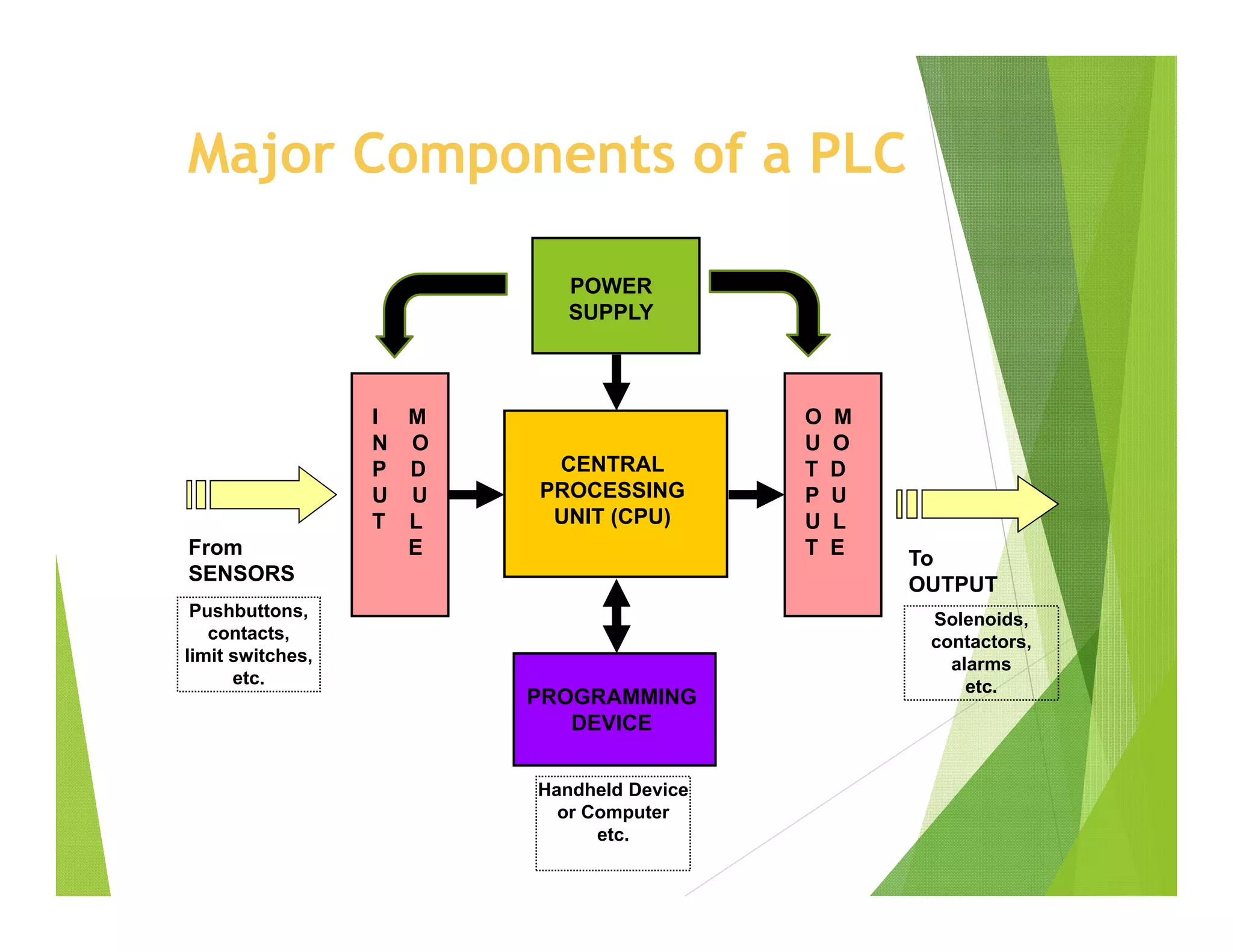

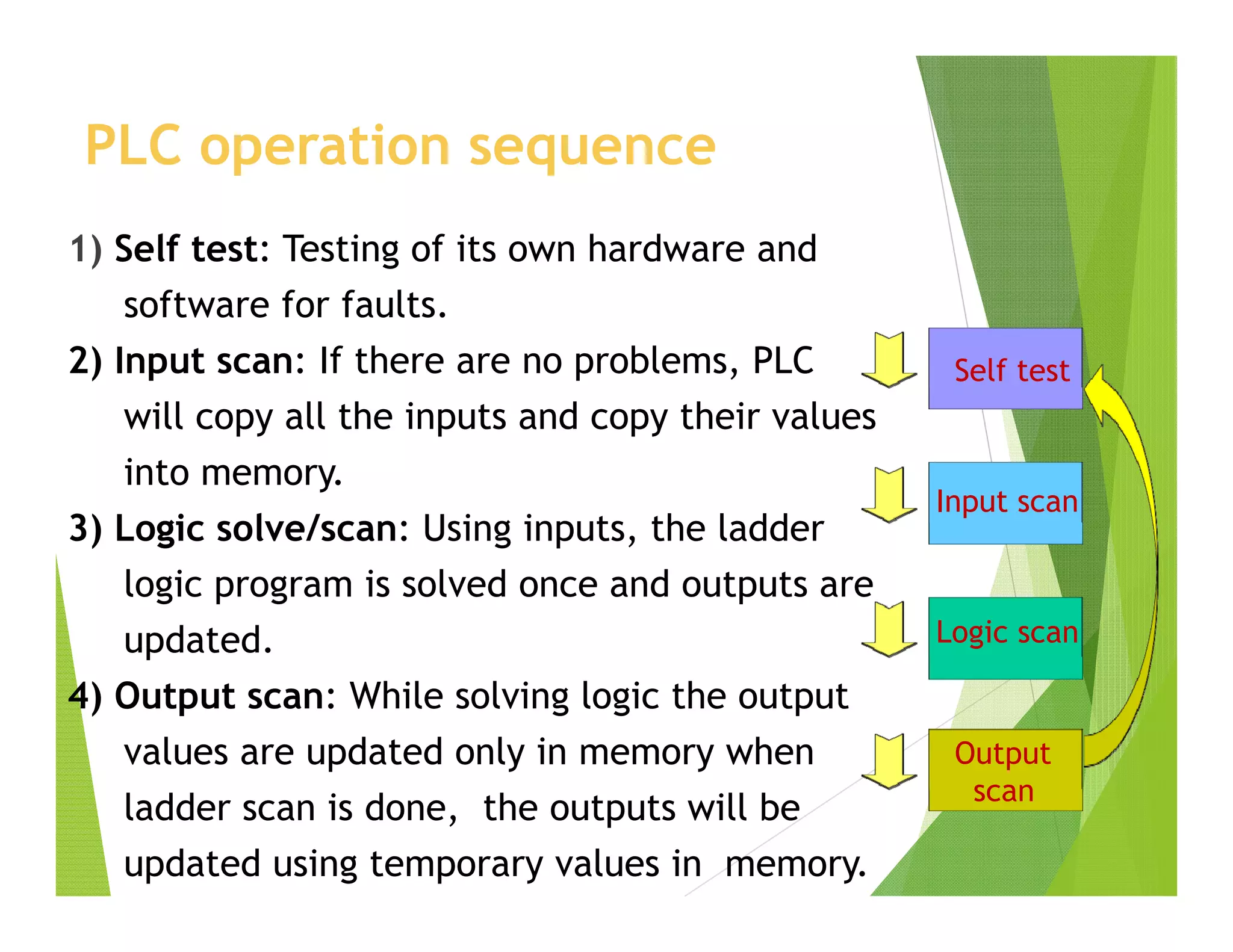

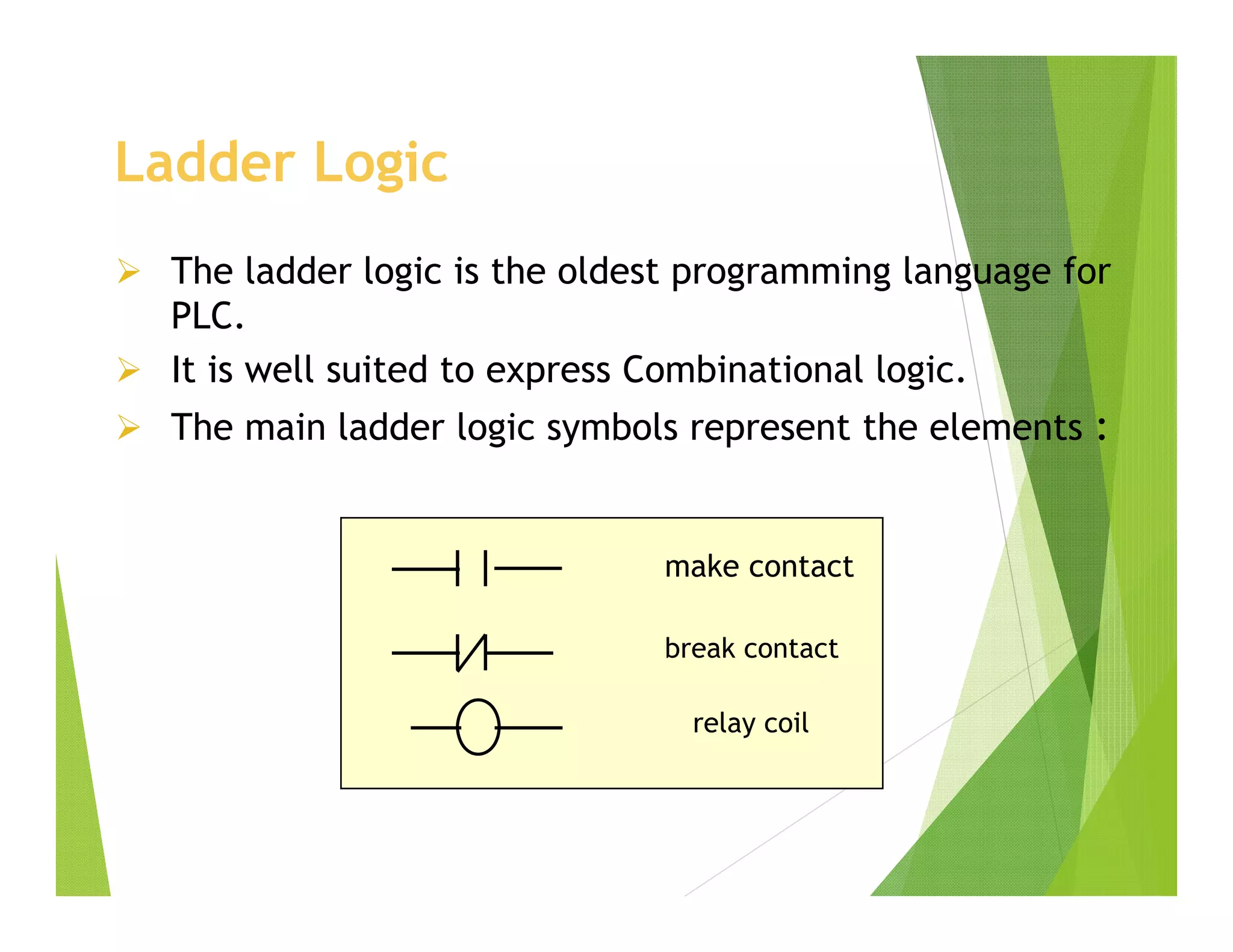

