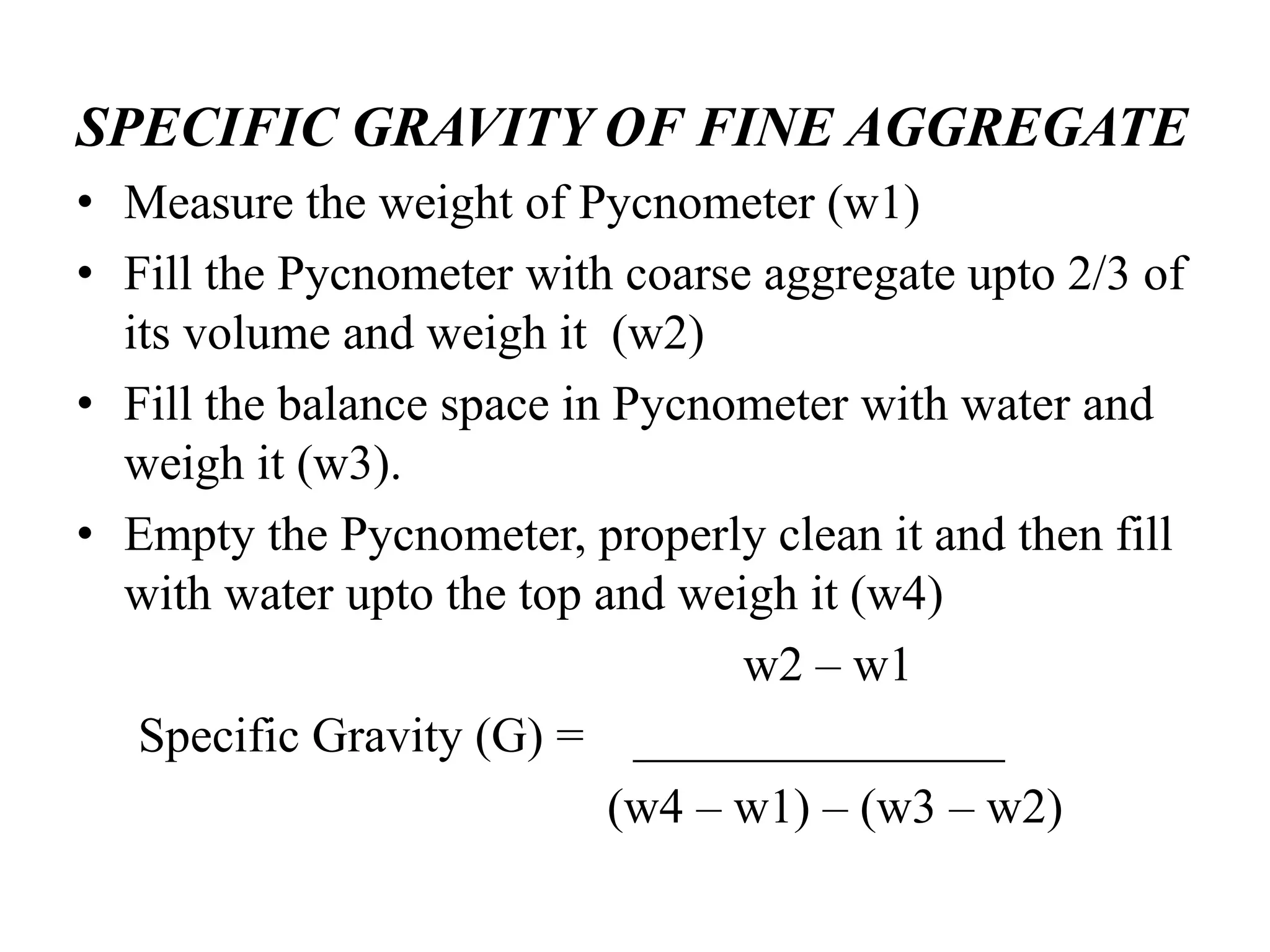

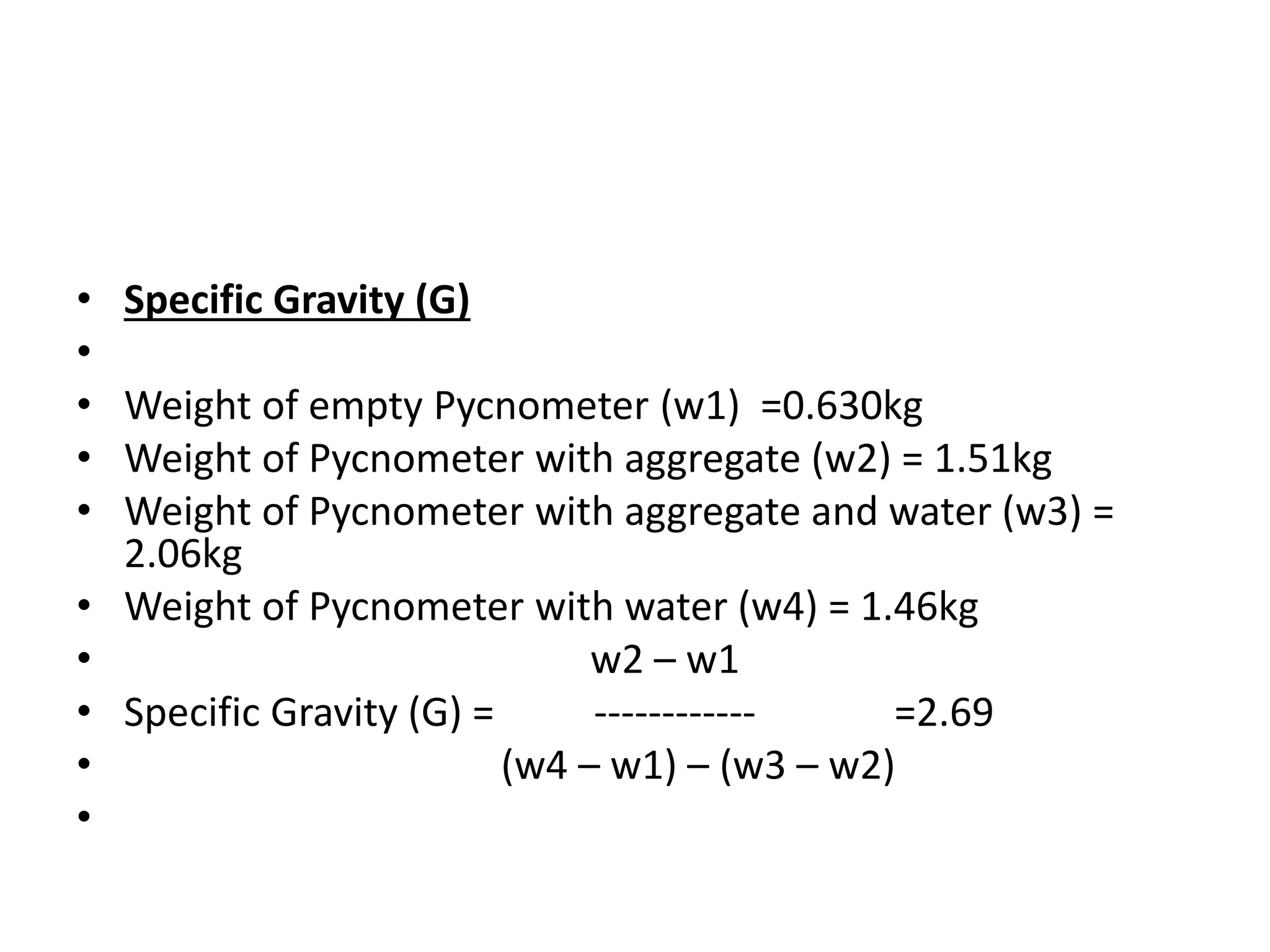

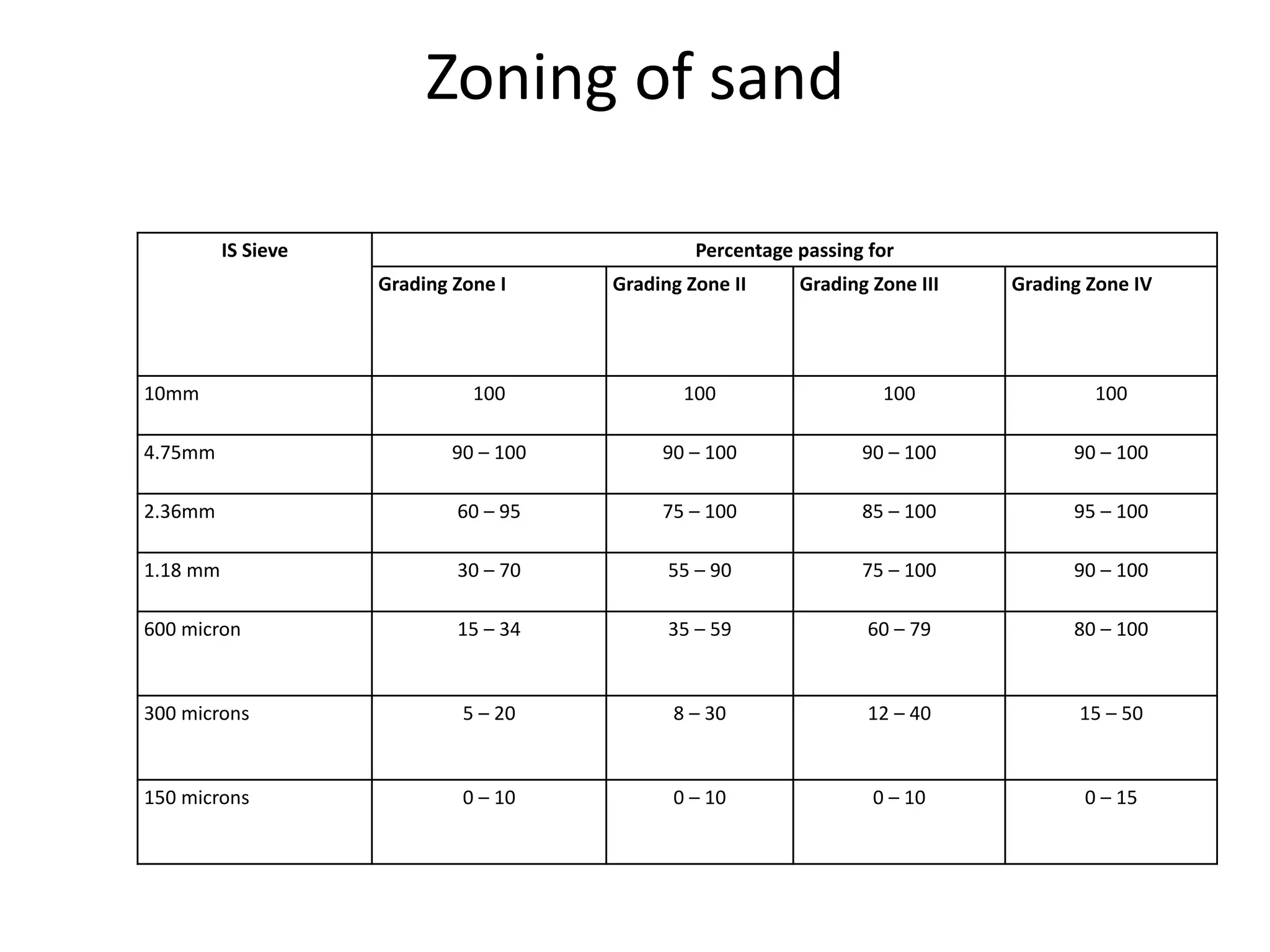

