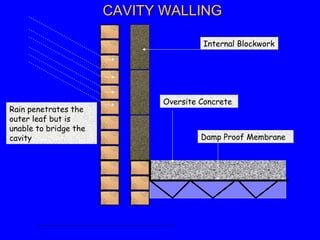

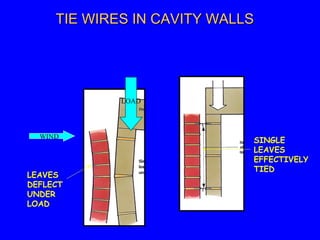

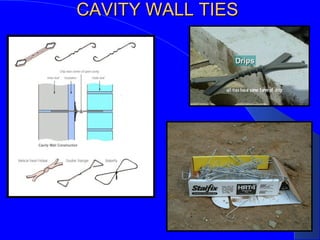

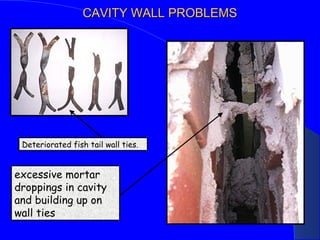

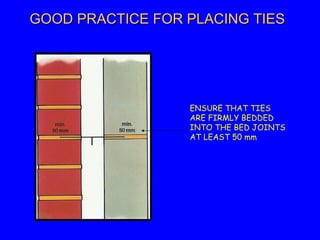

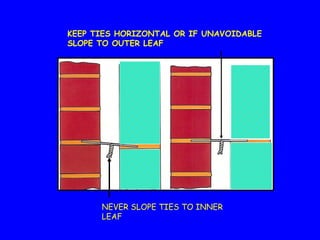

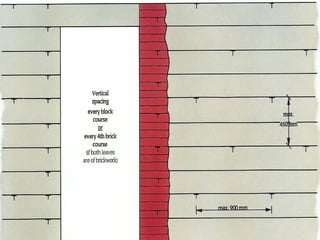

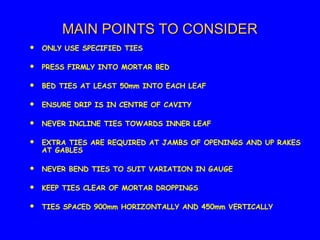

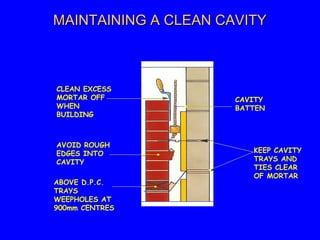

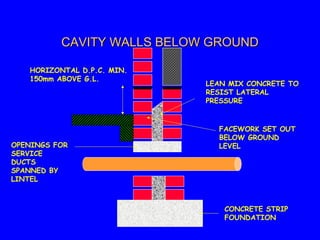

This document discusses cavity wall construction. It describes how to maintain a clean cavity, properly bed wall ties, and treat openings. Four types of wall ties are shown. Cavity walls are more rain resistant and better insulated than single skins, but require good design and workmanship. Ties should be spaced regularly and bedded firmly in mortar at least 50mm into each leaf. The cavity must be kept clear of mortar droppings to prevent deterioration of the ties.