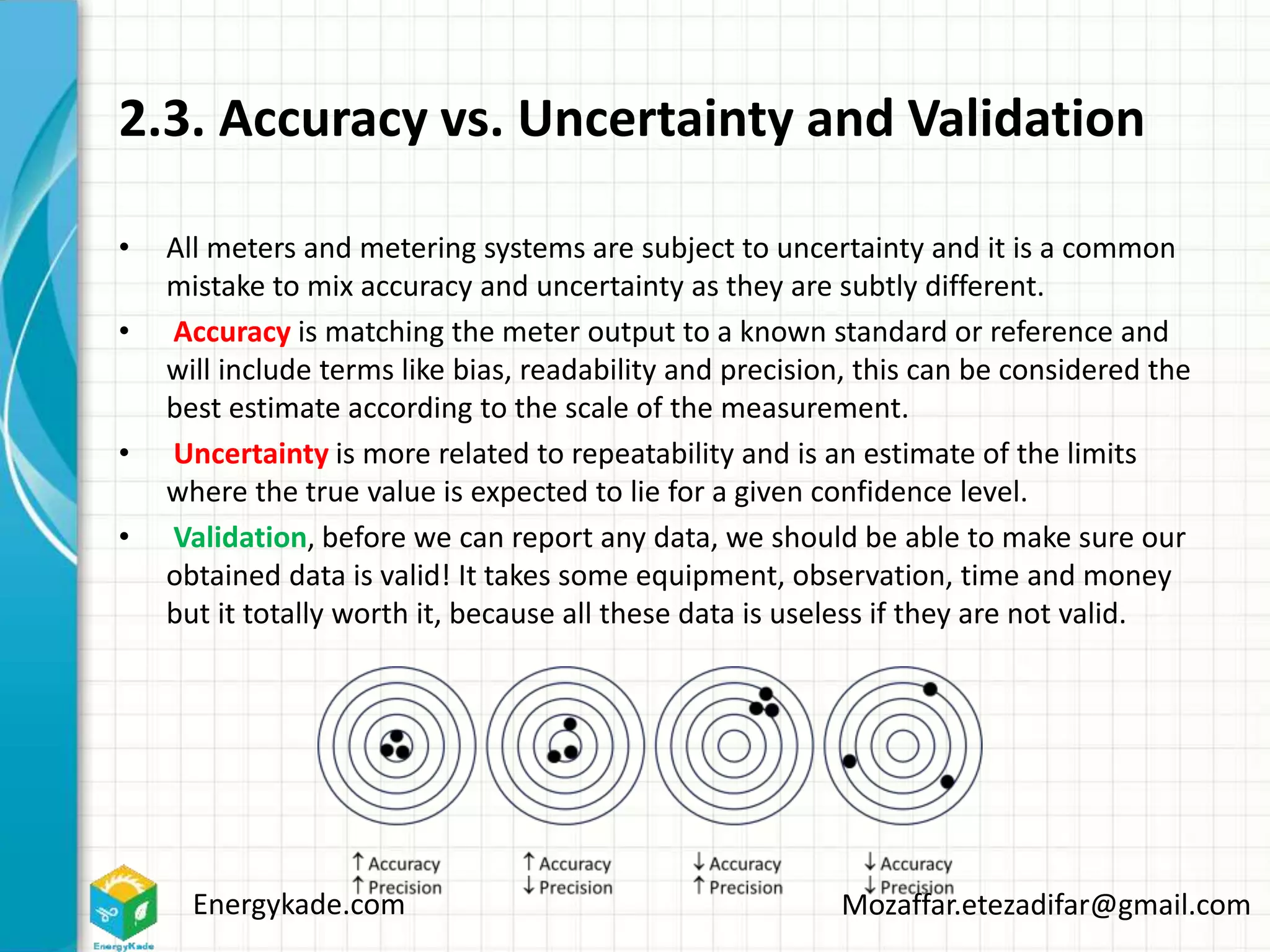

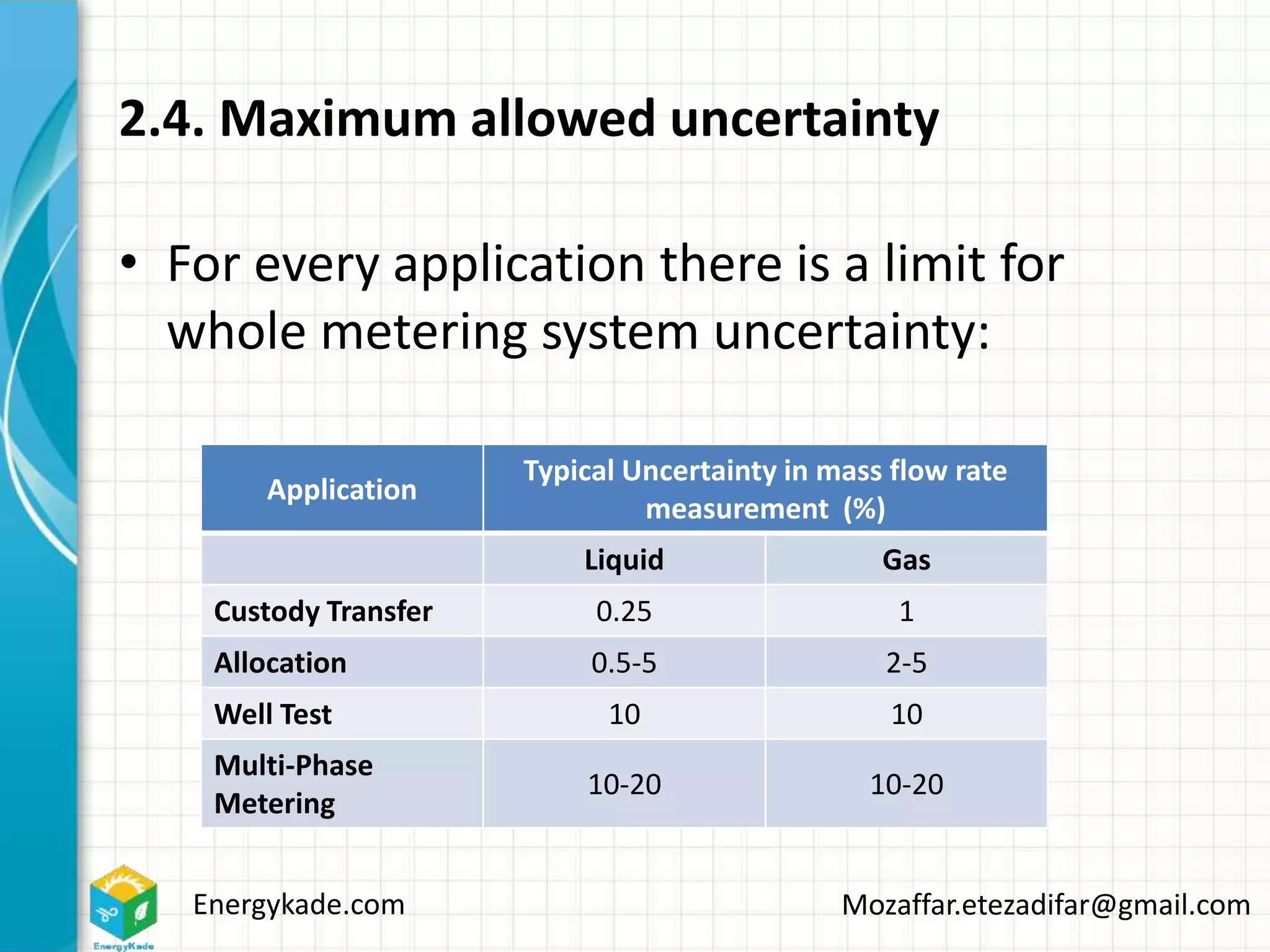

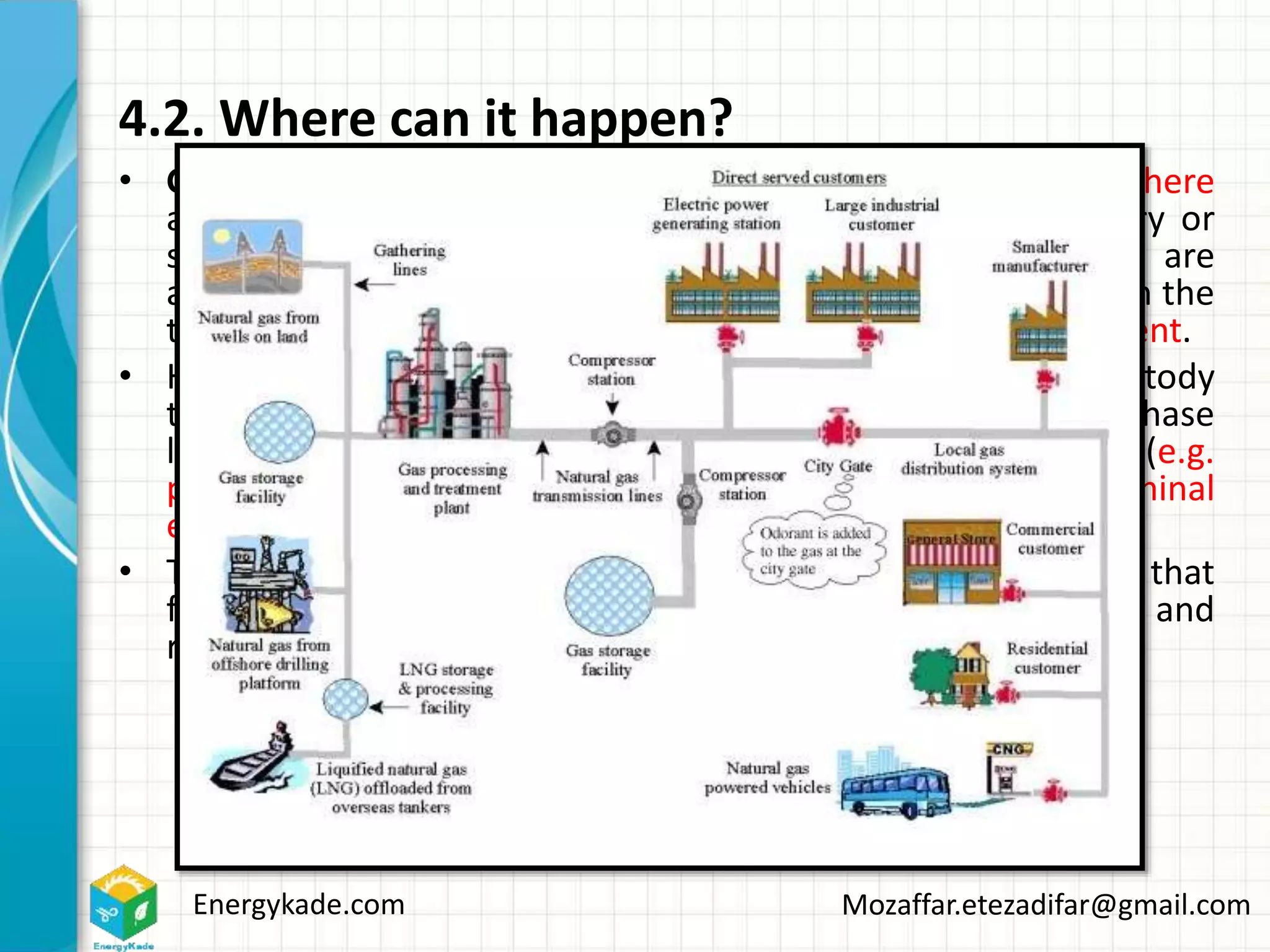

