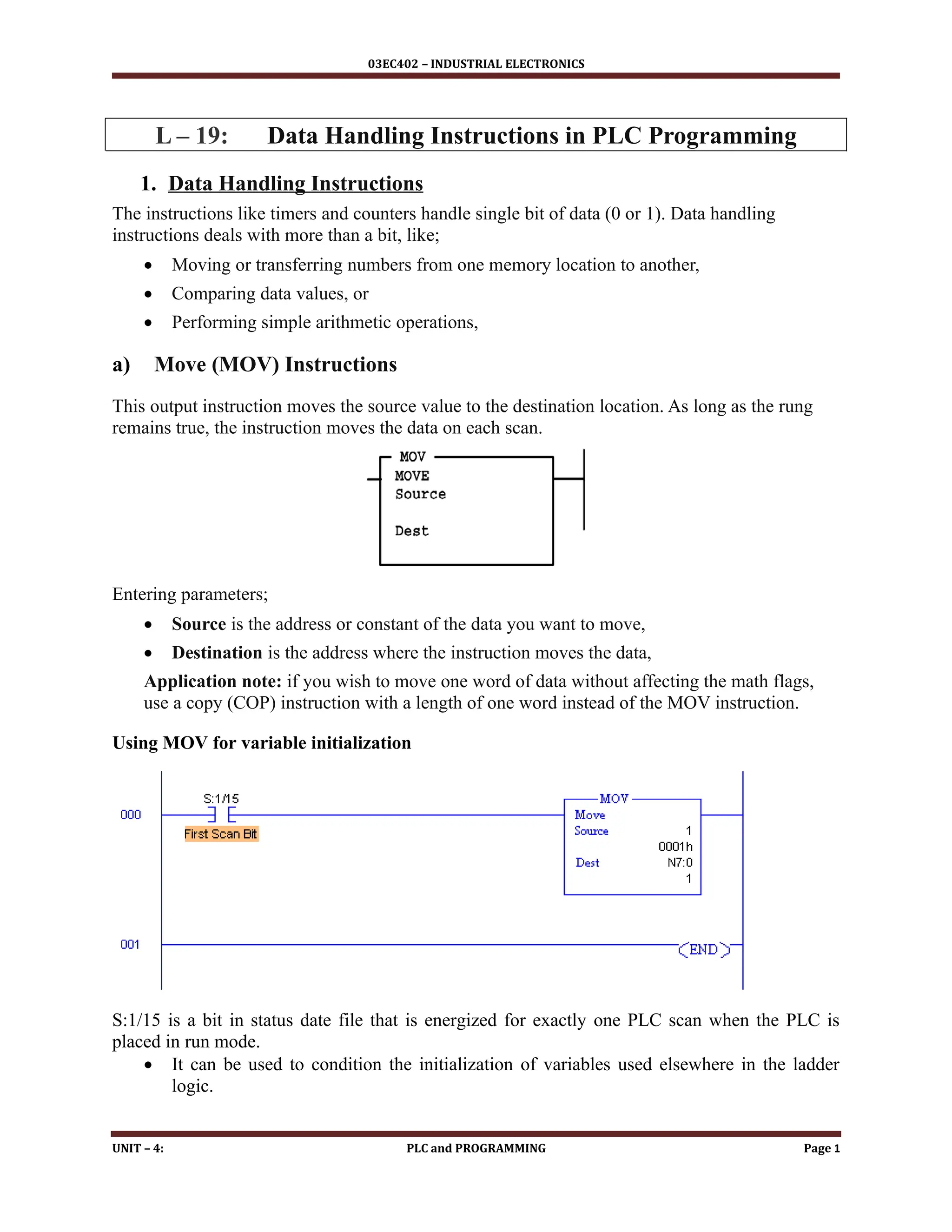

The document outlines various data handling instructions in PLC programming, including moving and masking data, performing logical operations, and executing math functions within ladder logic. It also covers jump instructions for controlling program flow and master control reset (MCR) instructions for managing program zones. Additionally, temporary end (TND) and suspend (SUS) instructions are discussed for controlling the processor's execution behavior.