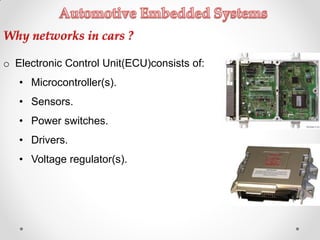

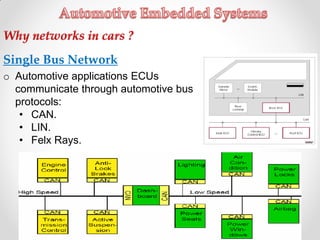

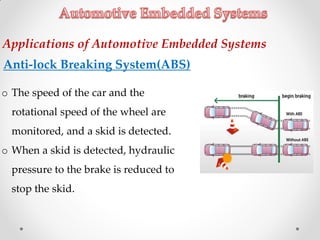

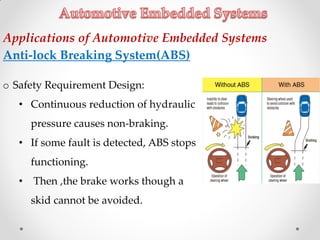

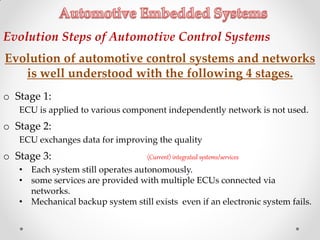

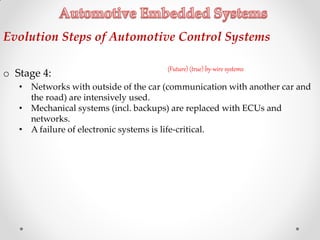

Drive-by-wire technology replaces traditional mechanical systems with electronic systems controlled by electronic control units (ECUs). ECUs consist of microcontrollers, sensors, power switches, drivers, and voltage regulators. They connect sensors and actuators to a central ECU. Modern cars contain up to 100 ECUs communicating over automotive bus protocols like CAN, LIN, and FlexRay. This allows for advanced driver assistance systems like anti-lock braking systems and electronic stability control.

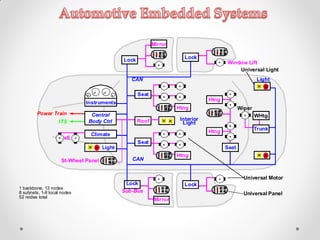

![Automotive Network protocol

Speed[bit/s]

Byteflight

optical bus

LIN

master-slave

single wire bus

no quartz

CAN-B

event triggered

fault tolerant

dual wire

CAN-C

event triggered

dual wire

Flex Ray

25.6M

20K

10M

1M

125K

incremental cost per node [$]

D2B, MOST

token ring

optical bus

1 2 4.5 10](https://image.slidesharecdn.com/intro-150328102135-conversion-gate01/85/Embedded-Systems-in-Automotive-27-320.jpg)