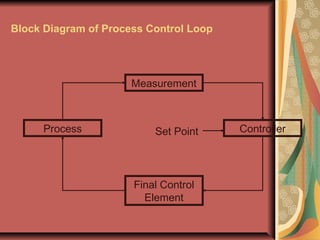

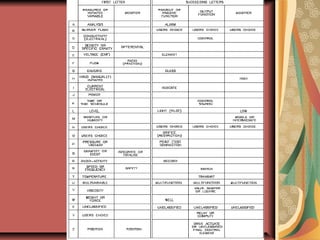

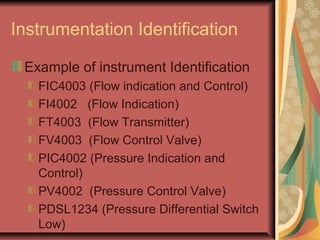

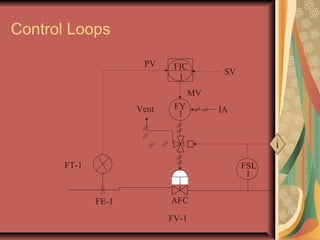

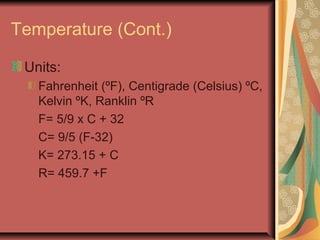

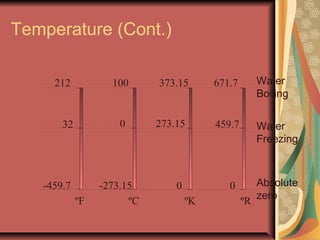

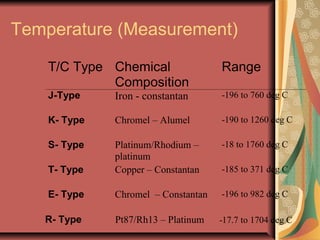

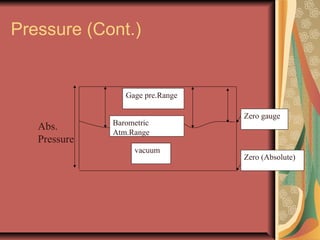

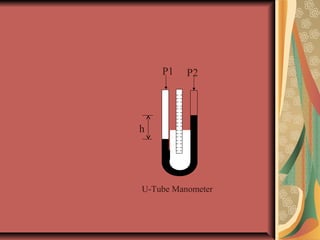

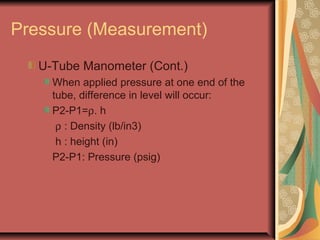

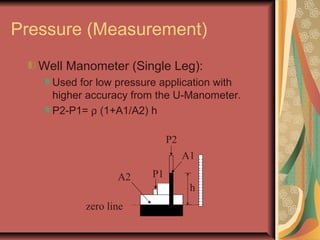

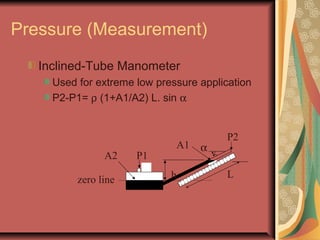

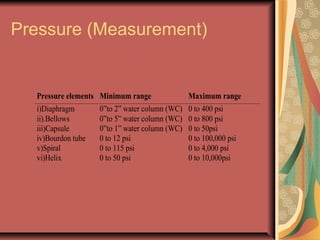

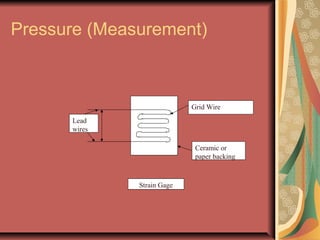

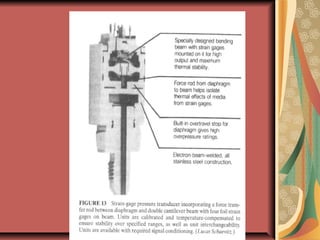

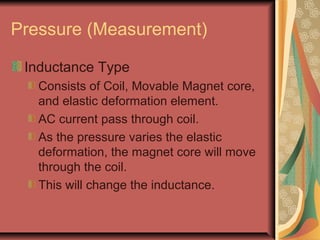

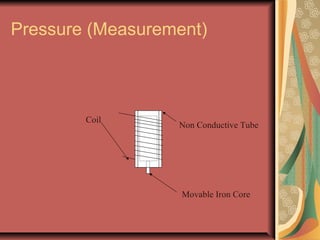

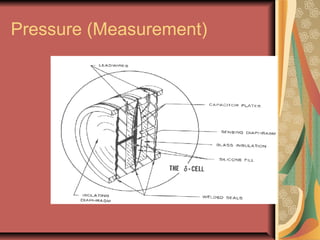

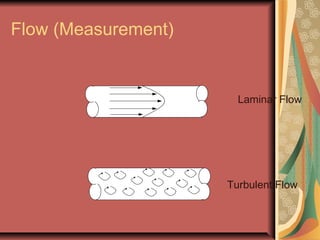