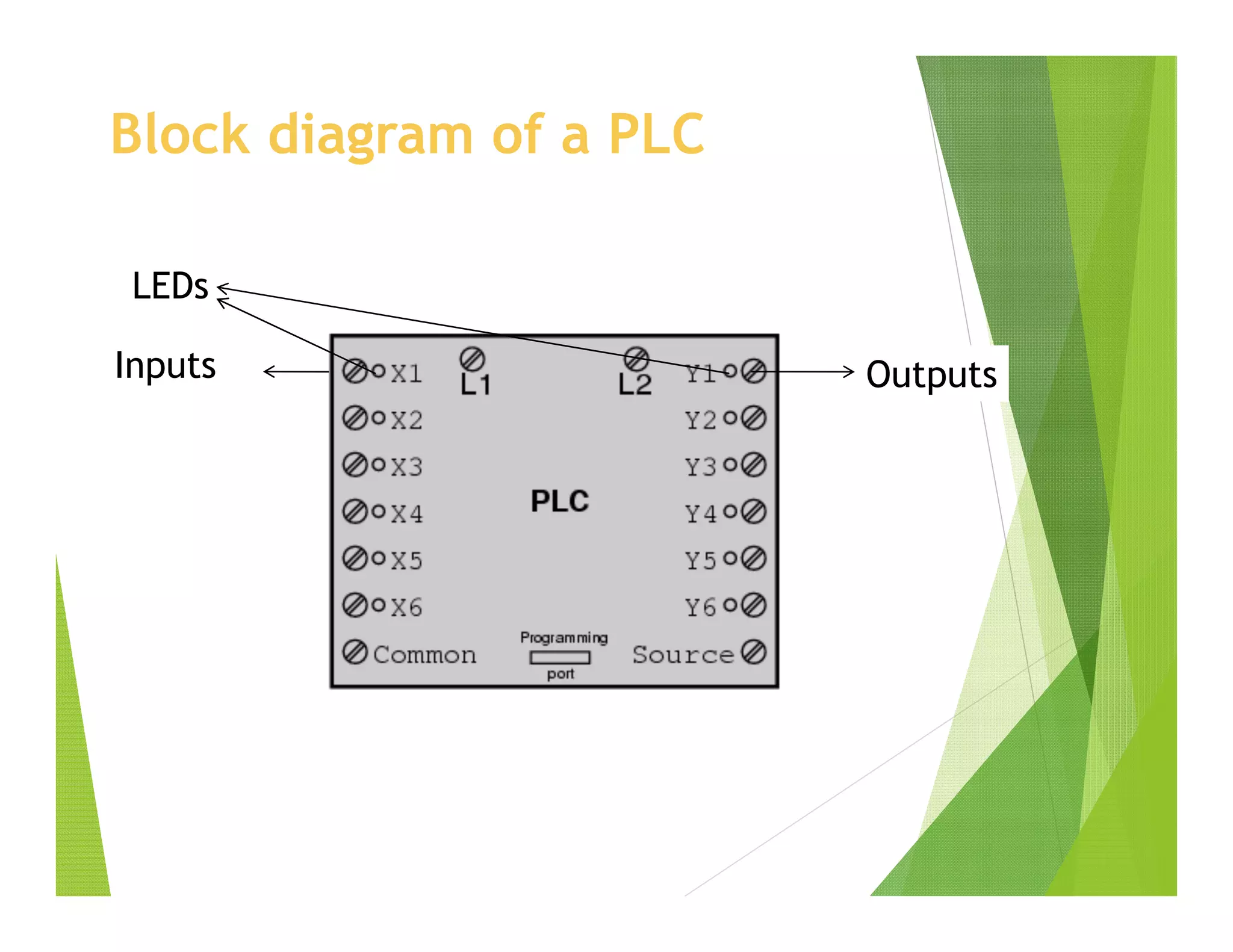

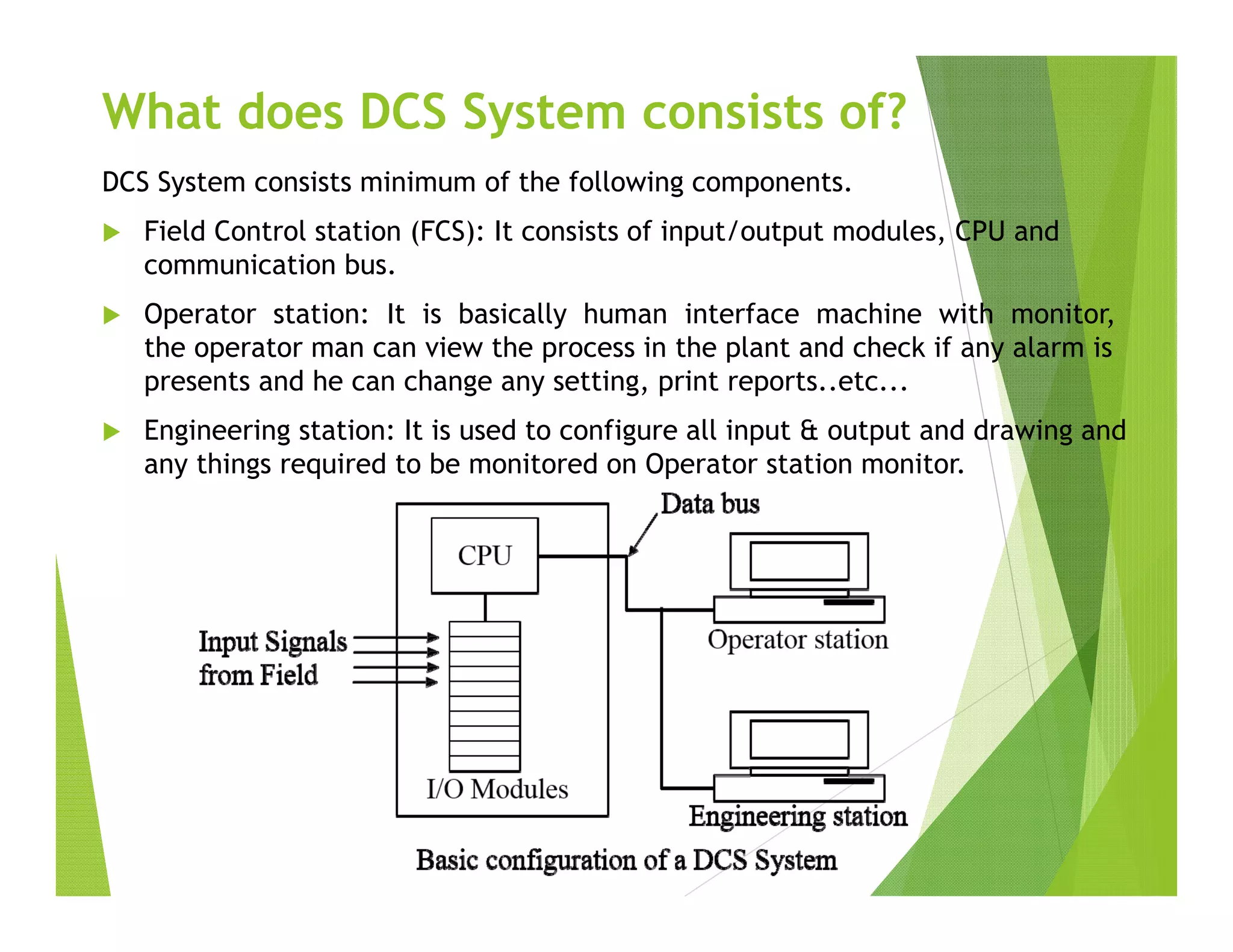

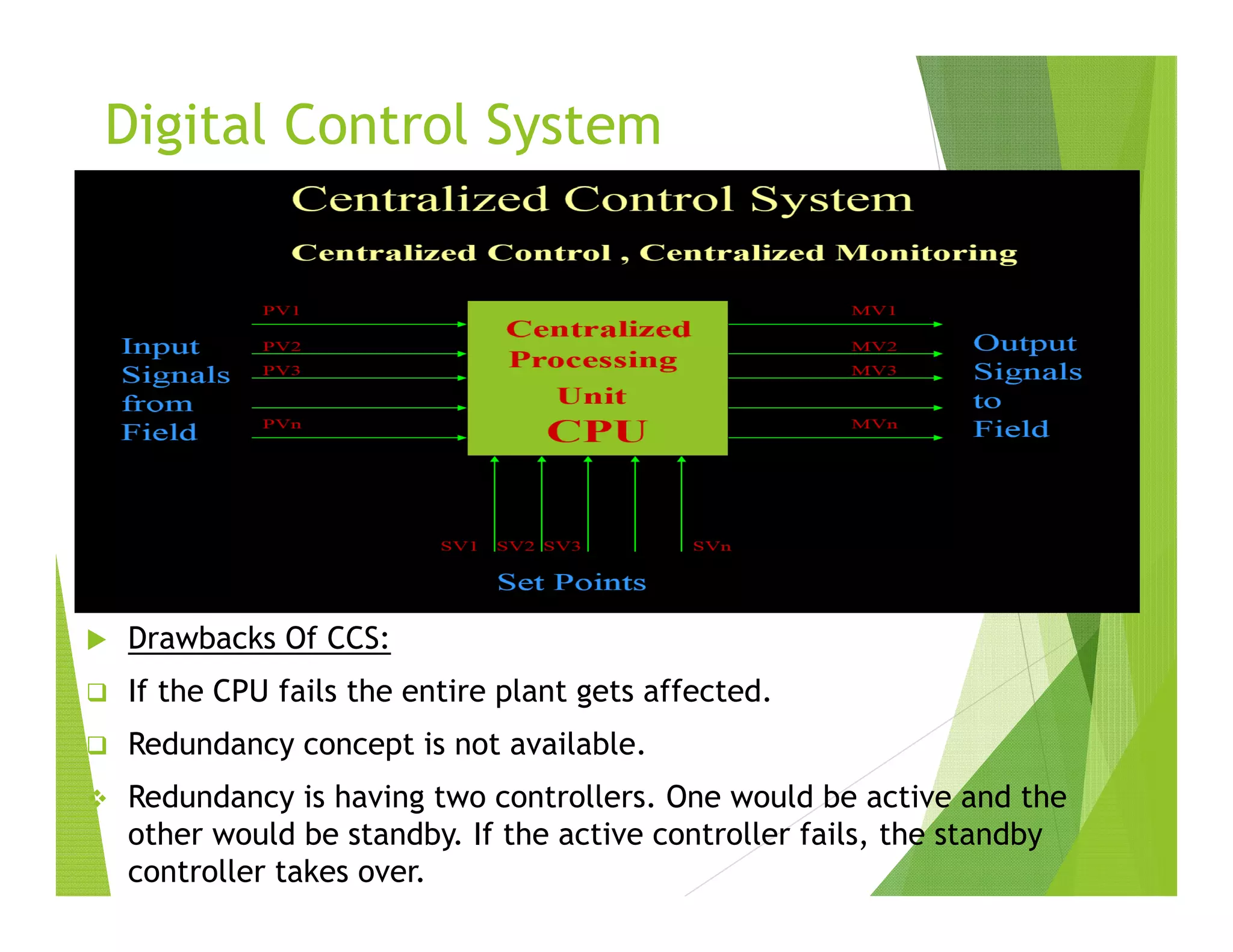