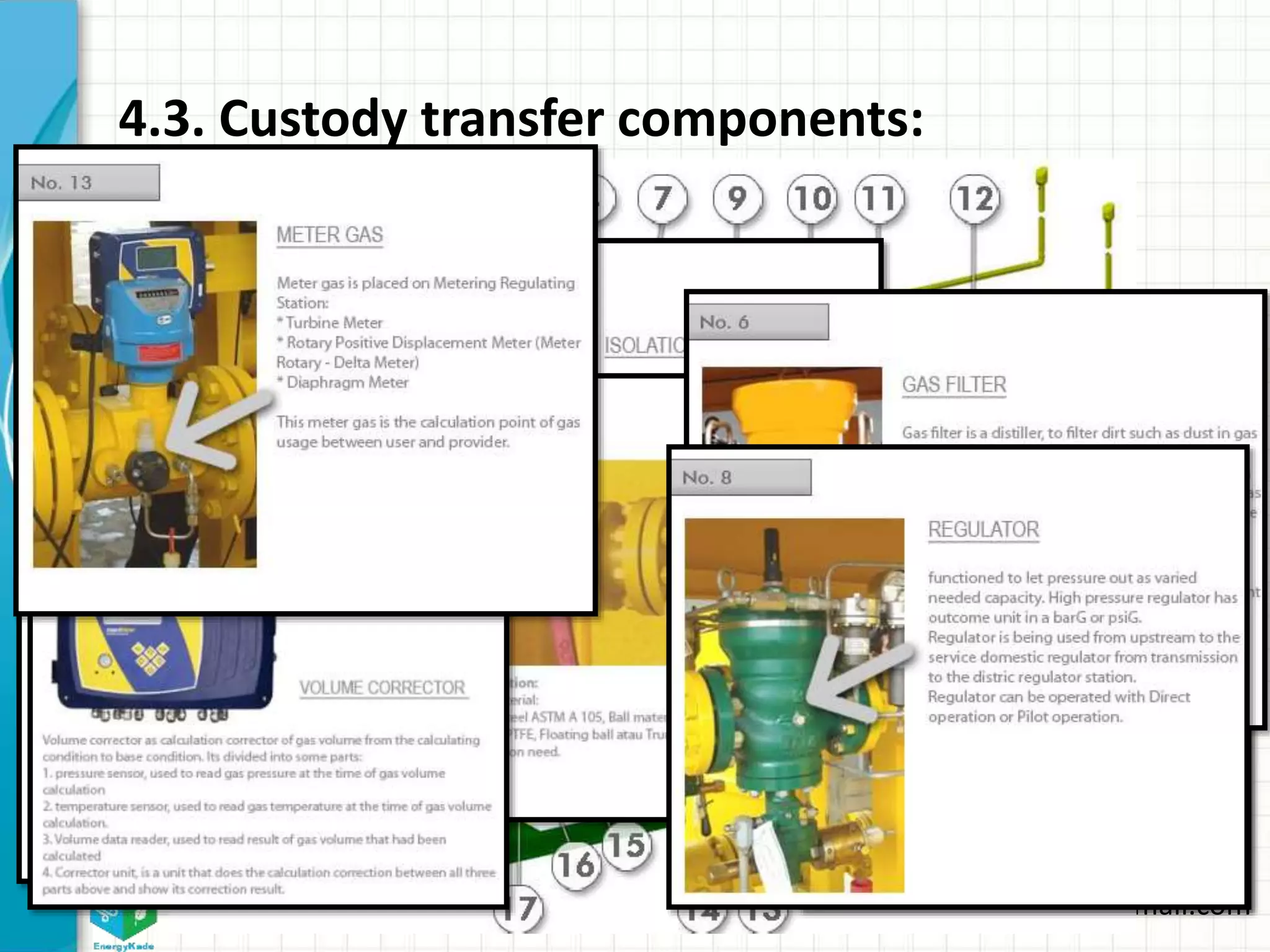

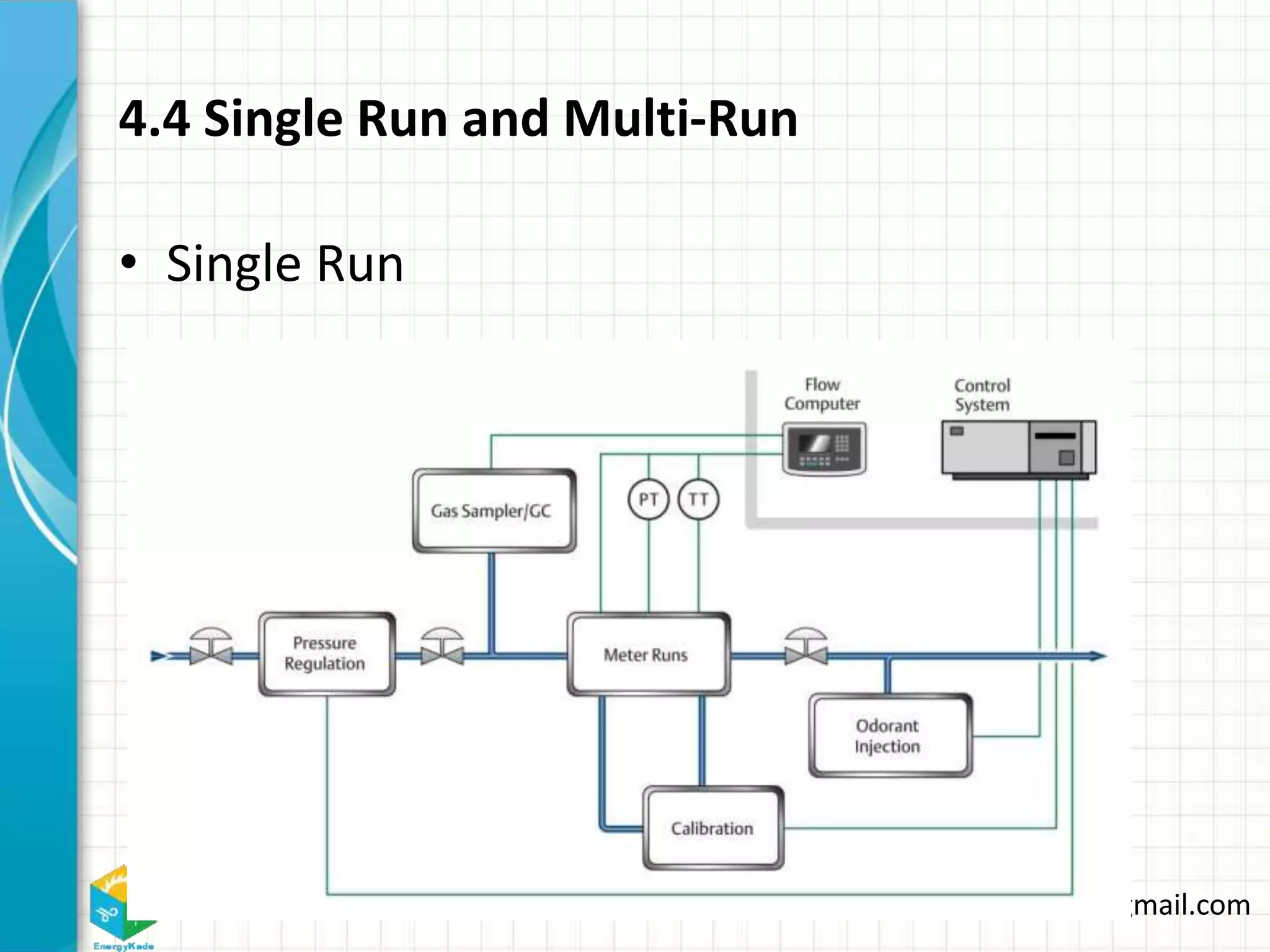

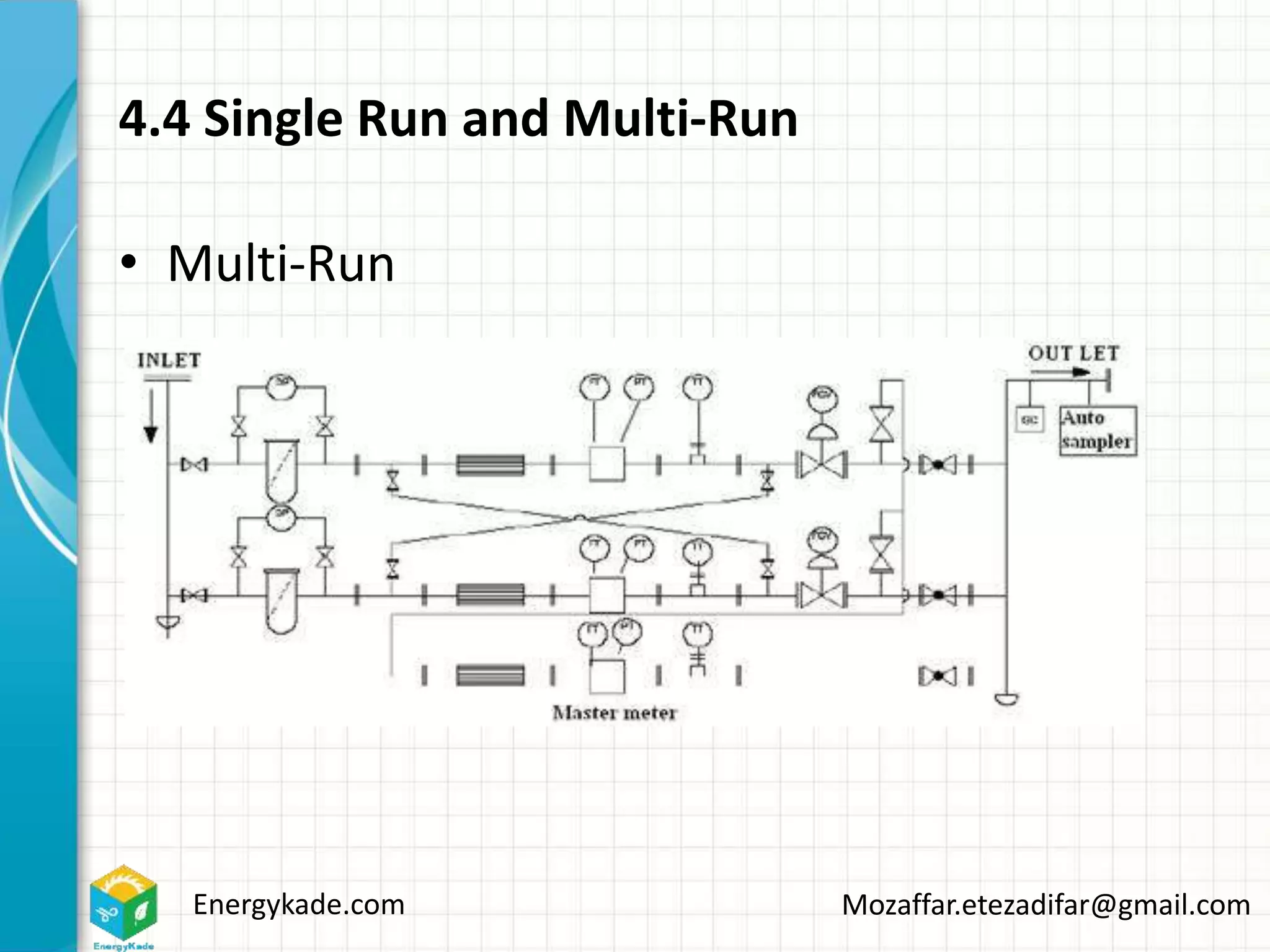

