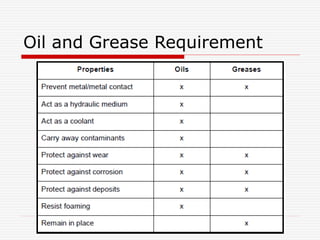

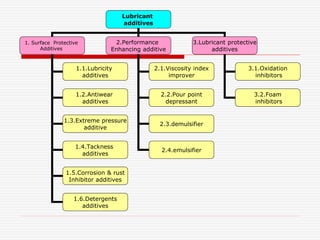

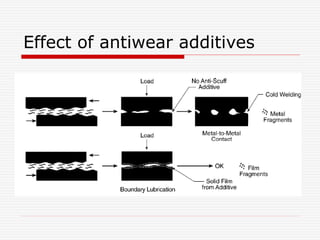

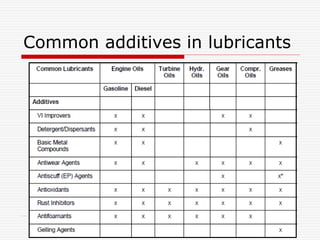

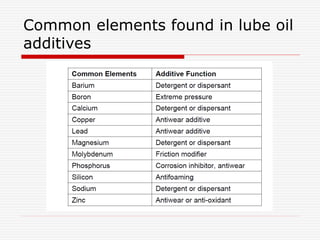

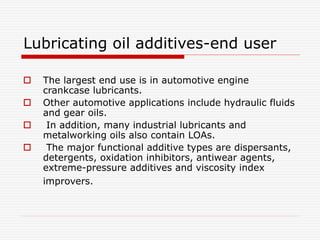

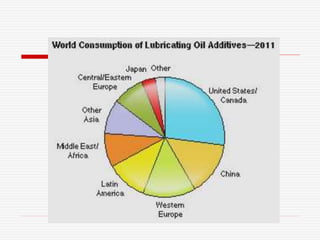

This document discusses lubricating oil additives. It begins by introducing lubrication theory and the importance of selecting appropriate lubricants. It then discusses the basic purposes of lubricants to reduce friction and wear. The document focuses on the types and purposes of various lubricating oil additives, including: surface protective additives like antiwear and extreme pressure additives; performance enhancing additives like viscosity index improvers and pour point depressants; and lubricant protective additives like oxidation inhibitors and foam inhibitors. It concludes by discussing common elements in lubricating oil additives and their major end uses.