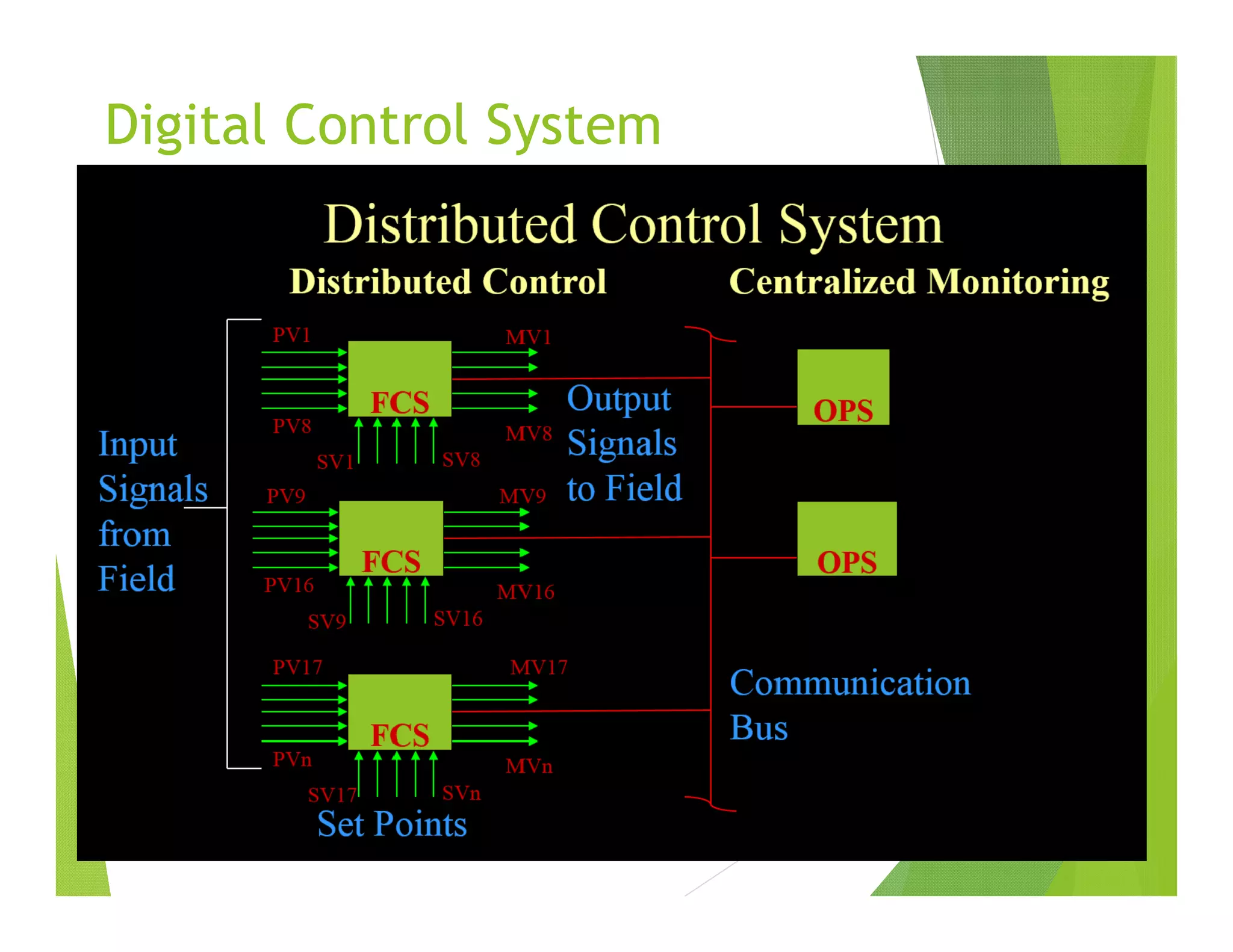

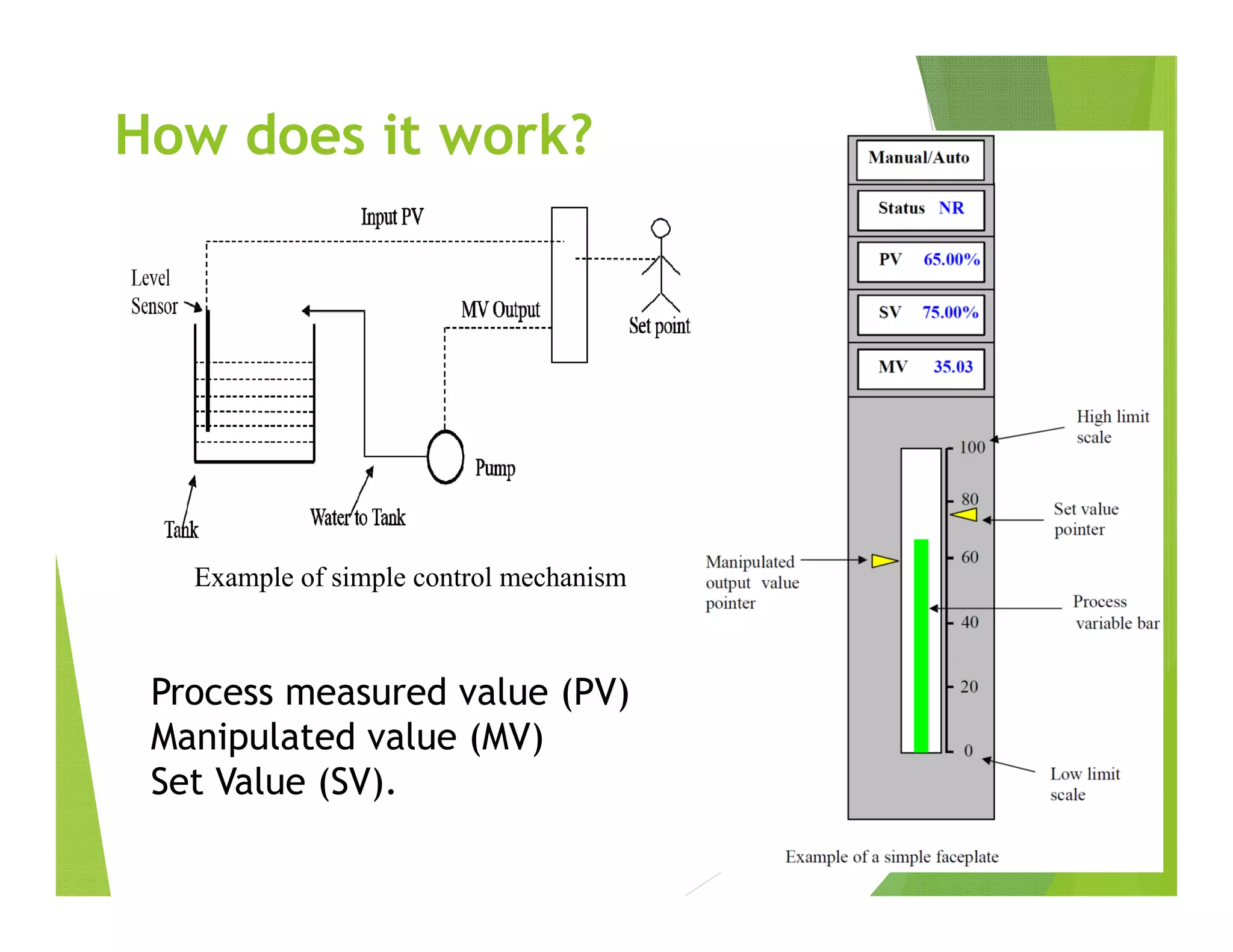

The document provides information about programmable logic controllers (PLCs) and distributed control systems (DCSs). It discusses the history and components of PLCs, including the central processing unit, input and output modules, power supply, and programming languages. DCSs are described as systems that divide plant control into areas managed by individual controllers connected by a communication network. Key advantages of DCSs include reliability, redundancy, flexibility in configuration, and ease of maintenance. The document compares PLCs and DCSs, noting that DCSs are more suitable for large-scale, complex plant control applications.