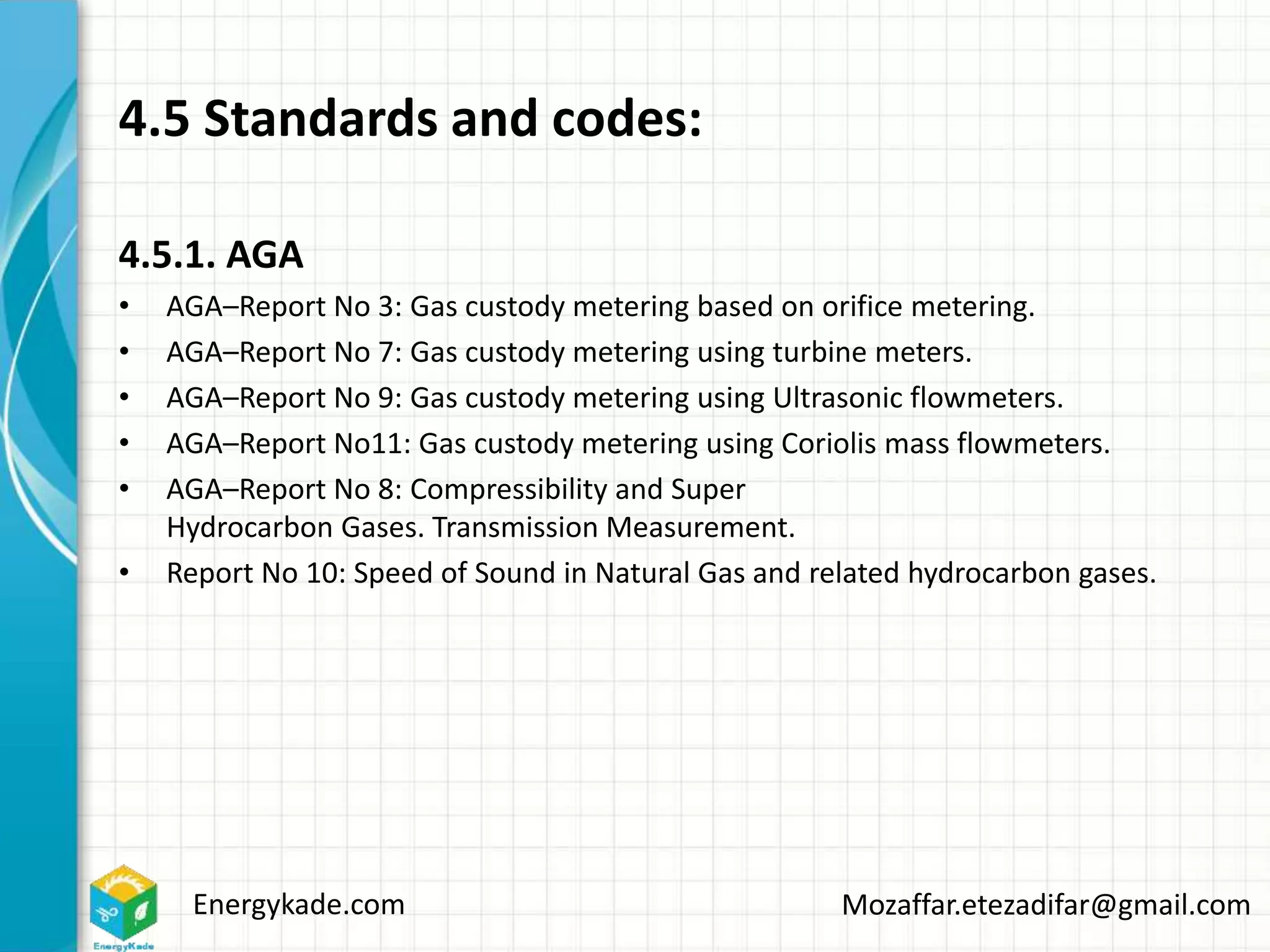

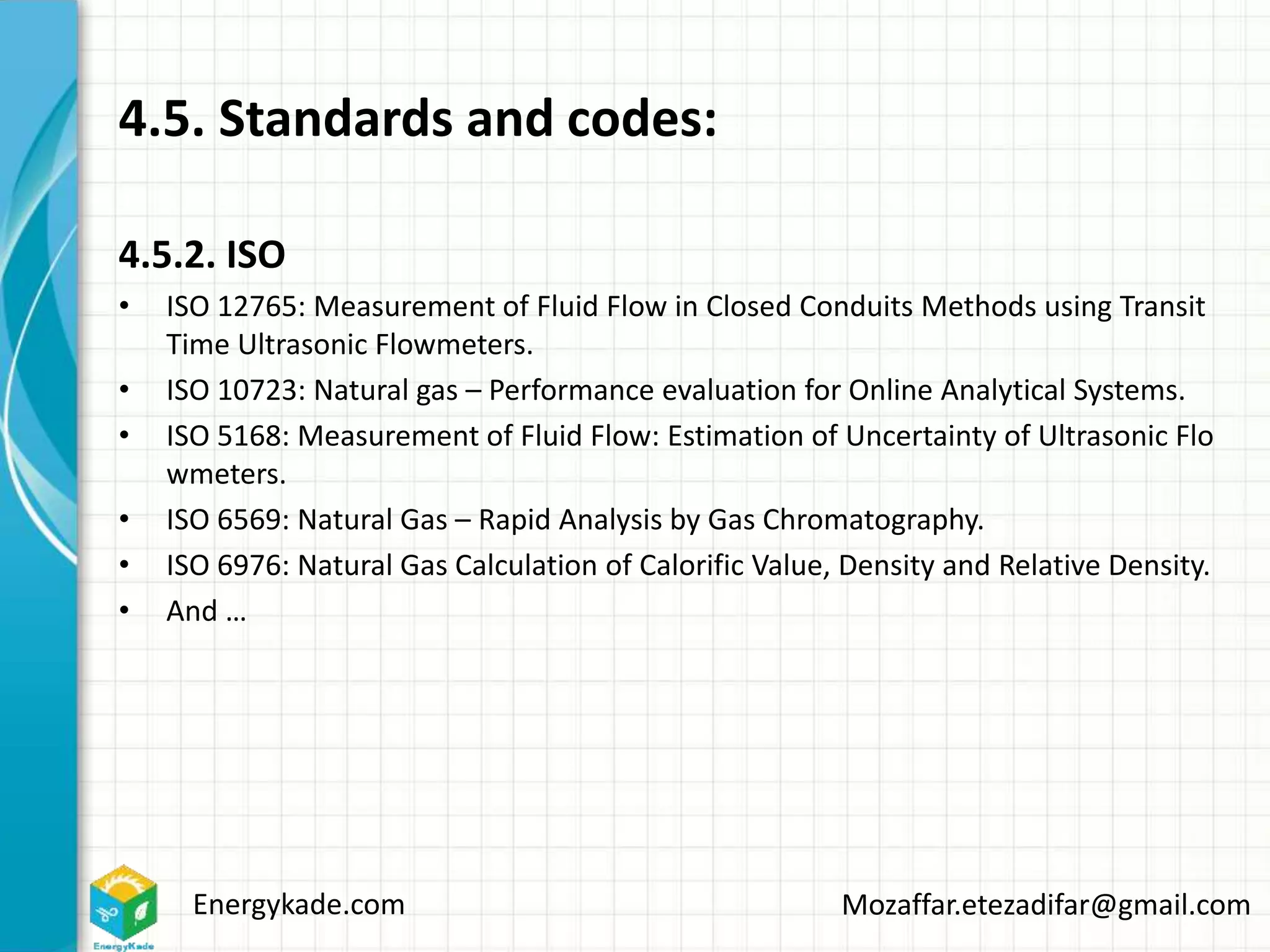

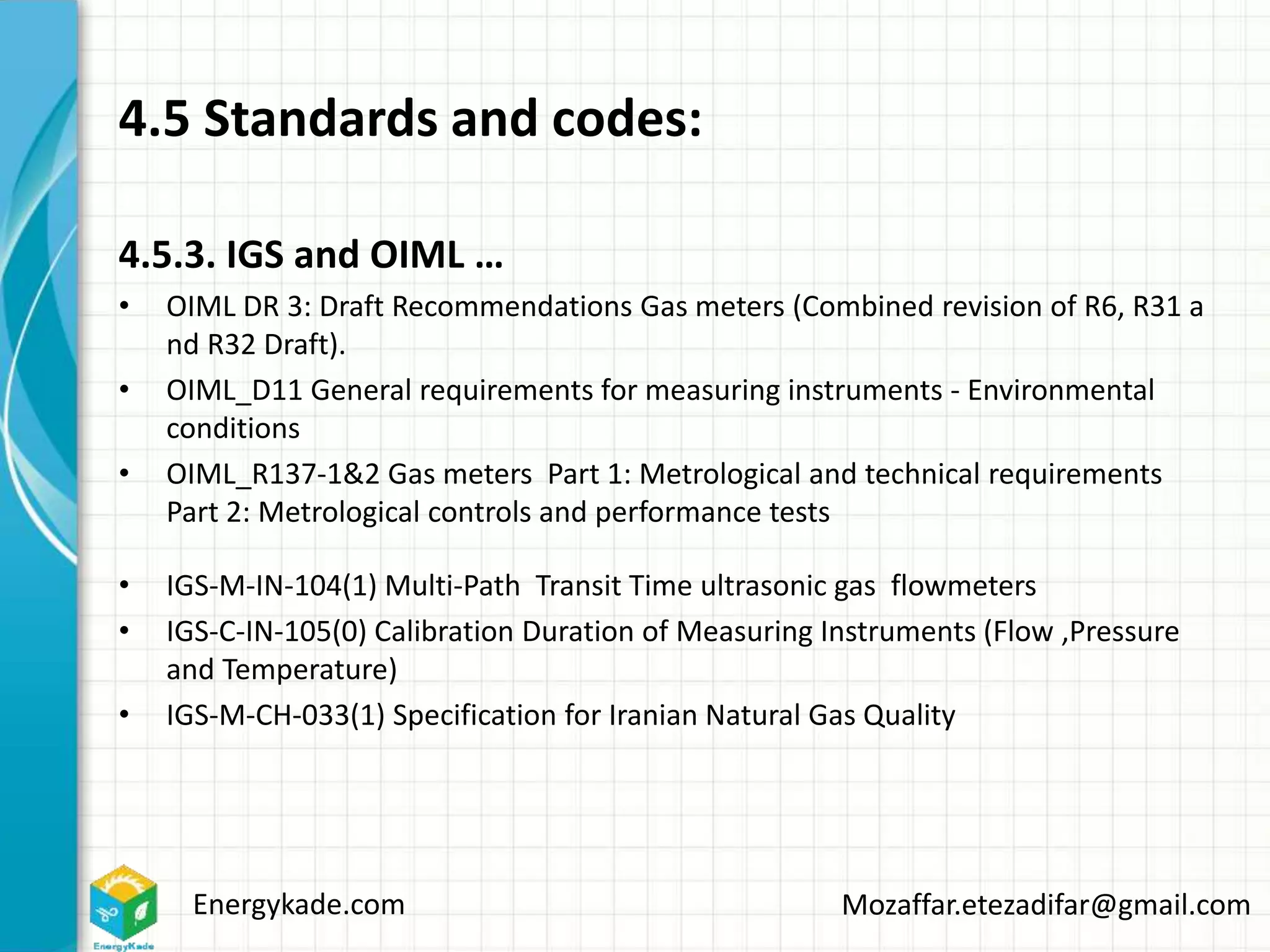

