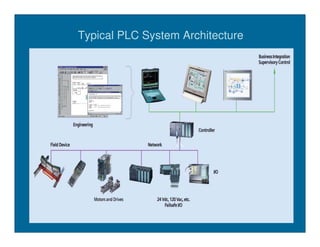

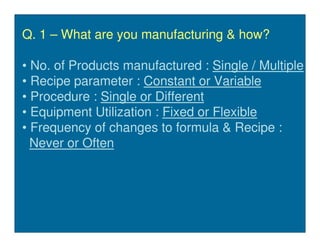

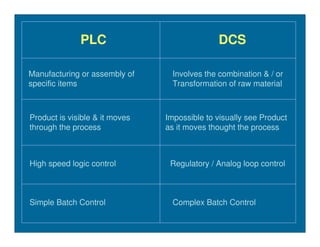

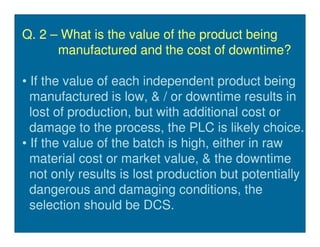

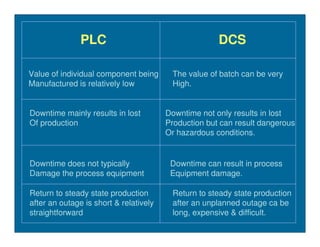

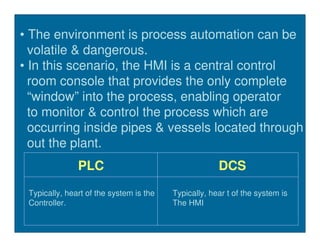

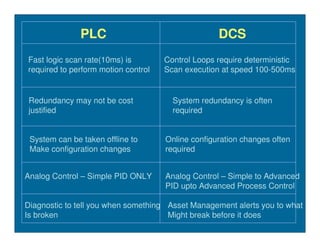

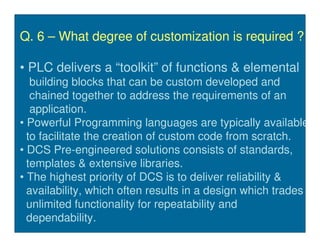

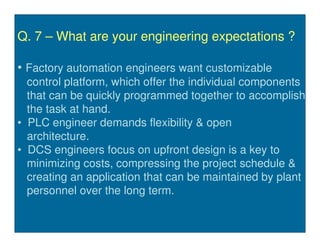

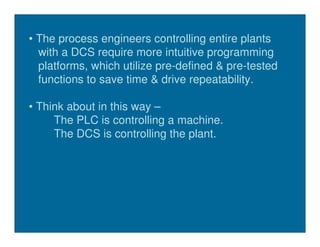

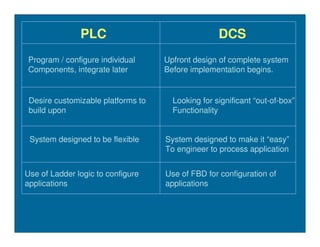

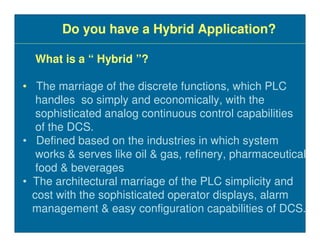

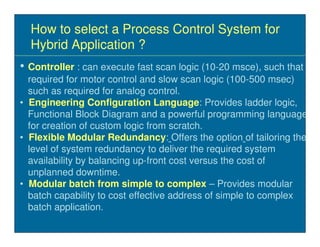

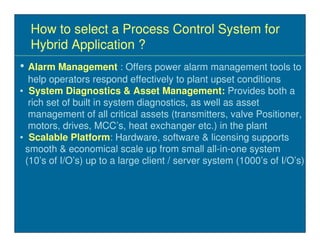

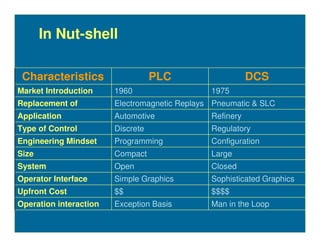

This document discusses the differences between programmable logic controllers (PLCs) and distributed control systems (DCSs) in order to help determine which type of system is best suited for different applications. It outlines seven key questions to consider regarding the manufacturing process, product value, system requirements, operator needs, engineering expectations, and whether the application is hybrid in nature. PLCs are generally better for discrete and simple batch control, while DCSs are more suitable for complex batch processes and facilities that require flexibility and recipe management where system availability is critical. A hybrid system may be needed if an application requires both fast logic control and regulatory analog loop control.

![References :

[1] Bob Nelson, “Making the Right Choice for

Process Industry”, Control Engineering Asia,

October-2008.

[2] “Process Automation”, SIEMENS Energy &

Automation.

[3] “Hybrid Control Identity Crisis: What's in a

Name?”, In-Tech Sept. 2007.

[4] Rich Merritt, “Does DCS have A Future?

If so, is it HMI/SCADA”, Control- Dec. 2008.](https://image.slidesharecdn.com/dcsorplc-090902011037-phpapp01/85/DCS-Or-PLC-30-320.jpg)