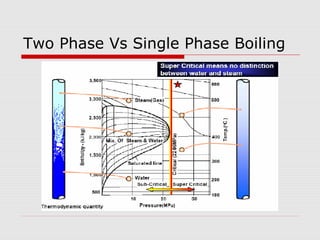

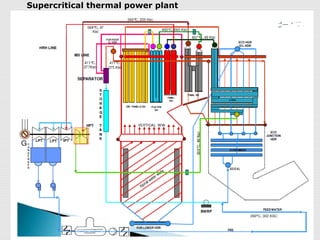

1. Supercritical boilers operate above the critical pressure of water (221 bar), where there is no distinction between water and steam.

2. Operating above the critical pressure provides benefits like higher cycle efficiency, lower fuel consumption and emissions, and improved load change flexibility compared to subcritical boilers.

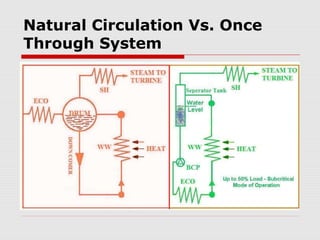

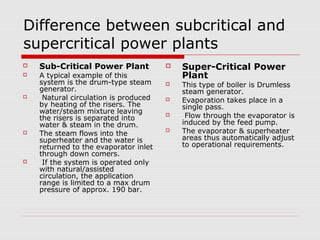

3. The key difference between subcritical and supercritical boilers is that supercritical boilers are drumless, with evaporation occurring in a single pass and flow induced by the feed pump rather than natural circulation.

![Increase of Cycle Efficiency due to

Steam Parameters

300

241

175 538 / 538

538 / 566

566 / 566

580 / 600

600 / 620

6,77

5,79

3,74

5,74

4,81

2,76

4,26

3,44

1,47

3,37

2,64

0,75

2,42

1,78

0

0

1

2

3

4

5

6

7

8

9

10

HP / RH outlet temperature [deg. C]Pressure [bar]

Increase of efficiency [%]](https://image.slidesharecdn.com/supercriticalboiler-140821064600-phpapp02/85/Super-critical-boiler-18-320.jpg)