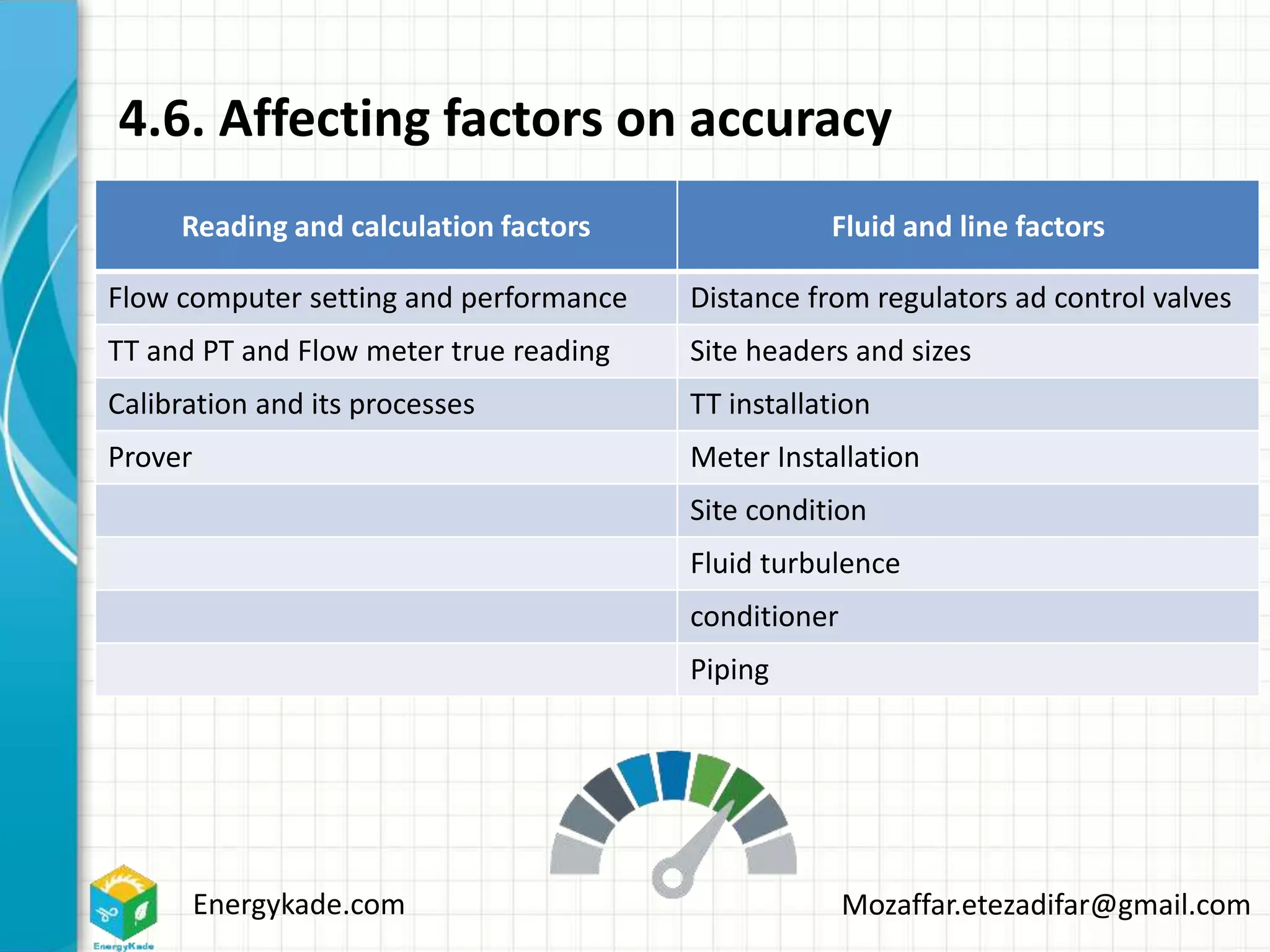

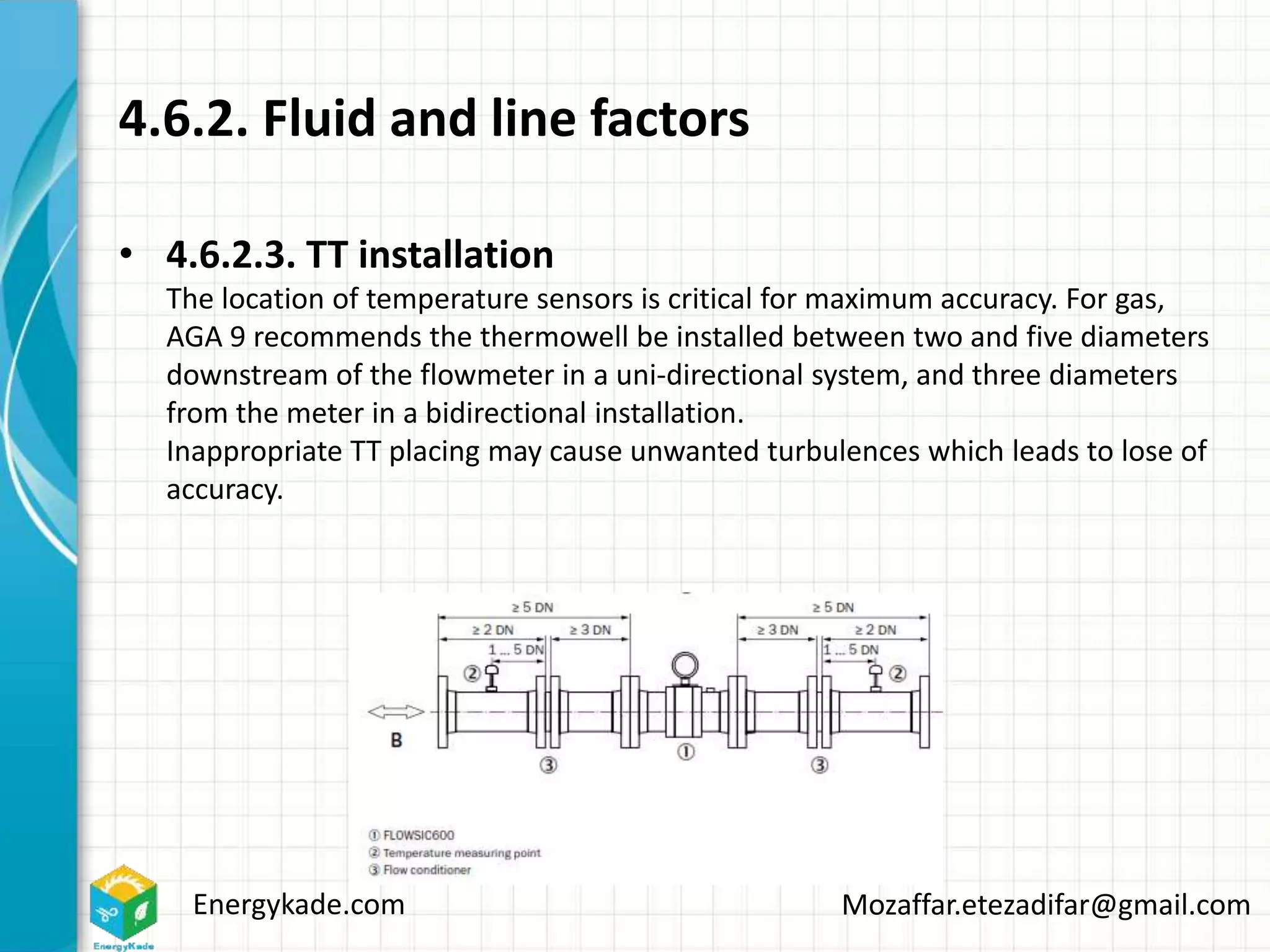

The document discusses fiscal metering, a critical process for accurately measuring and managing the transfer of valuable products, particularly in the oil and gas industry. It outlines key concepts such as custody transfer, allocation, accuracy versus uncertainty in measurements, and the importance of adhering to industry standards and regulations. The text emphasizes the necessity of reliable systems and practices to ensure precision and mitigate financial risks associated with measurement errors.