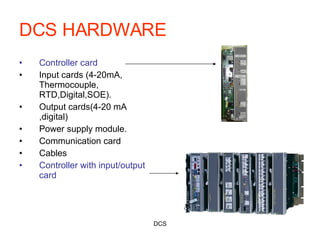

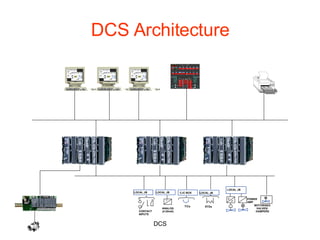

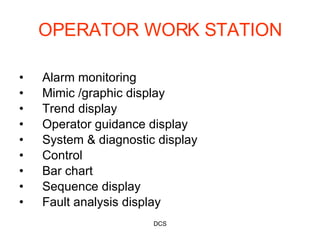

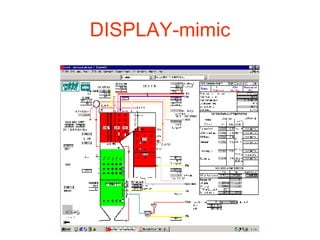

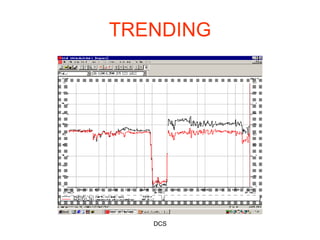

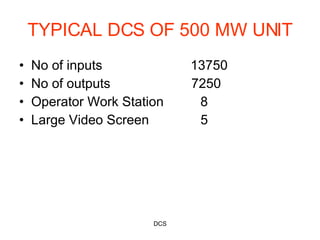

A distributed control system (DCS) provides safe, efficient, and reliable control of critical components in a thermal power plant. Key benefits of a DCS include high reliability, improved response time, improved operator interface, and historical data storage. A DCS uses controller cards, input/output cards, and communication cards to monitor and control elements like valves, pumps, temperatures, and pressures. Operators interact with the DCS through workstations with displays for alarms, graphics, trends, and reports. Automatic controls help optimize processes while interlocks ensure safe operation during startups, run cycles, and shutdowns.