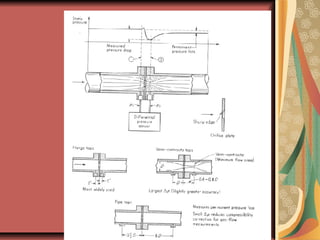

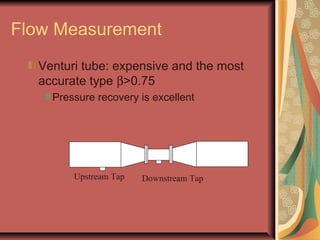

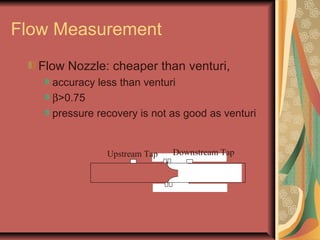

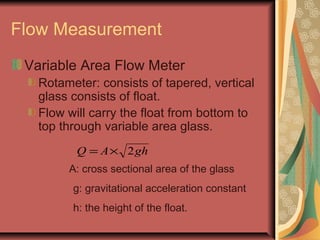

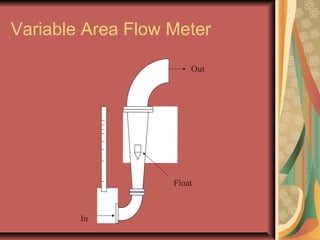

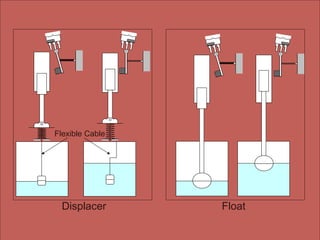

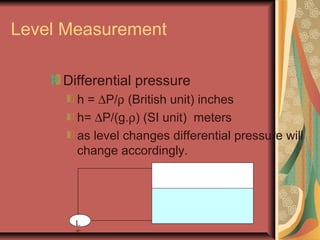

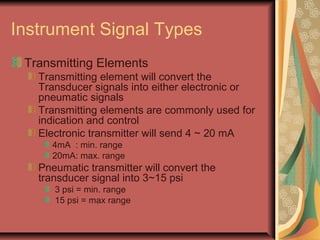

This document discusses basic instrumentation concepts and components. It defines instrumentation and process control, and describes their functions. It also covers common process measurements like temperature, pressure, flow, and level. For each it discusses units of measurement, measurement elements and principles, and examples of measurement devices. Finally, it briefly introduces how instrumentation signals are transmitted from field devices to control systems.