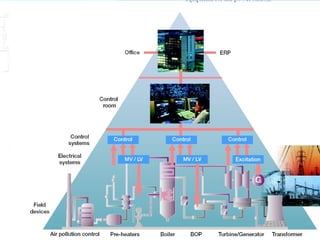

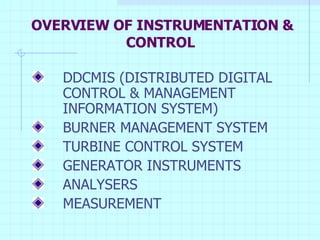

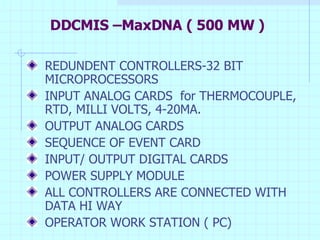

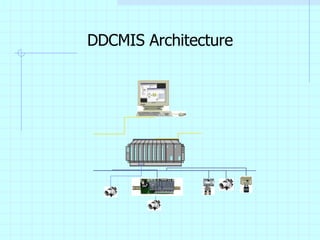

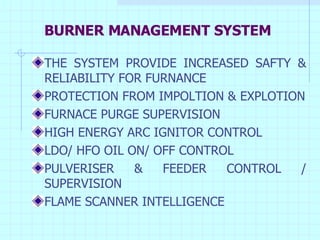

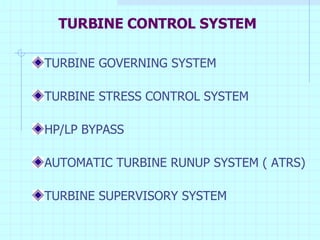

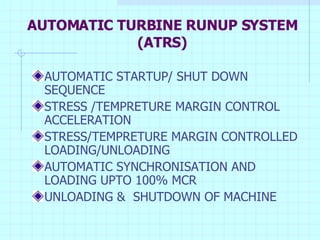

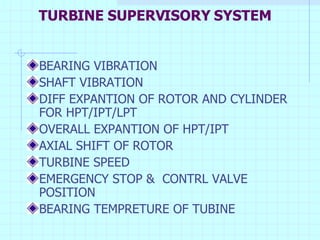

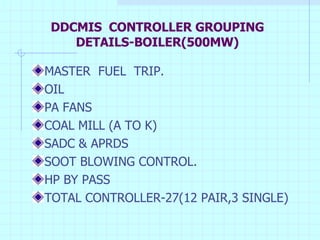

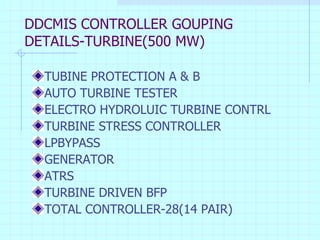

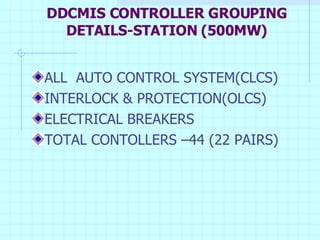

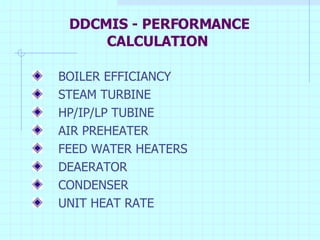

The document discusses instrumentation and control systems used in thermal power plants. It describes the objectives of instrumentation and control which include safe and efficient plant operation. It provides an overview of the Distributed Digital Control and Management Information System (DDCMIS) and its components, including the burner management system, turbine control system, and generator instruments. It explains the various functions, measurements, controls, and benefits provided by the DDCMIS.