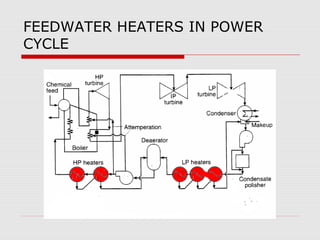

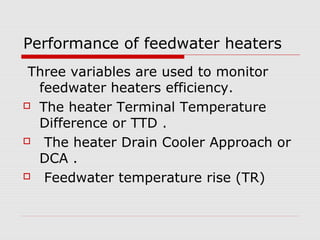

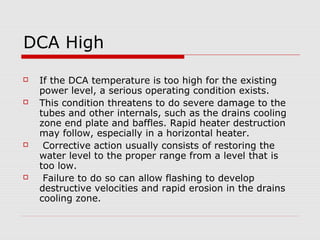

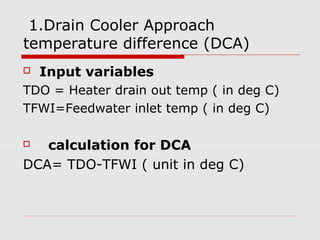

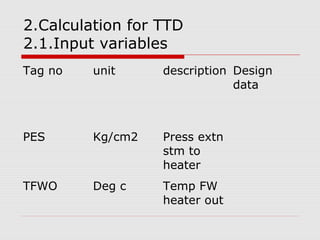

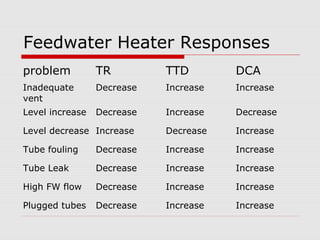

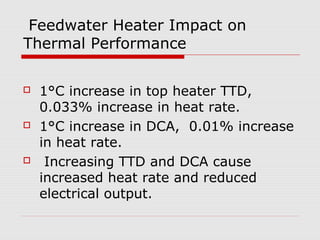

This document discusses the performance calculation and monitoring of feedwater heaters in thermal power plants. There are three key variables used to monitor feedwater heater efficiency: terminal temperature difference (TTD), drain cooler approach (DCA), and feedwater temperature rise (TR). The TTD measures how close the outlet water temperature is to the saturation temperature, and a higher TTD indicates poorer performance. The DCA measures how close the drain outlet temperature is to the inlet water temperature, and a higher DCA can cause damage. These variables are calculated and trended monthly to monitor heater performance and identify any issues.