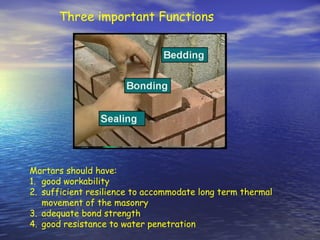

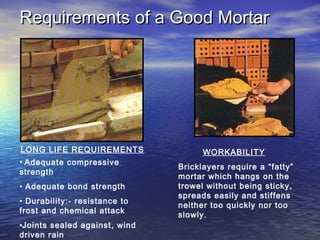

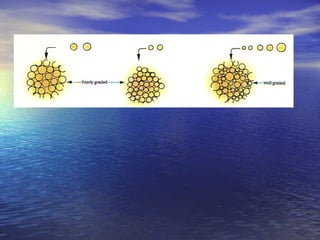

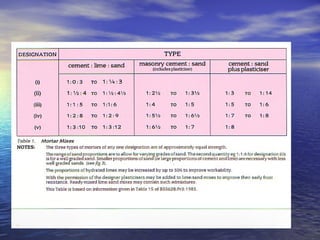

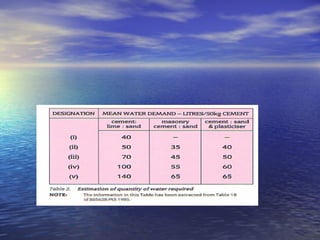

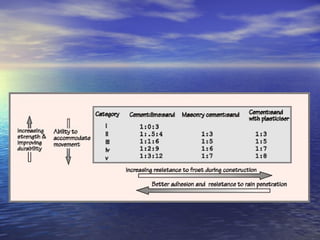

This document outlines the key functions and requirements of a good mortar mix. It explains that mortar cements bricks together to provide stability and seal gaps to resist weather penetration while accommodating irregularities. Good workability, resilience to movement, adequate bond strength, and resistance to water are important. Proper mixing and workmanship can improve sealing. The document also provides information on calculating mortar quantities for wall areas.