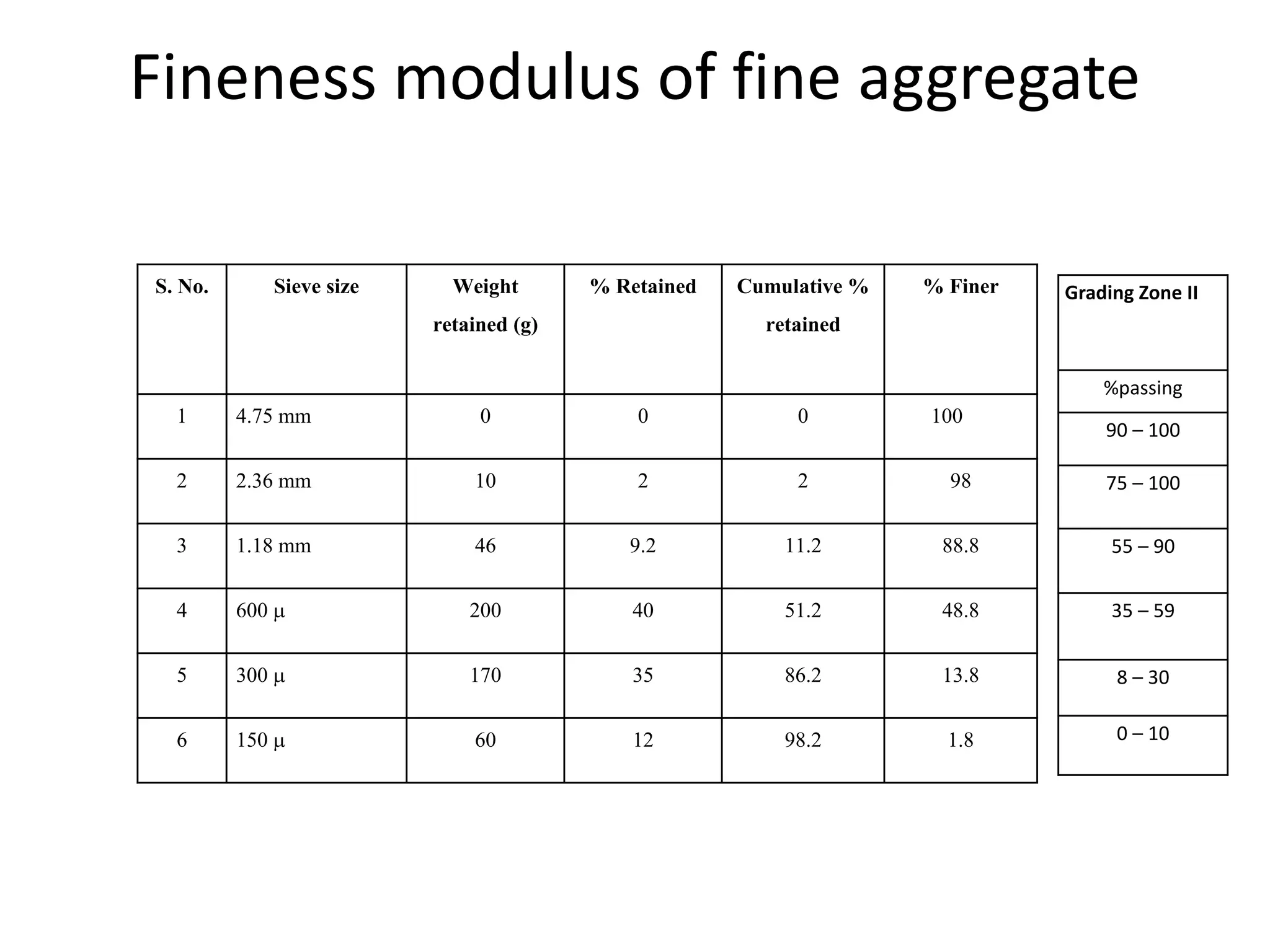

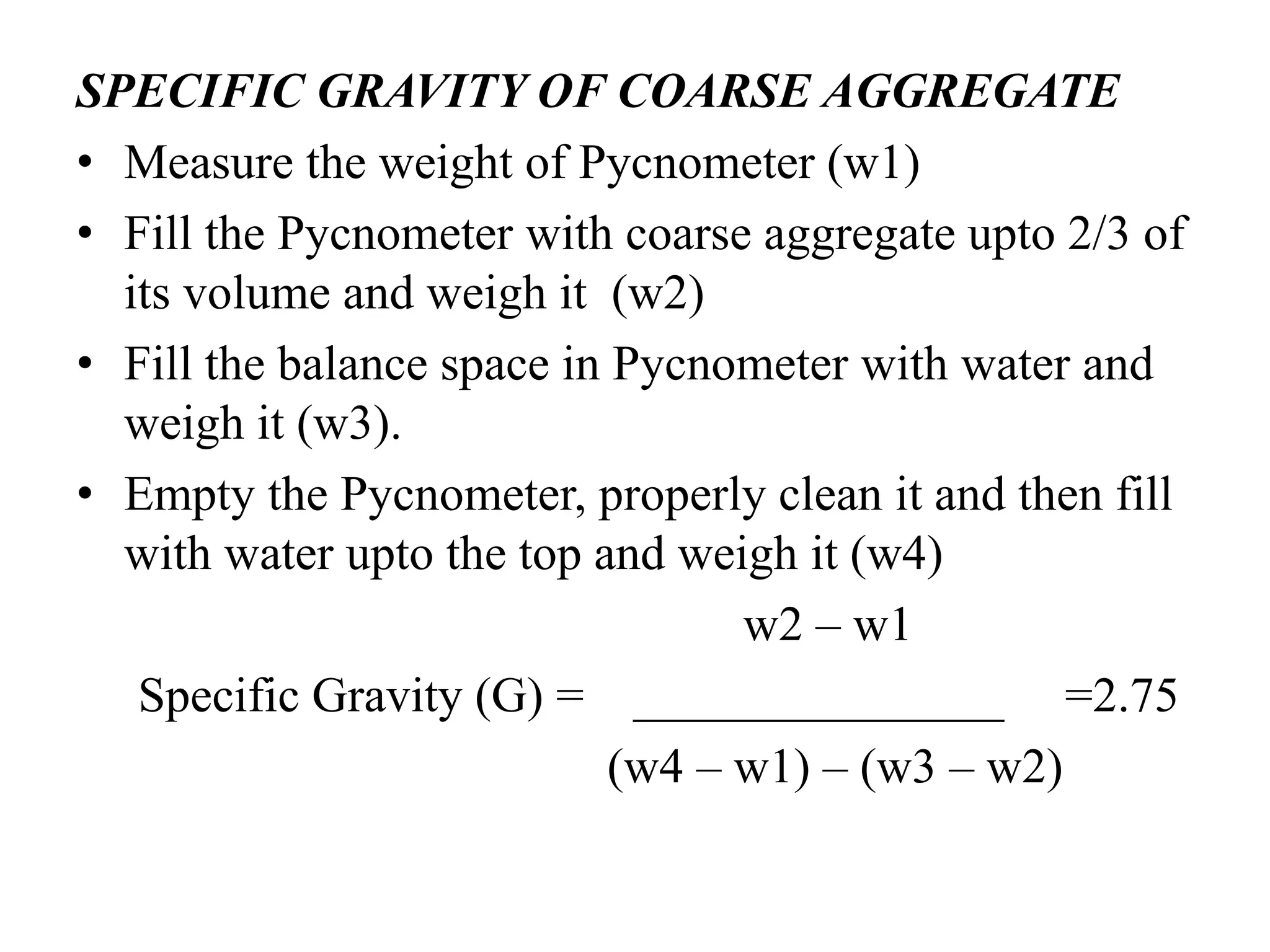

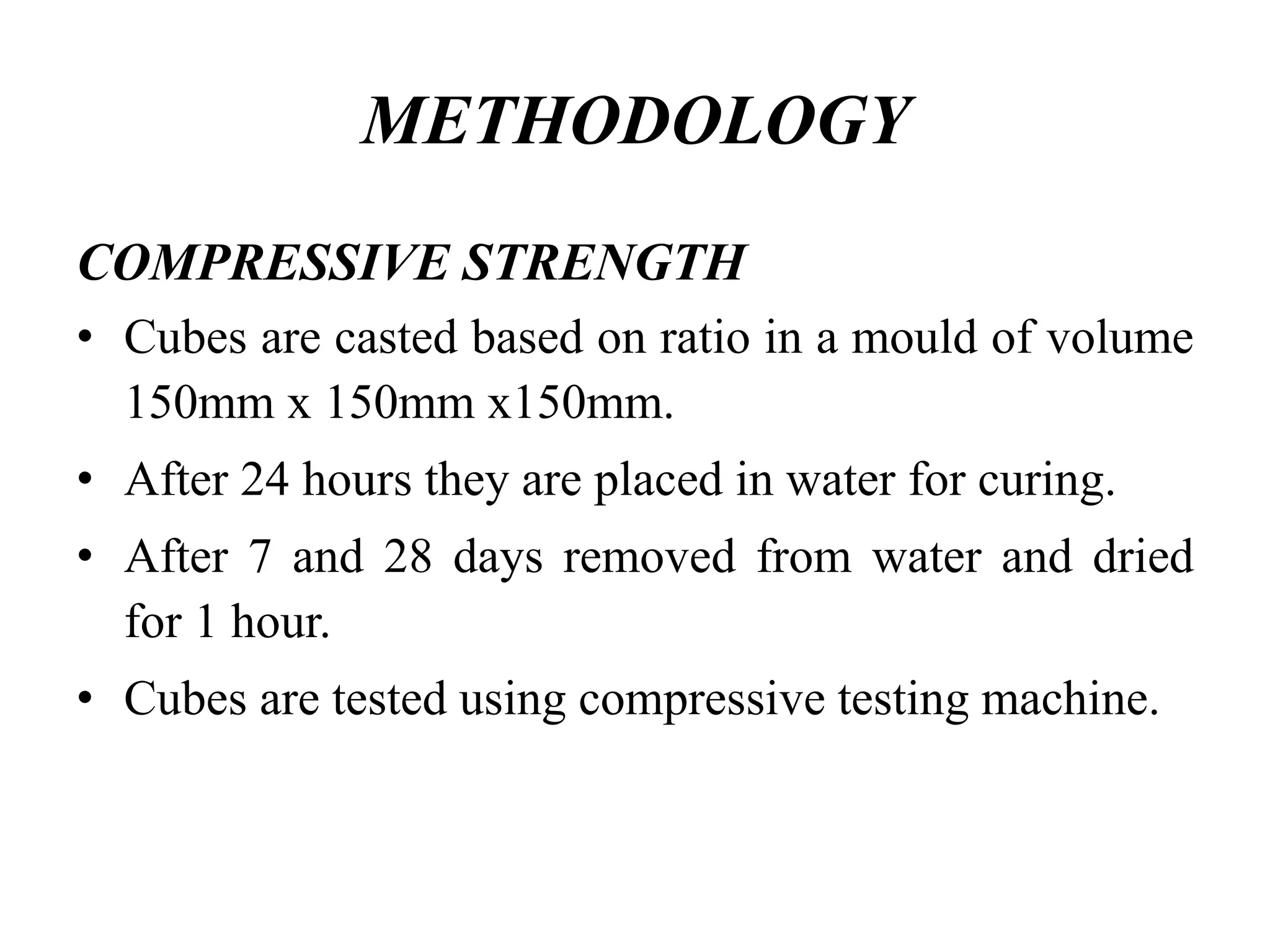

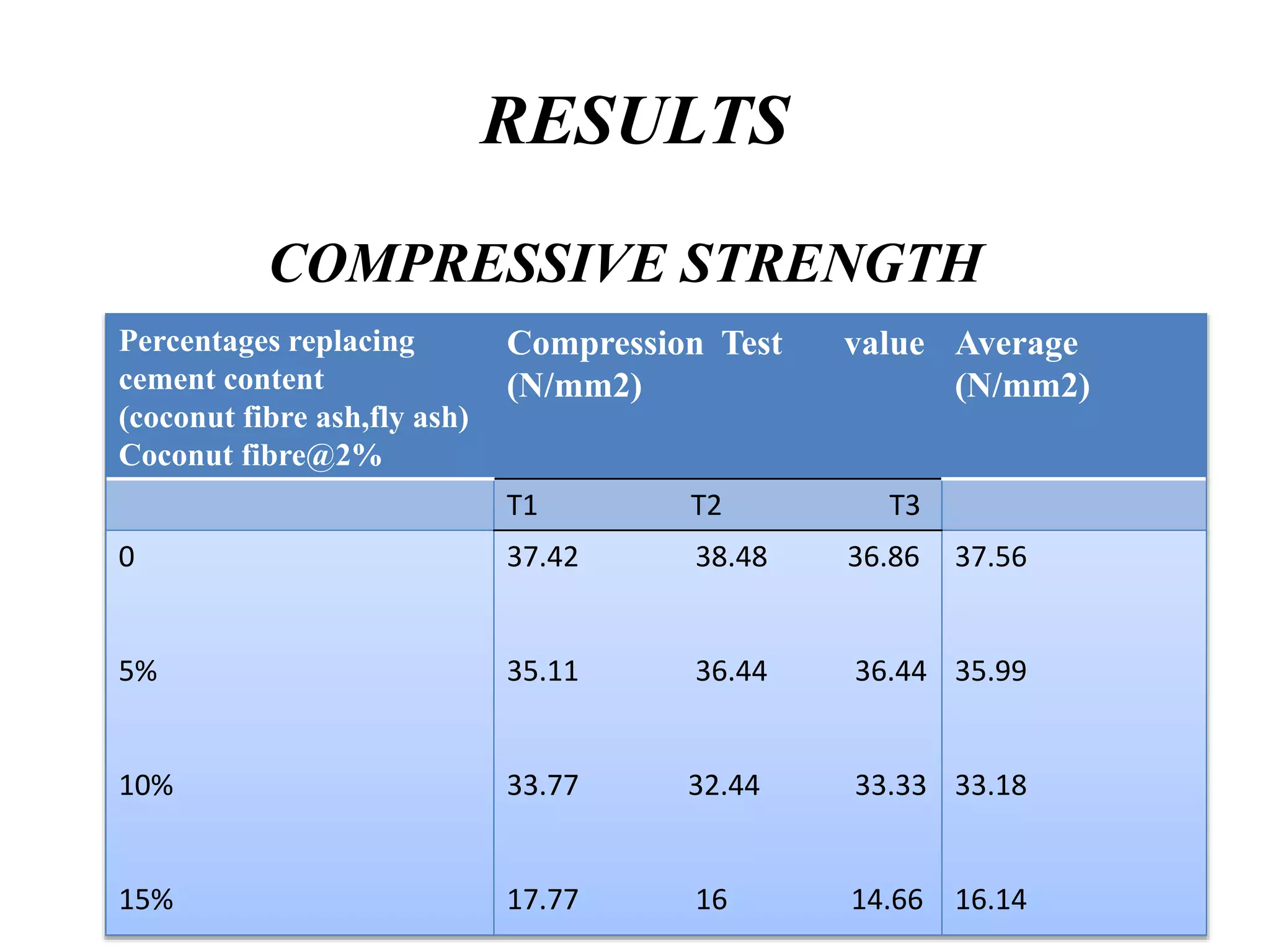

