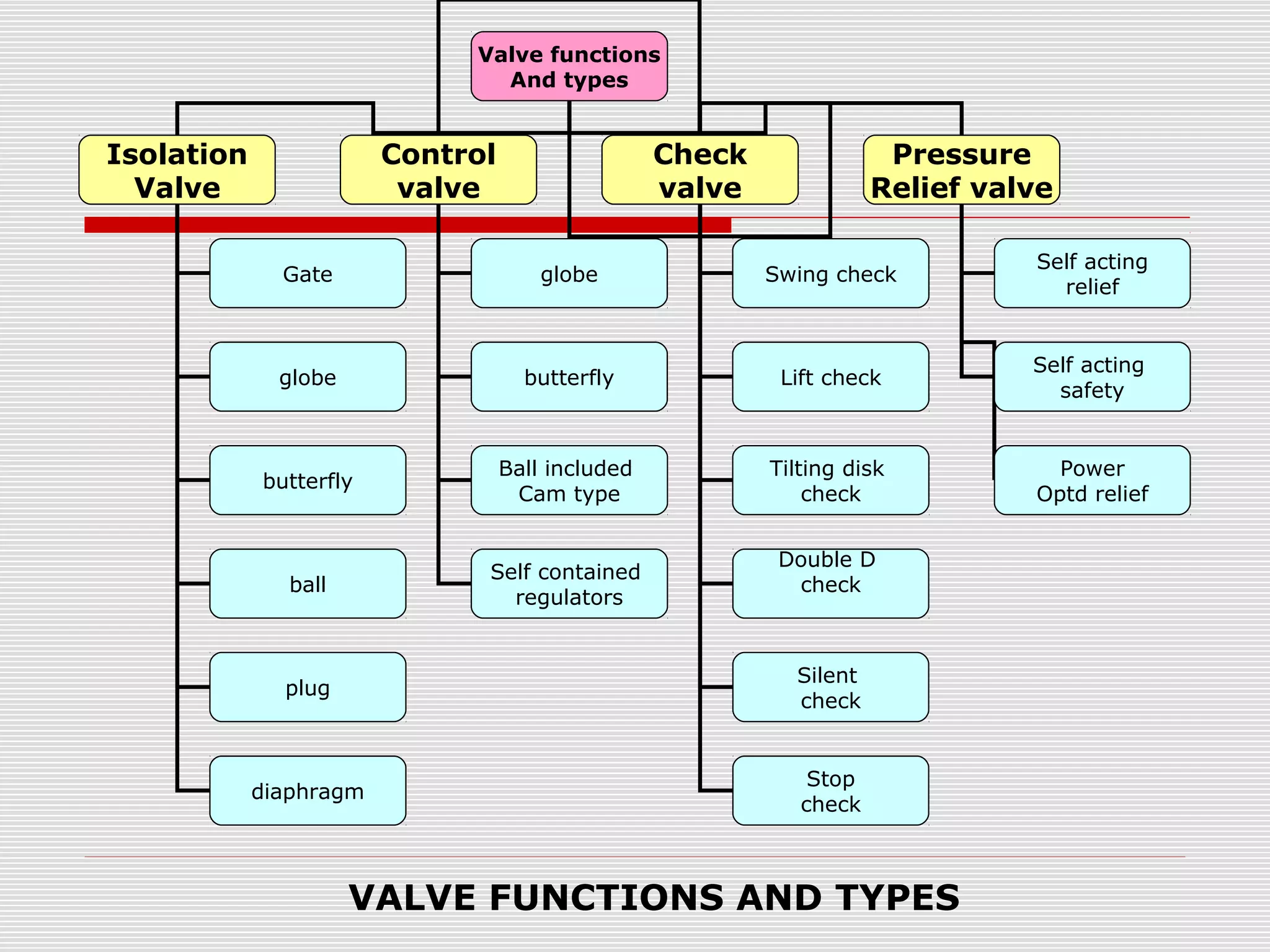

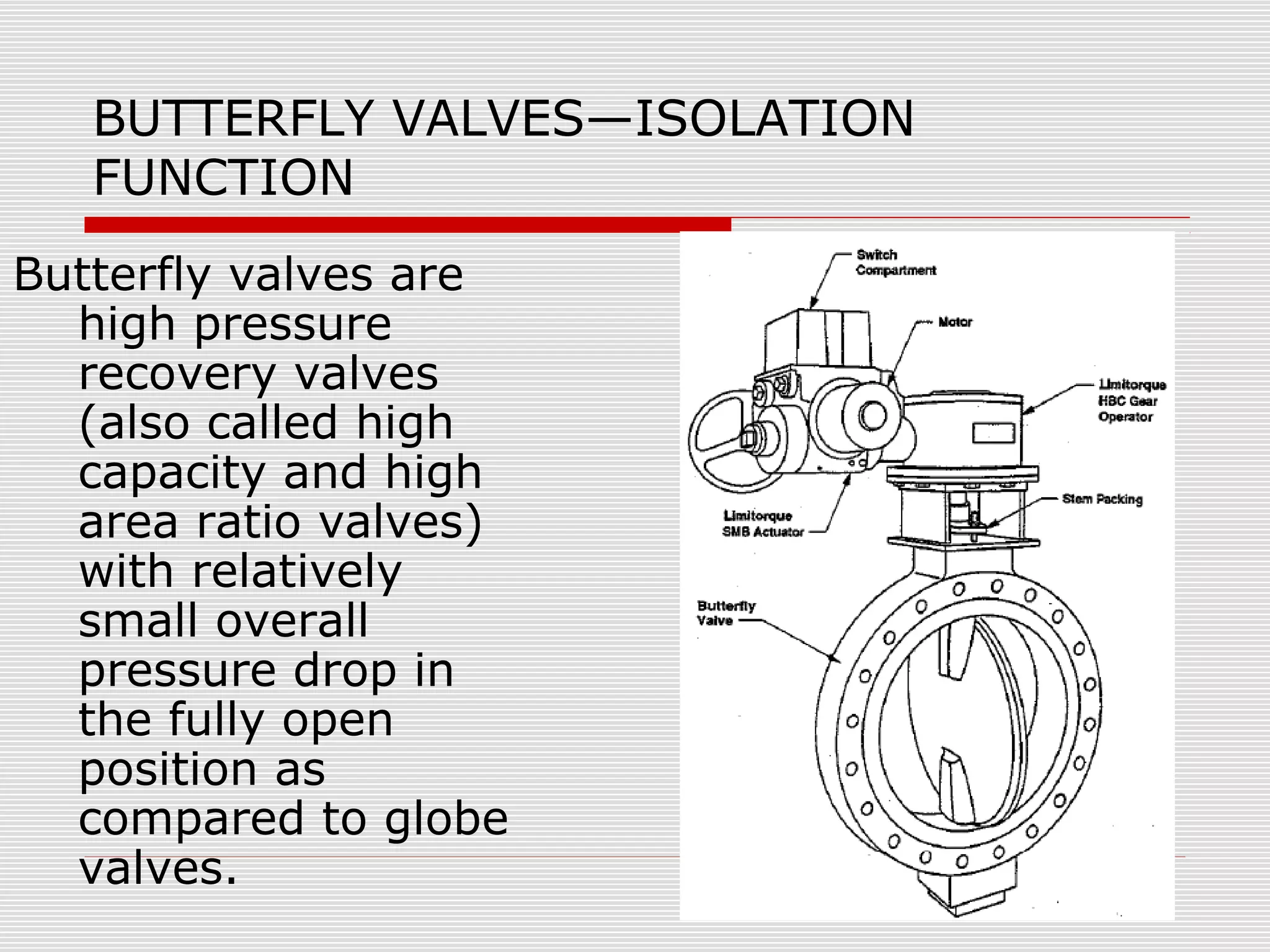

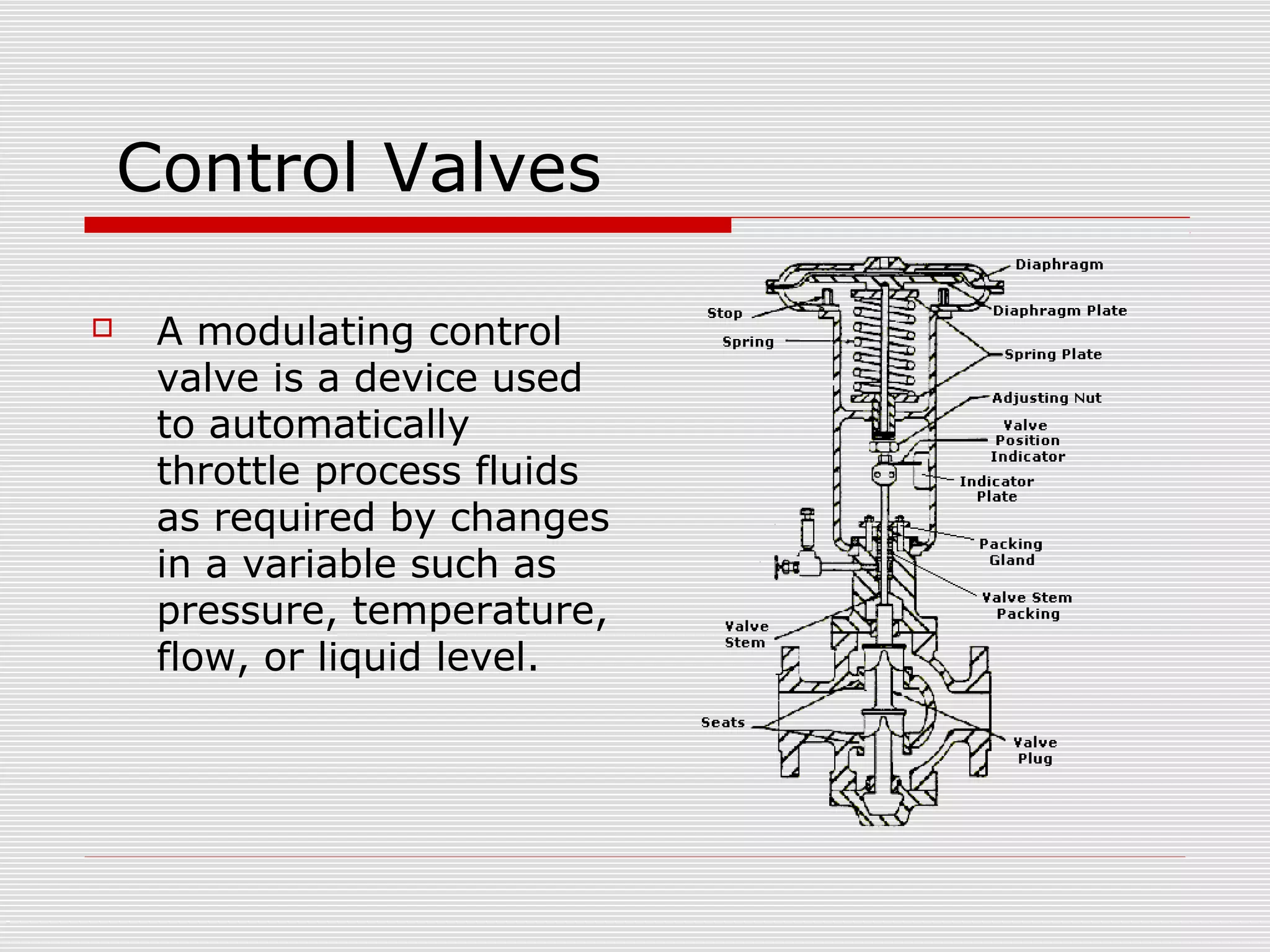

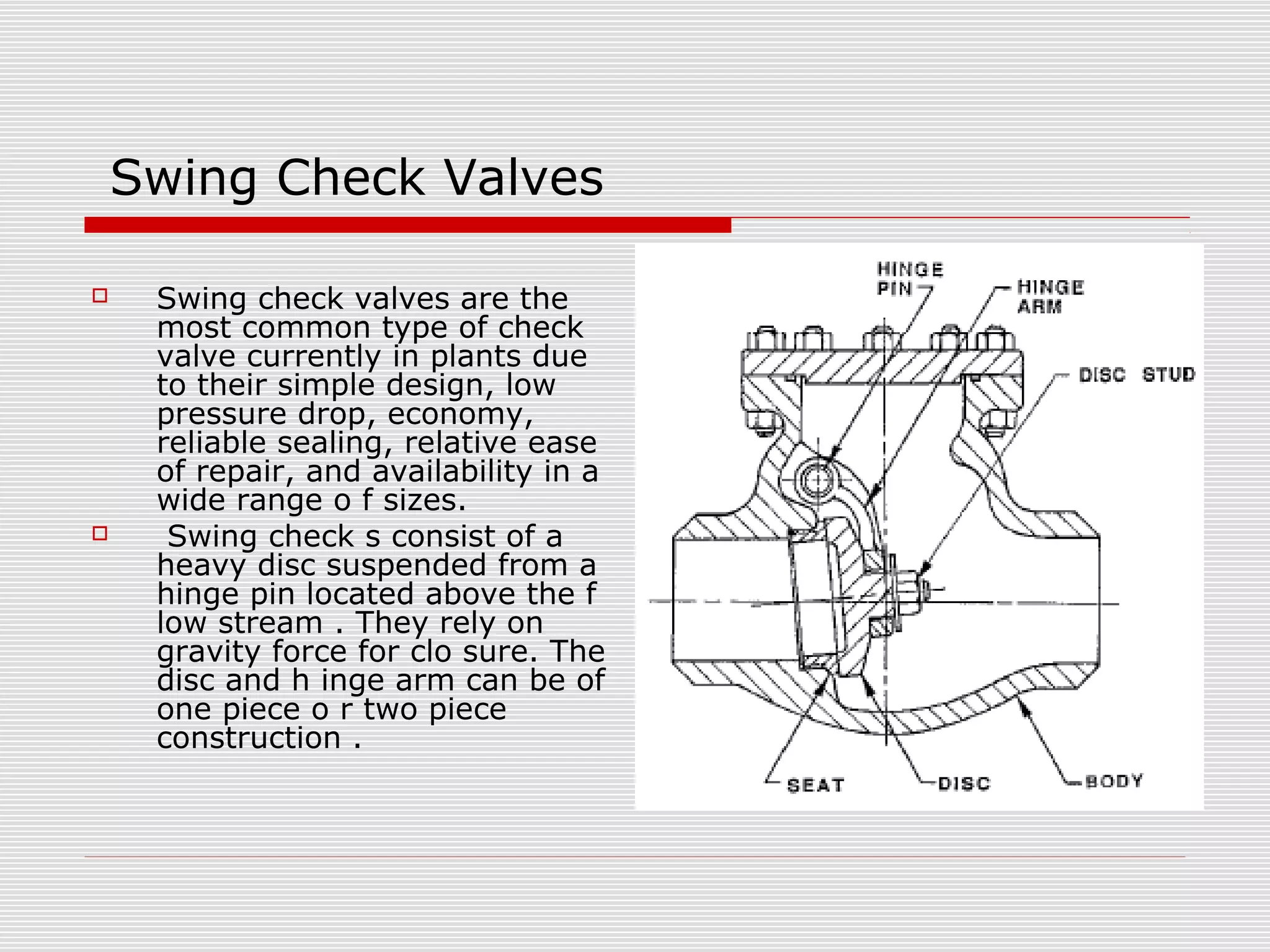

Valves serve various functions in industrial plants including isolation, control, pressure relief, and preventing backflow. There are several types of valves that can be categorized based on their function, including isolation valves like gate valves, globe valves, and butterfly valves used for on/off service. Control valves like top-guided and cage-guided valves are used for modulating or throttling flow in response to process parameters. Pressure relief valves open automatically to protect against overpressure, while check valves allow flow in one direction and prevent reverse flow using swing check, tilt disc, and lift check designs.