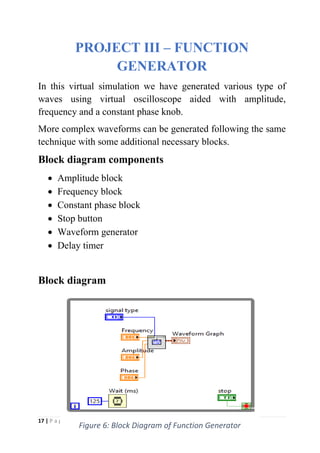

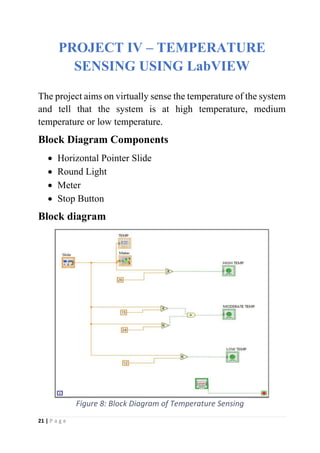

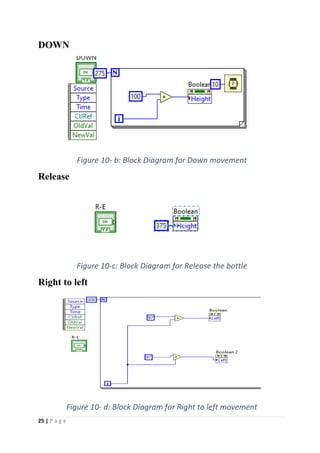

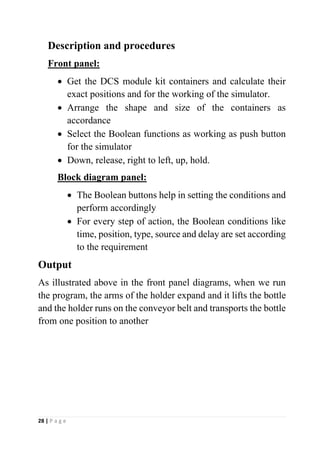

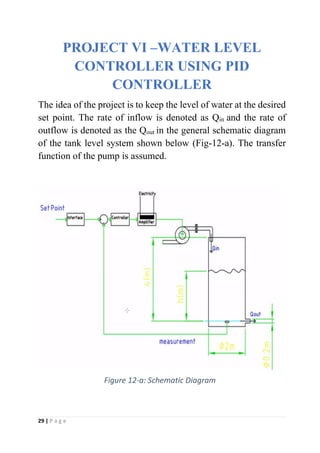

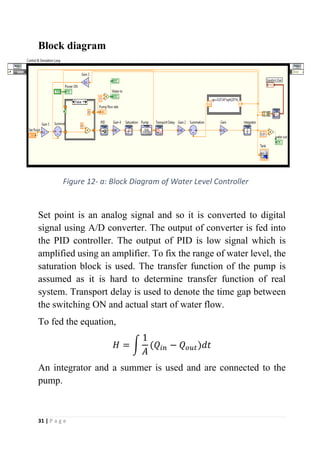

The document describes a virtual automation internship project completed using LabVIEW. It includes 6 mini projects: 1) a dice simulation; 2) a fan speed controller; 3) a function generator; 4) temperature sensing; 5) a bottle transporting robotic arm; and 6) a water level controller using a PID system. The intern gained experience in fields like data acquisition, instrument control, and industrial automation during the 45-day internship period. Completing the projects provided hands-on learning of concepts in LabVIEW, a graphical programming platform commonly used for automation.