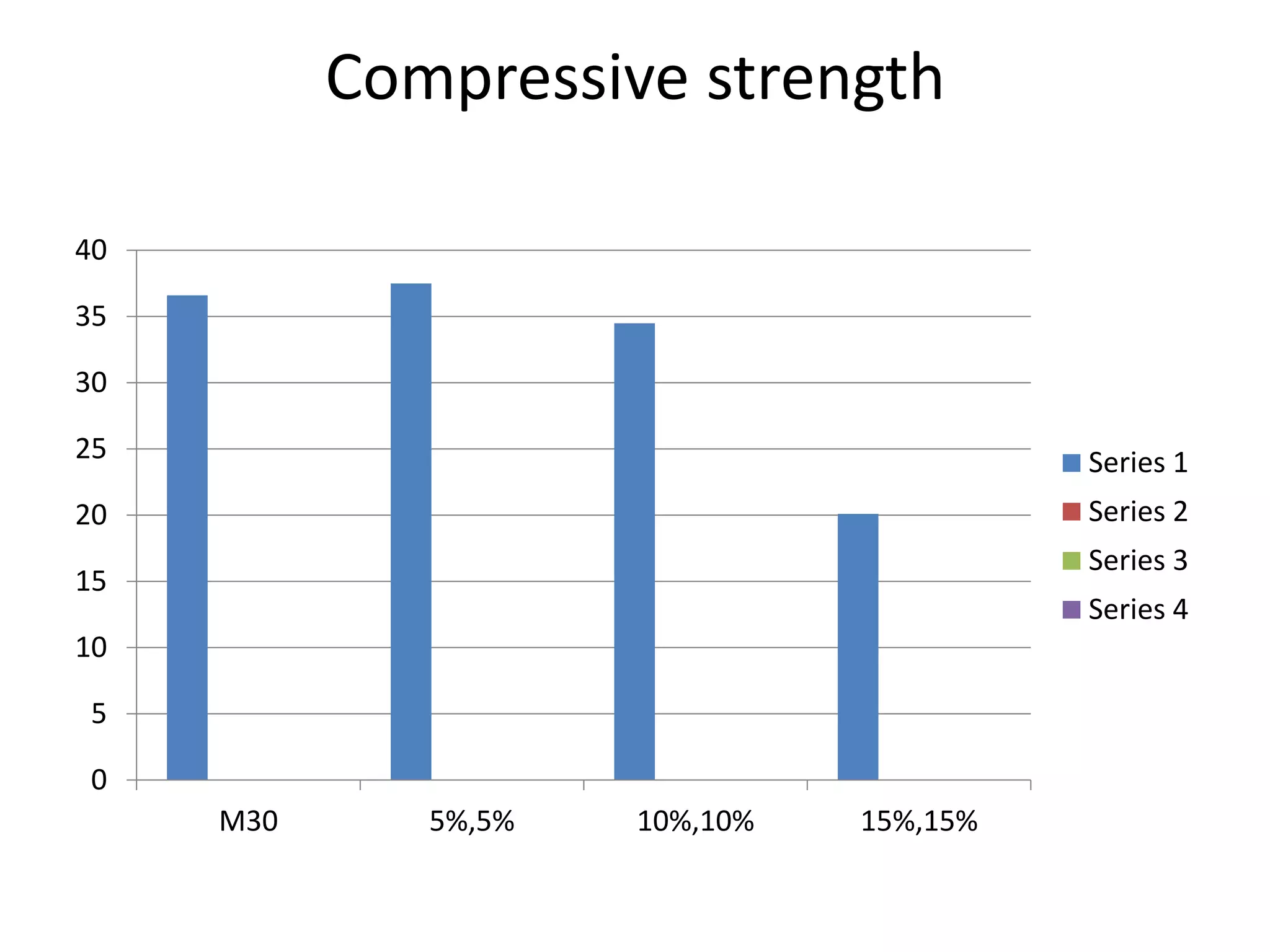

The document details the methodology and results of an experiment on the properties of blended cements using fly ash and coconut fibre ash in making M30 grade concrete. It includes procedures for measuring specific gravity of aggregates, compressive strength, and flexural strength of concrete mixtures with varying percentages of these materials. Results indicated that up to 10% replacement of cement with these materials was effective in maintaining strength levels above a standard M30 mix.

