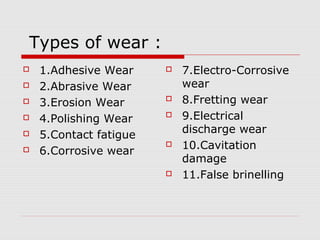

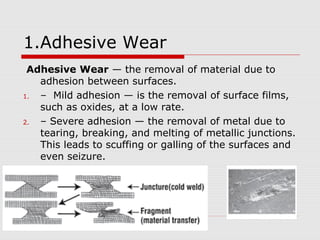

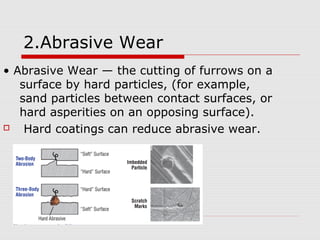

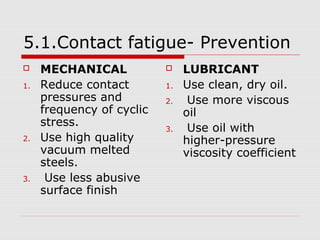

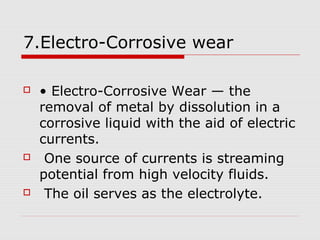

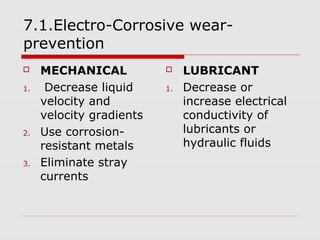

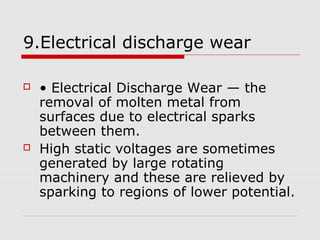

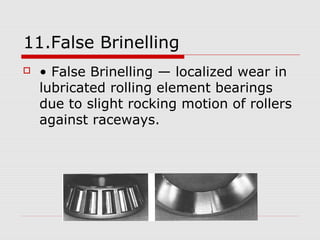

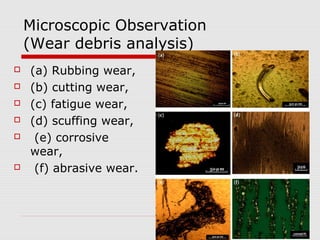

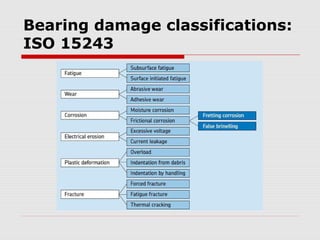

This document discusses various types of wear mechanisms that can occur in machines. It defines 11 main types of wear: adhesive, abrasive, erosion, polishing, contact fatigue, corrosive, electro-corrosive, fretting, electrical discharge, cavitation, and false brinelling wear. For each type of wear, it describes the wear process and provides recommendations for both mechanical and lubricant-based prevention methods. Microscopic analysis of wear debris is also discussed as a way to determine the specific type of wear that occurred.