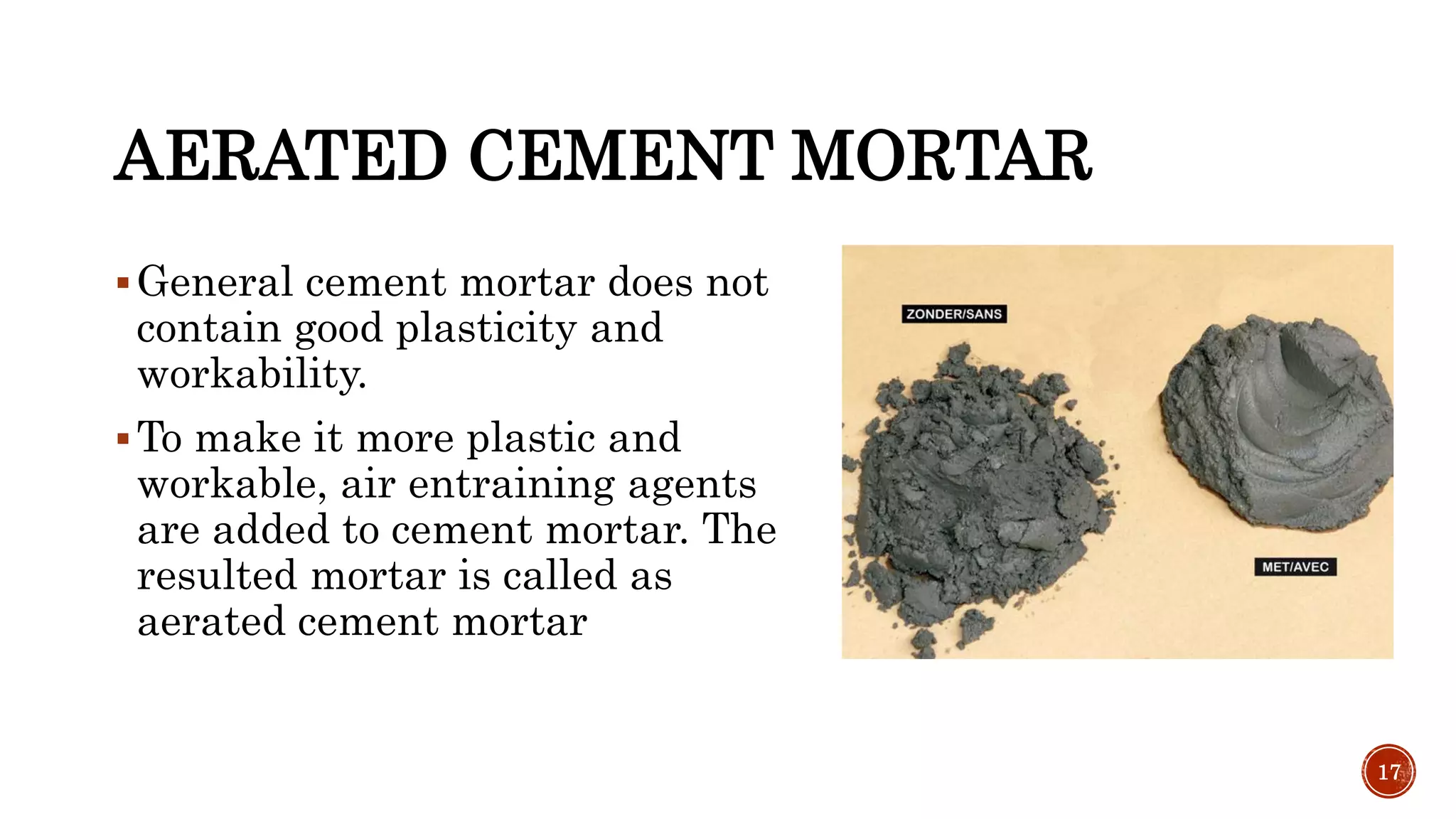

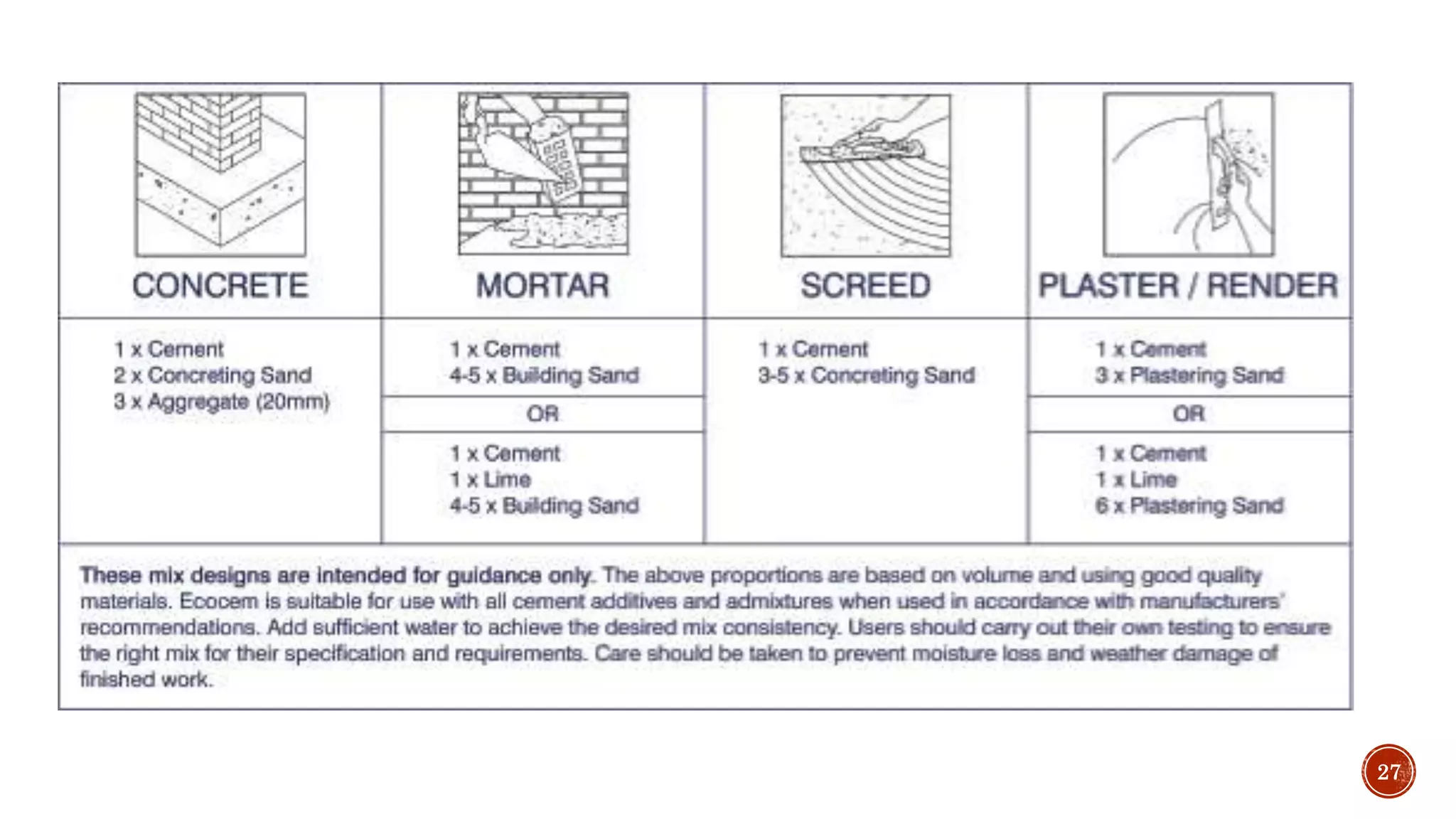

Mortar is a material used in masonry construction to bind bricks, blocks, and stones together. It provides strength and stability to walls. Mortar is a mixture of sand, a binding material like cement or lime, and water. The binding material determines the mortar type, such as cement mortar, lime mortar, or gypsum mortar. Mortars can also be classified based on density or special purpose, including fire resistant, sound absorbing, or chemical resistant mortars. The proper selection of mortar type depends on factors like durability, weather conditions, and intended use.