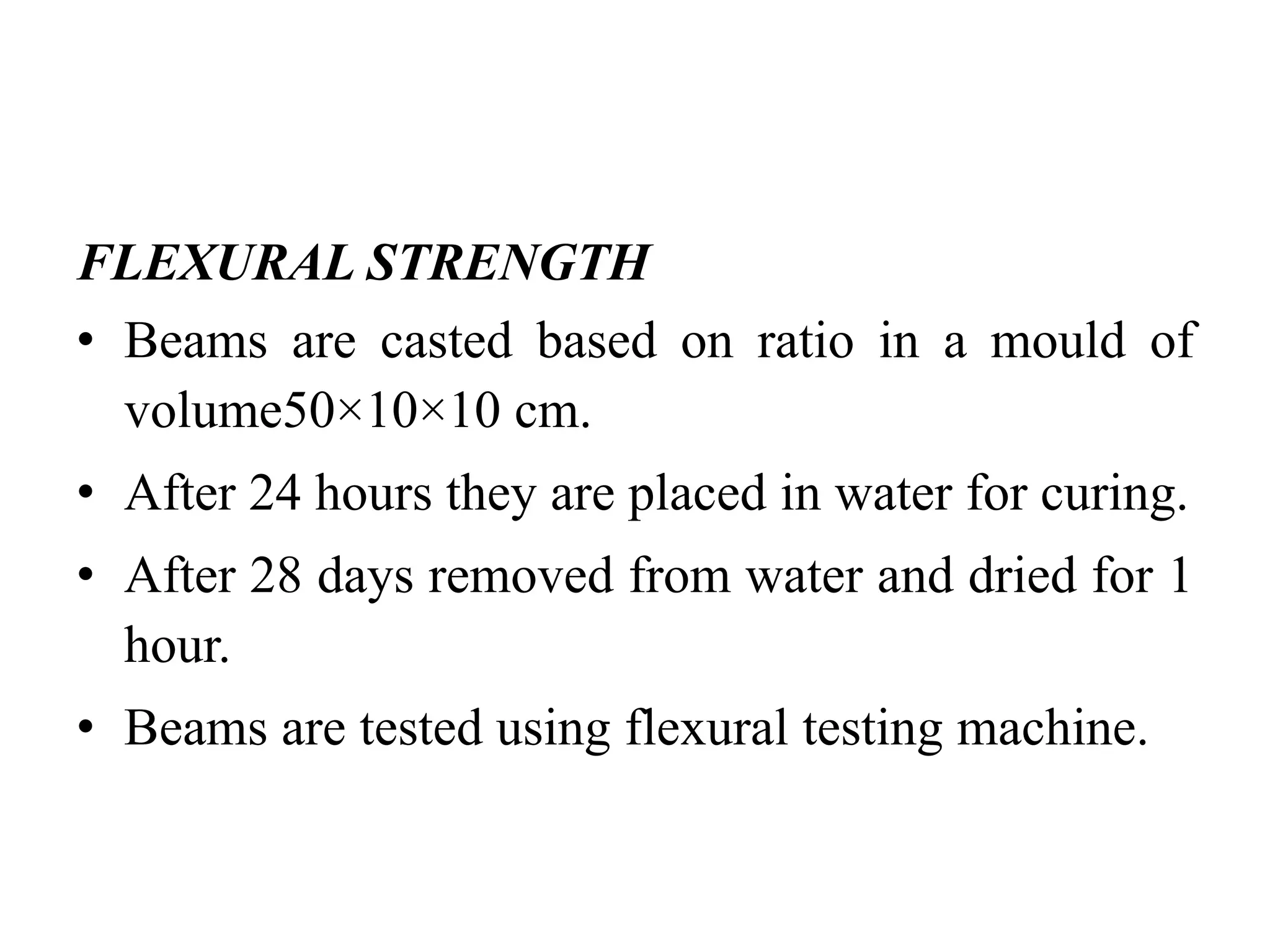

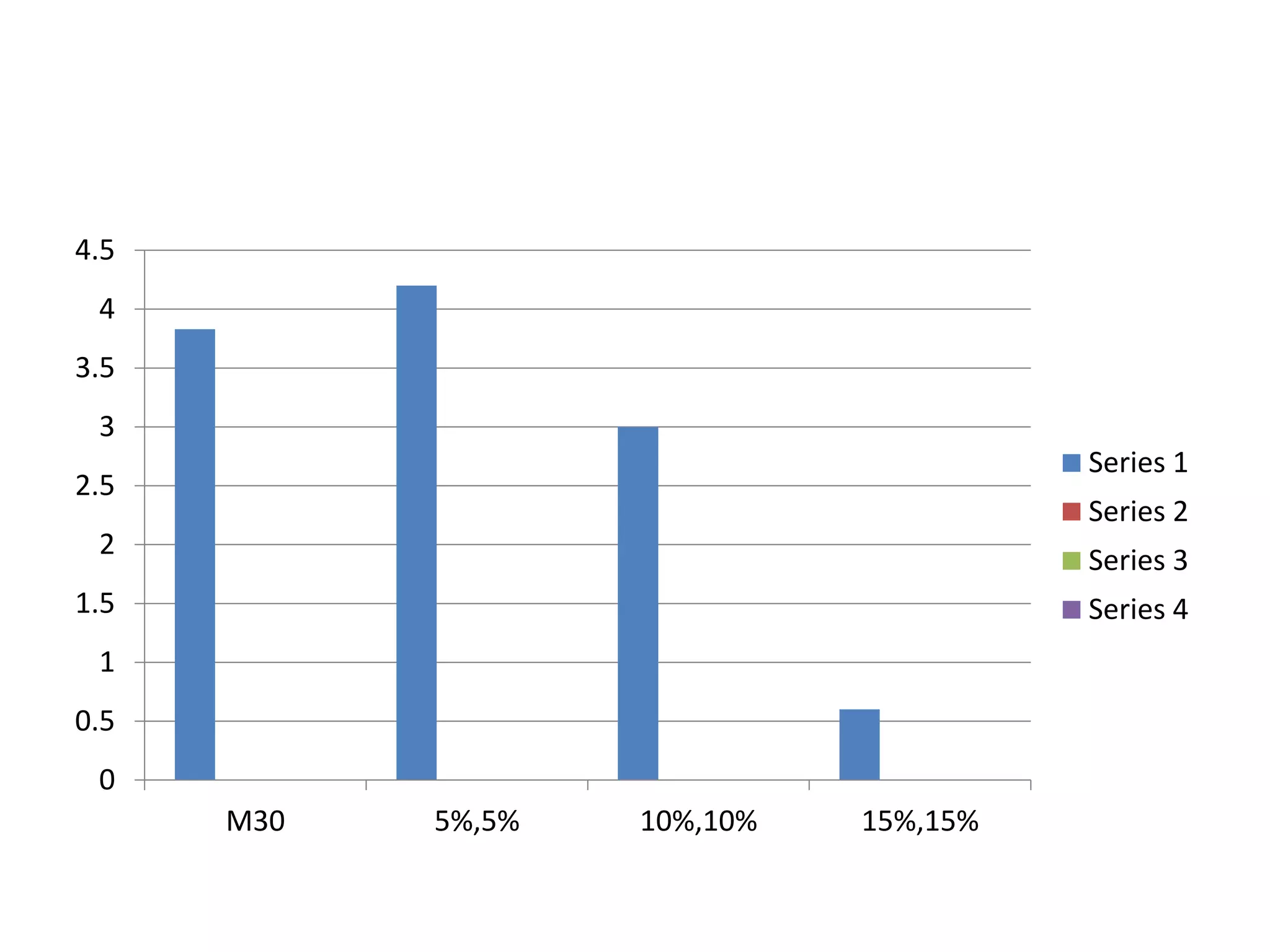

![FLEXURAL STRENGTH

Mix designation Flexural strength for 28 days Average flexural

strength

T1

N/mm^2

T2

N/mm^2

T3

N/mm^2 N/mm^2

FA [0%] + CFA [0%] 3.8 3.97 3.72 3.83

FA [5%] + CFA [5%] 4.21 4.35 4.17 4.2

FA [10%] + CFA [10%] 3 3 2.9 3

FA [15%] + CFA [15%] 0.6 0.58 0.6 0.6](https://image.slidesharecdn.com/finalreviewwithgraphsandvalues-150916155205-lva1-app6891/75/study-on-strenth-properties-of-blended-cement-concreate-17-2048.jpg)

![REFERENCES

• IS383:1970[zone of sand]

• IS456:2000[water content]

• IS10262:2009[mix design]

• Text book : Concrete technology by M.S.Shetty](https://image.slidesharecdn.com/finalreviewwithgraphsandvalues-150916155205-lva1-app6891/75/study-on-strenth-properties-of-blended-cement-concreate-20-2048.jpg)