Cement is tested through laboratory and field tests to evaluate its properties and suitability. Key laboratory tests described in the document include:

- Fineness tests which measure particle size and surface area to determine reactivity.

- Setting time tests which ensure cement sets within specified time limits.

- Compressive strength tests where cement mortar cubes are crushed to determine strength over time.

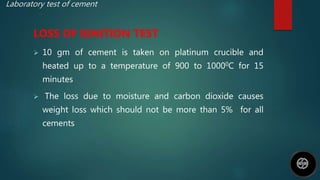

- Soundness and loss of ignition tests which evaluate volume stability and carbon/moisture content.

Results of laboratory tests help ensure cement meets standards before use in construction projects.